Configuration design and thermal conductivity of diamond-SiC/Al composites

-

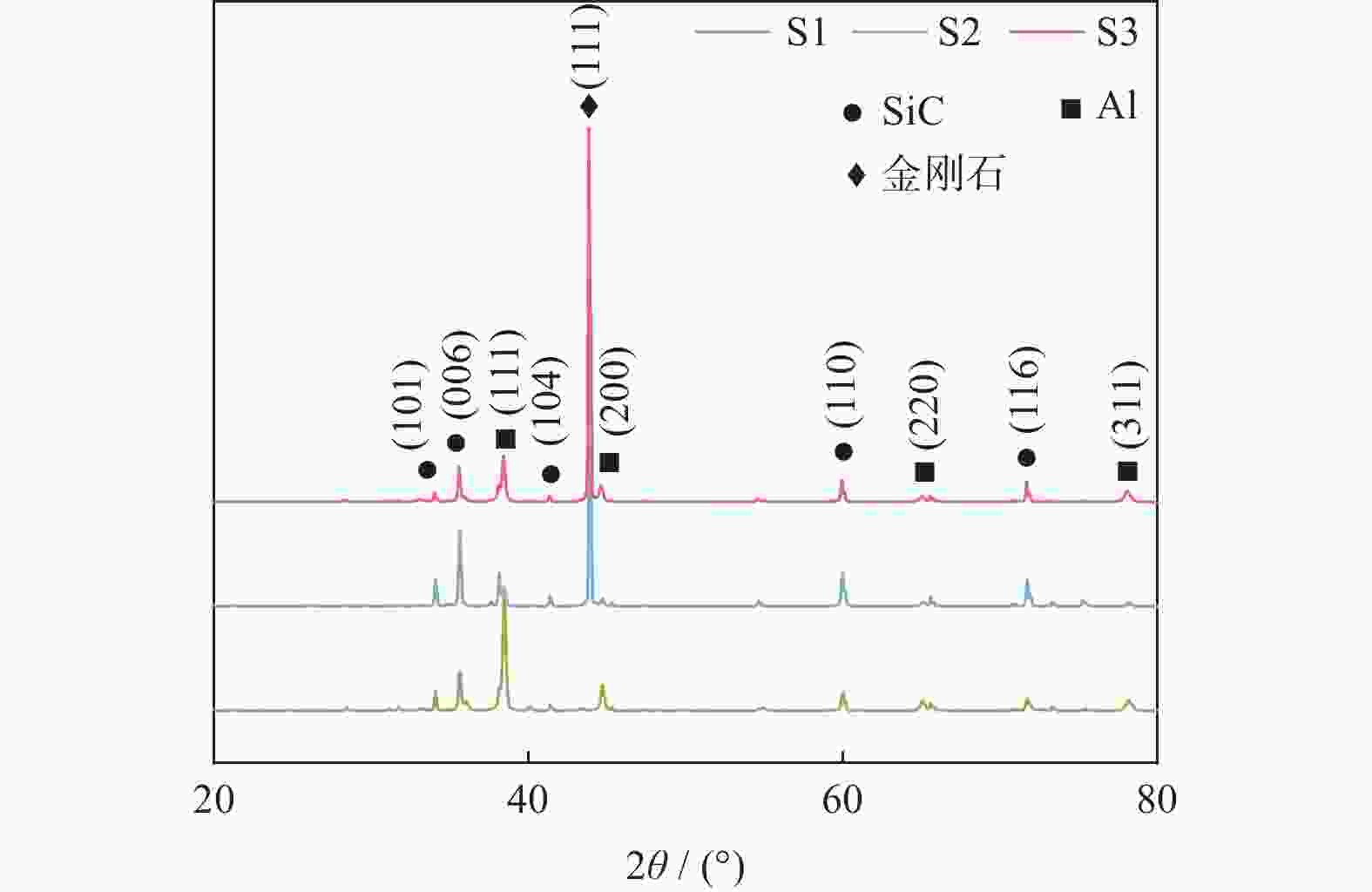

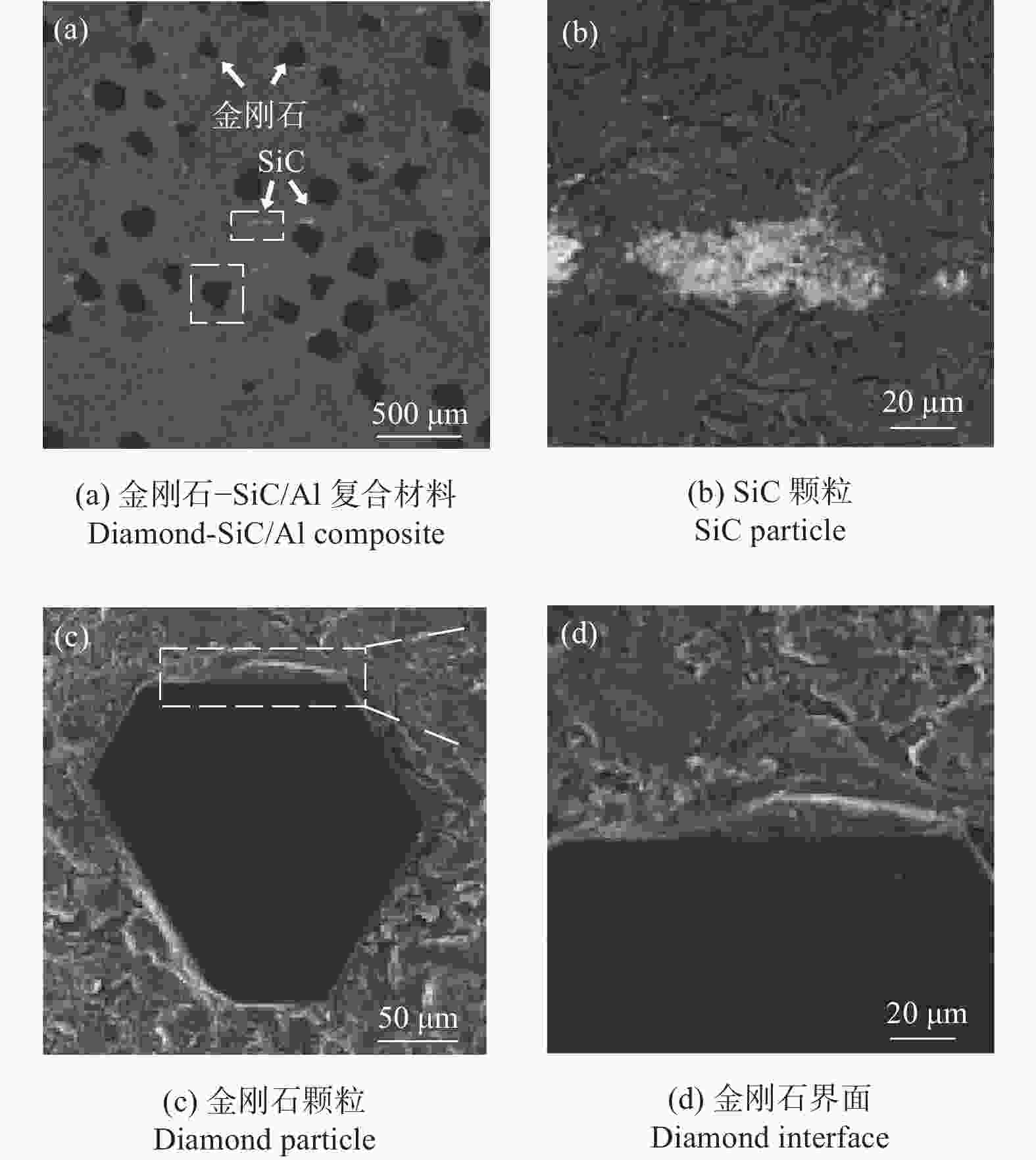

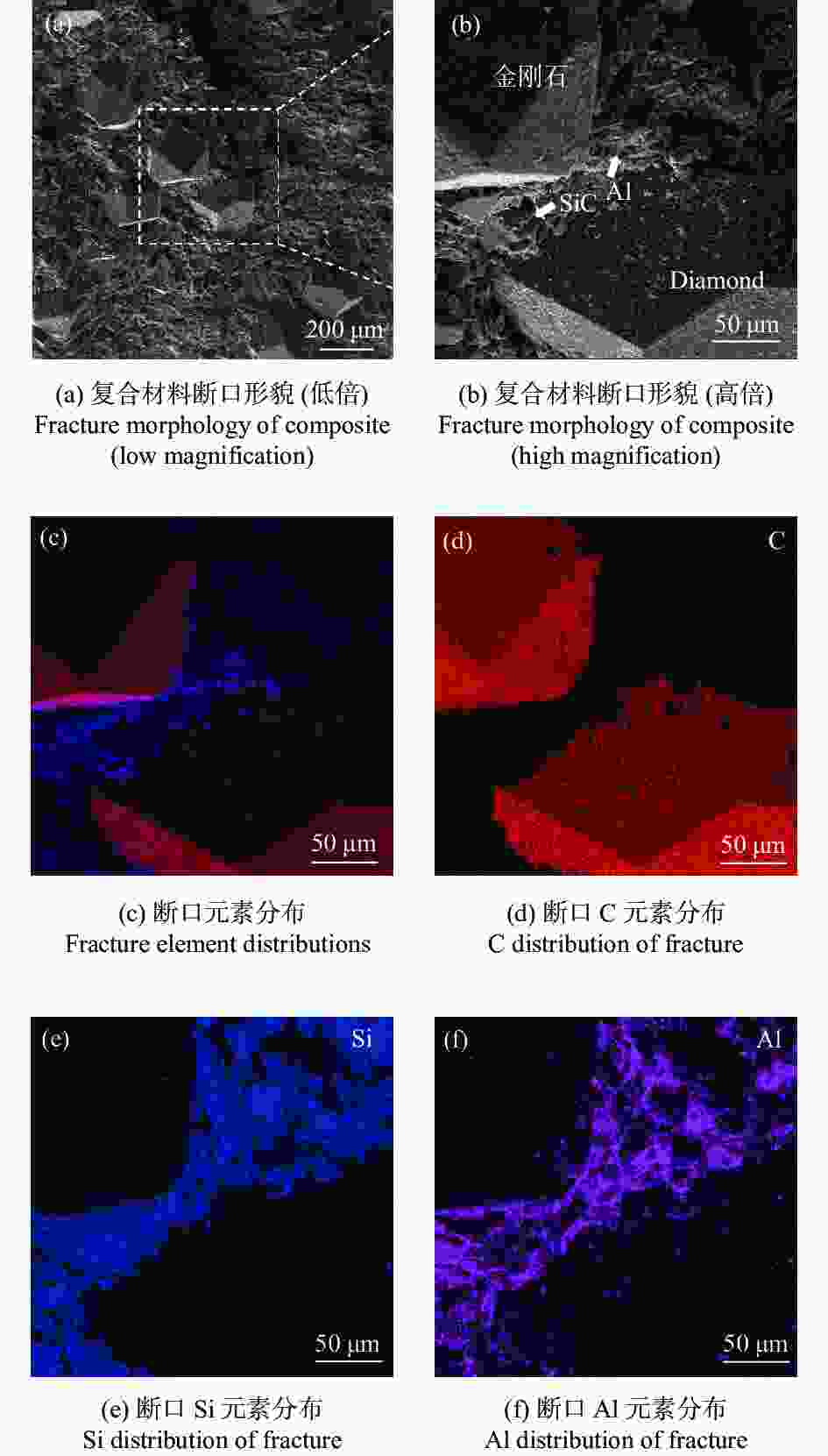

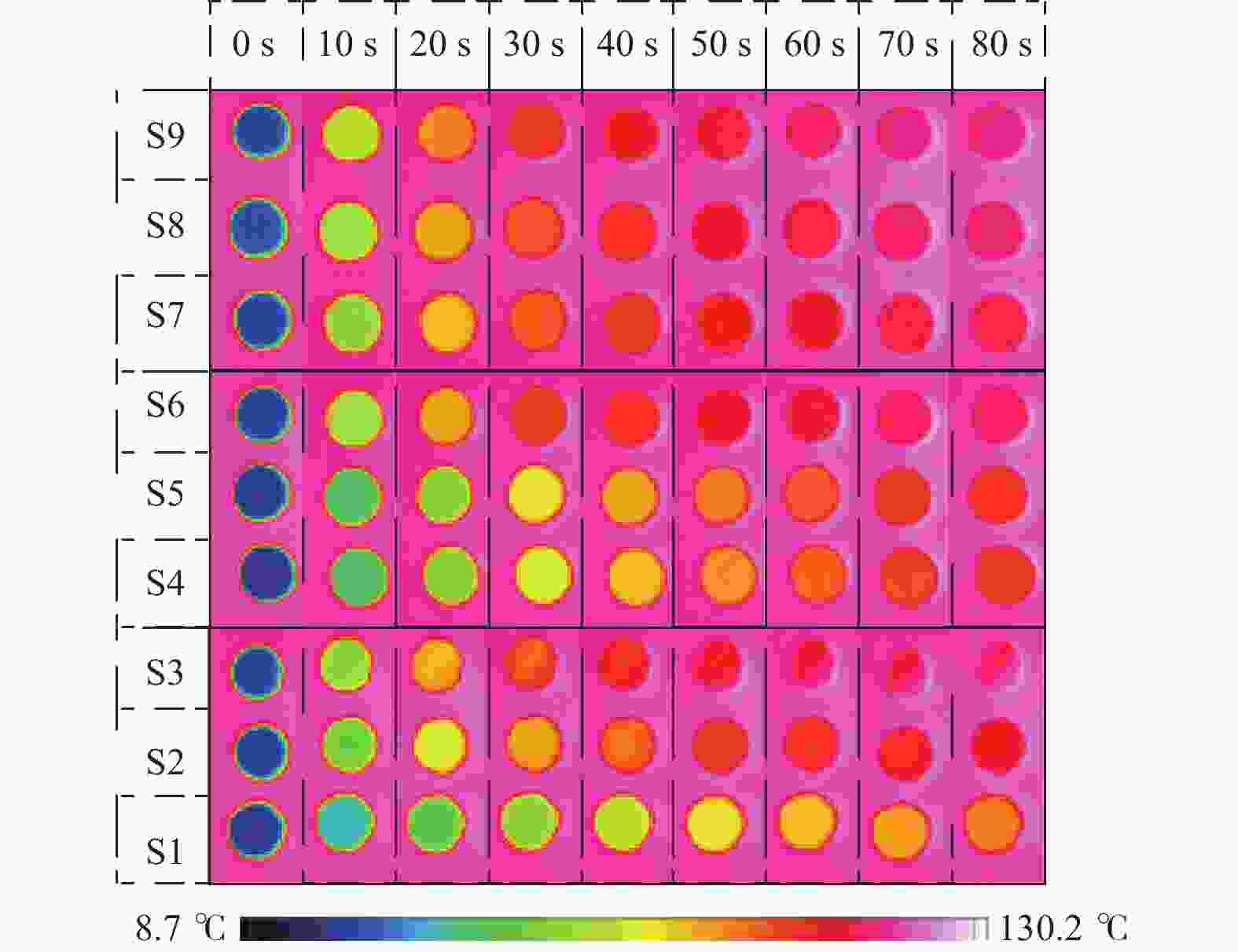

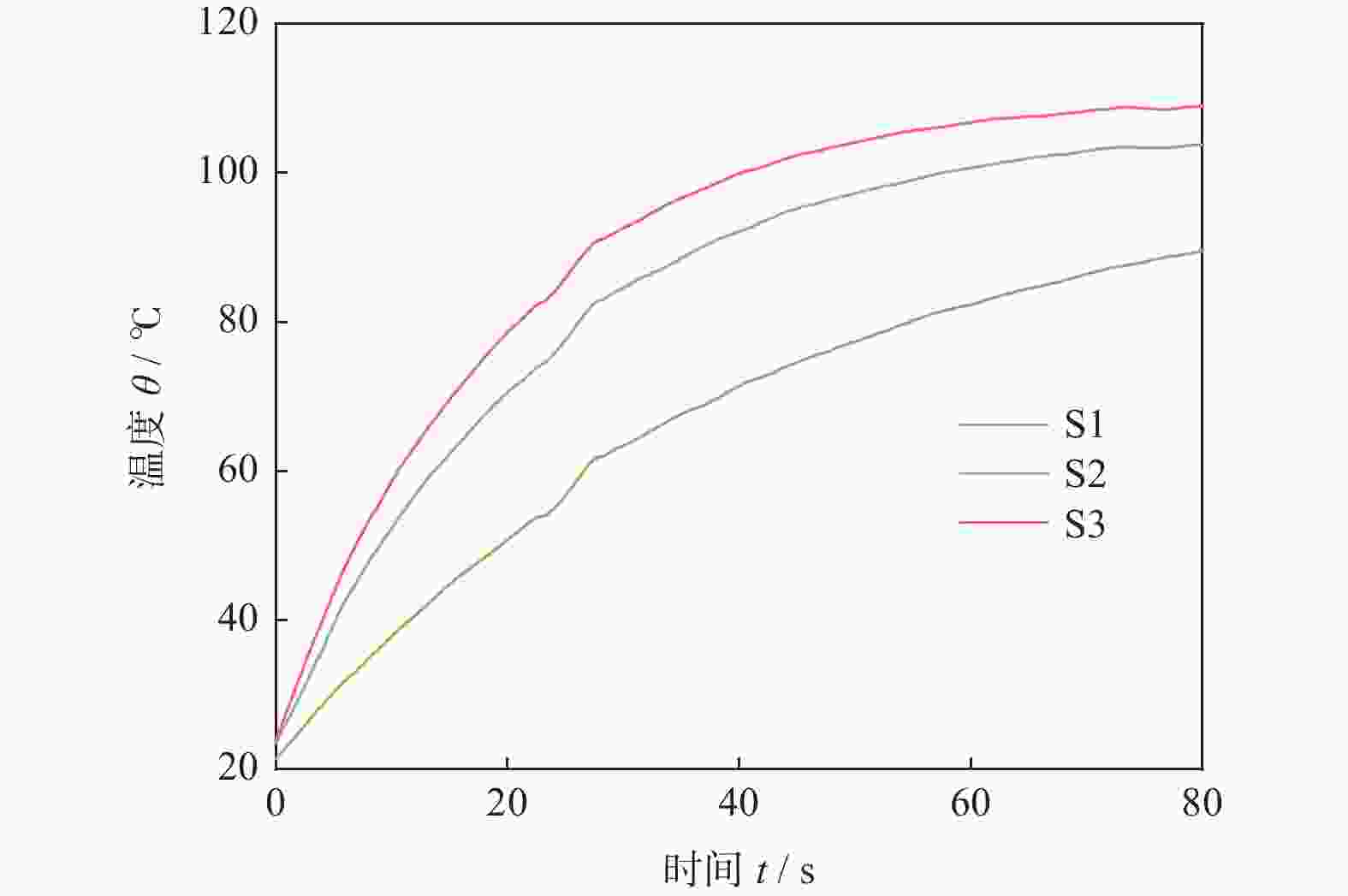

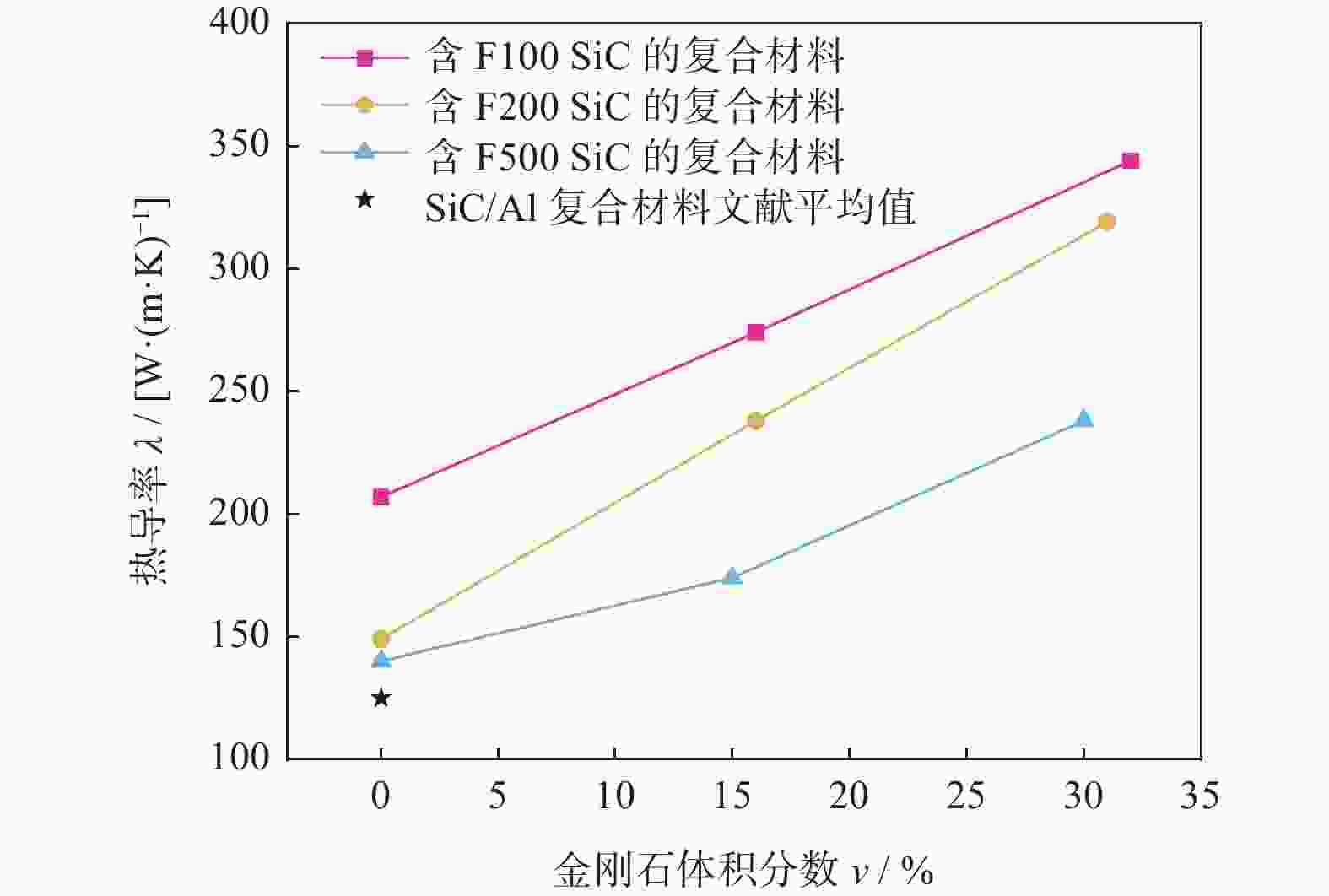

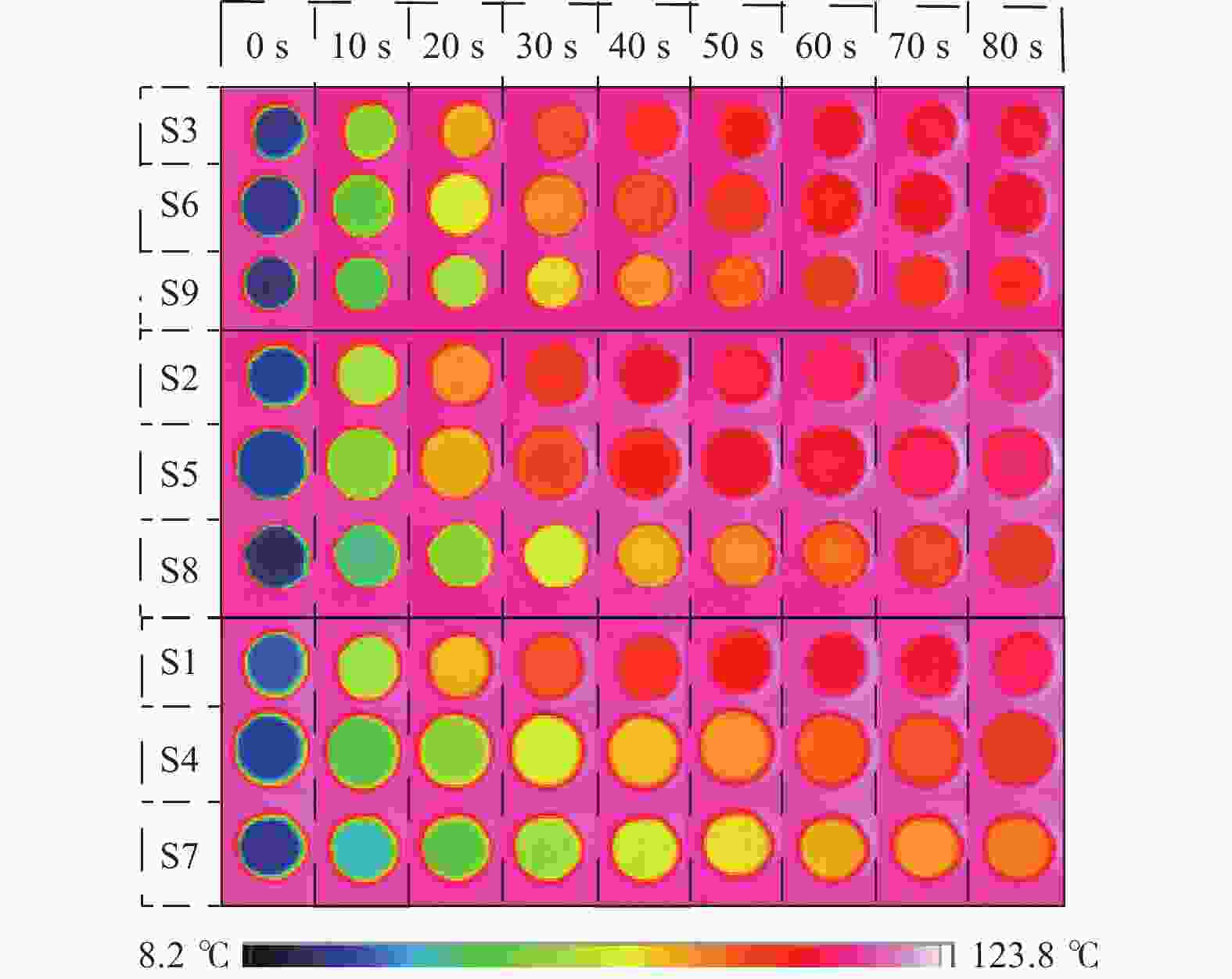

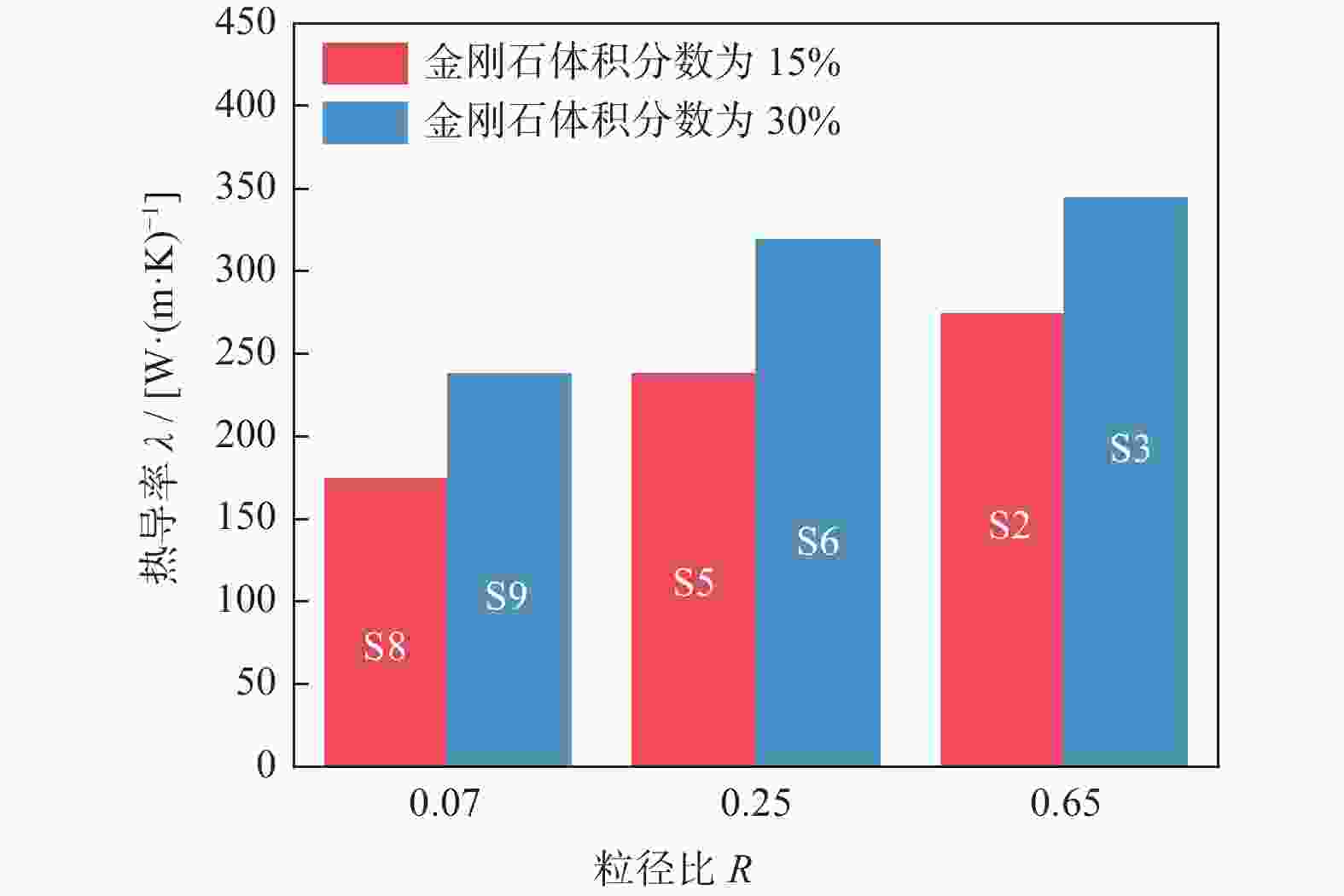

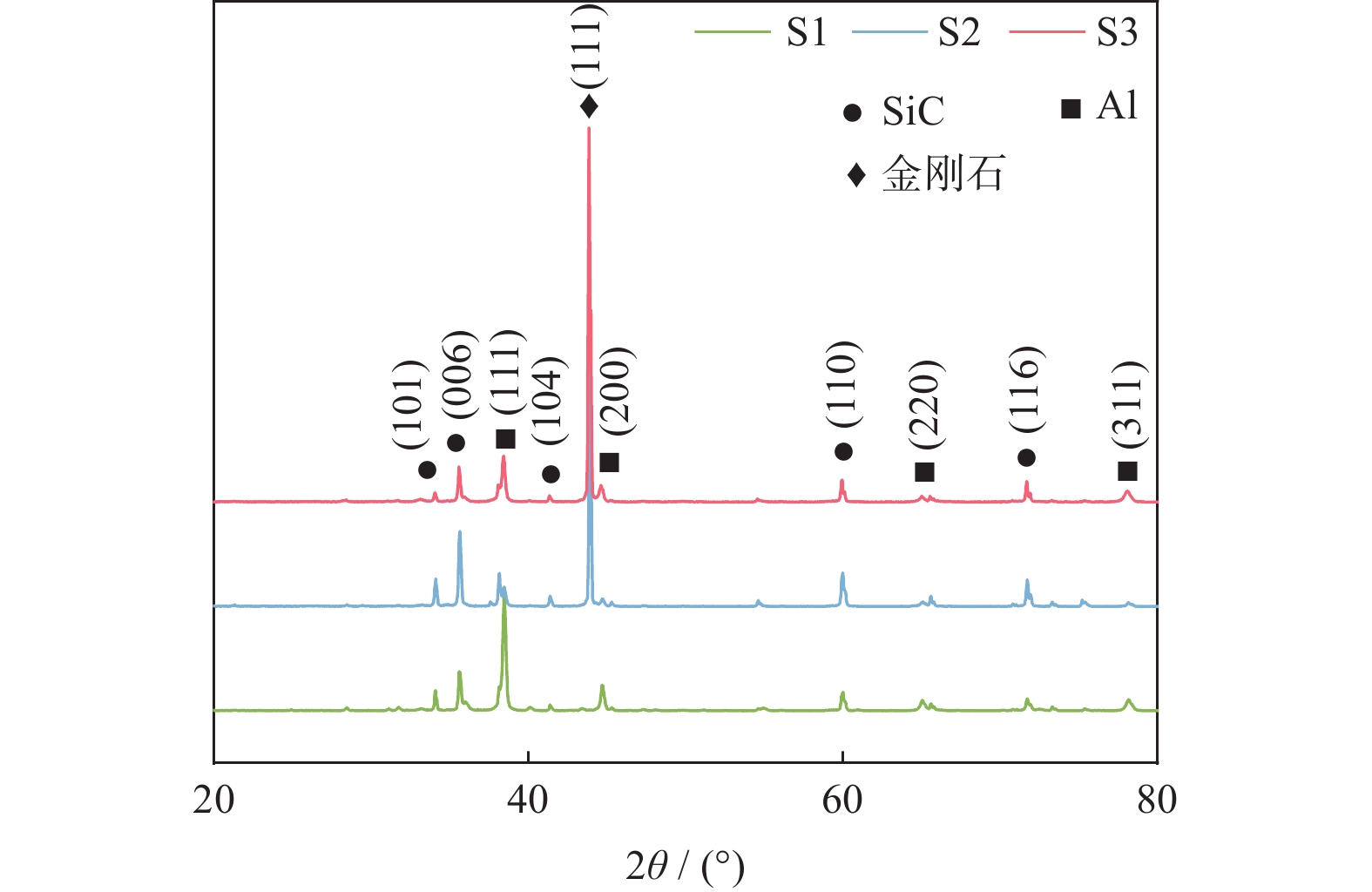

摘要: 以SiC和镀钨金刚石增强体为原料制备预制体,通过气压浸渗技术在800 ℃,5 MPa条件下制备金刚石–SiC/Al复合材料。利用扫描电镜、红外热成像仪、激光导热仪等对复合材料性能进行分析,研究SiC和金刚石的含量与粒径比对复合材料构型的影响,从而优化复合材料导热性能。结果表明:在相同的SiC粒径下,金刚石体积分数的增加将使复合材料的导热性能明显提升。当金刚石体积分数为30%时,含F100 SiC的复合材料导热性能最佳,其热导率为344 W/(m∙K)。当金刚石体积分数相同,粒径比从0.07增大到0.65时,复合材料导热性能依次提升;且在金刚石体积分数为15%时,复合材料的热导率增幅最大,从174 W/(m∙K)增大到274 W/(m∙K),增长了57%。通过改善金刚石–SiC/Al复合材料中增强体的含量和粒径比可以调控复合材料构型,充分发挥复合材料的导热潜力。

-

关键词:

- 金刚石–SiC/Al复合材料 /

- 气压浸渗法 /

- 复合构型 /

- 热导率

Abstract: The preforms were prepared with SiC and W-coated diamond reinforcements, and the diamond-SiC/Al composites were prepared by gas pressure infiltration technology at 800 ℃ and 5 MPa. The properties of composite materials were analyzed by scanning electron microscope, infrared thermal imager and laser thermal conductivity meter. The influences of the content and the particle size ratio R of SiC and diamond on the configuration of composites were investigated to optimize the thermal conductivity of the composites. The results show that with the same SiC particle size, the thermal conductivity of the composites will be significantly improved with the increase of diamond volume fraction. When the volume fraction of diamond is 30%, the thermal conductivity of the composites containing F100 SiC is the best, which reaches 344 W/(m∙K). When the volume fraction of diamond is the same and the particle size ratio R increases from 0.07 to 0.65, the thermal conductivity of the composite increases in turn. Moreover, the thermal conductivity of composites with diamond volume fraction of 15% increases from 174 W/(m∙K) to 274 W/(m∙K), which achieves the largest increase of 57%.Therefore, by improving the content and the particle size ratio of reinforcements in the diamond-SiC/Al composites, the configuration of composites can be regulated to realize full potential of thermal conductivity. -

表 1 复合材料中增强体粒径及体积分数

Table 1. Reinforcement particle sizes and volume fractions in composites

样品

编号金刚石体积分数

φ1 / %SiC体积分数

φ2 / %SiC颗粒粒径

d0 / μmSiC粒度

代号S1 0 77 150 F100 S2 15 62 150 F100 S3 30 47 150 F100 S4 0 77 58 F200 S5 15 62 58 F200 S6 30 47 58 F200 S7 0 77 17 F500 S8 15 62 17 F500 S9 30 47 17 F500 -

[1] 林宁, 李伟青, 康嘉杰, 等. 高导热涂层制备及其性能研究进展 [J]. 表面技术,2021,50(6):128-137. doi: 10.16490/j.cnki.issn.1001-3660.2021.06.013LIN ning, LI Weiqing, KANG Jiajie, et al. Research progress of preparation and performance of high thermal conductivity coatings [J]. Surface Technology,2021,50(6):128-137. doi: 10.16490/j.cnki.issn.1001-3660.2021.06.013 [2] MORRE G. Cramming more components onto integrated circuits [J]. Electronics,1965,38:114-117. [3] ZHANG P, YUAN P, JIANG X, et al. A theoretical review on interfacial thermal transport at the nanoscale [J]. Small,2018,14(2):19. [4] WALDROP M. The chips are down for Moore's law [J]. Nature,2016,530(7589):144-147. doi: 10.1038/530144a [5] EDWARDS C. Moore's law: What comes next? [J]. Communications of the Acm,2021,64(2):12-14. doi: 10.1145/3440992 [6] GRIER D. Forgetting Moore's law [J]. Computer,2021,54(6):46-48. doi: 10.1109/MC.2021.3070241 [7] XU B, HU S, HUNG S, et al. Weaker bonding can give larger thermal conductance at highly mismatched interfaces [J]. Science Advances,2021,7(17):7. [8] HOHENSEE G, WILSON R, CAHILL D. Thermal conductance of metal-diamond interfaces at high pressure [J]. Nature Communications,2015,6:9. [9] CHA S, KIM K, ARSHAD S, et al. Extraordinary strengthening effect of carbon nanotubes in metal-matrix nanocomposites processed by molecular-level mixing [J]. Advanced Materials,2005,17(11):1377. doi: 10.1002/adma.200401933 [10] 马如龙, 彭超群, 王日初, 等. 电子封装用diamond/Al复合材料研究进展 [J]. 中国有色金属学报,2014,24(3):689-699.MA Rulong, PENG Chaoqun, WANG Richu, et al. Research progress of diamond/aluminum composites for electronic packaging [J]. The Chinese Journal of Nonferrous metals,2014,24(3):689-699. [11] 胡海亭, 胡明, 孟君晟. 热压对喷涂SiCp/Al复合材料组织和热性能的影响 [J]. 表面技术,2009,38(5):6-8. doi: 10.3969/j.issn.1001-3660.2009.05.003HU Haiting, HU Ming, MENG Junsheng. Effects of hot pressed treatment on microstructures and thermal properties of spraying SiCp/Al composites [J]. Surface Technology,2009,38(5):6-8. doi: 10.3969/j.issn.1001-3660.2009.05.003 [12] CHE Z, LI J, WANG Q, et al. The formation of atomic-level interfacial layer and its effect on thermal conductivity of W-coated diamond particles reinforced Al matrix composites [J]. Composites Part A: Applied Science and Manufacturing,2018,107:164-170. doi: 10.1016/j.compositesa.2018.01.002 [13] WANG L, LI J, BAI G, et al. Interfacial structure evolution and thermal conductivity of Cu-Zr/diamond composites prepared by gas pressure infiltration [J]. Journal of Alloys and Compounds,2019,781:800-809. doi: 10.1016/j.jallcom.2018.12.053 [14] YANG W, CHEN G, WAN P, et al. Enhanced thermal conductivity in diamond/aluminum composites with tungsten coatings on diamond particles prepared by magnetron sputtering method [J]. Journal of Alloys and Compounds,2017,726:623-631. doi: 10.1016/j.jallcom.2017.08.055 [15] 张荻, 谭占秋, 熊定邦, 等. 热管理用金属基复合材料的应用现状及发展趋势 [J]. 中国材料进展,2018,37(12):994-1001.ZHANG Di, TAN Zhanqiu, XIONG Dingbang, et al. Application and prospect of matal matrix composites for thermal management: An overview [J]. Materials China,2018,37(12):994-1001. [16] XUE C, YU J, ZHU X. Thermal properties of diamond/SiC/Al composites with high volume fractions [J]. Materials & Design,2011,32(8/9):4225-4229. [17] GUO H, HAN Y, ZHANG X, et al. Microstructure and thermophysical properties of SiC/Al composites mixed with diamond [J]. Transactions of Nonferrous Metals Society of China,2015,25(1):170-174. doi: 10.1016/S1003-6326(15)63592-0 [18] ZHANG L, WEI Q, AN J, et al. Construction of 3D interconnected diamond networks in Al-matrix composite for high-efficiency thermal management [J]. Chemical Engineering Journal,2020,380:9. [19] YE W, WEI Q, ZHANG L, et al. Macroporous diamond foam: A novel design of 3D interconnected heat conduction network for thermal management [J]. Materials & Design,2018,156:32-41. [20] 安俊杰, 魏秋平, 叶文涛, 等. 泡沫铜表面改性对化学气相沉积高质量泡沫金刚石的影响 [J]. 表面技术,2020,49(3):97-105.AN Junjie, WEI Qiuping, YE Wentao, et al. High quality diamond films deposited on surface modified Cu foams by chemical vapor deposition method [J]. Surface Technology,2020,49(3):97-105. [21] MIZUUCHI K, INOUE K, AGARI Y, et al. Bimodal and monomodal diamond particle effect on the thermal properties of diamond-particle-dispersed Al-matrix composite fabricated by SPS [J]. Microelectronics Reliability,2014,54(11):2463-2470. doi: 10.1016/j.microrel.2014.04.006 [22] MAIORANO L, MOLINA J. Guiding heat in active thermal management: One-pot incorporation of interfacial nano-engineered aluminium/diamond composites into aluminium foams [J]. Composites Part A: Applied Science and Manufacturing,2020,133:12. [23] LEE H, JEON K, KIM H, et al. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications [J]. Journal of Materials Science,2000,35(24):6231-6236. doi: 10.1023/A:1026749831726 [24] TAN Z, XIONG D, FAN G, et al. Enhanced thermal conductivity of diamond/aluminum composites through tuning diamond particle dispersion [J]. Journal of Materials Science,2018,53(9):6602-6612. doi: 10.1007/s10853-018-2024-y -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS