Experimental study on chemical-assisted magnetic compound fluid polishing of TA1 pure titanium capillary tube

-

摘要:

对医用TA1纯钛毛细管内表面进行镜面抛光,有助于减小检测样本残留、提高毛细管移液精度,从而提高体外诊断设备的检测精度与可靠性。针对纯钛毛细管内表面质量差、材质难抛光的问题,提出一种新型化学辅助磁性复合流体抛光方法,将化学氧化与机械去除相结合,实现对毛细管内表面的高效精密抛光。采用单因素实验探究抛光液中的铁粉质量、过氧化氢质量分数与苹果酸质量分数对毛细管内表面材料去除率和粗糙度的影响,获得最佳抛光参数;检测在抛光过程中毛细管内表面的材料去除与元素变化,分析该技术用于纯钛毛细管内表面的综合抛光效果。结果表明:在铁粉质量为2 mg、过氧化氢质量分数为7.2%、苹果酸质量分数为6%的条件下抛光90 min后,纯钛毛细管内表面粗糙度由Ra 675 nm降至Ra 75 nm,无原始裂隙的平整抛光区域粗糙度低至Ra 19.5 nm,材料去除深度达28 μm,原始表面的细微裂痕被基本去除,粗壮裂隙减小;抛光过程没有引入其他元素。

-

关键词:

- 化学辅助磁性复合流体抛光 /

- TA1纯钛毛细管 /

- 内表面 /

- 粗糙度

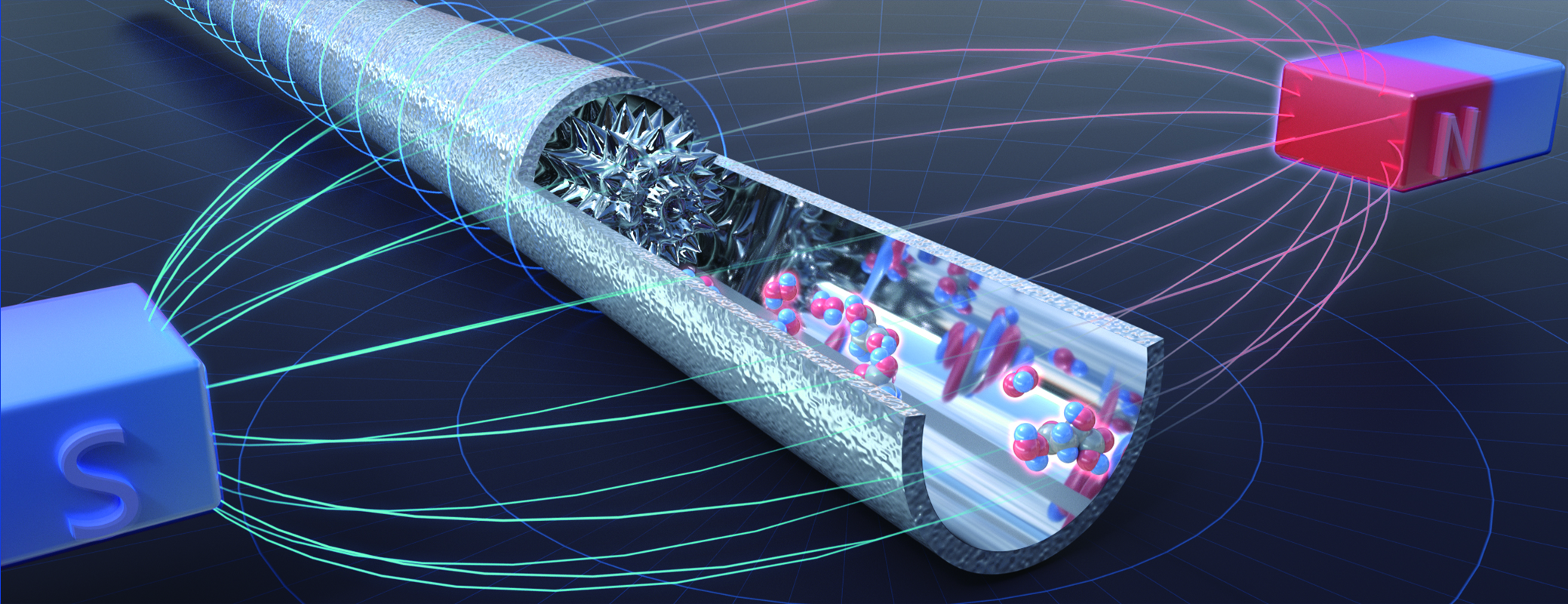

Abstract:[OBJECTIVES] To perform mirror polishing on the inner surface of medical TA1 pure titanium capillary tubes to reduce the residual of test samples and improve the precision of capillary pipetting, thereby enhancing the detection accuracy and reliability of in vitro diagnostic equipment. A novel chemical-assisted magnetic compound fluid polishing method is proposed to address the issues of poor quality and difficulty in polishing the inner surface of pure titanium capillaries. This method combines chemical oxidation with mechanical removal to achieve efficient and precise polishing of the inner surface of medical TA1 pure titanium capillaries.

[METHODS] By combining chemical oxidation with mechanical removal principles, a chemical-assisted magnetic compound fluid polishing method was developed to achieve efficient and precise polishing of the inner surface of medical TA1 pure titanium capillaries. Initially, single-variable experiments explored the effects of iron powder mass, hydrogen peroxide mass fraction, and malic acid mass fraction in the polishing fluid on the material removal rate and roughness of the TA1 capillary inner surface. The surface changes of TA1 material in an acidic oxidative environment were observed, and the polishing principle was analyzed comprehensively. Subsequently, energy spectrum analysis of the inner surface elements of the TA1 capillary before and after polishing was conducted to assess the impact of the polishing process on the changes in element types and content. Finally, the surface morphology of the TA1 capillary inner surface before and after polishing was characterized using a scanning electron microscope and a contact profilometer, analyzing the patterns and reasons for changes in inner surface roughness.

[RESULTS] Single-factor polishing experiments on TA1 capillaries showed that the mass of iron powder, the mass fraction of hydrogen peroxide, and the mass fraction of malic acid in the polishing fluid significantly affected the post-polishing surface roughness and material removal rate. As the mass of iron powder increased, the surface roughness decreased then increased, and the material removal rate increased then decreased. With the increase in hydrogen peroxide mass fraction, the surface roughness slightly decreased, and the material removal rate slightly increased. As the malic acid mass fraction increased, the surface roughness continued to decrease, and the material removal rate continued to rise. Etching experiments indicated that a porous oxide layer formed on the TA1 surface in an acidic oxidative environment, demonstrating the CAMCF's principle of simultaneous oxidation and mechanical removal. Compared to the original inner surface of the TA1 capillary, the polished inner surface showed no change in element types, with a slight increase in oxygen content. Characterization of the TA1 capillary inner surface before and after polishing with a scanning electron microscope and contact profilometer revealed that the original surface had deep and wide drawing cracks and varied cracks and pits on the split titanium blocks. The original roughness was Ra 675nm. After polishing, minor cracks and subtle defects were essentially eliminated, deep and wide drawing cracks significantly reduced, and uniform abrasive scratches appeared in the flat areas, reducing the surface roughness to Ra 19.5nm.

[CONCLUSION] The chemical-assisted magnetic compound fluid polishing technique demonstrated its feasibility for efficient and precise polishing of the inner surface of medical TA1 pure titanium capillaries. Within the experimental parameter range, the optimal polishing fluid composition was 2mg of iron powder, 7.2% hydrogen peroxide mass fraction, and 6% malic acid mass fraction. The polishing process did not alter the element types on the inner surface of the TA1 capillary, only slightly increasing the oxygen content. After polishing with the optimal parameters, the cracks on the inner surface of the TA1 pure titanium capillary were essentially eliminated, the maximum material removal depth in the polished area was 28μm, and the surface roughness reduced from Ra 675nm to Ra 75nm, with the crack-free area reaching a roughness of Ra 19.5nm, achieving mirror polishing of the inner surface of the pure titanium capillary.

-

表 1 加工参数

Table 1. Experiment conditions

参数名称 型号/数值 工件 外径为2.5 mm,内径为1.0 mm,

长度为200 mm磁铁 50 mm × 10 mm × 5 mm,

N52 NdFeB,Br = 0.5 T聚磁头 底面10 mm × 5 mm,

聚磁面为2 mm × 5 mm,

高度为15 mm,45号钢工件转速 nc / (r·min−1) 10000 磁铁往复距离 Lm / mm 4 磁铁进给速度 vm / (mm·s−1) 2 抛光时间 t / min 90,每15 min更换1次抛光液 表 2 抛光液组分取值

Table 2. Polishing fluid component values

参数名称 取值 抛光点铁粉质量 m1 / mg 1,2,3,4 金刚石磨粒质量分数 ω1 /% 15 过氧化氢H2O2质量分数 ω2 /% 0,2.4,4.8,7.2 苹果酸质量分数 ω3 /% 0,2,4,6 表 3 未抛光和抛光后毛细管内表面的氧、钛原子占比

Table 3. Atomic ratio (O/Ti) of unpolished and polishedinner tube surfaces

位置 O物质的量分数

wO / %Ti物质的量分数

wTi / %原始表面 11.6 88.4 抛光表面

(90 min抛光后)13.5 86.5 -

[1] 张鑫洋. 全自动生化仪加样系统研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.ZHANG Xinyang. Research on sampling system of automatic biochemical analyzer [D]. Harbin: Harbin Institute of Industry, 2018. [2] BRUNETTE M D, TENGVALL P, TEXTOR M. Titanium in medicine [M]. Berlin: Springer, 2001. [3] 贾艳艳. 强旋制备医用细晶粒纯钛关键技术研究[D]. 长春: 长春理工大学, 2021.JIA Yanyan. Research on the key technology of preparing medical fine-grained pure titanium by strong spinning [D]. Changchun: Changchun University of Science and Technology, 2021. [4] 张凯悦, 姚修楠, 赵鸿磊, 等. 加工工艺对小口径TA2钛管组织及性能的影响 [J]. 热加工工艺,2022,51(23):102-104,108. doi: 10.14158/j.cnki.1001-3814.20221076ZHANG Kaiyue, YAO Xiunan, ZHAO Honglei, et al. Effect of processing technology on microstructure and properties of small diameter TA2 titanium tubes [J]. Hot Working Technology,2022,51(23):102-104,108. doi: 10.14158/j.cnki.1001-3814.20221076 [5] 马海生. 镍毛细管内表面的化学抛光研究 [D]. 秦皇岛: 燕山大学, 2015.MA Haisheng. Investigation on chemical polishing of the inner surface of the nickel capillary [D]. Qinhuangdao: Yanshan University, 2015. [6] WANG F, ZHOU J, KANG X, et al. Experimental research on chemical polishing of metal capillary inner wall for laser-assisted electrochemical machining [J]. Procedia CIRP,2022,113:477-482. doi: 10.1016/j.procir.2022.09.203 [7] KUROBE T, YAMADA Y, YAMAMOTO K. Development of high speed slurry flow finishing of the inner wall of stainless steel capillary: Polishing and gas flow characteristics of various size of capillaries [J]. Precision Engineering,2001,25(2):100-106. doi: 10.1016/S0141-6359(00)00060-X [8] 邓乾发, 郭晨曦, 袁巨龙, 等. 基于自激振荡脉冲特性的磨粒流抛光不锈钢细管内壁的仿真与实验研究 [J]. 表面技术,2019,48(10):363-371. doi: 10.16490/j.cnki.issn.1001-3660.2019.10.045DENG Qianfa, GUO Chenxi, YUAN Julong, et al. Simulation and experimental study on polishing inner surface of tubule by self-excited oscillation abrasive flow [J]. Surface Technology,2019,48(10):363-371. doi: 10.16490/j.cnki.issn.1001-3660.2019.10.045 [9] LIU Y G, SONG G Z, HOU B W, et al. Study on the correlation between grain size and processing limit in abrasive flow machining[C]. England: IOP Publishing, 2021, 1884(1): 012002. [10] SHINMURA T, YAMAGUCHI H. Study on a new internal finishing process by the application of magnetic abrasive machining: Internal finishing of stainless steel tube and clean gas bomb [J]. JSME International Journal, Ser. C: Dynamics, Control, Robotics, Design and Manufacturing,1995,38(4):798-804. doi: 10.1299/jsmec1993.38.798 [11] YAMAGUCHI H, SHINMURA T, IKEDA R. Study of internal finishing of austenitic stainless steel capillary tubes by magnetic abrasive finishing [J]. Journal of Manufacturing Science and Engineering,2007,129(5):885-892. doi: 10.1115/1.2738957 [12] YAMAGUCHI H, KANG J, HASHIMOTO F. Metastable austenitic stainless steel tool for magnetic abrasive finishing [J]. CIRP Annals,2011,60(1):339-342. doi: 10.1016/j.cirp.2011.03.119 [13] KANG J, YAMAGUCHI H. Internal finishing of capillary tubes by magnetic abrasive finishing using a multiple pole-tip system [J]. Precision Engineering,2012,36(3):510-516. doi: 10.1016/j.precisioneng.2012.01.006 [14] YAMAGUCHI H, NTEZIYAREMYE V, STEIN M, et al. Hybrid tool with both fixed-abrasive and loose-abrasive phases [J]. CIRP Annals,2015,64(1):337-340. doi: 10.1016/j.cirp.2015.04.006 [15] 潘明诗, 陈燕, 张东阳. 仿形磁极头对电磁研磨管件内表面形成的影响 [J]. 中国表面工程,2022,35(6):274-285. doi: 10.11933/j.issn.1007−9289.20220119001PAN Mingshi, CHEN Yan, ZHANG Dongyang. Effect of profiling magnetic pole head on the inner surface of electromagnetic finishing pipe fittings [J]. China Surface Engineering,2022,35(6):274-285. doi: 10.11933/j.issn.1007−9289.20220119001 [16] 薛玉峰. 基于磁性复合流体毛细管内壁的精密抛光研究 [D]. 青岛: 中国海洋大学, 2019.XUE Yufeng. Research on precision polishing of capillary inner surface based on magnetic compound fluid [D]. Qingdao: Ocean University of China, 2019 [17] XUE Y F, ZHANG W T, WANG Y L, et al. Feasibility study on high efficiency and high quality internal polishing of capillary tubes using magnetic compound fluid (MCF) slurry[C]. Hokkaido: The Japan Society for Precision Engineering, 2021, 23: 290-295. [18] ZHANG Z Y, SHI Z F, DU Y F, et al. A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry [J]. Applied Surface Science,2018,427:409-415. doi: 10.1016/j.apsusc.2017.08.064 [19] DENG C B, JIANG L, QIN N, et al. Effects of pH and H2O2 on the chemical mechanical polishing of titanium alloys [J]. Journal of Materials Processing Technology,2021,295:117204. doi: 10.1016/j.jmatprotec.2021.117204 [20] WANG Y L. Mirror surface finishing of miniature V-grooves using MCF (magnetic compound fluid) slurry [D]. Akita, Japan: Akita Prefectural University, 2016. [21] CHIU S Y, WANG Y L, LIU C P, et al. The application of electrochemical metrologies for investigating chemical mechanical polishing of Al with a Ti barrier layer [J]. Materials Chemistry and Physics,2003,82(2):444-451. doi: 10.1016/S0254-0584(03)00312-2 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS