Experimental study on flexible fiber assisted stress rheological passivation and polishing of complex edge of cemented carbide insert

-

摘要:

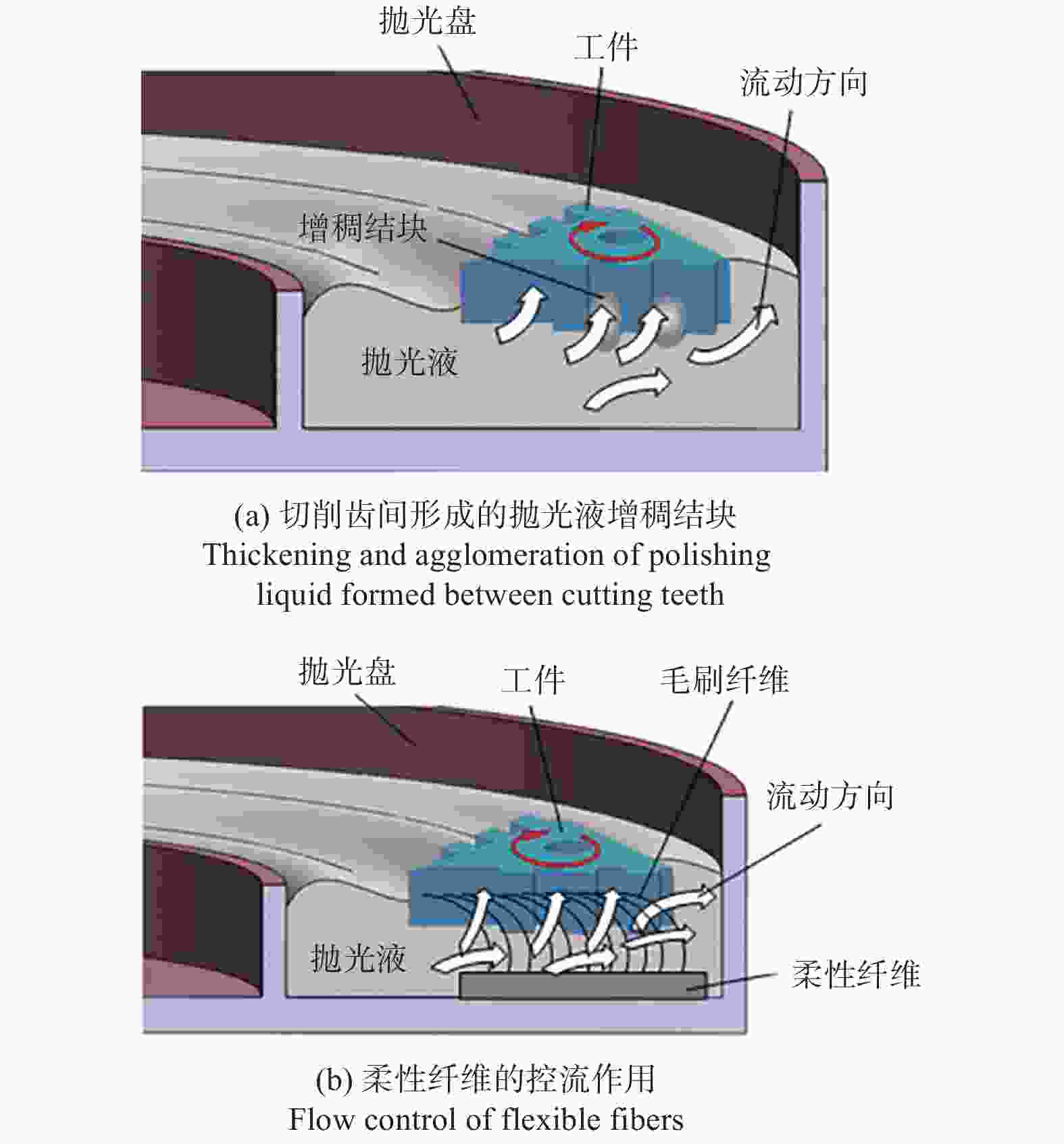

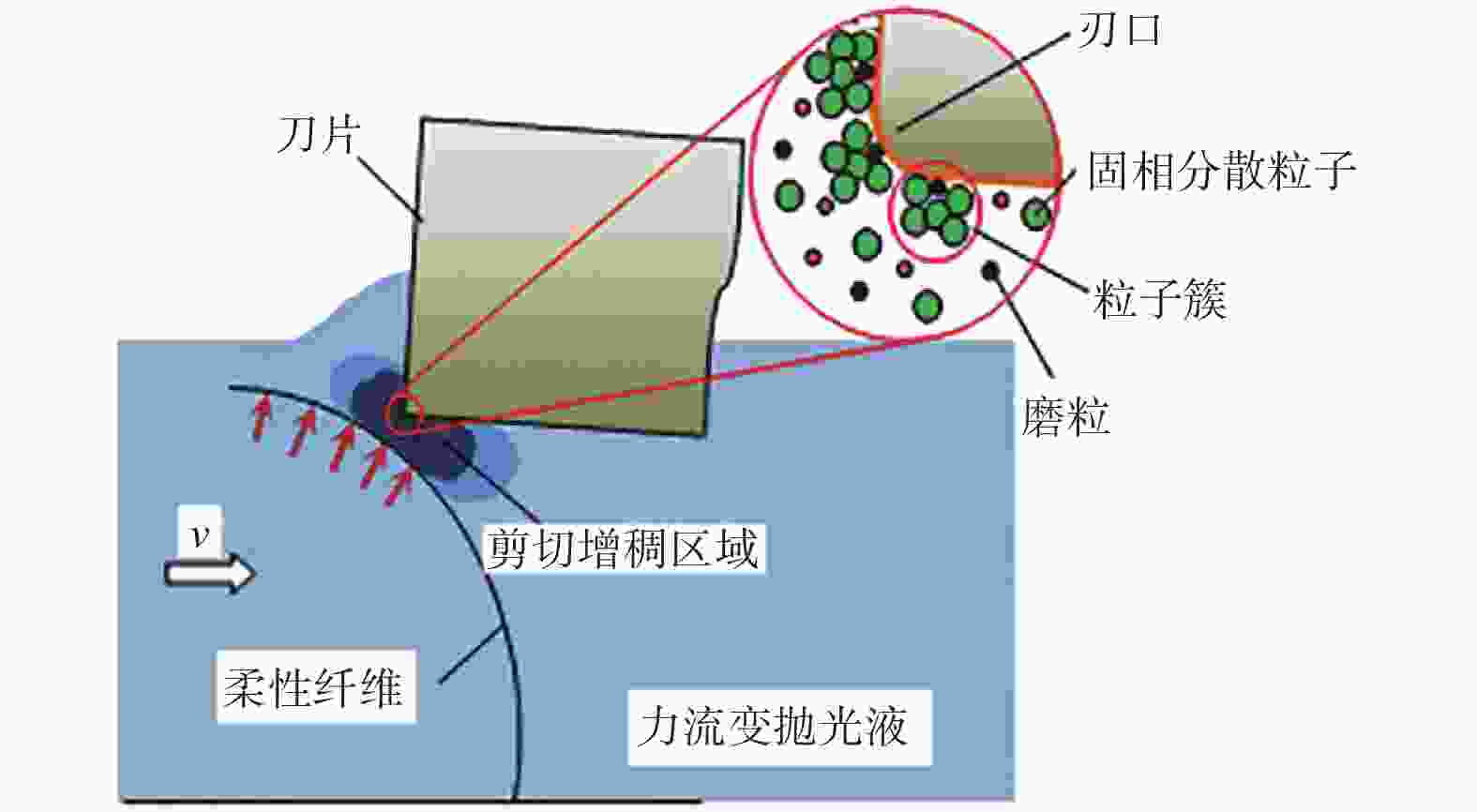

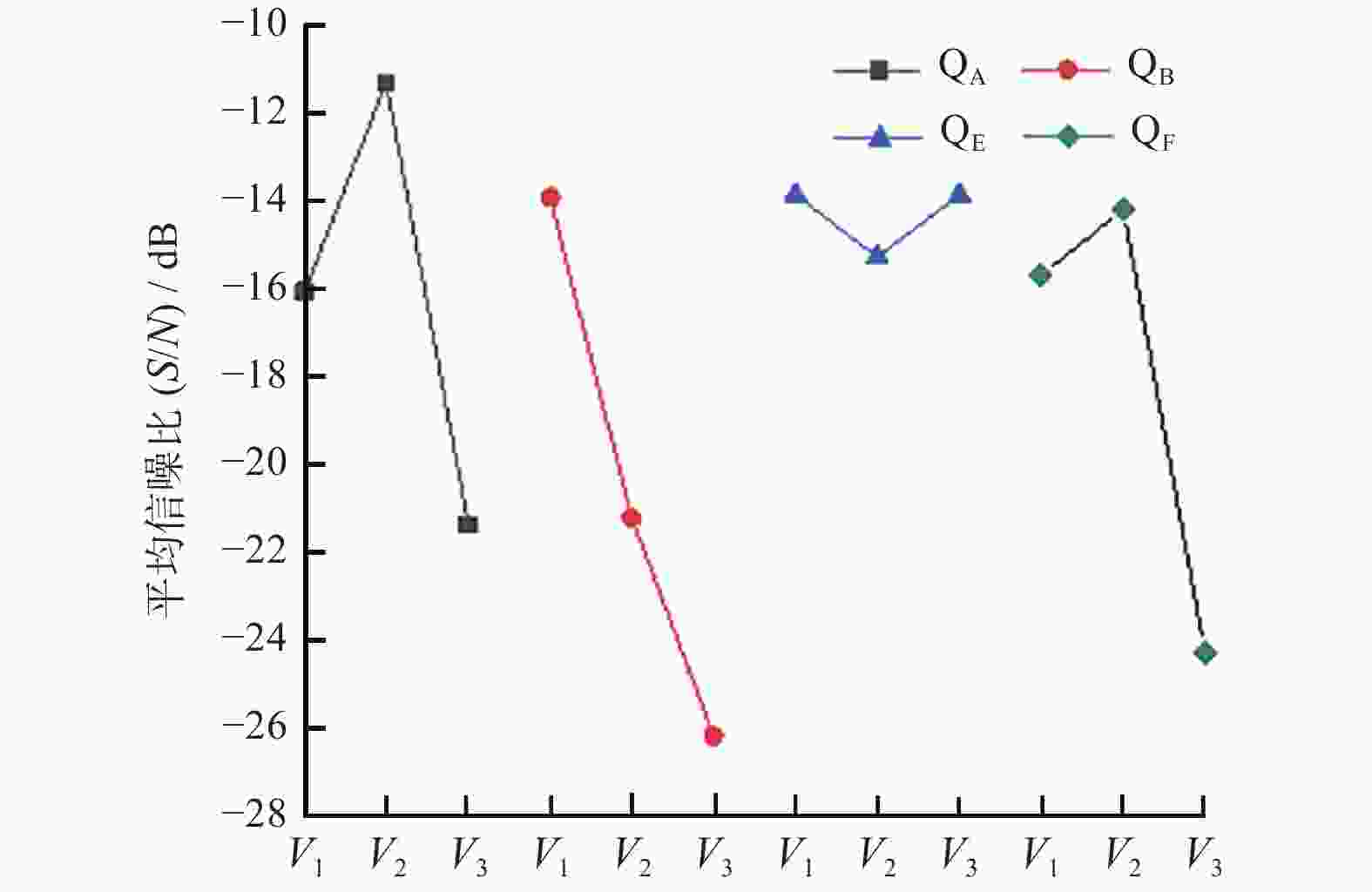

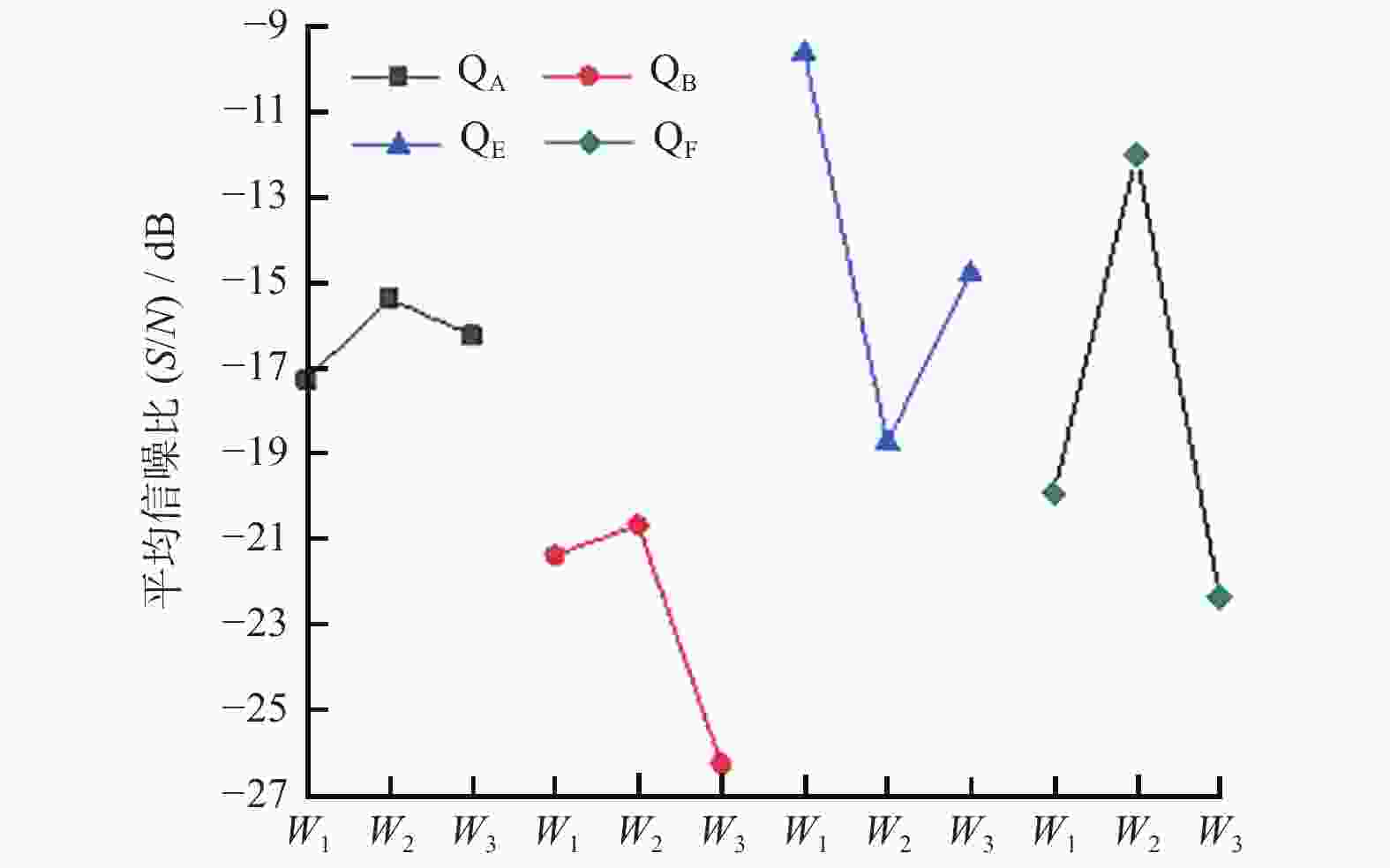

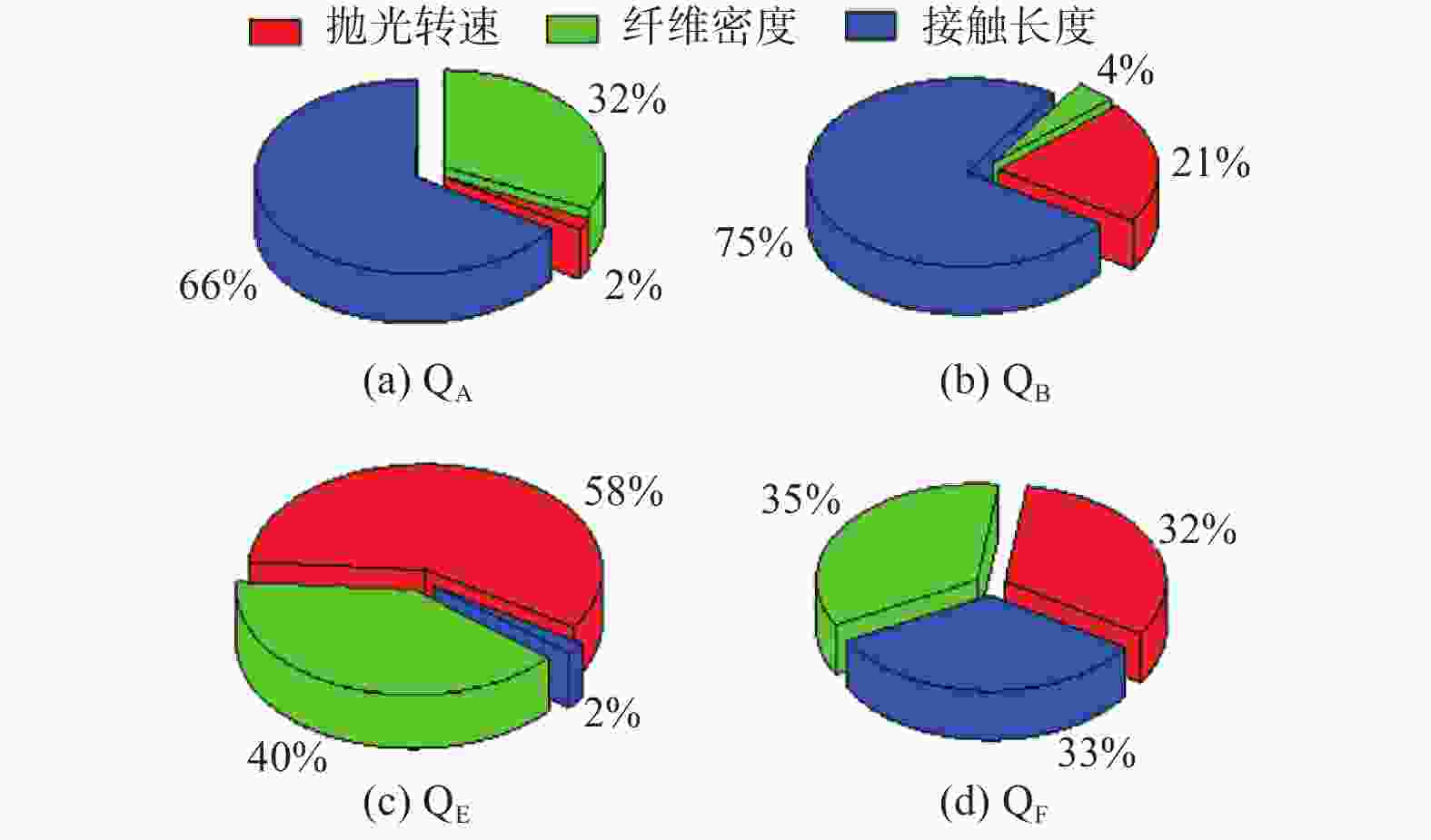

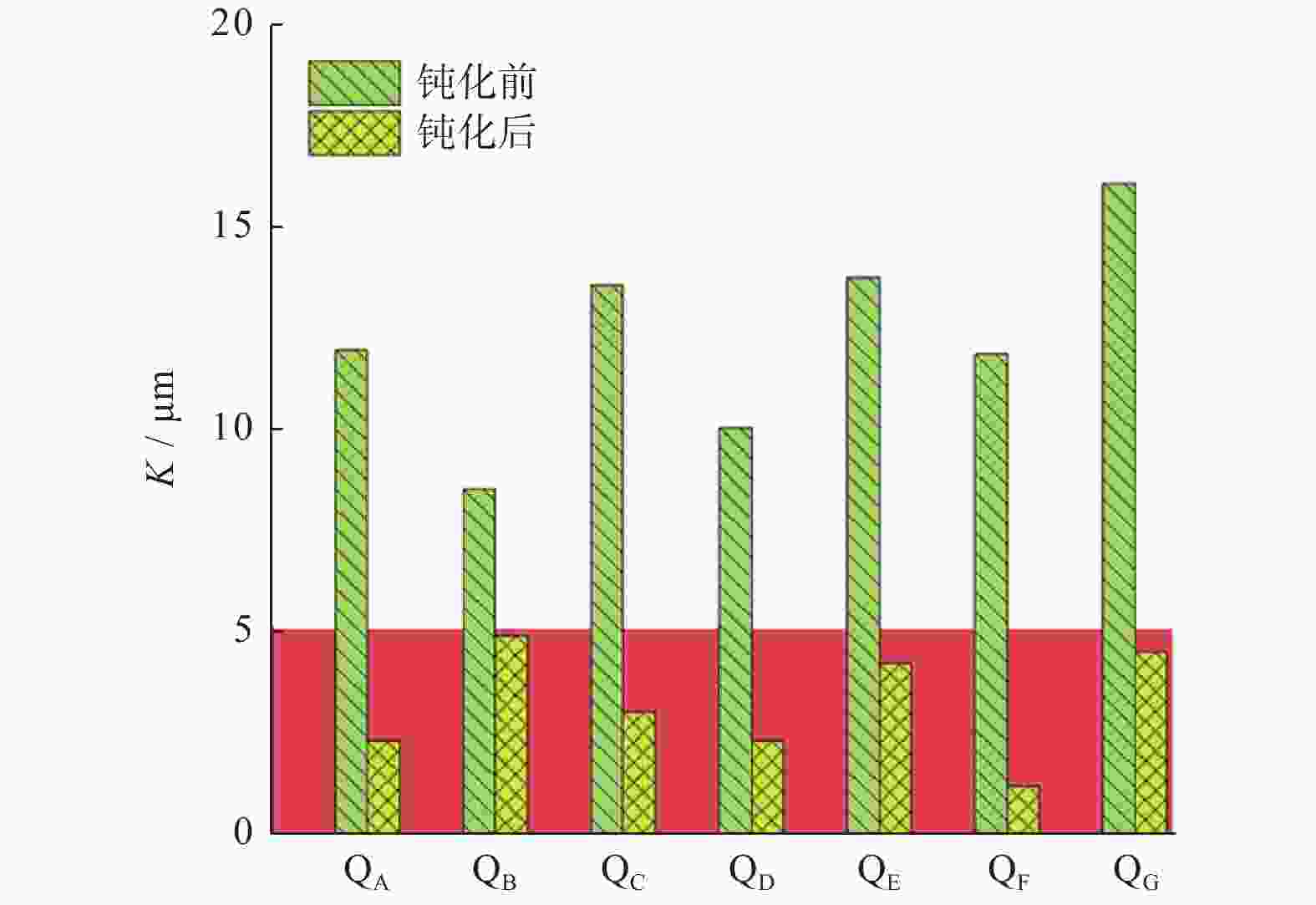

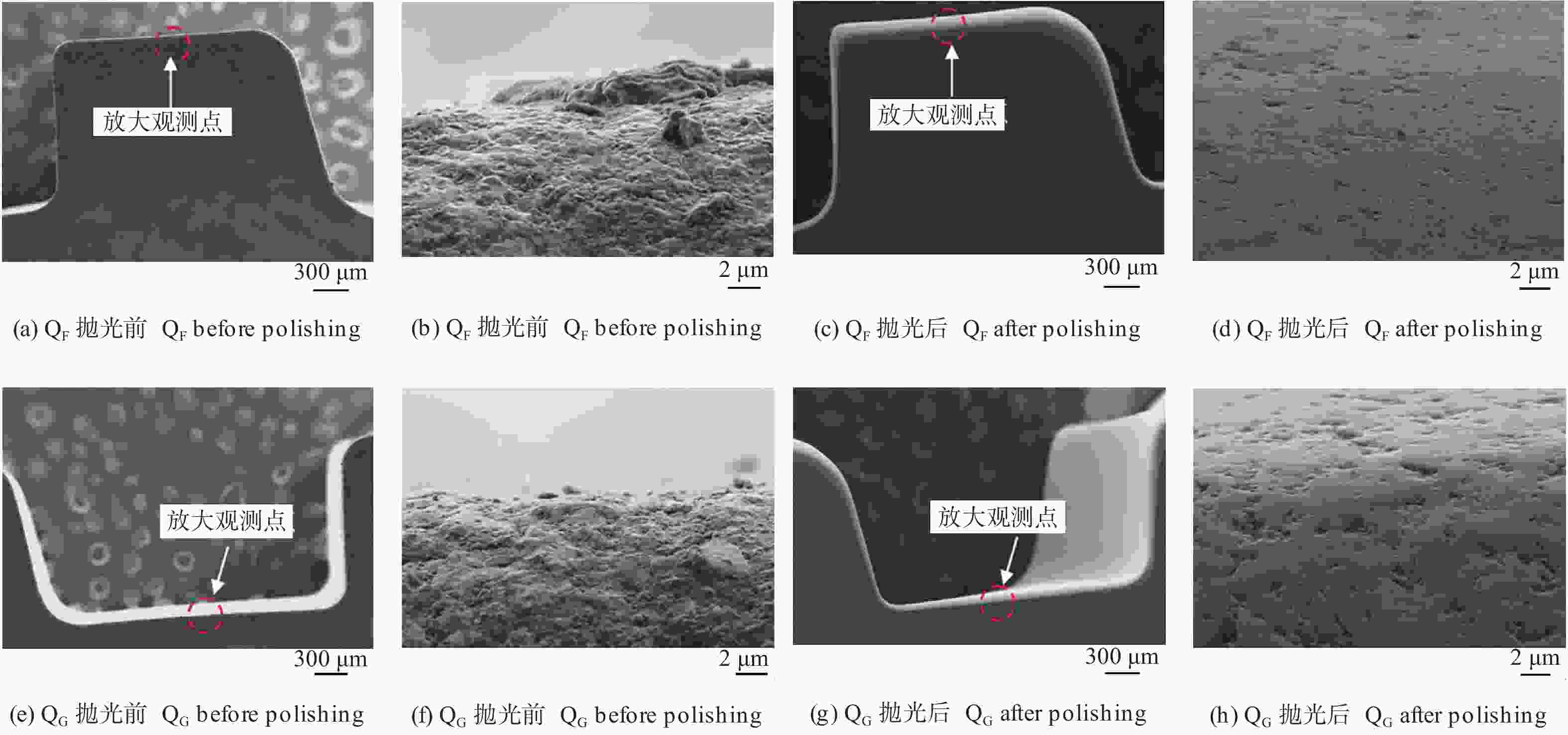

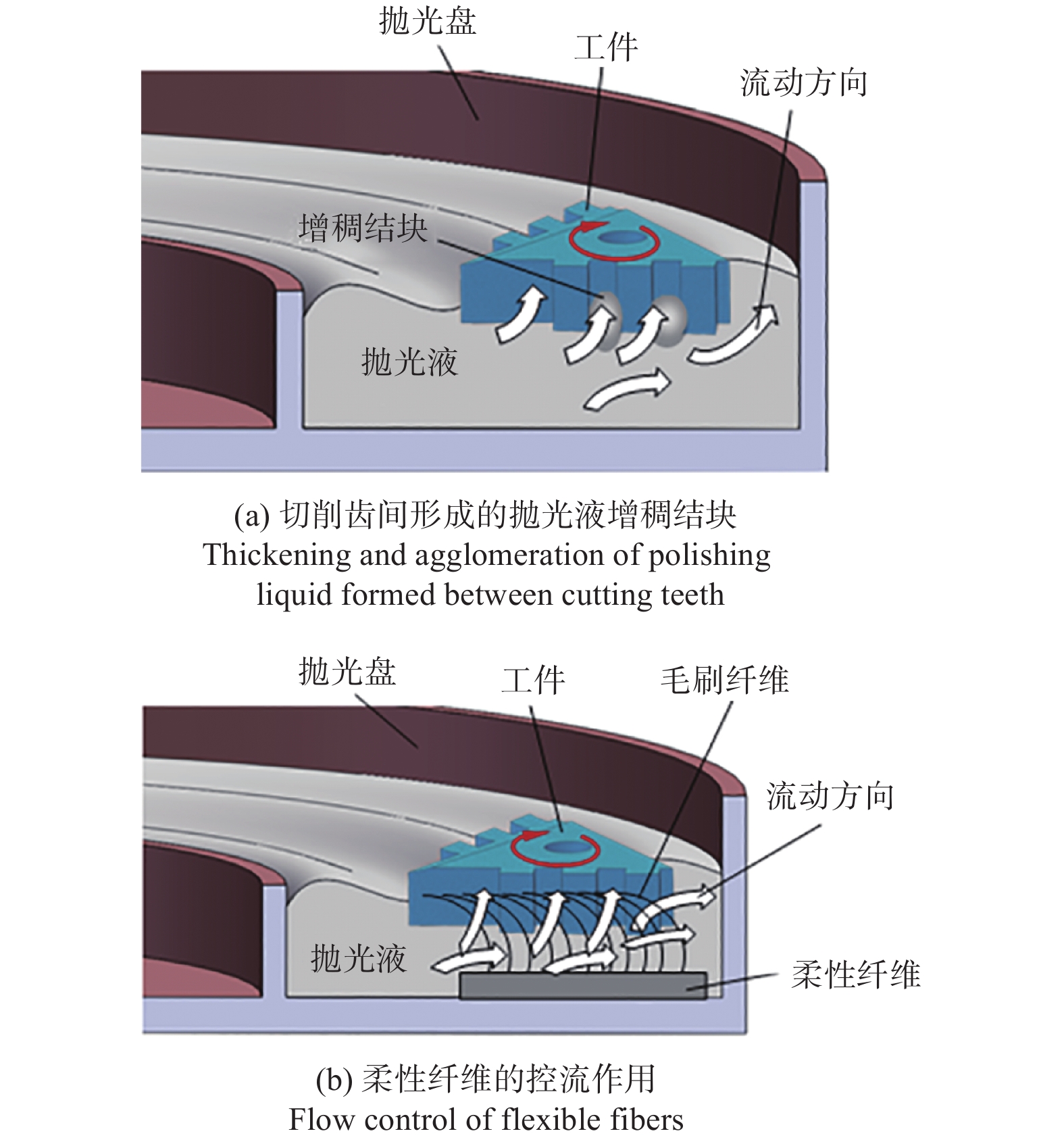

为实现硬质合金刀片复杂形状刃口的一致性钝化,提升刀片使用性能和寿命,采用柔性纤维辅助力流变抛光方法,利用非牛顿流体在剪切应力作用下的流变特性和柔性纤维的控流作用,对硬质合金刀片复杂形状刃口进行抛光。以刃口钝圆半径偏离值K为评价指标,用田口法分析抛光转速、纤维密度、纤维与刀片接触长度等工艺参数对刃口钝圆半径及其一致性的影响,并采用方差分析法评估各因素的权重,综合抛光参数对不同位置切削刃的影响,得到的最优工艺参数组合为纤维密度为200~250 根/cm2,接触长度为4 mm,抛光转速为55 r/min。在最优工艺参数组合下抛光10 min,7个切削刃的钝圆半径均能达到(50.0±5.0) μm的钝化要求,且其切削刃表面粗糙度Ra从(118.00 ± 10.00) nm降至(9.35 ± 0.75) nm,刃口完整无缺陷。

Abstract:To obtain the high consistency passivation of cutting edge of the cemented carbide insert with complex shape and improve the tool performance and life, the flexible fiber assisted stress rheological polishing method, which utilizes the rheological properties of non-Newtonian fluid under shear stress and the flow control effect of flexible fibers, was proposed to polish the complex shape edge of cemented carbide insert. The deviation value K of the passivation radius of the cutting edge was used as the evaluation index, and Taguchi method was employed to analyze the effects of the polishing speed, the fiber density and the fiber-insert contact length on the edge passivation radius and its consistency. The weight of each factor was evaluated by variance analysis method, and the optimal process parameters were obtained by combining the influence of the polishing parameters on the cutting edge at different positions. The optimal combination of process parameters is that the fiber density is 200 to 250 fibers/cm2, the contact length is 4 mm and the polishing speed is 55 r/min. Under the optimal combination of process parameters, the passivation radius of seven cutting edges can reach (50.0 ± 5.0) μm after polishing for 10 min, the surface roughness Ra of the cutting edges are reduced from (118.00 ± 10.00) nm to (9.35 ± 0.75) nm and the cutting edge is complete and free of defects.

-

表 1 试验条件

Table 1. Experimental conditions

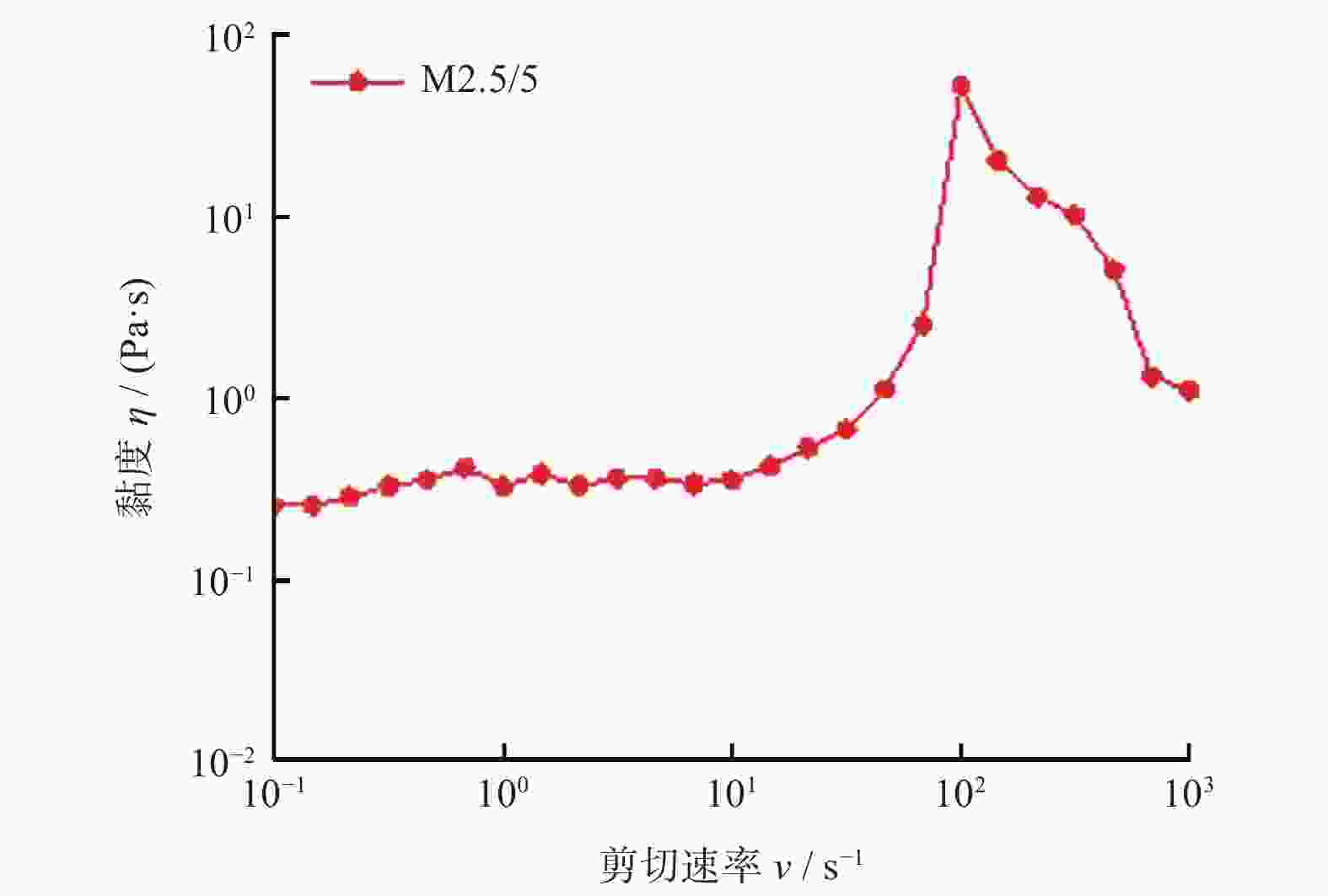

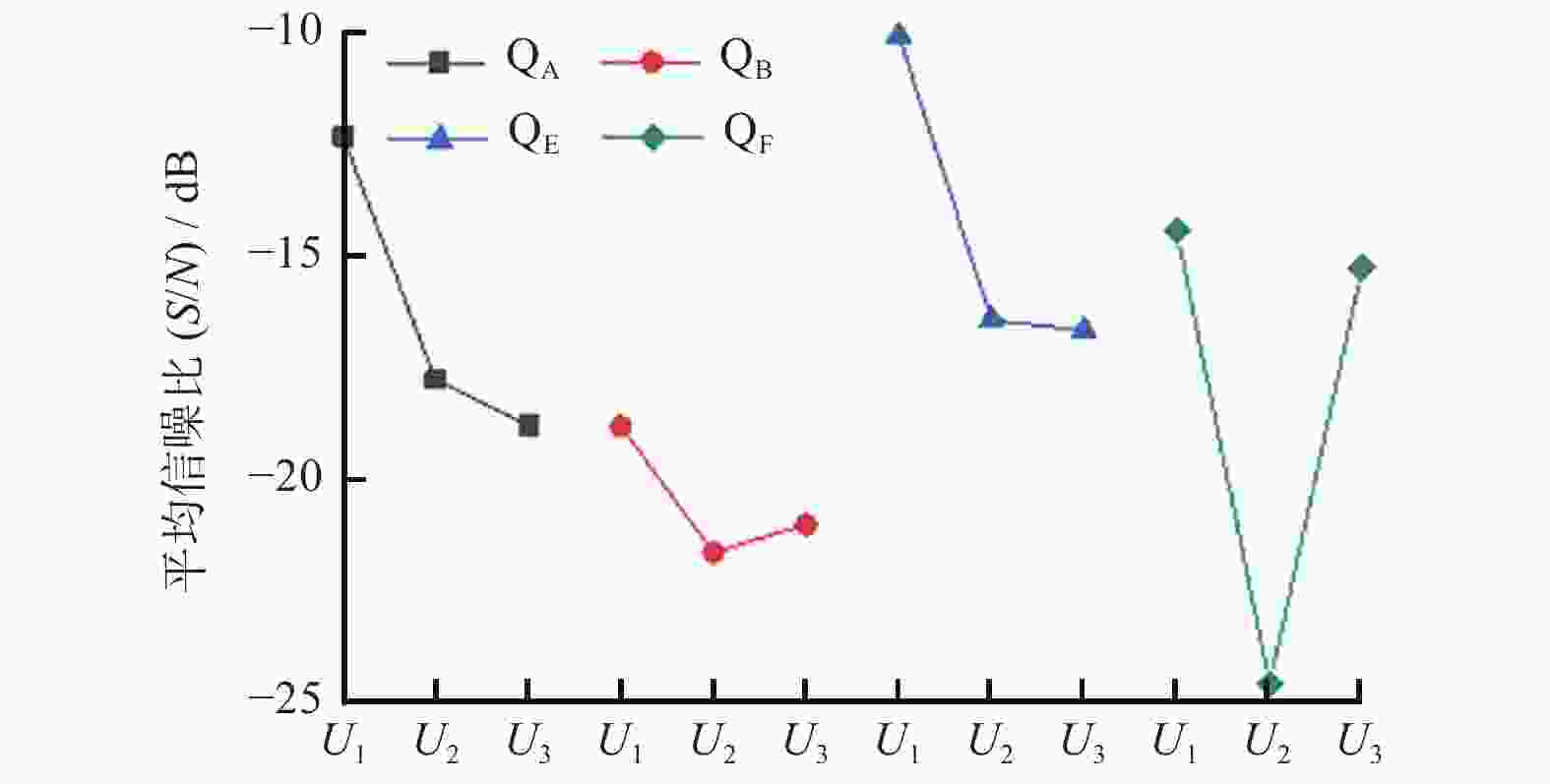

试验参数 条件或取值 齿根刃初始半径 r1 / μm 36.0 ± 3.0 齿尖刃初始半径 r2 / μm 40.0 ± 2.0 抛光转速 n1 / (r·min−1) 40,55,70 夹具轴转速 n2 / (r·min−1) 25 金刚石磨粒粒度代号 M2.5/5 金刚石磨粒质量分数 ω / % 6 纤维密度 低,中,高 接触长度 L / mm 2,4,6 夹具倾斜角度 θ / (°) 4 表 2 正交试验的因素和水平

Table 2. Factors and levels of orthogonal experiment

水平 因素 纤维密度

U接触长度

V抛光转速

W1 低 2 40 2 中 4 55 3 高 6 70 表 3 正交试验参数组合及试验结果

Table 3. Combinations of orthogonal experimental parameters and experimental results

试验序号 因素 结果 U V W KA ${\left( {S/N} \right)_{{{\rm{Q}}_{\rm{A}}}}} $ KB ${\left( {S/N} \right)_{{{\rm{Q}}_{\rm{B}}}}} $ KE ${\left( {S/N} \right)_{{{\rm{Q}}_{\rm{E}}}}} $ KF ${\left( {S/N} \right)_{{{\rm{Q}}_{\rm{F}}}}} $ 1 低 2 40 2.82 −9.00 4.35 −12.77 1.99 −5.96 5.59 −14.94 2 低 4 55 2.35 −7.43 6.33 −16.03 5.98 −15.53 1.18 −1.44 3 低 6 70 10.60 −20.50 23.87 −27.56 2.72 −8.69 22.03 −26.86 4 中 2 55 9.77 −19.80 3.91 −11.84 8.86 −18.95 8.07 −18.14 5 中 4 70 2.70 −8.64 17.17 −24.69 8.77 −18.86 20.02 −26.03 6 中 6 40 17.41 −24.82 26.02 −28.31 3.72 −11.42 29.95 −29.53 7 高 2 70 9.42 −19.48 7.32 −17.29 6.92 −16.81 5.06 −14.09 8 高 4 40 7.92 −17.97 14.08 −22.97 3.77 −11.53 5.76 −15.21 9 高 6 55 8.76 −18.85 13.64 −22.69 7.01 −16.91 6.66 −16.47 -

[1] CRUZ D, SORDI V L, VENTURA C E H. Surface analysis of WC-5%Co cemented tungsten carbide cutting insert after plunge-face grinding [J]. The International Journal of Advanced Manufacturing Technology,2020,108(1/2):1-8. doi: 10.1007/s00170-020-05074-7 [2] 江湘颜, 何云. 整体硬质合金波刃铣刀磨削加工的工艺研究 [J]. 硬质合金,2009,26(2):102-105.JIANG Xiangyan, HE Yun. Research on grinding technology of solid hardmetal milling cutter with waved edges [J]. Cemented Carbide,2009,26(2):102-105. [3] BOUZAKIS K D, KLOCKE F, SKORDARIS G, et al. Influence of dry micro-blasting grain quality on wear behaviour of TiAlN coated tools [J]. Wear,2011,271(5/6):783-791. doi: 10.1016/j.wear.2011.03.010 [4] ZHANG S, ZOU B, LIU Y, et al. Edge passivation and quality of carbide cutting inserts treated by wet micro-abrasive blasting [J]. The International Journal of Advanced Manufacturing Technology,2018,96:2307-2318. doi: 10.1007/s00170-018-1705-7 [5] WANG W, SAIFULLAH M K, ASSMUTH R, et al. Effect of edge preparation technologies on cutting edge properties and tool performance [J]. International Journal of Advanced Manufacturing Technology,2020,106(5/6):1-16. [6] 李荣敏, 赵雪峰, 郑鹏飞, 等. 磁盘间隙对刀具刃口钝化的影响 [J]. 机械设计与制造,2020(1):119-122.LI Rongmin, ZHAO Xuefeng, ZHENG Pengfei, et al. Research on the influence of the magnetic disk gap on the tool edge preparation [J]. Machinery Design & Manufacture,2020(1):119-122. [7] 曾伟, 牟伟旭, 王培, 等. 柔性纤维式机械抛光柔性纤维磨损及加工效率的研究 [J]. 工具技术,2013,47(7):13-17.ZENG Wei, MOU Weixu, WANG Pei, et al. Study on brush wear and polishing efficiency by mechanical polishing with brush [J]. Tool Engineering,2013,47(7):13-17. [8] LI M, LYU B H, YUAN J L, et al. Shear-thickening polishing method [J]. International Journal of Machine Tools and Manufacture,2015,94:88-99. doi: 10.1016/j.ijmachtools.2015.04.010 [9] LI M, LYU B H, YUAN J L, et al. Evolution and equivalent control law of surface roughness in shear-thickening polishing [J]. International Journal of Machine Tools & Manufacture,2016,108:113-126. [10] SHAO Q, LYU B H, YUAN J L, et al. Shear thickening polishing of the concave surface of high-temperature nickel-based alloy turbine blade [J]. Journal of Materials Research and Technology,2021,11:72-84. doi: 10.1016/j.jmrt.2020.12.112 [11] LYU B H, HE Q K, CHEN S, et al. Experimental study on shear thickening polishing of cemented carbide insert with complex shape [J]. The International Journal of Advanced Manufacturing Technology,2019,103:585-595. [12] YANG W H, TARNG Y S. Design optimization of cutting parameters for turning operations based on the Taguchi method [J]. Journal of Materials Processing Technology,1998,84(1/2/3):122-129. doi: 10.1016/S0924-0136(98)00079-X [13] 刘志飞, 王晓强, 朱其萍, 等. 超声滚挤压轴承套圈的表层性能预测模型建立及工艺参数优化 [J]. 锻压技术,2021,46(3):118-125.LIU Zhifei, WANG Xiaoqiang, ZHU Qiping, et al. Establishment on prediction model of surface performance for ultrasonic roll extrusion bearing ring and optimization on process parameters [J]. Forging and Stamping Technology,2021,46(3):118-125. [14] 王斌, 邓小川, 史一飞, 等. 田口实验设计法优化碳酸锂反应结晶制备工艺 [J]. 无机盐工业,2021,53(8):60-65.WANG Bin, DENG Xiaochuan, SHI Yifei, et al. Optimizing preparation process of lithium carbonate reaction crystallization by Taguchi experimental design method [J]. Inorganic Chemicals Industry,2021,53(8):60-65. [15] NGUYEN H P, PHAM V D, NGO N V. Application of TOPSIS to Taguchi method for multi-characteristic optimization of electrical discharge machining with titanium powder mixed into dielectric fluid [J]. The International Journal of Advanced Manufacturing Technology,2018,98:1179-1198. doi: 10.1007/s00170-018-2321-2 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS