Design and simulation analysis of rust removal grinding block on inner wall of elbow at constant pressure

-

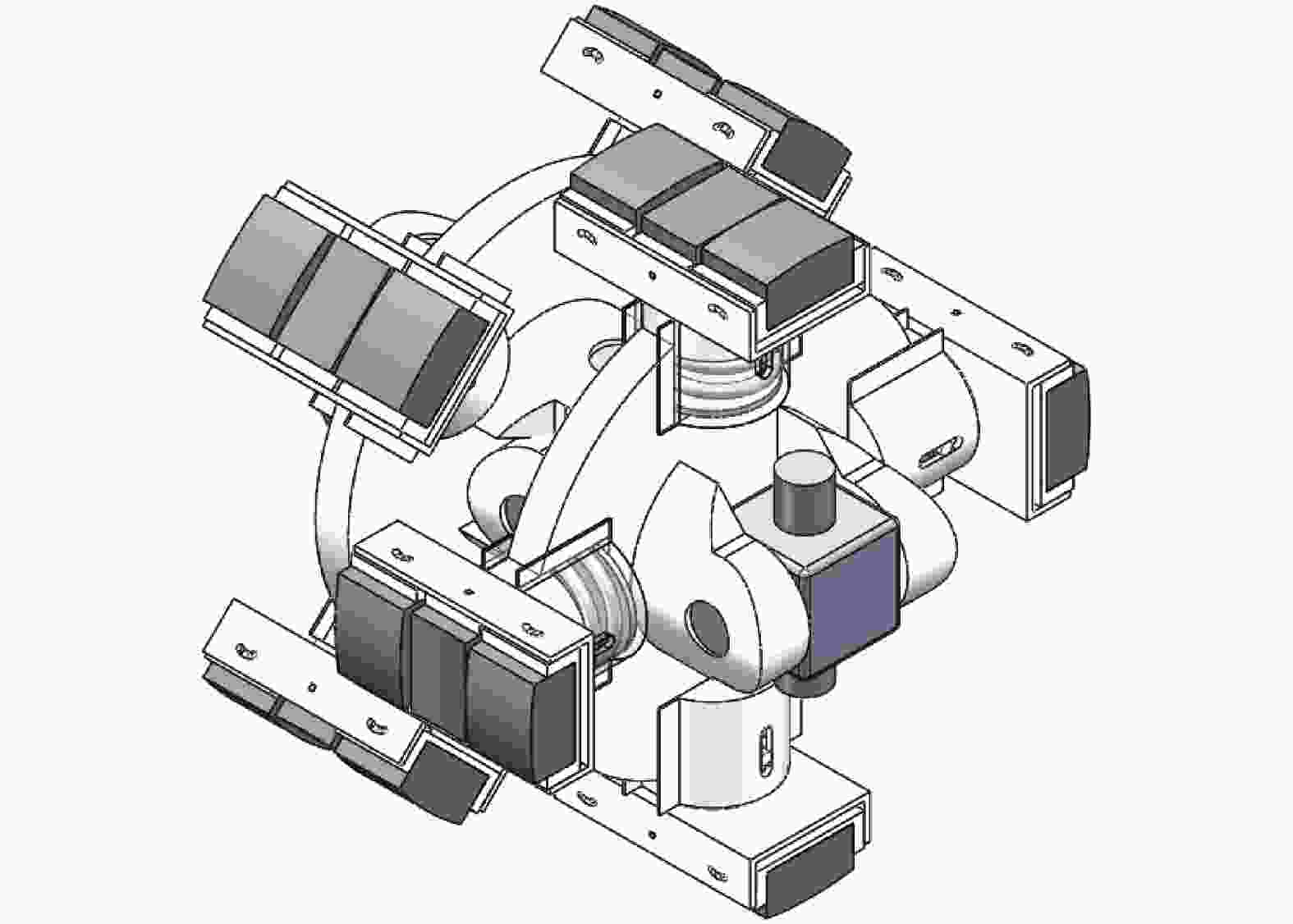

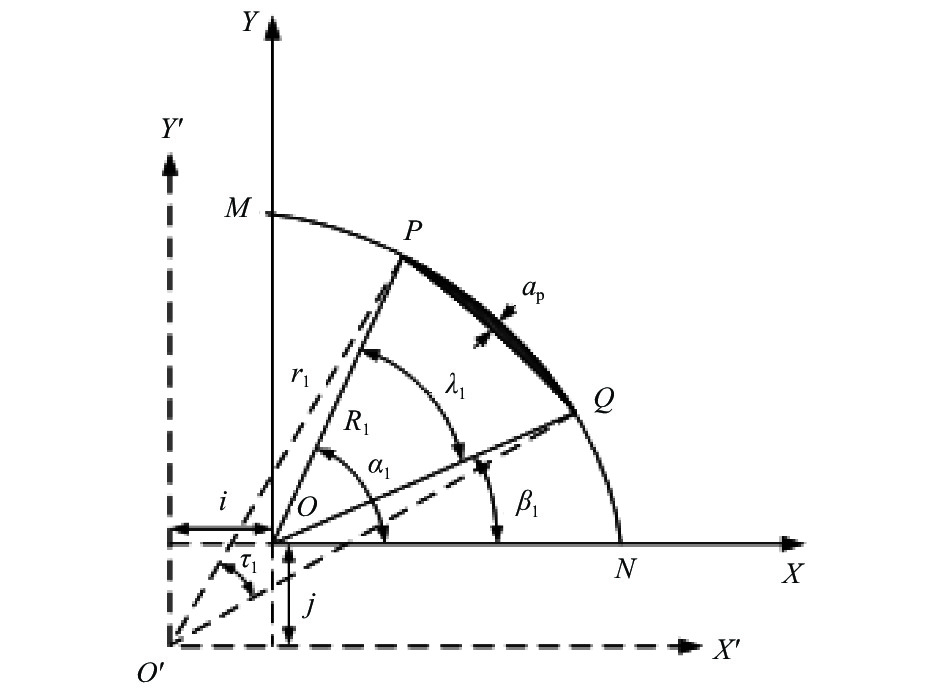

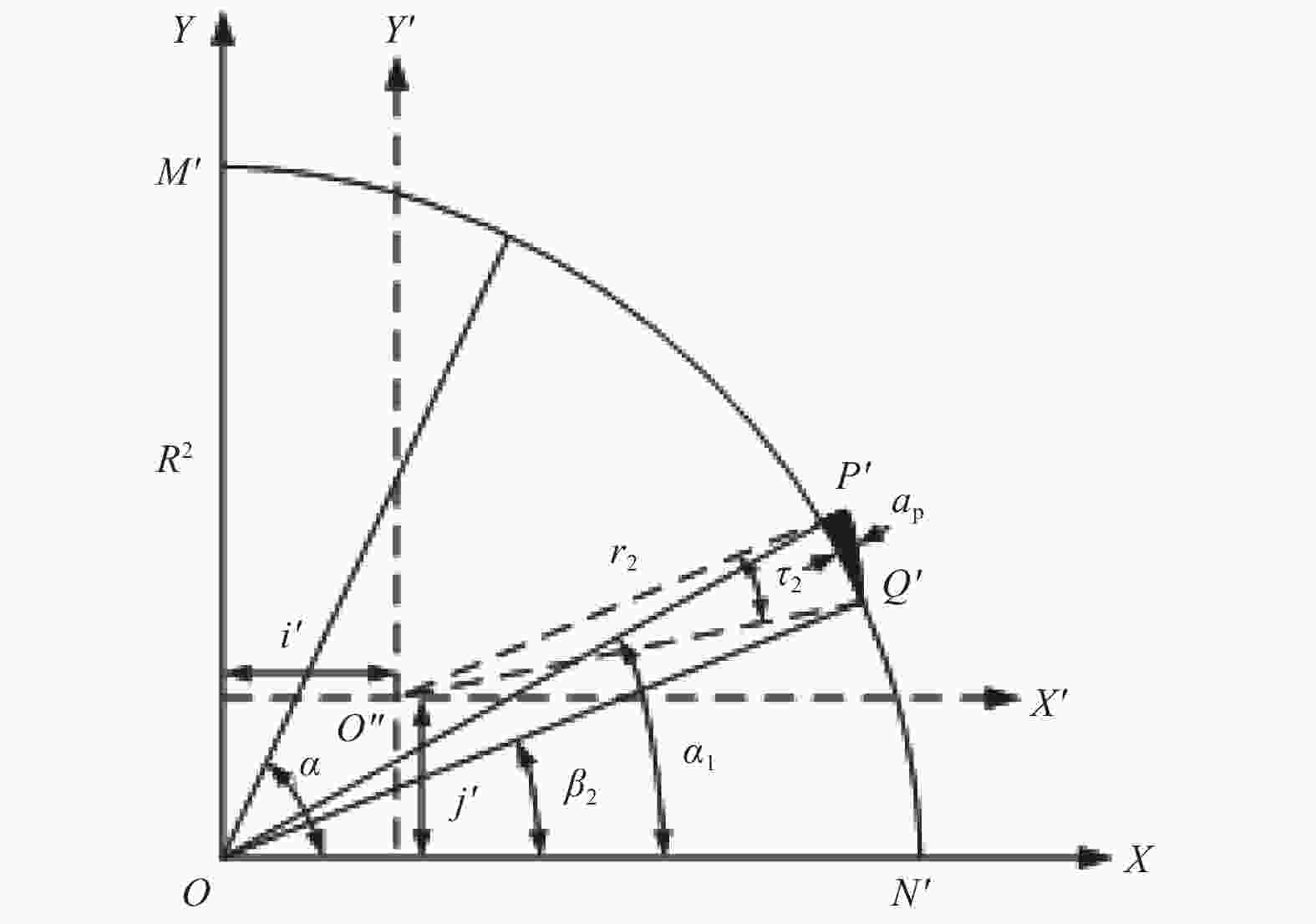

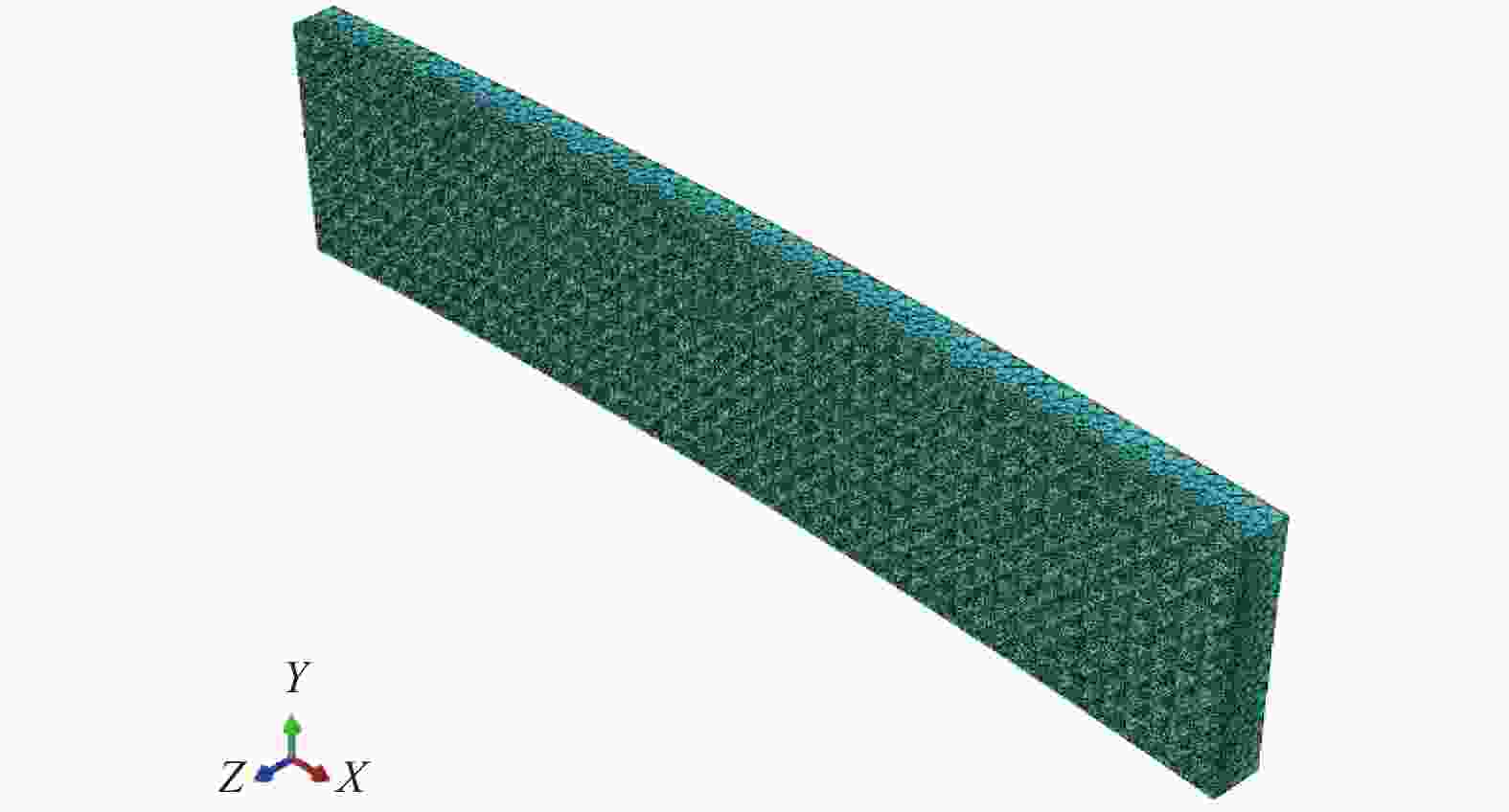

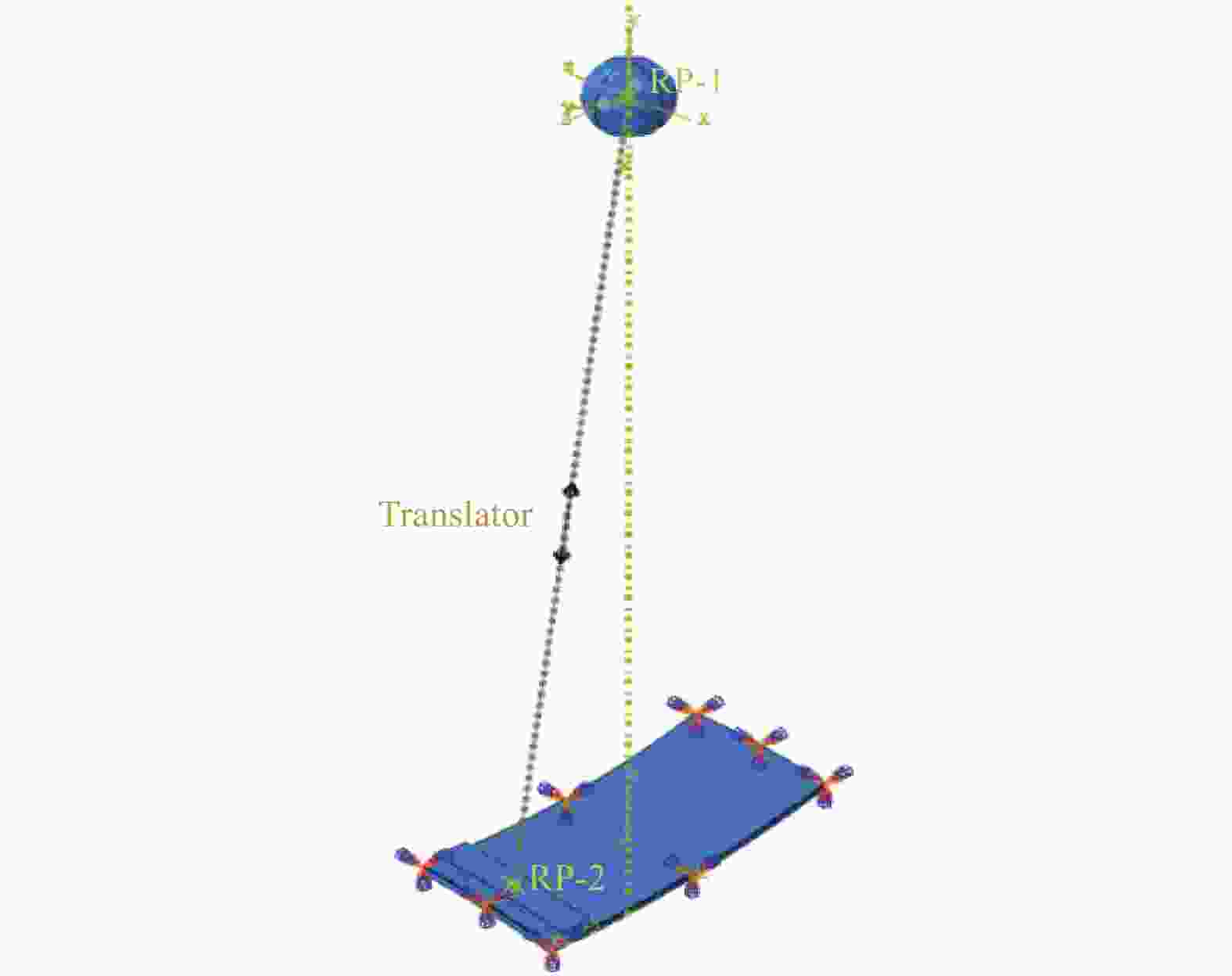

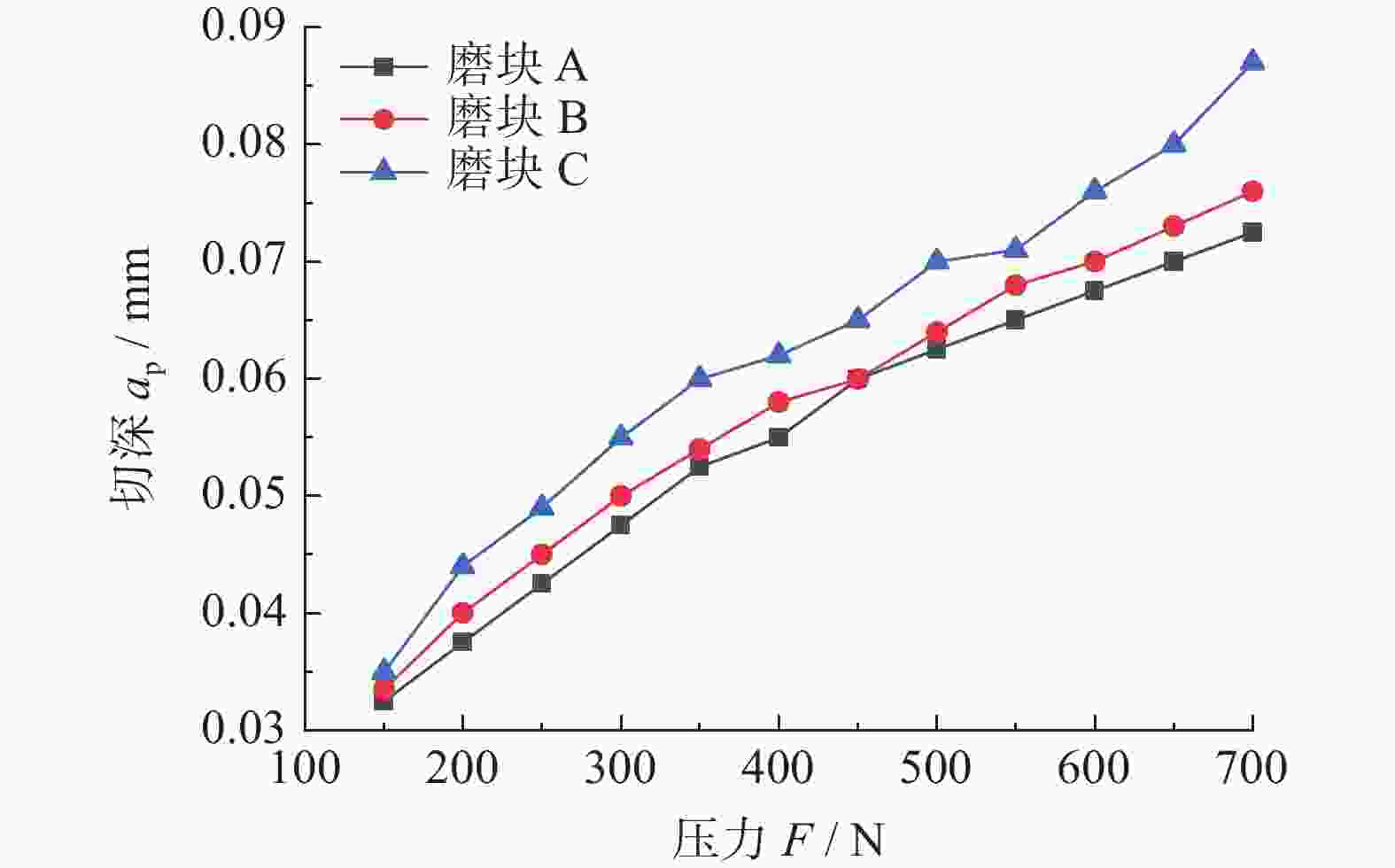

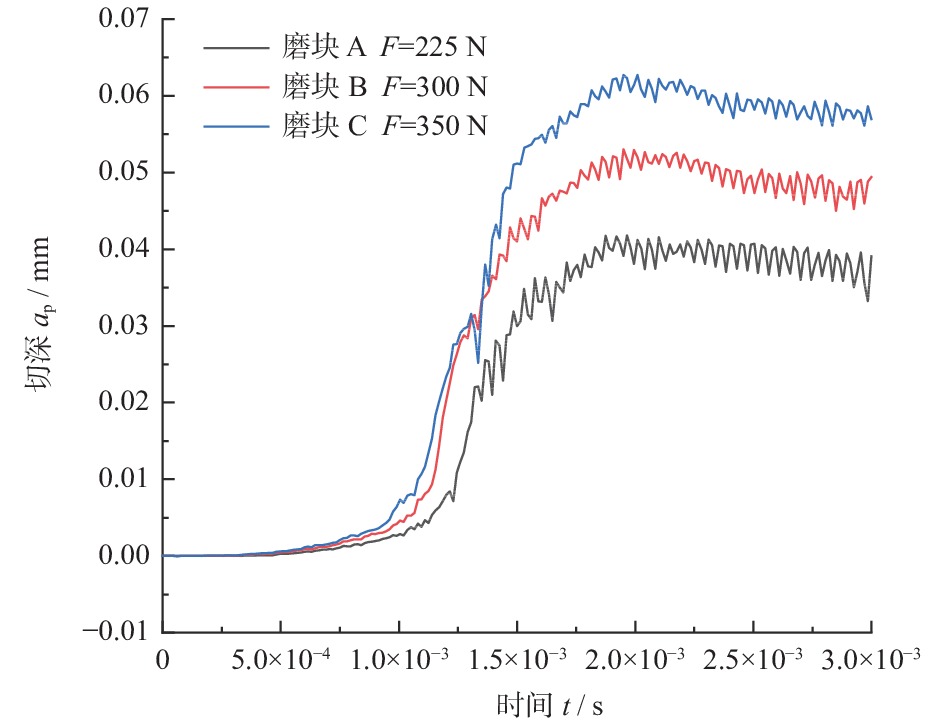

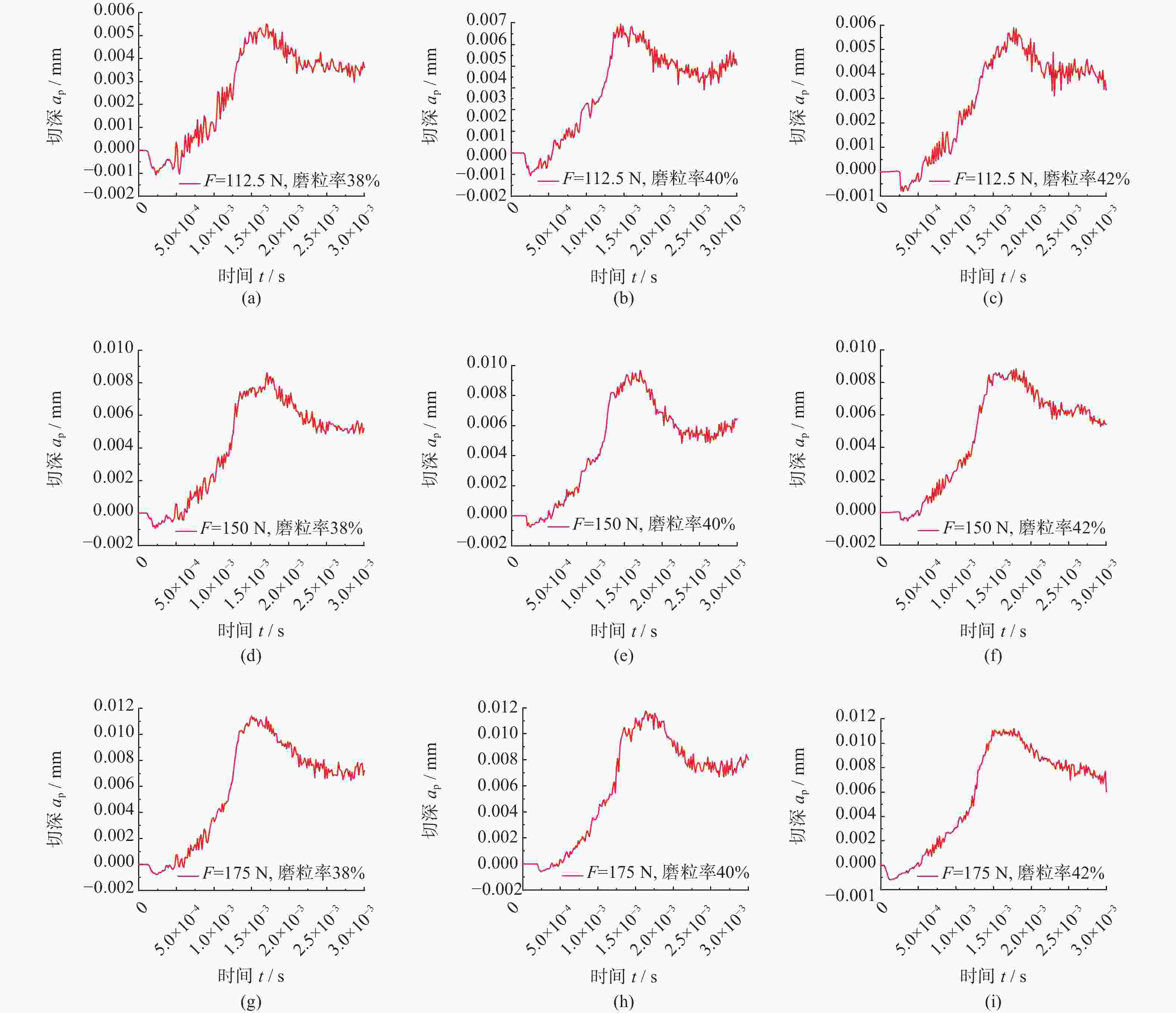

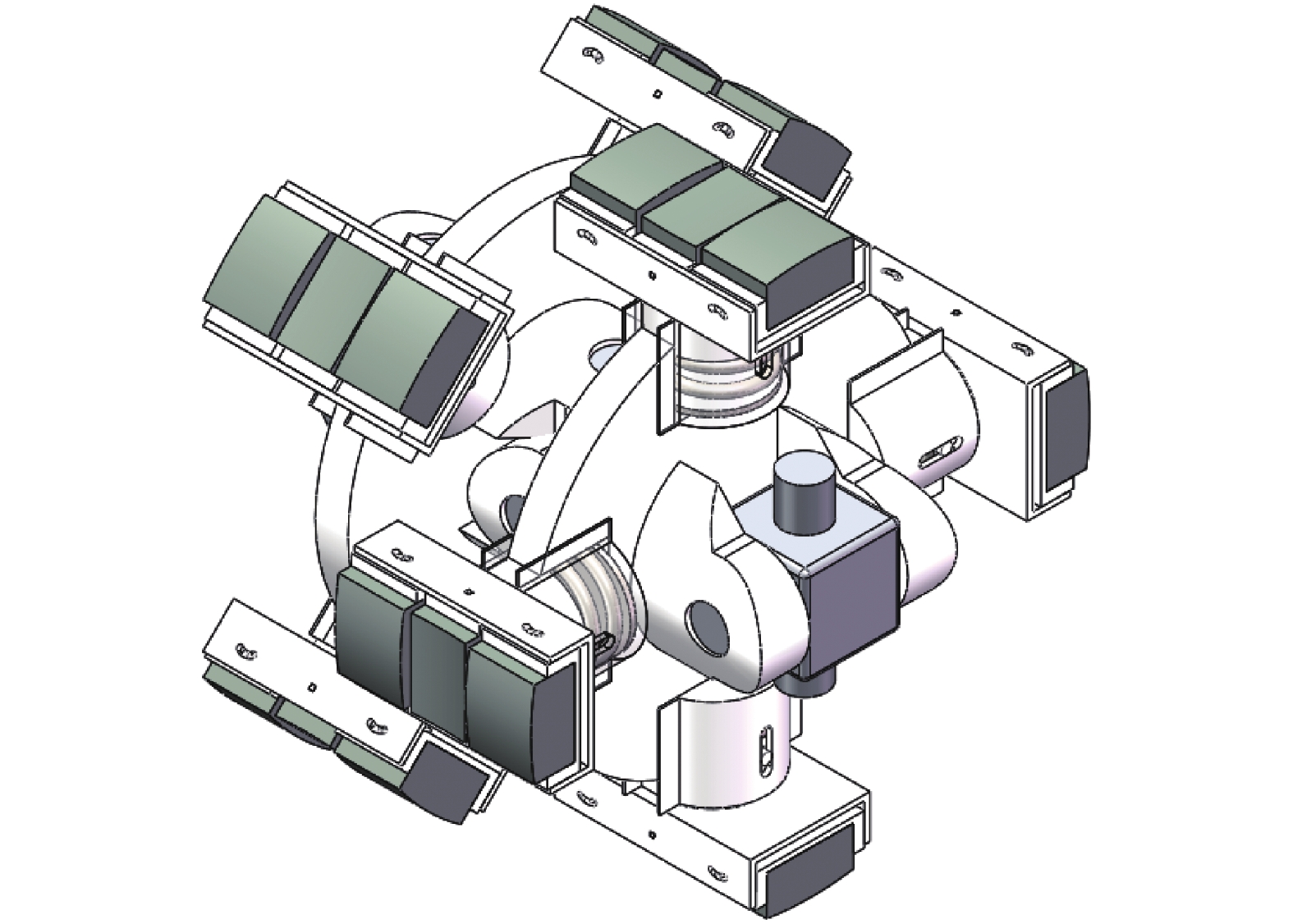

摘要: 为除去弯管内壁在涂层前的锈层,设计3种能够作用于100 mm直径弯管的除锈用磨块(分别为磨块A、磨块B和磨块C),并对磨块进行除锈仿真来分析弯管弯曲处内壁的锈层的去除效果。通过理论计算得出3种磨块的尺寸。磨块的凹弧半径范围为65.130~74.556 mm,凹弧圆心角范围为6.97°~7.98°,凸弧半径范围为145.522~147.618 mm,凸弧圆心角范围为6.06°~6.15°。磨块上的磨粒材料选用白刚玉。利用Solidworks和Creo进行建模并导入Abaqus中进行仿真分析,在仿真过程中要保证磨块对弯管弯曲处内管壁的压力恒定。结果表明:磨块B对弯管内壁的磨削达到稳定后,凹弧磨削深度的范围为0.045~0.053 mm,平均值为0.0498 mm,算术平均偏差为0.0016 mm;磨粒率为38%的凸弧磨削深度的算术平均偏差为2.2×10−4 mm。经数据分析,磨块B的磨削比其他2种磨块的磨削稳定,其除锈效果最好。Abstract: To remove the embroidery layer on the inner wall of the elbow before coating, three kinds of grinding blocks, namely Block A, Block B and Block C, were designed to act on the 100-mm-diameter elbow. The removal result of the embroidery layer on the inner wall of the elbow bend was analyzed by using the grinding block for rust removal simulation. Firstly, the sizes of three kinds of grinding blocks were obtained by theoretical calculation. The radius and the center angle of concave arc of the block were 65.130~74.556 mm and 6.97°~7.98°, while those of convex arc were 145.522~147.618 mm and 6.06°~6.15°. The abrasive material on the grinding block was white corundum. Then, Solidworks and Creo were used for modeling and imported into Abaqus for simulation analysis. In the simulation process, it is necessary to ensure that the pressure of the grinding block on the inner wall of the elbow bend is constant and equal. Results show that when the grinding on the inner wall of the elbow by the grinding block B is stable, the range of the concave-arc grinding depth is 0.045 0~0.053 0 mm, whose average value is 0.049 8 mm and arithmetic average deviation is 0.001 6 mm. The arithmetic mean deviation of convex arc grinding depth with 38% abrasive rate is 2.2 × 10−4 mm. After data analysis, grinding stability of Block B is better than that of other two grinding blocks. It can be concluded that the rust removal effect of Block B is the best.

-

Key words:

- constant pressure /

- elbow pipe /

- rust removal /

- finite element simulation

-

表 1 磨块的参数

Table 1. Parameters of grinding block

名称 凹弧 半径${r_1}$ / mm 横坐标 $i$/ mm 纵坐标 $j$/ mm 磨削面积 ${S_1}$ / mm2 磨块A 65.130 9.312 9.312 0.234 磨块B 69.524 12.427 12.427 0.301 磨块C 74.556 15.992 15.992 0.364 名称 凸弧 半径${r_2}$/ mm 横坐标 $i'$ / mm 纵坐标$j'$ / mm 磨削面积 ${ S_2}$ / mm2 磨块A 147.618 3.127 3.127 0.727 磨块B 146.563 3.880 3.880 0.905 磨块C 145.522 4.623 4.623 1.058 表 2 压力与磨削深度数据

Table 2. Pressure and grinding depth data

序号 压力 $F$ / N 切深 ${a_{\rm{p}}}$ / mm 1 200 0.038 2 250 0.043 3 300 0.048 4 350 0.053 5 400 0.055 6 450 0.060 7 500 0.063 8 550 0.065 9 600 0.068 10 650 0.070 11 700 0.073 12 750 0.075 表 3 平均值与算术平均值

Table 3. Average and arithmetic average

类型 平均值 $a$ / mm 算术平均值 $d$ / mm 磨块A磨粒率38% 3.7×10−3 2.5×10−4 磨块A磨粒率40% 3.8×10−3 3.4×10−4 磨块A磨粒率42% 4.0×10−3 2.7×10−4 磨块B磨粒率38% 5.3×10−3 2.2×10−4 磨块B磨粒率40% 5.6×10−3 3.7×10−4 磨块B磨粒率42% 6.0×10−3 3.4×10−4 磨块C磨粒率38% 7.2×10−3 4.1×10−4 磨块C磨粒率40% 7.5×10−3 4.2×10−4 磨块C磨粒率42% 7.6×10−3 3.8×10−4 -

[1] 张鹏, 彭杨. 考虑随机变量相关性的腐蚀管道失效概率 [J]. 石油学报,2016,37(10):1293-1294. doi: 10.7623/syxb201610010ZHANG Peng, PENG Yang. Corrosion pipeline failure probability considering random variable correlation [J]. Acta Petrolei Sinica,2016,37(10):1293-1294. doi: 10.7623/syxb201610010 [2] 张新生, 李亚云, 王小完. 基于逆高斯过程的腐蚀油气管道维修策略 [J]. 石油学报,2017,38(3):356-362. doi: 10.7623/syxb201703013ZHANG Xinsheng, LI Yayun, WANG Xiaowan. Maintenance strategy of corroded oil-gas pipeline based on inverse Gaussian process [J]. Acta Petrolei Sinica,2017,38(3):356-362. doi: 10.7623/syxb201703013 [3] 王天瑜. 天然气管道风险分析与安全距离计算方法研究 [D]. 北京: 中国矿业大学(北京), 2017.WANG Tianyu. Risk analysis and study on calculation method of safety distances for natural gas pipeline [D]. Beijing: China University of Mining & Technology(Beijing), 2017. [4] 邢潇, 崔淦, 杨紫晴, 等. 管线钢的裂纹生长预测新模型 [J]. 石油学报,2019,40(6):740-747. doi: 10.7623/syxb201906010XING Xiao, CUI Gan, YANG Ziqing, et al. A new model to predict crack growth rate in pipeline steel [J]. Acta Petrolei Sinica,2019,40(6):740-747. doi: 10.7623/syxb201906010 [5] 杨锋平, 罗金恒, 李鹤, 等. X90超高强度输气钢管材料本构关系及断裂准则 [J]. 石油学报,2017,38(1):112-118. doi: 10.7623/syxb201701013YANG Fengping, LUO Jinheng, LI He, et al. Constitutive law and fracture criteria of X90 ultrahigh-strength gas transmission steel pipe material [J]. Acta Petrolei Sinica,2017,38(1):112-118. doi: 10.7623/syxb201701013 [6] 张鹏. 油气长输管线的安全性、可靠性和风险技术的研究策略 [J]. 石油工业技术监督,2000,16(9):5-8.ZHANG Peng. Study on the safety, reliability and risk technology of pipeline [J]. Supervision in Petroleum Industry,2000,16(9):5-8. [7] 罗自治, 张传涛, 杨勇, 等. 国外管道失效原因分析及我国管道管理建议 [J]. 煤气与热力,2011,31(3):29-32.LUO Zizhi, ZHANG Chuantao, YANG Yong, et al. Cause analysis of foreign pipeline failures and suggestions on domestic pipeline managements [J]. Gas & Heat,2011,31(3):29-32. [8] 王旭. 长输管道事故案例统计分析及对策研究 [J]. 广州化工,2013,41(14):233-235.WANG Xu. Statistical analysis of pipeline accident cases and the research on strategies [J]. Guangzhou Chemical Industry,2013,41(14):233-235. [9] 张玲辰, 包文勃. 管道除锈方法对比及除锈意义 [J]. 黑龙江科技信息,2016(14):13.ZHANG Lingchen, BAO Wenbo. Pipeline derusting method comparison of grade derusting significance [J]. Heilongjiang Science and Technology Information,2016(14):13. [10] 宋贤杰, 张平宽, 张卓, 等. 机械式弯管内壁除锈均匀性研究 [J]. 机械设计与制造,2020(7):143-144.SONG Xianjie, ZHANG Pingkuan, ZHANG Zhuo, et al. Study on derusting uniformity of inner wall of mechanical bend pipe [J]. Machinery Design and Manufacture,2020(7):143-144. [11] 张宇尧. 基于恒压力的弯管内壁除锈用磨块设计及其除锈仿真研究 [D]. 太原: 太原科技大学, 2021.ZHANG Yuyao. Design of grinding block for derusting of elbow wall based on constant pressure and simulation study of derusting [D]. Taiyuan: Taiyuan University of Science and Technology, 2021. [12] 李印江. 磨具成品组织号的计算 [J]. 磨料磨具与磨削,1988(5):23.LI Yinjiang. Calculate the organization number of abrasive products [J]. Abrasives and Grinding,1988(5):23. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS