End face wear of small brazed diamond grinding head for 3C ceramics

-

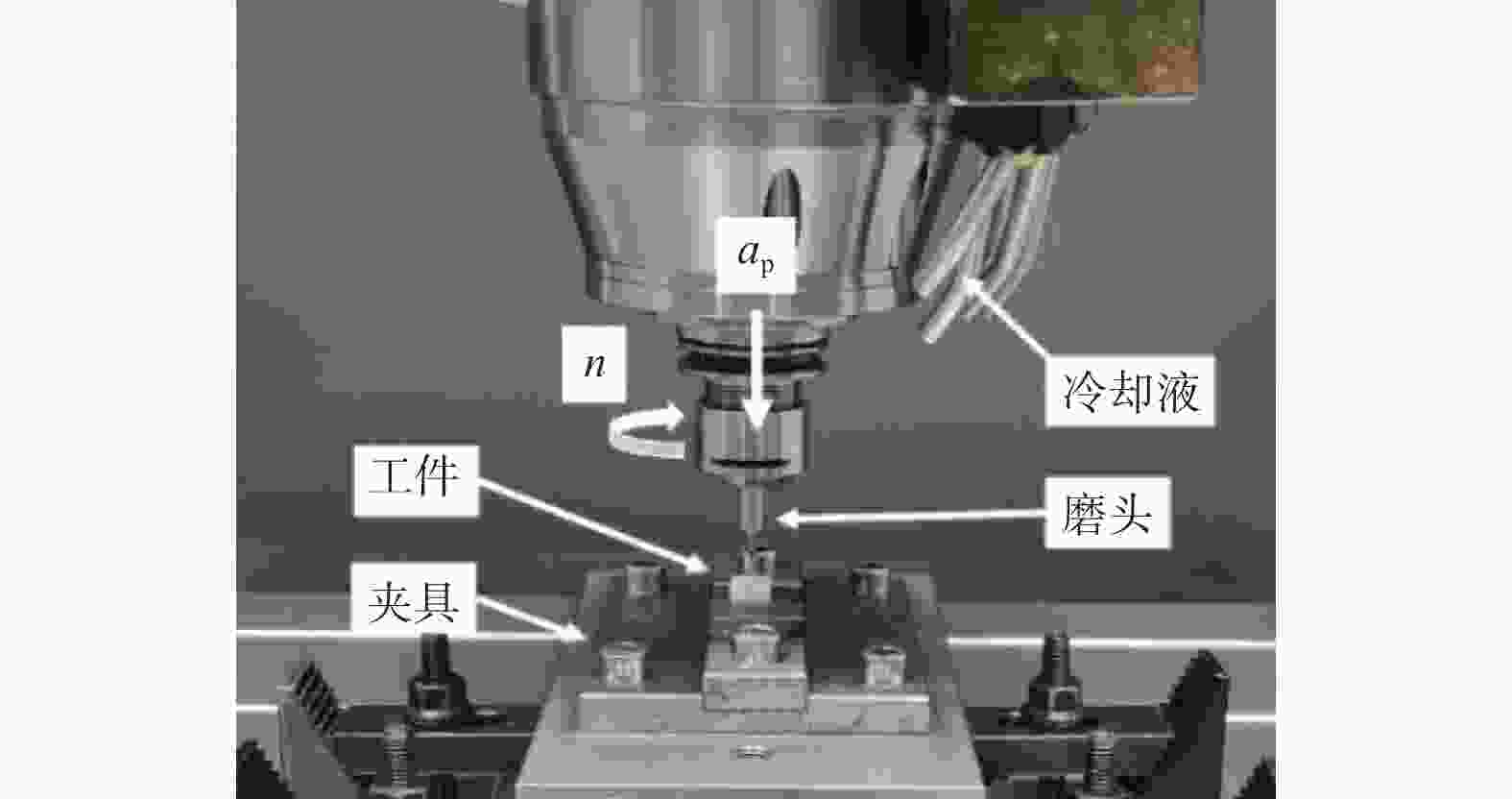

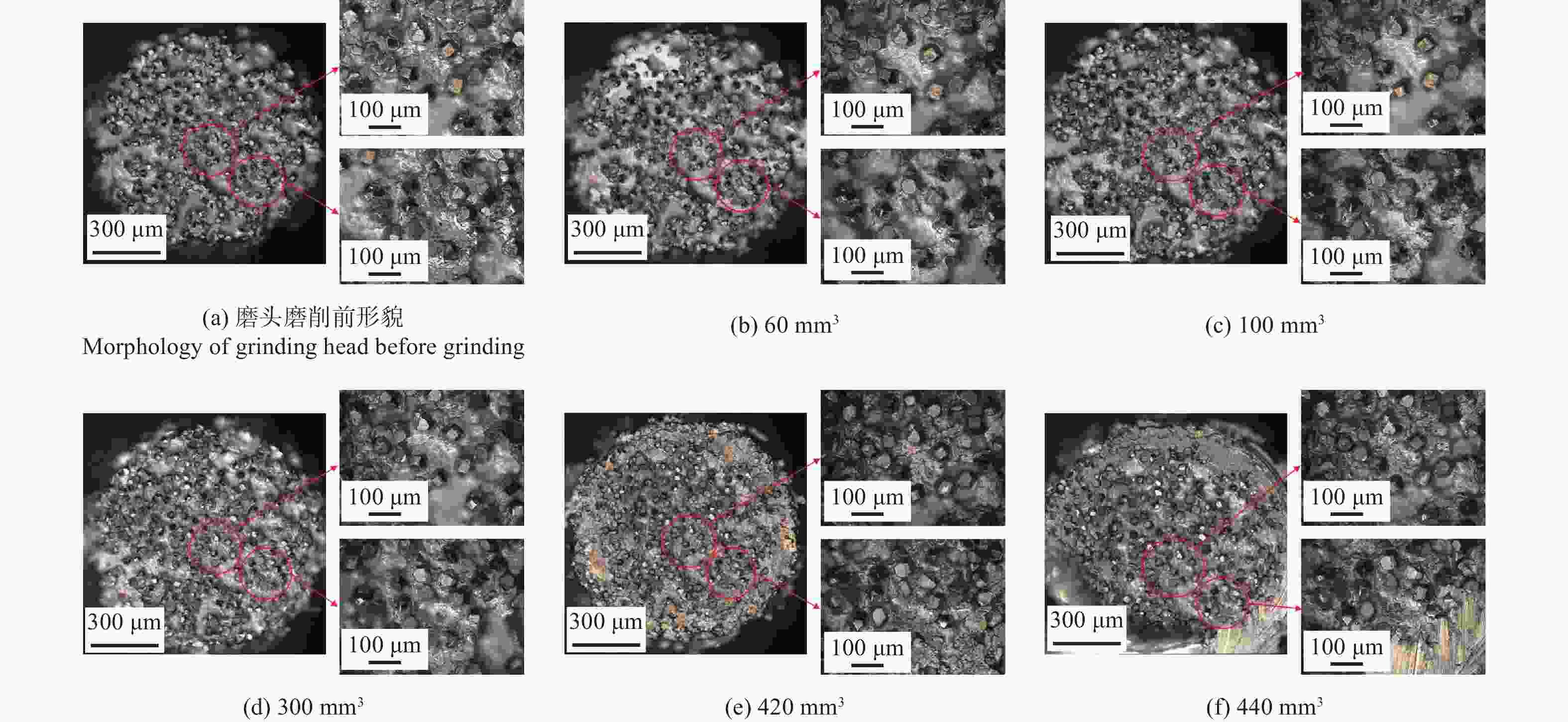

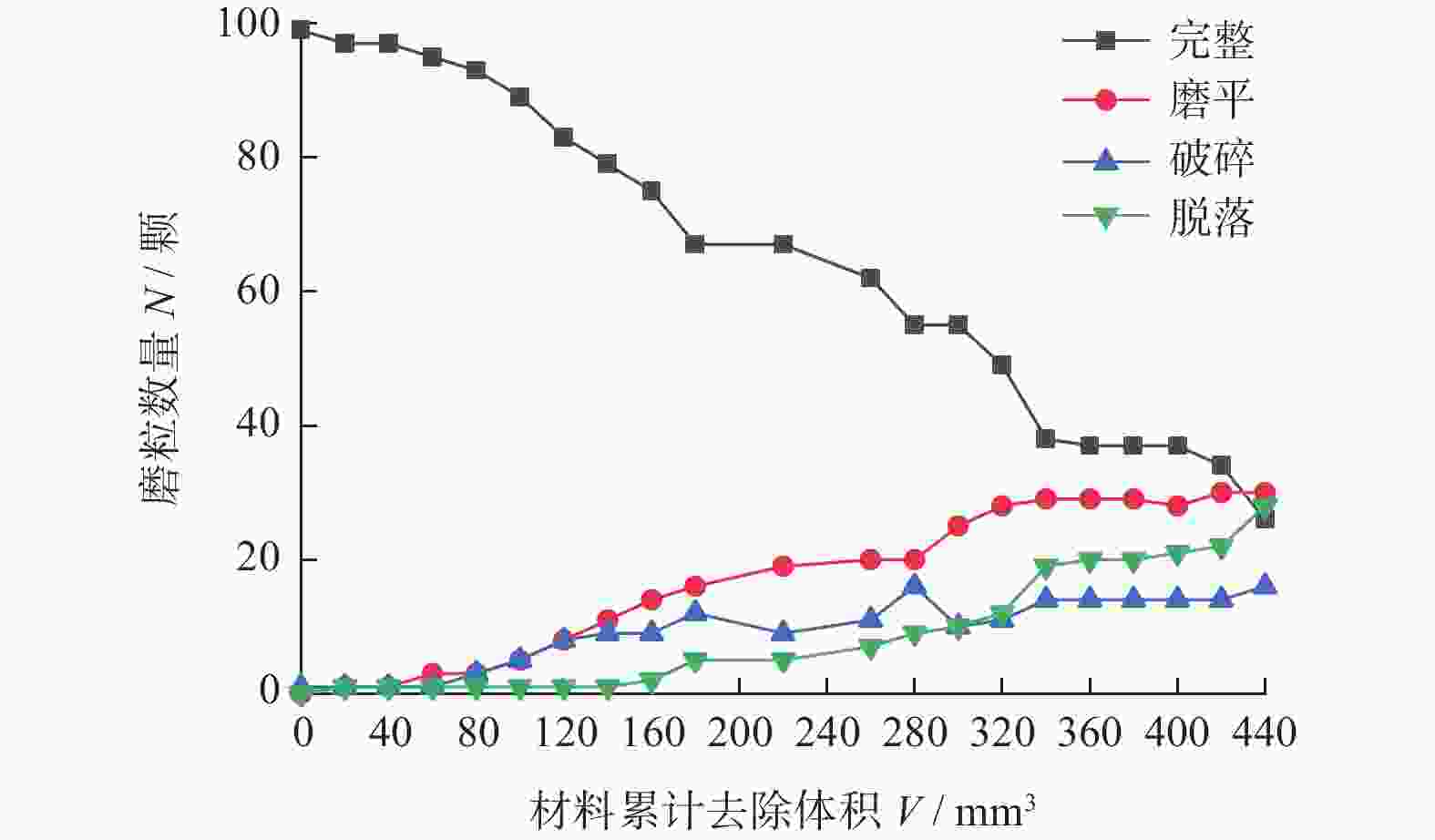

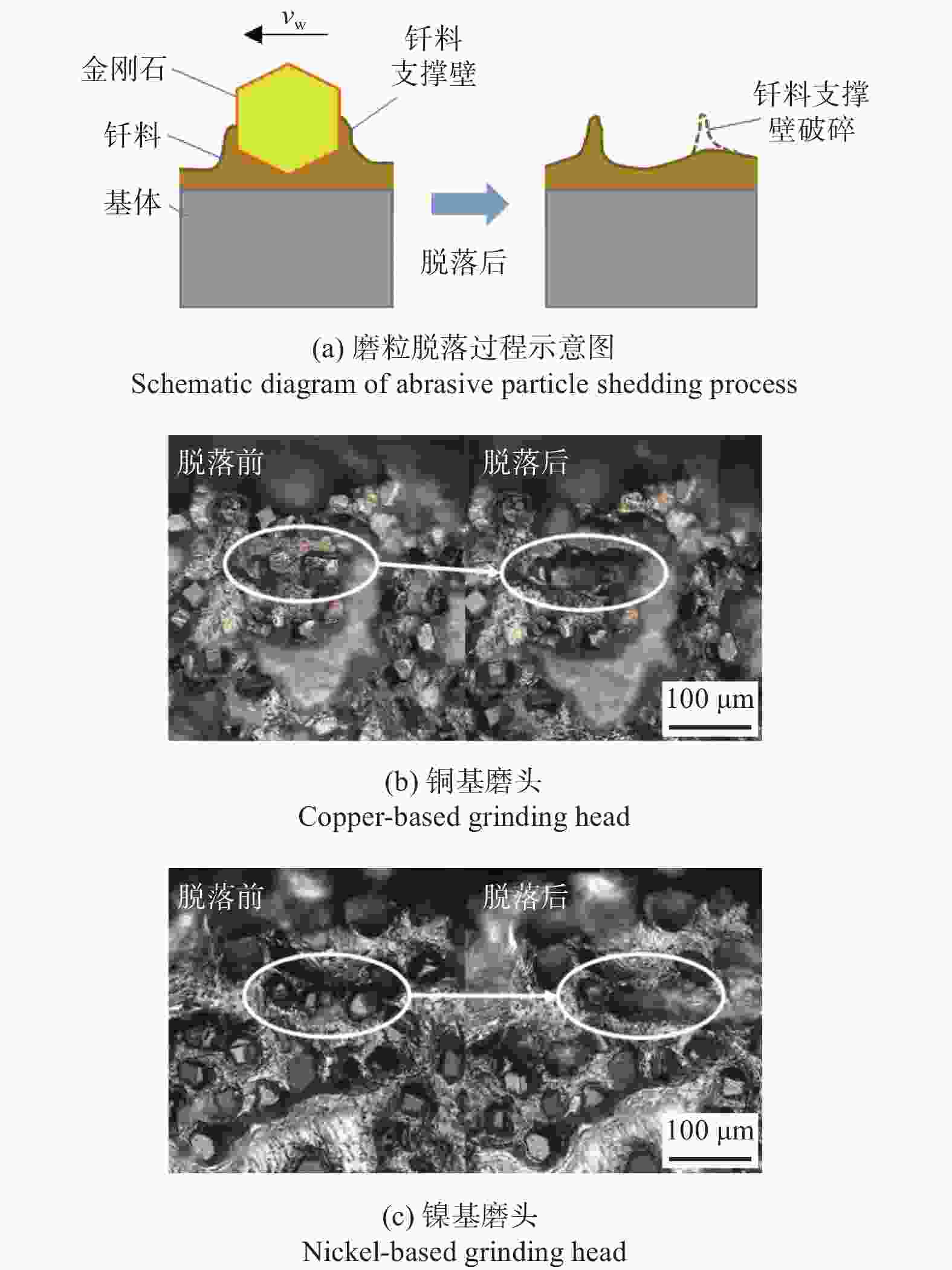

摘要: 金刚石微铣磨头广泛用于3C产品的先进陶瓷构件加工中。通过对3C产品中最常用的氧化锆陶瓷工件进行磨削试验,观察钎焊金刚石微铣磨头磨损过程中的形貌演变,并统计氧化锆陶瓷的累计去除体积与磨头上金刚石磨粒磨损数量的对应关系,对比分析铜基和镍基钎料金刚石微铣磨头的磨损失效情况及寿命。结果表明:在相同加工参数条件下,铜基磨头的寿命较长,是镍基磨头寿命的1.2倍;在磨削过程中,金刚石磨头端面的磨粒存在破碎、磨平、脱落3种主要失效形式,且磨头的磨损主要从磨头端面边缘开始,逐步向其中心扩散,直至磨粒磨损严重而导致磨头失效。Abstract: The diamond micro-milling head is widely used in the processing of advanced ceramic components of 3C products. Through the grinding tests on the zirconia ceramic workpiece most commonly used in 3C products, the morphology evolution of the brazed diamond micro milling head was observed, and the corresponding relationship between the accumulated removal volume of zirconia ceramics and the wear amount of diamond abrasive grains on the grinding head was counted. The wear failure and the service life of the copper-based and the nickel-based brazed diamond micro milling heads were compared and analyzed. The results show that under the same processing parameters, the life of the copper-based grinding head is longer, which is 1.2 times that of the nickel-based grinding head. In the process of grinding, there are three main failure modes of grinding particles on the end face of diamond grinding head: crushing, flattening and falling off. The wear of grinding head mainly starts from the edge of the end face of the grinding head and gradually spreads to the center until the abrasive wear is serious and the grinding head fails.

-

Key words:

- diamond /

- brazing /

- micro-milling head /

- zirconia ceramics /

- wear failure

-

表 1 2种磨头端面的磨粒数及密度

Table 1. Number and density of abrasive grains on the end face of two kinds of grinding heads

项目 Cu基 Ni基 端面磨粒数量 N / 颗 280 282 端面磨粒密度 ρ / (颗·mm−2) 89.17 89.81 表 2 陶瓷磨削参数

Table 2. Parameters for grinding ceramic

参数 取值或类型 主轴转速 n /(r·min−1) 20 000 线速度 v /(m·s−1) 2.09 进给速度 vw /(mm·min−1) 300 切削深度 ap / μm 20 加工深度 h / mm 0.2 冷却液 STA20切削液 -

[1] 卢建. 3C产品展示设计研究 [D]. 福州: 福建师范大学, 2011.LU Jian. Research on display design of 3C product [D]. Fuzhou: Fujian Normal University, 2011. [2] 谢志鹏, 余诺婷. 纳米氧化锆陶瓷在手机背板上的应用与发展 [J]. 中国陶瓷,2021,57(5):1-10.XIE Zhipeng, YU Nuoting. Application and development of nano zirconia ceramics on mobile phone backboards [J]. Chinese Ceramics,2021,57(5):1-10. [3] 朱学文, 廖列文, 张明月, 等. 无机功能材料二氧化锆的应用及研究进展 [J]. 化学推进剂与高分子材料,2001(4):22-24. doi: 10.3969/j.issn.1672-2191.2001.04.007ZHU Xuewen, LIAO Liewen, ZHANG Mingyue, et al. Application and research progress of inorganic functional material zirconium dioxide [J]. Chemical Propellant and Polymer Materials,2001(4):22-24. doi: 10.3969/j.issn.1672-2191.2001.04.007 [4] BOCANEGRA-BERNAL M, DIAZ DE LA TORRE S. Phase transitions in zirconium dioxide and related materials for high performance engineering ceramics [J]. Journal of Materials Science,2002,37:4947-4971. doi: 10.1023/A:1021099308957 [5] 巫兰萍, 费文宗. 氧化锆性质及其应用前景概述 [J]. 四川化工,2013,16(1):25-27. doi: 10.3969/j.issn.1672-4887.2013.01.007WU Lanping, FEI Wenzong. Overview of zirconium oxide properties and application prospects [J]. Sichuan Chemical Industry,2013,16(1):25-27. doi: 10.3969/j.issn.1672-4887.2013.01.007 [6] 王海旺. 加工氧化锆陶瓷的金刚石涂层刀具的制备与应用研究 [D]. 上海: 上海交通大学, 2014.WANG Haiwang. Study on the fabrication and application of CVD diamond coated tools for milling zirconia ceramics [D]. Shanghai: Shanghai Jiaotong University, 2014. [7] HUANG H. High speed grinding of advanced ceramics: A review [J]. Key Engineering Materials,2009,404:11-22. doi: 10.4028/www.scientific.net/KEM.404.11 [8] 甘可. 电镀金刚石工具镀层脱落的原因分析 [J]. 超硬材料工程,2010,22(2):32-34. doi: 10.3969/j.issn.1673-1433.2010.02.008GAN Ke. Analysis on coating shedding of electroplated diamond tool [J]. Superhard Materials Engineering,2010,22(2):32-34. doi: 10.3969/j.issn.1673-1433.2010.02.008 [9] 武志斌, 肖冰, 徐鸿钧. 单层钎焊金刚石砂轮工艺研究初探 [J]. 机械设计与制造工程,2001(1):53-54. doi: 10.3969/j.issn.1672-1616.2001.01.024WU Zhibin, XIAO Bing, XU Hongjun. Preliminary experimental study of monolayer diamond brazed grinding wheel [J]. Mechanical Design and Manufacture Engineering,2001(1):53-54. doi: 10.3969/j.issn.1672-1616.2001.01.024 [10] 苏宏华, 徐鸿钧, 傅玉灿, 等. 多层烧结超硬磨料工具现状综述与未来发展构想 [J]. 机械工程学报,2005(3):12-17. doi: 10.3321/j.issn:0577-6686.2005.03.002SU Honghua, XU Hongjun, FU Yucan, et al. Overview of the current situation and future development of multi-layer sintered super abrasive tools [J]. Chinese Journal of Mechanical Engineering,2005(3):12-17. doi: 10.3321/j.issn:0577-6686.2005.03.002 [11] 王双喜, 刘雪敬, 耿彪, 等. 金属结合剂金刚石磨具的研究进展 [J]. 金刚石与磨料磨具工程,2006(4):71-75. doi: 10.3969/j.issn.1006-852X.2006.04.021WANG Shuangxi, LIU Xuejing, GENG Biao, et al. Development of metal bonded diamond abrasive tools [J]. Diamond & Abrasives Engineering,2006(4):71-75. doi: 10.3969/j.issn.1006-852X.2006.04.021 [12] CHEN J Y, XU X P. Tribological characteristics in high-speed grinding of alumina with brazed diamond wheels [J]. The International Journal of Advanced Manufacturing Technology,2014,71:1579-1585. doi: 10.1007/s00170-013-5583-8 [13] 李文霞, 张子煜. 钎焊金刚石工具的发展现状及改进研究 [J]. 热加工工艺,2021(17):12-17.LI Wenxia, ZHANG Ziyu. Development status and improvement research of brazed diamond tools [J]. Hot Working Technology,2021(17):12-17. [14] XU S, YAO Z Q, HE J W, et al. Grinding characteristics, material removal, and damage formation mechanisms of zirconia ceramics in hybrid laser/grinding [J]. Journal of Manufacturing Science and Engineering,2018,140(7):071010. doi: 10.1115/1.4039645 [15] MOHAMMAD R, NICOLAS J, FREDY K. High performance grinding of zirconium oxide (ZrO2 ) using hybrid bond diamond tools [J]. CIRP Annals - Manufacturing Technology,2013,62:343-346. doi: 10.1016/j.cirp.2013.03.073 [16] 董光耀. 铣磨非球面透镜的金刚石工具制备及加工技术研究 [D]. 厦门: 华侨大学, 2017.DONG Guangyao. Study on the preparation of diamond tools and the machining technology of aspheric surface [D]. Xiamen: Huaqiao University, 2017. [17] 王阳光. 3C陶瓷用细粒度钎焊金刚石铣磨头的研制与性能评价 [D]. 厦门: 华侨大学, 2020.WANG Yangguang. Development and performance evaluation of fine-grained brazed diamond milling and grinding tools for 3C ceramics [D]. Xiamen: Huaqiao University, 2020. [18] 王宗伟, 丛岩. 基于旋转超声振动的氧化锆陶瓷小孔磨削加工质量研究 [J]. 金刚石与磨料磨具工程,2020,40(1):24-28.WANG Zongwei, CONG Yan. Study on machining quality of zirconia ceramic hole grinding based on rotating ultrasound vibration [J]. Diamond & Abrasives Engineering,2020,40(1):24-28. [19] 向孙祖. 细粒度金刚石磨料钎焊工艺研究 [D]. 南京: 南京航空航天大学, 2012.XIANG Sunzu. Research on brazing process of fine-grained diamond abrasive [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. [20] 吴燕平, 燕青芝. 金属结合剂金刚石工具研究进展 [J]. 金刚石与磨料磨具工程,2019,39(2):37-45.WU Yanping, YAN Qingzhi. Research progress of metal bond diamond tools [J]. Diamond & Abrasives Engineering,2019,39(2):37-45. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS