Nanoscale removal mechanisms in abrasive machining of brittle solids

-

摘要: 以共价键或离子键结合的脆性单晶、多晶和光学玻璃是能源、通信、交通和医疗领域新兴微电子和光电器件的核心材料。为满足高性能器件的制造需求,脆性材料通常需要经过磨削、研磨、抛光等超精密磨粒加工,获得具有原子级光滑的表面、近无损伤的亚表面和微米甚至纳米级的加工精度。优化磨粒加工工艺不仅可以有效地提高加工效率,降低制造成本,还能够延长脆性材料元器件的服役寿命,但开发高效率、低损伤超精密磨粒加工技术需深入理解脆性材料纳米尺度的去除机理。本文基于划擦力学原理,揭示脆性材料纳米尺度磨粒加工去除的本质,阐明磨粒加工过程中脆性材料脆性–塑性转变去除的基本原理,概述单磨粒纳米划擦脆性材料的形变和去除机制,以及磨粒加工过程中脆性材料的去除机理及材料微观结构对其局部变形及后续去除的影响规律,提出实现脆性材料高效延性加工的控制策略,有助于推动脆性材料超精密磨粒加工技术的进一步发展。Abstract: Brittle solids with dominant covalent-ionic bonding, including single crystals, polycrystals, and optical glass, are core materials for modern microelectronic and optoelectronic devices that are widely used in energy, communication, transportation, and medicine sectors. In high performance device applications, those brittle materials must be machined into parts that often have an extremely smooth surface and a damage-free subsurface with sub-micron precision. Optimisation of an abrasive machining process for the brittle solids can significantly enhance production efficiency and reduce manufacturing cost, as well as prolong device life. The development of high efficiency and low damage ultraprecision shaping technologies for this class of solids requires an in-depth understanding of their deformation and removal mechanisms at nanoscale. In this work, the fundamental mechanisms of deformation and removal of brittle materials involved in individual or cumulative contacts with blunt and sharp grits are analysed, using the scratch-related micromechanics as the theoretical basis. Essentials of brittle-to-ductile transitions in abrasive machining are outlined. Influence of the diversity in material microstructures in determining local deformation and subsequent removal is highlighted. Practical requirements are suggested for further advancing ultraprecision abrasive machining of those brittle solids.

-

Key words:

- brittle materials /

- abrasive machining /

- deformation /

- fracture /

- removal mechanism

-

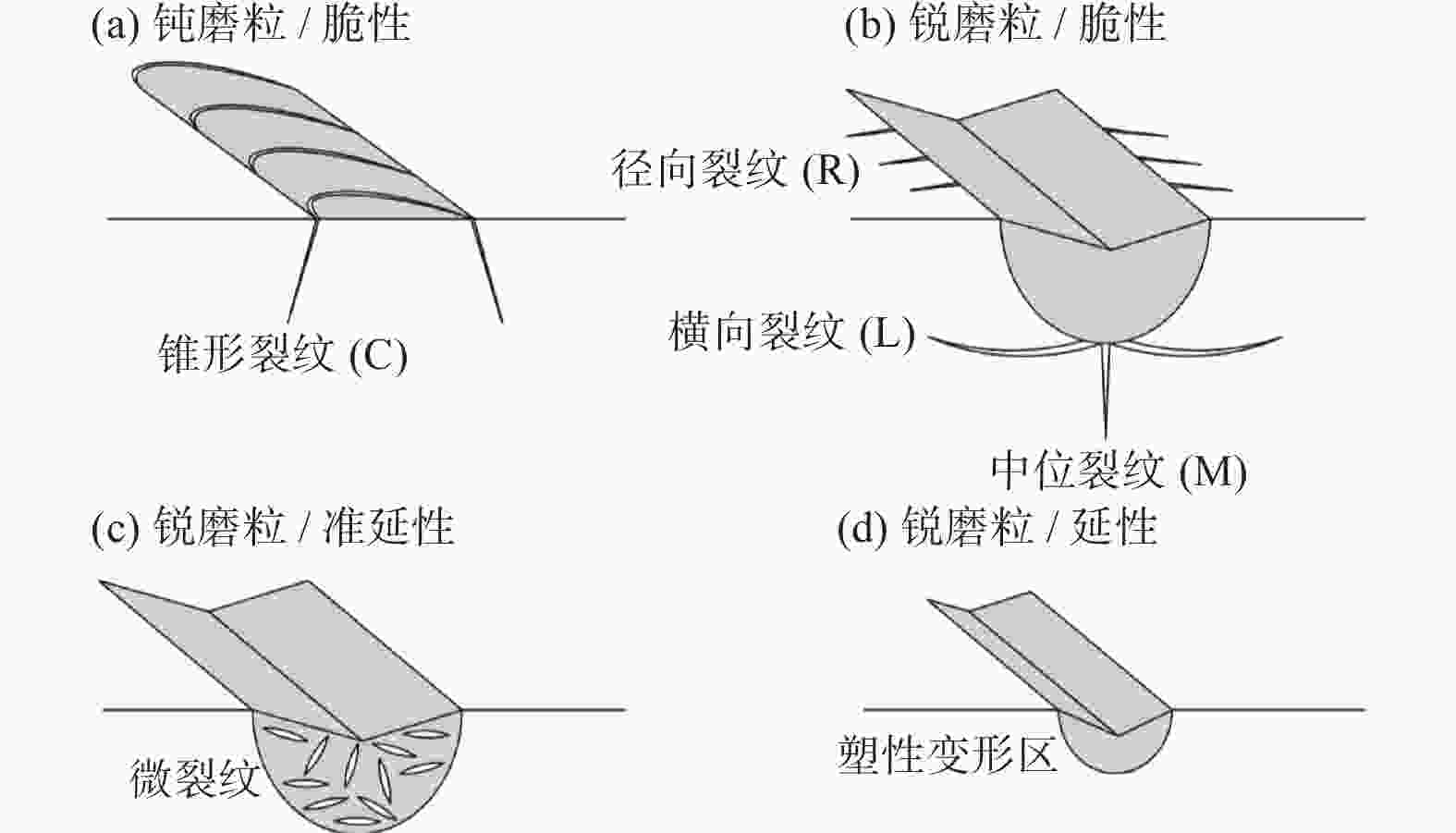

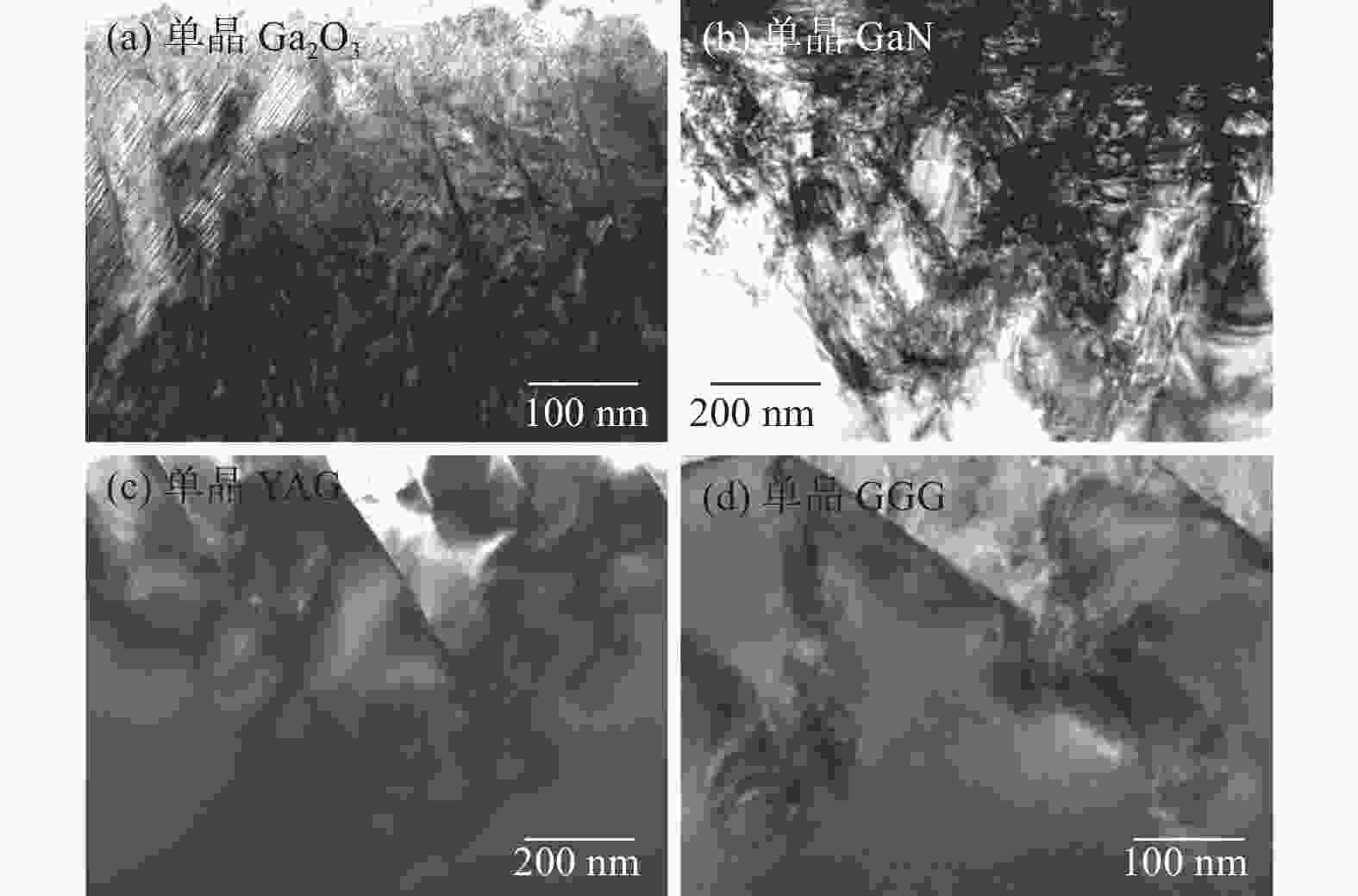

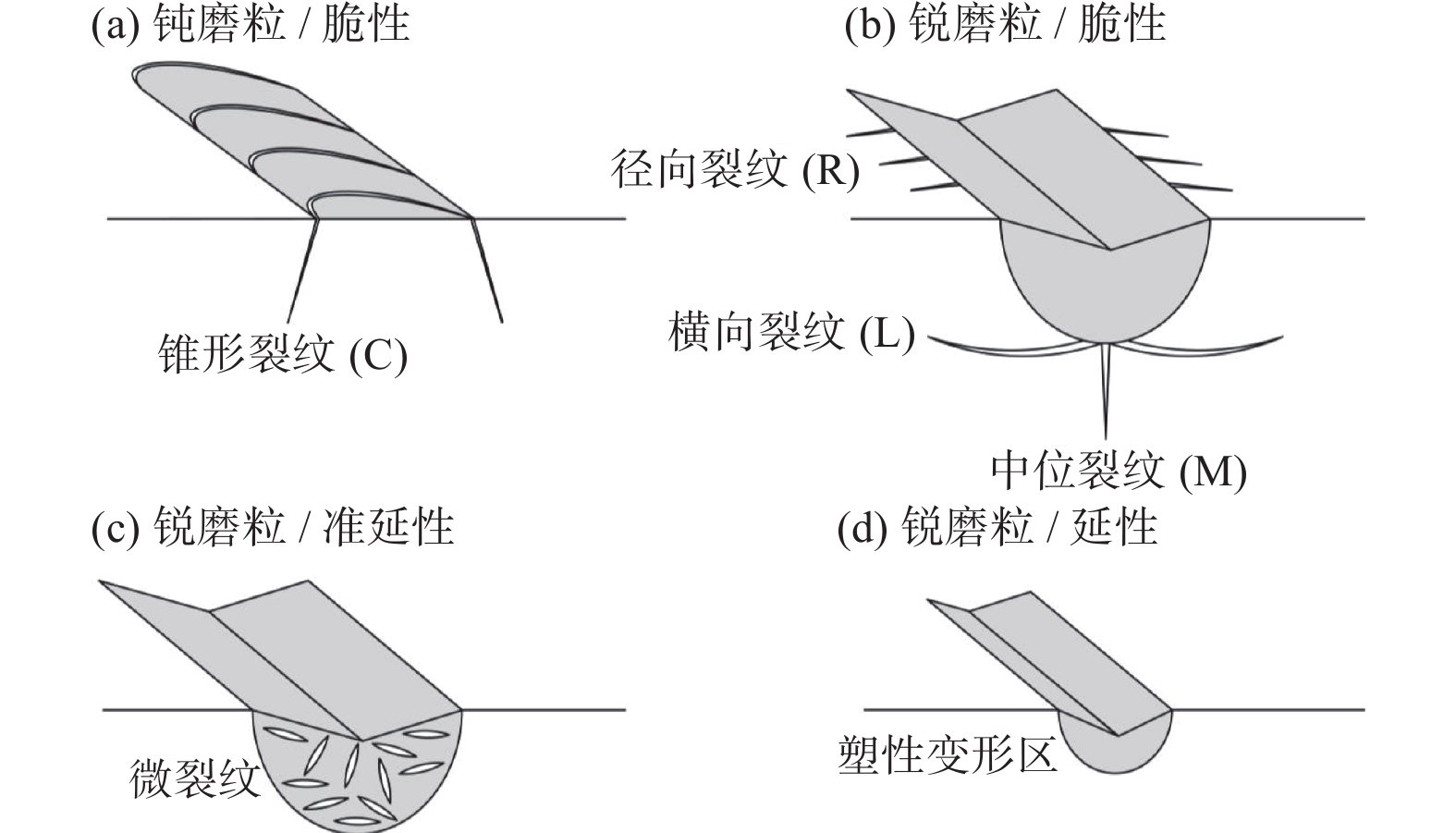

图 1 脆性材料磨粒划擦诱导的形变和断裂模式

(a) 钝磨粒划擦诱导高脆性材料产生间断的锥形裂纹[12];(b) 锐磨粒划擦诱导高脆性材料产生中位裂纹、横向裂纹和径向裂纹,以及伴随横向裂纹及中位裂纹的塑性变形区[13-14];(c) 锐磨粒划擦较软的脆性材料产生具有微裂纹的近塑性变形[15];(d) 锐磨粒划擦脆性材料产生无裂纹的纯塑性变形[1]

Figure 1. Deformation and fracture modes of brittle materials in translating blunt and sharp contacts

(a) Intermittent partial conical cracks on highly brittle surface induced by blunt abrasive scratching[12]; (b) Median crack, lateral crack and radical crack in highly brittle body induced by sharp abrasive scratching[13-14]; (c) Quasi-plastic deformation with micro cracks in relatively soft brittle material scratched by sharp abrasives[15]; (d) Plastic deformation without cracks in brittle solid induced by sharp abrasive scratching[1]

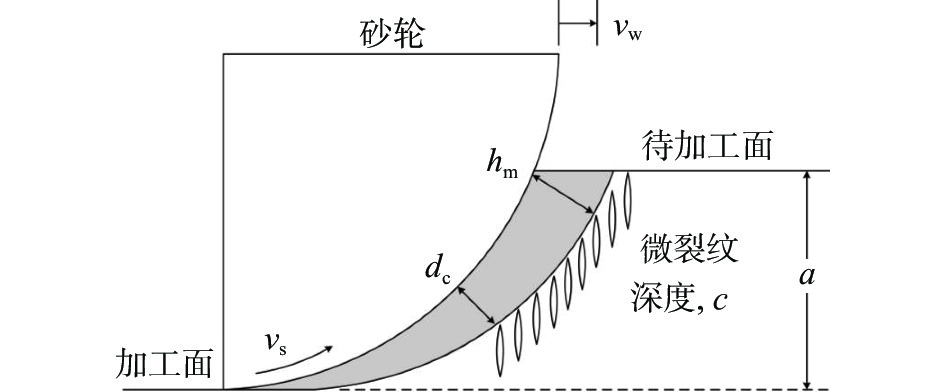

(a) 钝磨粒多次重叠划擦导致破碎去除;(b) 锐磨粒划擦诱导材料横向断裂去除;(c) 锐磨粒划擦多晶材料诱导晶粒脱落去除;(d) 锐磨粒划擦产生挤压去除

Figure 2. Removal modes of brittle materials[1-2]

(a) Fracture removal induced by overlapping scratches of blunt abrasive; (b) Lateral fracture generated by sharp abrasive scratching; (c) Grain ejecting produced by sharp abrasive scratching polycrystalline material; (d) Extrusion by sharp abrasive scratching

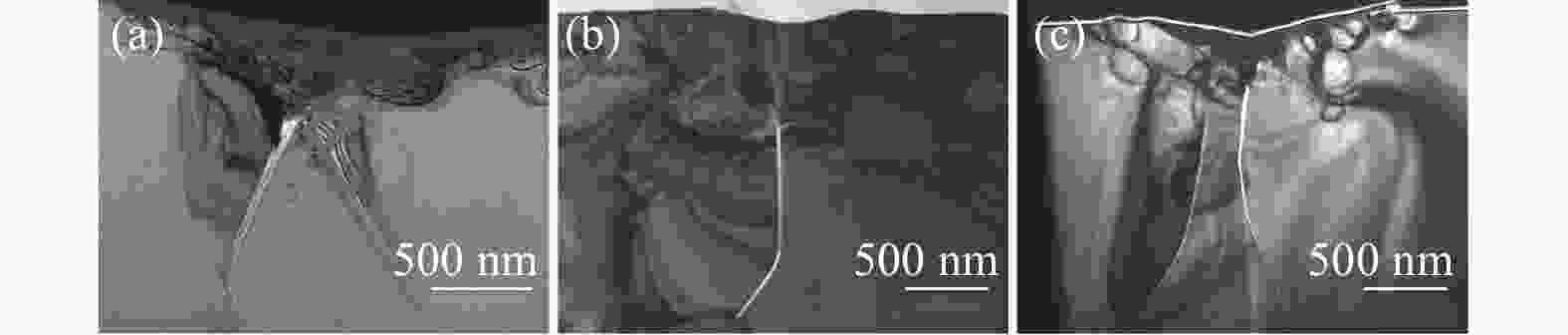

图 4 单晶材料脆性域纳米划擦的亚表面TEM显微图

(a) 锐金刚石压头30 mN法向力划擦单晶Si;(b) 钝金刚石压头6 mN法向力划擦单晶GaAs[3];(c) 锐金刚石压头8 mN法向力划擦单晶GGG[29]

Figure 4. TEM micrographs of nano-scratched subsurfaces of single crystal materials in brittle regime

(a) Single-crystal Si scratched with sharp diamond indenter at normal force of 30 mN; (b) Single-crystal GaAs[3] scratched with blunt diamond indenter at normal force of 6 mN; (c) Single-crystal GGG[29] scratched with sharp diamond indenter at normal force of 8 mN

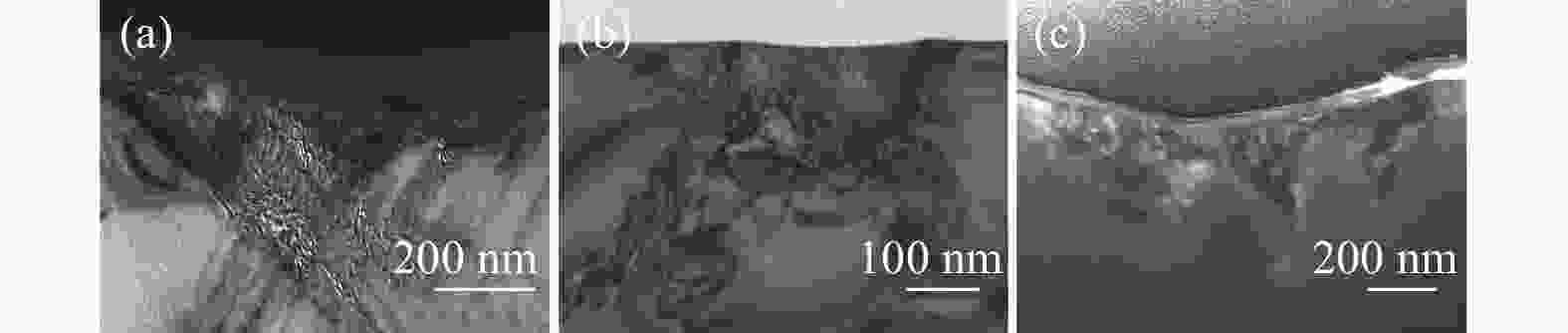

图 5 单晶材料延性域纳米划擦的亚表面TEM显微图

(a) 锐金刚石压头25 mN法向力划擦单晶Si导致{111}晶面发生滑移;(b) 钝金刚石压头1 mN法向力划擦单晶GaAs[3]导致{111}晶面发生滑移;(c) 锐金刚石压头3 mN法向力划擦单晶GGG[30]导致{114}晶面发生滑移

Figure 5. TEM micrographs of nano-scratched subsurfaces of single crystal materials in ductile regime

(a) Slip of {111} crystal planes when scratching single-crystal Si with sharp diamond indenter at normal force of 25 mN; (b) Slip of {111} crystal planes when scratching single-crystal GaAs[3] with blunt diamond indenter at normal force of 1 mN; (c) Slip of {114} crystal planes when scratching single-crystal GGG[30] with sharp diamond indenter at normal force of 3 mN

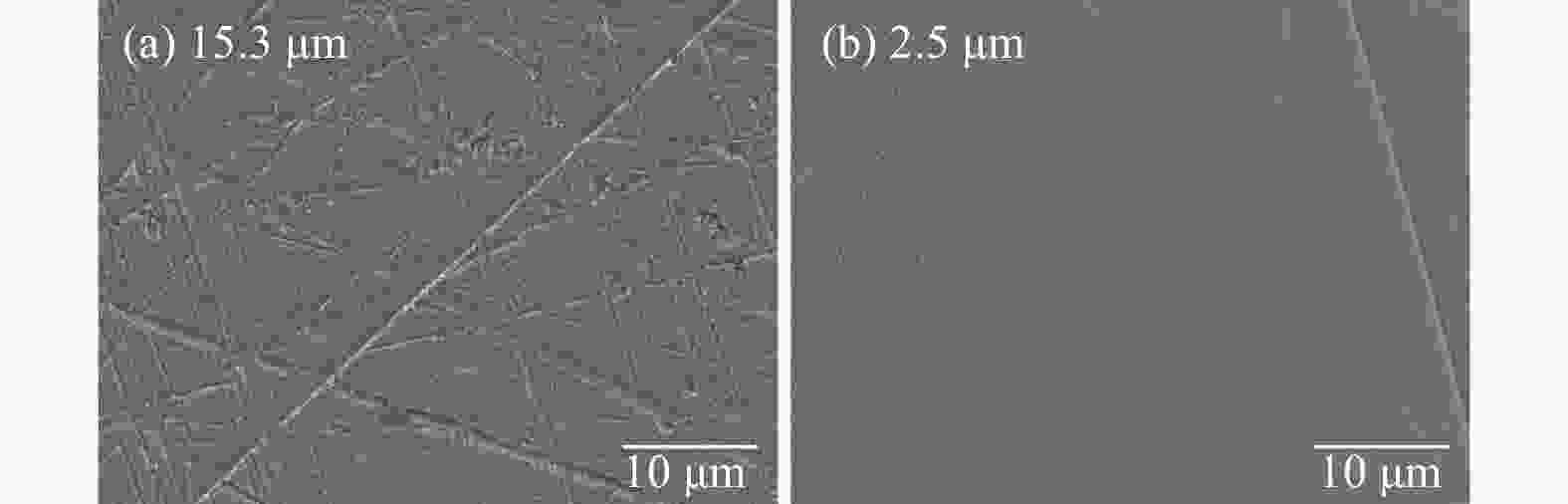

图 7 单晶材料经金刚石砂轮脆性域磨削的亚表面TEM观测结果

(a) 磨粒粒径为20 μm,单晶GaAs[46];(b) 磨粒粒径为20 μm,单晶YAG[9];(c) 磨粒粒径约3 μm,单晶Ga2O3[47]

Figure 7. Subsurface TEM micrographs of single crystals after brittle grinding with diamond grinding wheels

(a) Single-crystal GaAs[46], grain size of 20 μm; (b) Single-crystal YAG[9], grain size of 20 μm; (c) Single-crystal Ga2O3[47], grain size of 3 μm

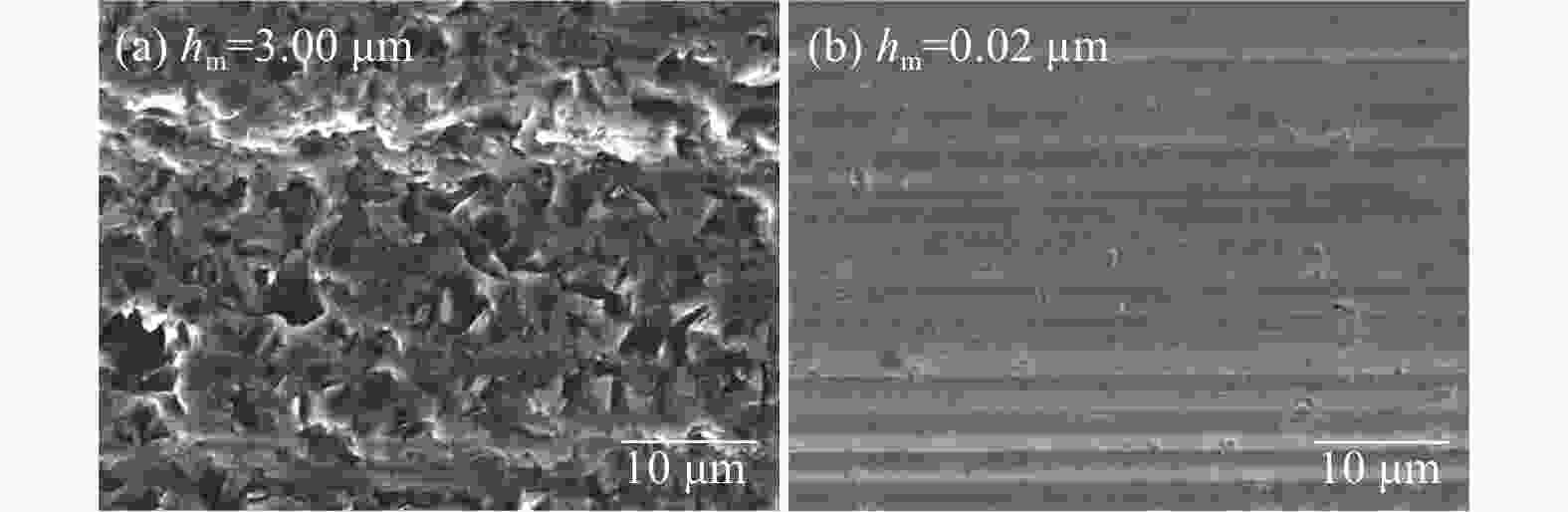

图 8 单晶材料经金刚石砂轮延性域磨削的亚表面TEM显微图

(a) 磨粒粒径为9.0 μm,材料为Ga2O3[48];(b) 磨粒粒径为5.0 μm,单晶GaN;(c) 磨粒粒径为2.5 μm,单晶YAG[9]; (d) 磨粒粒径为3.8 μm,单晶GGG[10]

Figure 8. Subsurface TEM micrographs of single-crystal materials after ductile grinding with diamond grinding wheels

(a) Single-crystal Ga2O3[48], grain size of 9.0 μm; (b) Single-crystal GaN, grain size of 5.0 μm; (c) Single-crystal YAG[9], grain size of 2.5 μm; (d) Single-crystal GGG[10], grain size of 3.8 μm

-

[1] HUANG H, LI X, MU D, et al. Science and art of ductile grinding of brittle solids [J]. International Journal of Machine Tools and Manufacture,2020,161:103675. doi: 10.1016/j.ijmachtools.2020.103675 [2] LAWN B R, BORRERO-LOPEZ O, HUANG H, et al. Micromechanics of machining and wear in hard and brittle materials [J]. Journal of the American Ceramic Society,2020,104(1):5-22. doi: 10.1111/jace.17502 [3] WU Y, MU D, HUANG H. Deformation and removal of semiconductor and laser single crystals at extremely small scales [J]. International Journal of Extreme Manufacturing,2020,2(2):12006. doi: 10.1088/2631-7990/ab7a2a [4] SREEJITH P S, NGOI B K A. Material removal mechanisms in precision machining of new materials [J]. International Journal of Machine Tools and Manufacture,2001,41(12):1831-1843. doi: 10.1016/S0890-6955(01)00014-1 [5] PEI Z J, FISHER G R, LIU J. Grinding of silicon wafers: A review from historical perspectives [J]. International Journal of Machine Tools and Manufacture,2008,48(12/13):1297-1307. doi: 10.1016/j.ijmachtools.2008.05.009 [6] FENG P, WANG J, ZHANG J, et al. Damage formation and suppression in rotary ultrasonic machining of hard and brittle materials: A critical review [J]. Ceramics International,2017,44:1227-1239. doi: 10.1016/j.ceramint.2017.10.050 [7] YAN J, ZHANG Z, KURIYAGAWA T. Mechanism for material removal in diamond turning of reaction-bonded silicon carbide [J]. International Journal of Machine Tools and Manufacture,2009,49(5):366-374. doi: 10.1016/j.ijmachtools.2008.12.007 [8] MUKAIDA M, YAN J. Ductile machining of single-crystal silicon for microlens arrays by ultraprecision diamond turning using a slow tool servo [J]. International Journal of Machine Tools and Manufacture,2017,115:2-14. doi: 10.1016/j.ijmachtools.2016.11.004 [9] LI C, LI X, WU Y, et al. Deformation mechanism and force modelling of the grinding of YAG single crystals [J]. International Journal of Machine Tools and Manufacture,2019,143:23-37. doi: 10.1016/j.ijmachtools.2019.05.003 [10] LI C, WU Y, LI X, et al. Deformation characteristics and surface generation modelling of crack-free grinding of GGG single crystals [J]. Journal of Materials Processing Technology,2020,279:116577. doi: 10.1016/j.jmatprotec.2019.116577 [11] ZHANG C, RENTSCH R, BRINKSMEIER E. Advances in micro ultrasonic assisted lapping of microstructures in hard–brittle materials: A brief review and outlook [J]. International Journal of Machine Tools and Manufacture,2005,45(7/8):881-890. doi: 10.1016/j.ijmachtools.2004.10.018 [12] LAWN B R. Partial cone crack formation in a brittle material loaded with a sliding spherical indenter [J]. Proceedings of the Royal Society of London. Series A:Mathematical and Physical Sciences,1967,299(1458):307-316. doi: 10.1098/rspa.1967.0138 [13] LAWN B R, COOK R F. Probing material properties with sharp indenters: A retrospective [J]. Journal of Materials Science,2012,47:1-22. doi: 10.1007/s10853-011-5865-1 [14] LAWN B, WILSHAW R. Indentation fracture: Principles and applications [J]. Journal of Materials Science,1975,10:1049-1081. doi: 10.1007/BF00823224 [15] LAWN B R, PADTURE N P, CAIT H, et al. Making ceramics “ductile” [J]. Science,1994,263(5150):1114-1116. doi: 10.1126/science.263.5150.1114 [16] OLIVER W C, PHARR G M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology [J]. Journal of Materials Research,2004,19(1):3-20. doi: 10.1557/jmr.2004.19.1.3 [17] JUNG Y G, PAJARES A, BANERGEE R, et al. Strength of silicon, sapphire and glass in the subthreshold flaw region [J]. Acta Materialia,2004,52(12):3459-3466. doi: 10.1016/j.actamat.2004.03.043 [18] XU H H, JAHANMIR S. Microfracture and material removal in scratching of alumina [J]. Journal of Materials Science,1995,30(9):2235-2247. doi: 10.1007/BF01184566 [19] BIFANO T G, DOW T A, SCATTERGOOD R O. Ductile-regime grinding: A new technology for machining brittle materials [J]. Journal of Engineering for Industry,1991,113(2):184-189. doi: 10.1115/1.2899676 [20] ZHONG Z W. Ductile or partial ductile mode machining of brittle materials [J]. The International Journal of Advanced Manufacturing Technology,2003,21:579-585. doi: 10.1007/s00170-002-1364-5 [21] NEO W K, KUMAR A S, RAHMAN M. A review on the current research trends in ductile regime machining [J]. The International Journal of Advanced Manufacturing Technology,2012,63:465-480. doi: 10.1007/s00170-012-3949-y [22] WU H, MELKOTE S N. Study of ductile-to-brittle transition in single grit diamond scribing of silicon: Application to wire sawing of silicon wafers [J]. Journal of Engineering Materials and Technology,2012,134(4):041011. doi: 10.1115/1.4006177 [23] BEAUCAMP A, SIMON P, CHARLTON P, et al. Brittle-ductile transition in shape adaptive grinding (SAG) of SiC aspheric optics [J]. International Journal of Machine Tools and Manufacture,2017,115:29-37. doi: 10.1016/j.ijmachtools.2016.11.006 [24] NAKASUJI T, KODERA S, HARA S, et al. Diamond turning of brittle materials for optical components [J]. CIRP Annals-Manufacturing Technology,1990,39:89-92. doi: 10.1016/S0007-8506(07)61009-9 [25] KOVALCHENKO A M. Studies of the ductile mode of cutting brittle materials (A review) [J]. Journal of Superhard Materials,2013,35:259-276. doi: 10.3103/S1063457613050018 [26] HUANG H, LAWN B R, COOK R F, et al. Critique of materials‐based models of ductile machining in brittle solids [J]. Journal of the American Ceramic Society,2020,103:6096-6100. doi: 10.1111/jace.17344 [27] MALKIN S, GUO C. Grinding technology: Theory and application of machining with abrasives [M]. Norwalk: Industrial Press Inc. , 2008. [28] HUANG H, LIU Y C. Experimental investigations of machining characteristics and removal mechanisms of advanced ceramics in high speed deep grinding [J]. International Journal of Machine Tools and Manufacture,2003,43:811-823. doi: 10.1016/S0890-6955(03)00050-6 [29] LI C, ZHANG F, MENG B, et al. Research of material removal and deformation mechanism for single crystal GGG (Gd3Ga5O12) based on varied-depth nanoscratch testing [J]. Materials & Design,2017,125:180-188. doi: 10.1016/j.matdes.2017.04.018 [30] LI C, ZHANG F, PIAO Y. Strain-rate dependence of surface/subsurface deformation mechanisms during nanoscratching tests of GGG single crystal [J]. Ceramics International,2019,45(12):15015-15024. doi: 10.1016/j.ceramint.2019.04.238 [31] KOSMAC T, OBLAK C, JEVNIKAR P, et al. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic [J]. Dental Materials,1999,15(6):426-433. doi: 10.1016/S0109-5641(99)00070-6 [32] WU H, ROBERTS S G, DERBY B. Residual stress and subsurface damage in machined alumina and alumina/silicon carbide nanocomposite ceramics [J]. Acta Materialia,2001,49(3):507-517. doi: 10.1016/S1359-6454(00)00333-5 [33] COLILLA M, MANZANO M, VALLET-REGI M. Recent advances in ceramic implants as drug delivery systems for biomedical applications [J]. International Journal of Nanomedicine,2008,3(4):403-414. doi: 10.2147/IJN.S3548 [34] YIN L, HUANG H. Ceramic response to high speed grinding [J]. Machining Science and Technology,2004,8(1):21-37. doi: 10.1081/MST-120034240 [35] BOCANEGRA-BERNAL M H, MATOVIC B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures [J]. Materials Science and Engineering: A,2010,527(6):1314-1338. doi: 10.1016/j.msea.2009.09.064 [36] XU H H, WEI L, JAHANMIR S. Influence of grain size on the grinding response of alumina [J]. Journal of the American Ceramic Society,1996,79:1307-1313. doi: 10.1111/j.1151-2916.1996.tb08589.x [37] XU H H, PADTURE N P, JAHANMIR S. Effect of microstructure on material‐removal mechanisms and damage tolerance in abrasive machining of silicon carbide [J]. Journal of the American Ceramic Society,1995,78(9):2443-2448. doi: 10.1111/j.1151-2916.1995.tb08683.x [38] XU H H K, JAHANMIR S, IVES L K. Effect of grinding on strength of tetragonal zirconia and zirconia-toughened alumina [J]. Machining Science and Technology,1997,1(1):49-66. doi: 10.1080/10940349708945637 [39] XU H H, WEI L, JAHANMIR S. Grinding force and microcrack density in abrasive machining of silicon nitride [J]. Journal of Materials Research,1995,10(12):3204-3209. doi: 10.1557/JMR.1995.3204 [40] CAI L, GUO X, GAO S, et al. Material removal mechanism and deformation characteristics of AlN ceramics under nanoscratching [J]. Ceramics International,2019,45(16):20545-20554. doi: 10.1016/j.ceramint.2019.07.034 [41] YIN L, HUANG H, RAMESH K, et al. High speed versus conventional grinding in high removal rate machining of alumina and alumina-titania [J]. International Journal of Machine Tools and Manufacture,2005,45(7/8):897-907. doi: 10.1016/j.ijmachtools.2004.10.016 [42] COOK R F, PHARR G M. Direct observation and analysis of indentation cracking in glasses and ceramics [J]. Journal of the American Ceramic Society,1990,73(4):787-817. doi: 10.1111/j.1151-2916.1990.tb05119.x [43] BURGHARD Z, ZIMMERMANN A, RODEL J, et al. Crack opening profiles of indentation cracks in normal and anomalous glasses [J]. Acta Materialia,2004,52(2):293-297. doi: 10.1016/j.actamat.2003.09.014 [44] GU W, YAO Z, LIANG X. Material removal of optical glass BK7 during single and double scratch tests [J]. Wear,2011,270(3):241-246. doi: DOI:10.1016/j.wear.2010.10.064 [45] LEE K, MARIMUTHU K P, KIM C L, et al. Scratch-tip-size effect and change of friction coefficient in nano/micro scratch tests using XFEM [J]. Tribology International,2018,120:398-410. doi: 10.1016/j.triboint.2018.01.003 [46] LI X, HUANG S, WU Y, et al. Performance evaluation of graphene oxide nanosheet water coolants in the grinding of semiconductor substrates [J]. Precision Engineering,2019,60:291-298. doi: 10.1016/j.precisioneng.2019.08.016 [47] WANG Y, LI X, WU Y, et al. The removal mechanism and force modelling of gallium oxide single crystal in single grit grinding and nanoscratching [J]. International Journal of Mechanical Sciences,2021,204:106562. doi: 10.1016/j.ijmecsci.2021.106562 [48] GAO S, WU Y, KANG R, et al. Nanogrinding induced surface and deformation mechanism of single crystal β-Ga2O3 [J]. Materials Science in Semiconductor Processing,2018,79:165-170. doi: 10.1016/j.mssp.2017.12.017 [49] ZHANG Z, WU Y, HUANG H. New deformation mechanism of soft-brittle CdZnTe single crystals under nanogrinding [J]. Scripta Materialia,2010,63(6):621-624. doi: 10.1016/j.scriptamat.2010.05.043 [50] IRWAN R, HUANG H, ZHENG H Y, et al. Mechanical properties and material removal characteristics of soft-brittle HgCdTe single crystals [J]. Materials Science and Engineering: A,2013,559:480-485. doi: 10.1016/j.msea.2012.08.129 [51] MALKIN S, HWANG T W. Grinding mechanisms for ceramics [J]. CIRP Annals-Manufacturing Technology,1996,45(2):569-580. doi: 10.1016/S0007-8506(07)60511-3 [52] ZHANG B, HOWES T D. Material-removal mechanisms in grinding ceramics [J]. CIRP Annals Manufacturing Technology,1994,43(1):305-308. doi: 10.1016/S0007-8506(07)62219-7 [53] ZAHEDI A, TAWAKOLI T, AKBARI J. Energy aspects and workpiece surface characteristics in ultrasonic-assisted cylindrical grinding of alumina-zirconia ceramics [J]. International Journal of Machine Tools and Manufacture,2015,90:16-28. doi: 10.1016/j.ijmachtools.2014.12.002 [54] ZARUDI I, ZHANG L. On the limit of surface integrity of alumina by ductile-mode grinding [J]. Journal of Engineering Materials and Technology,2000,122(1):129-134. doi: 10.1115/1.482776 [55] COOK R F. Fracture mechanics of sharp scratch strength of polycrystalline alumina [J]. Journal of the American Ceramic Society,2017,100(3):1146-1160. doi: 10.1111/jace.14634 [56] YANG Z, ZHU L, LIN B, et al. The grinding force modeling and experimental study of ZrO2 ceramic materials in ultrasonic vibration assisted grinding [J]. Ceramics International,2019,45(7):8873-8889. doi: 10.1016/j.ceramint.2019.01.216 [57] REKOW E, SILVA N, COELHO P, et al. Performance of dental ceramics: Challenges for improvements [J]. Journal of Dental Research,2011,90(8):937-952. doi: 10.1177/0022034510391795 [58] YIN L, JAHANMIR S, IVES L K. Abrasive machining of porcelain and zirconia with a dental handpiece [J]. Wear,2003,255:975-989. doi: 10.1016/S0043-1648(03)00195-9 [59] SHIH A J, SCATTERGOOD R O, CURRY A C, et al. Cost-effective grinding of zirconia using the dense vitreous bond silicon carbide wheel [J]. Journal of Manufacturing Science & Engineering,2003,125(2):297-303. doi: DOI:10.1115/1.1559167 [60] ANAND P S P, ARUNACHALAM N, VIJAYARAGHAVAN L. Investigation on grindability of medical implant material using a silicon carbide wheel with different cooling conditions [J]. Procedia Manufacturing,2017,10:417-428. doi: 10.1016/j.promfg.2017.07.016 [61] LEE S K, TANDON R, READEY M J, et al. Scratch damage in zirconia ceramics [J]. Journal of the American Ceramic Society,2000,83(6):1428-1432. doi: 10.1111/j.1151-2916.2000.tb01406.x [62] DAI J, SU H, YU T, et al. Experimental investigation on materials removal mechanism during grinding silicon carbide ceramics with single diamond grain [J]. Precision Engineering,2018,51:271-279. doi: 10.1016/j.precisioneng.2017.08.019 [63] LI Z, ZHANG F, LUO X. Subsurface damages beneath fracture pits of reaction-bonded silicon carbide after ultra-precision grinding [J]. Applied Surface Science,2018,448:341-350. doi: 10.1016/j.apsusc.2018.04.038 [64] BORRERO-LOPEZ O, ORTIZ A L, GUIBERTEAU F, et al. Improved sliding‐wear resistance in in situ‐toughened silicon carbide [J]. Journal of the American Ceramic Society,2005,88(12):3531-3534. doi: 10.1111/j.1551-2916.2005.00628.x [65] PADTURE N P, EVANS C J, XU H H, et al. Enhanced machinability of silicon carbide via microstructural design [J]. Journal of the American Ceramic Society,1995,78(1):215-217. doi: 10.1111/j.1151-2916.1995.tb08386.x [66] YIN L, VANCOILLE E Y J, RAMESH K, et al. Surface characterization of 6H-SiC (0001) substrates in indentation and abrasive machining [J]. International Journal of Machine Tools and Manufacture,2004,44(6):607-615. doi: 10.1016/j.ijmachtools.2003.12.006 [67] AGARWAL S, RAO P V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding [J]. International Journal of Machine Tools and Manufacture,2008,48(6):698-710. doi: 10.1016/j.ijmachtools.2007.10.013 [68] LEE S K, LEE K S, LAWN B R, et al. Effect of starting powder on damage resistance of silicon nitrides [J]. Journal of the American Ceramic Society,1998,81(8):2061-2070. doi: 10.1111/j.1151-2916.1998.tb02588.x [69] HUANG H, YIN L, ZHOU L. High speed grinding of silicon nitride with resin bond diamond wheels [J]. Journal of Materials Processing Technology,2003,141:329-336. doi: 10.1016/S0924-0136(03)00284-X [70] AZARHOUSHANG B, SOLTANI B, ZAHEDI A. Laser-assisted grinding of silicon nitride by picosecond laser [J]. The International Journal of Advanced Manufacturing Technology,2017,93(3/4):2517-2529. doi: 10.1007/s00170-017-0440-9 [71] HUANG S, LI X, YU B, et al. Machining characteristics and mechanism of GO/SiO2 nanoslurries in fixed abrasive lapping [J]. Journal of Materials Processing Technology,2020,277:116444. doi: 10.1016/j.jmatprotec.2019.116444 [72] WU Y Q, HUANG H, ZOU J, et al. Nanoscratch-induced phase transformation of monocrystalline Si [J]. Scripta Materialia,2010,63(8):847-850. doi: 10.1016/j.scriptamat.2010.06.034 [73] MYLVAGANAM K, ZHANG L C. Nanotwinning in monocrystalline silicon upon nanoscratching [J]. Scripta Materialia,2011,65(3):214-216. doi: 10.1016/j.scriptamat.2011.04.012 [74] LIU H, XIE W, SUN Y, et al. Investigations on brittle-ductile cutting transition and crack formation in diamond cutting of mono-crystalline silicon [J]. The International Journal of Advanced Manufacturing Technology,2018,95:317-326. doi: 10.1007/s00170-017-1108-1 [75] LI C, PIAO Y, MENG B, et al. Phase transition and plastic deformation mechanisms induced by self-rotating grinding of GaN single crystals [J]. International Journal of Machine Tools and Manufacture,2022,172:103827. doi: 10.1016/j.ijmachtools.2021.103827 [76] WANG J, GUO B, ZHAO Q, et al. Dependence of material removal on crystal orientation of sapphire under cross scratching [J]. Journal of the European Ceramic Society,2017,37(6):2465-2472. doi: 10.1016/j.jeurceramsoc.2017.01.032 [77] DEMIR E, MERCAN C. A physics-based single crystal plasticity model for crystal orientation and length scale dependence of machining response [J]. International Journal of Machine Tools and Manufacture,2018,134:25-41. doi: 10.1016/j.ijmachtools.2018.06.004 [78] LUO Q, LU J, XU X. Study on the processing characteristics of SiC and sapphire substrates polished by semi-fixed and fixed abrasive tools [J]. Tribology International,2016,104:191-203. doi: 10.1016/j.triboint.2016.09.003 [79] HERMAN D, KRZOS J. Influence of vitrified bond structure on radial wear of CBN grinding wheels [J]. Journal of Materials Processing Technology,2009,209:5377-5386. doi: 10.1016/j.jmatprotec.2009.03.013 [80] ZHOU Y, ATWOOD M, GOLINI D, et al. Wear and self-sharpening of vitrified bond diamond wheels during sapphire grinding [J]. Wear,1998,219(1):42-45. doi: 10.1016/S0043-1648(98)00230-0 [81] HUANG H, CHEN W, YIN L, et al. Micro/meso ultra precision grinding of fibre optic connectors [J]. Precision Engineering,2004,28(1):95-105. doi: 10.1016/j.precisioneng.2003.08.001 [82] AXINTE D, BUTLER-SMITH P, AKGUN C, et al. On the influence of single grit micro-geometry on grinding behavior of ductile and brittle materials [J]. International Journal of Machine Tools and Manufacture,2013,74:12-18. doi: 10.1016/j.ijmachtools.2013.06.002 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS