| [1] |

WALSH M J. Riblets as a viscous drag reduction technique [J]. Aiaa Journal,1983,21(4):485-486. doi: 10.2514/3.60126

|

| [2] |

李强, 刘清磊, 杜玉晶, 等. 织构化表面优化设计及应用的研究进展 [J]. 中国表面工程,2021,34(6):59-73. doi: 10.11933/j.issn.1007-9289.20210608003LI Qiang, LIU Qinglei, DU Yujing, et al. Advances in optimization design and application of textured surfaces [J]. China Surface Engineering,2021,34(6):59-73. doi: 10.11933/j.issn.1007-9289.20210608003

|

| [3] |

STEPIEN P. Mechanism of grinding wheel surface reproduction in regular surface texture generation [J]. Surface Engineering,2008,24(3):219-225. doi: 10.1179/174329408X282596

|

| [4] |

STEPIEN P. Regular surface texture generated by special grinding process [J]. Journal of Manufacturing Science and Engineering,2009,131(1):123-136.

|

| [5] |

STEPIEN P. Deterministic and stochastic components of regular surface texture generated by a special grinding process [J]. Wear,2010,271(34):514-518.

|

| [6] |

DENKENA B, LEON L, WANG B. Grinding of microstructured functional surfaces: A novel strategy for dressing of microprofiles [J]. Production Engineering,2009,3(1):41-48. doi: 10.1007/s11740-008-0134-0

|

| [7] |

DENKENA B, KöHLER J, WANG B. Manufacturing of functional riblet structures by profile grinding [J]. CIRP Journal of Manufacturing Science and Technology,2010,3(1):14-26. doi: 10.1016/j.cirpj.2010.08.001

|

| [8] |

KIM H, KO T J. Verification of simulation of surface texturing on planar surface by grinding [J]. International Journal of Precision Engineering and Manufacturing,2015,16(2):225-231. doi: 10.1007/s12541-015-0030-4

|

| [9] |

MOHAMED A O, WARKENTIN A, BAUER R. Prediction of workpiece surface texture using circumferentially grooved grinding wheels [J]. The International Journal of Advanced Manufacturing Technology,2017,89(1/2/3/4):1149-1160.

|

| [10] |

GUO B, ZHAO Q. Ultrasonic vibration assisted grinding of hard and brittle linear micro-structured surfaces [J]. Precision Engineering,2016,48:98-106.

|

| [11] |

XIE J, ZHUO Y W, TAN T W. Experimental study on fabrication and evaluation of micro pyramid-structured silicon surface using a V-tip of diamond grinding wheel [J]. Precision Engineering,2010,35(1):173-182.

|

| [12] |

谢晋, 谭廷武, 郑佳华, 等. 金刚石砂轮V形尖端的数控对磨微细修整技术 [J]. 金刚石与磨料磨具工程,2010,30(5):1-5 , 10.XIE Jin, TAN Yanwu, ZHENG Jiahua, et al. CNC mutual-wear micro truing technique of diamond wheel V-tip [J]. Diamond and Abrasives Engineering,2010,30(5):1-5 , 10.

|

| [13] |

AURICH J C, BRAUN O, WARNECKE G, et al. Development of a superabrasive grinding wheel with defined grain structure using kinematic simulation [J]. Cirp Annals Manufacturing Technology,2003,52(1):275-280. doi: 10.1016/S0007-8506(07)60583-6

|

| [14] |

SILVA E J, KIRSCH B, BOTTENE A C, et al. Manufacturing of structured surfaces via grinding [J]. Journal of Materials Processing Technology,2017,243:170-183. doi: 10.1016/j.jmatprotec.2016.12.009

|

| [15] |

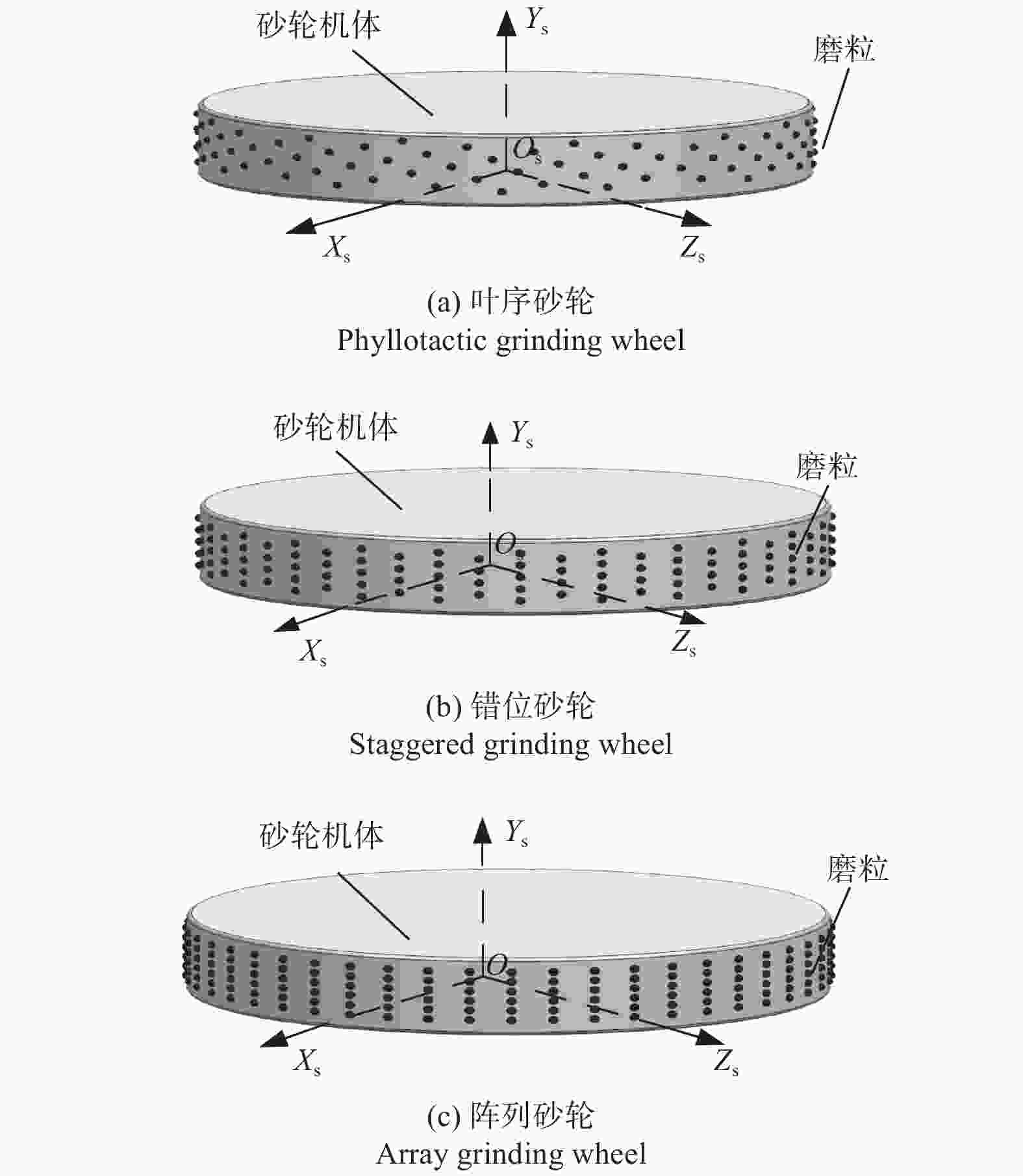

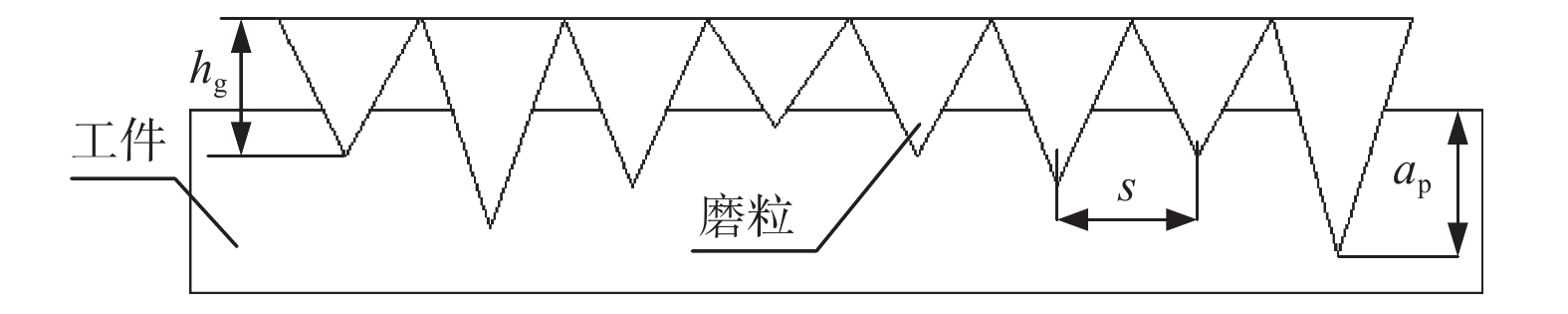

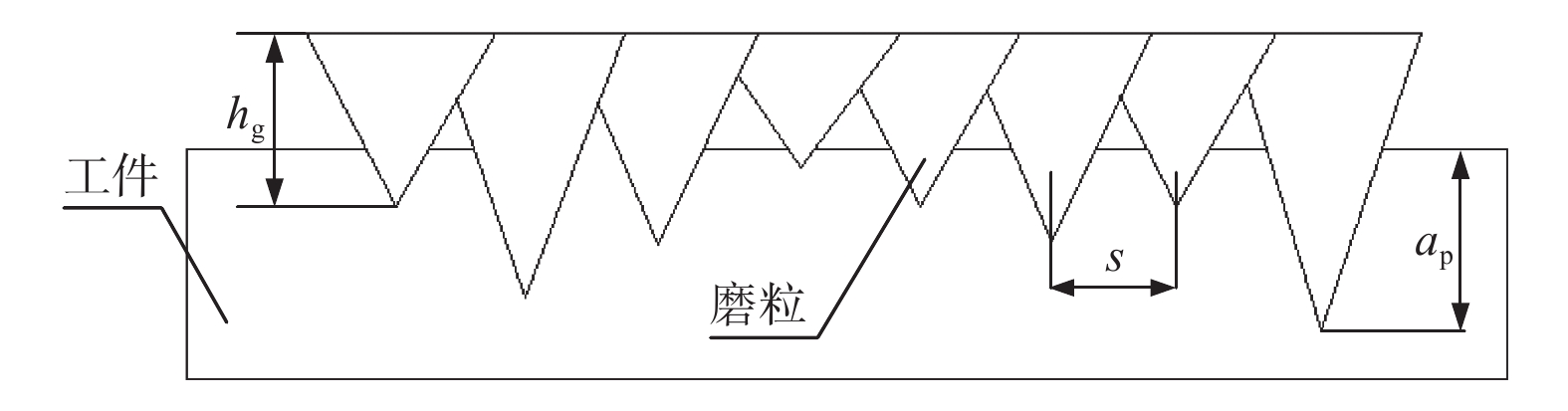

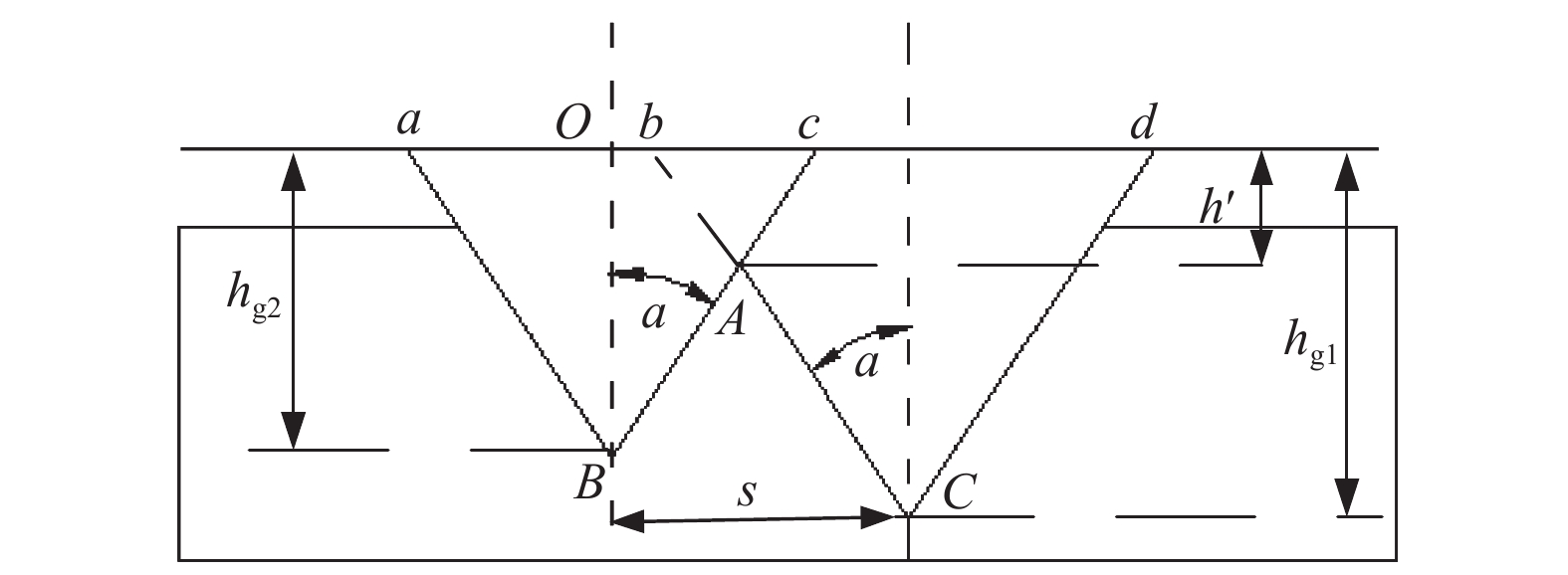

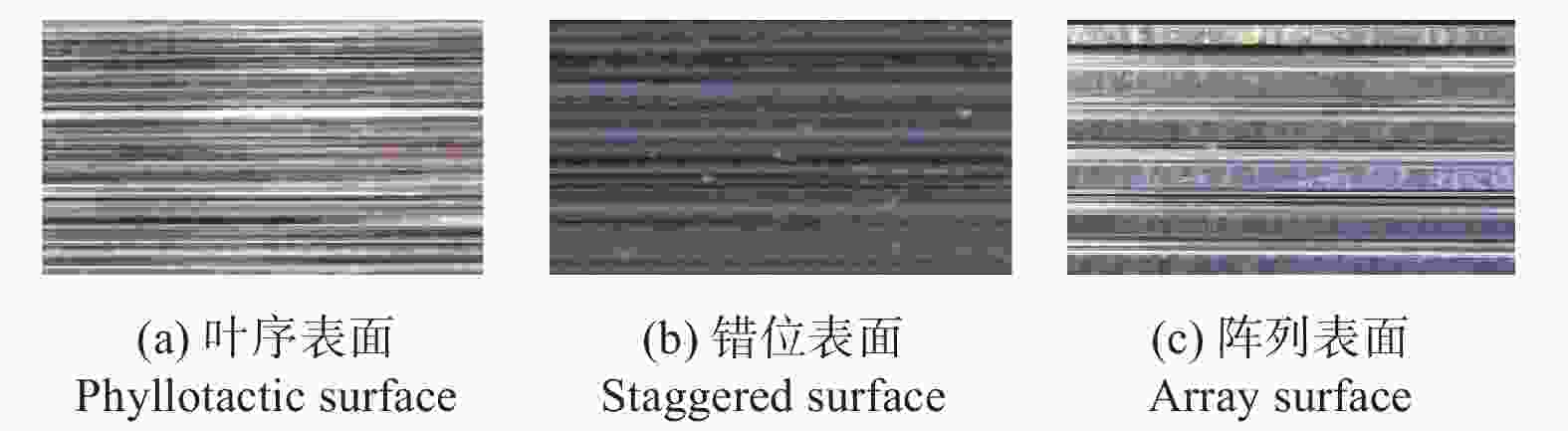

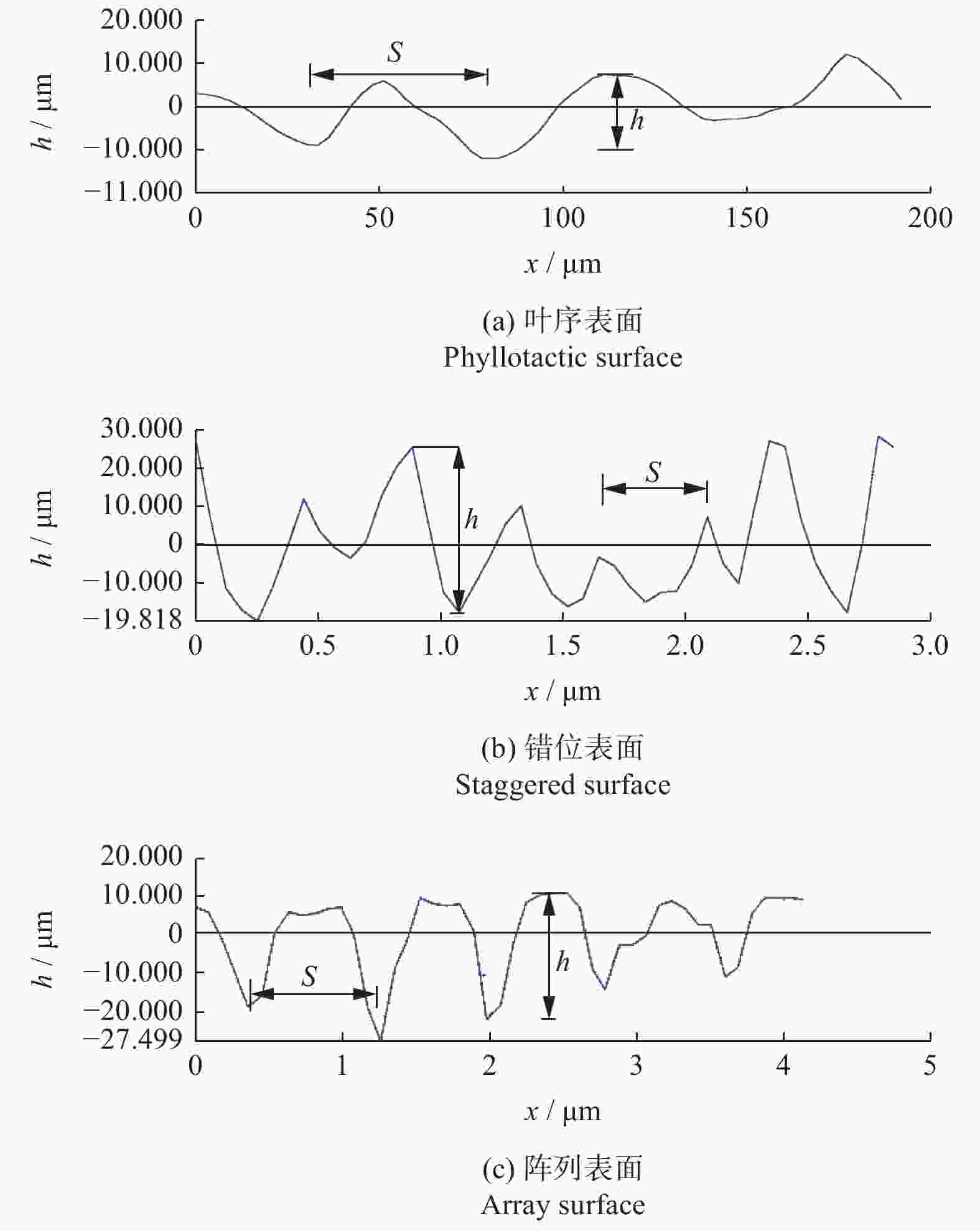

陶思远, 吕玉山, 汪宇晨, 等. 叶序排布砂轮磨削微结构化表面的仿真研究 [J]. 组合机床与自动化加工技术,2020(9):130-133, 138.TAO Siyuan, LYU Yushan, WANG Yuchen, et al. Simulation study on grinding microstructured surface by the grinding wheels with abrasive phyllotactic pattern [J]. Modular Machine Tool and Automatic Manufacturing Technique,2020(9):130-133, 138.

|

| [16] |

BECHERT D W, BRUSE M, HAGE W, et al. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry [J]. Journal of Fluid Mechanics,1997,338:59-87. doi: 10.1017/S0022112096004673

|

| [17] |

HIRT G, THOME M. Rolling of functional metallic surface structures [J]. CIRP Annals-Manufacturing Technology,2008,57(1):317-320. doi: 10.1016/j.cirp.2008.03.034

|

| [18] |

肖贵坚, 贺毅, 黄云, 等. 基于单颗粒模型的航发叶片砂带磨削微观仿生锯齿状表面形成及实验 [J]. 航空学报,2020,41(7):33-42.XIAO GuiJian, HE Yi, HUANG Yun, et al. Single particle removal model and experimental study on micro bionic zigzag surface of aeronautical blade using belt grinding [J]. Acta Aeronautica et Astronautica Sincia,2020,41(7):33-42.

|

| [19] |

SHI Z, MALKIN S. Wear of electroplated CBN grinding wheels [J]. Journal of Manufacturing Science and Engineering,2006,128(1):110-118. doi: 10.1115/1.2122987

|

| [20] |

李兴山, 熊伟, 陈天宇, 等. 磨粒簇叶序排布砂轮外圆磨削凹坑结构化减阻表面的仿真 [J]. 机械设计与制造,2021(3):261-265. doi: 10.3969/j.issn.1001-3997.2021.03.059LI Xingshan, XIONG Wei, CHEN Tianyu, et al. Simulation study on the grinding of cylindrical structured surface by the grinding wheel with phyllotactic abrasive cluster machinery [J]. Design and Manufacture,2021(3):261-265. doi: 10.3969/j.issn.1001-3997.2021.03.059

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS