| [1] |

毛雅梅, 黑鸿君, 高洁, 等. 钎焊金刚石研究进展及其工具的应用 [J]. 机械工程学报,2022,58(4):80-93. doi: 10.3901/JME.2022.04.080MAO Yamei, HEI Hongjun, GAO Jie, et al. Research progress of brazing diamond and application of tools [J]. Journal of Mechanical Engineering,2022,58(4):80-93. doi: 10.3901/JME.2022.04.080

|

| [2] |

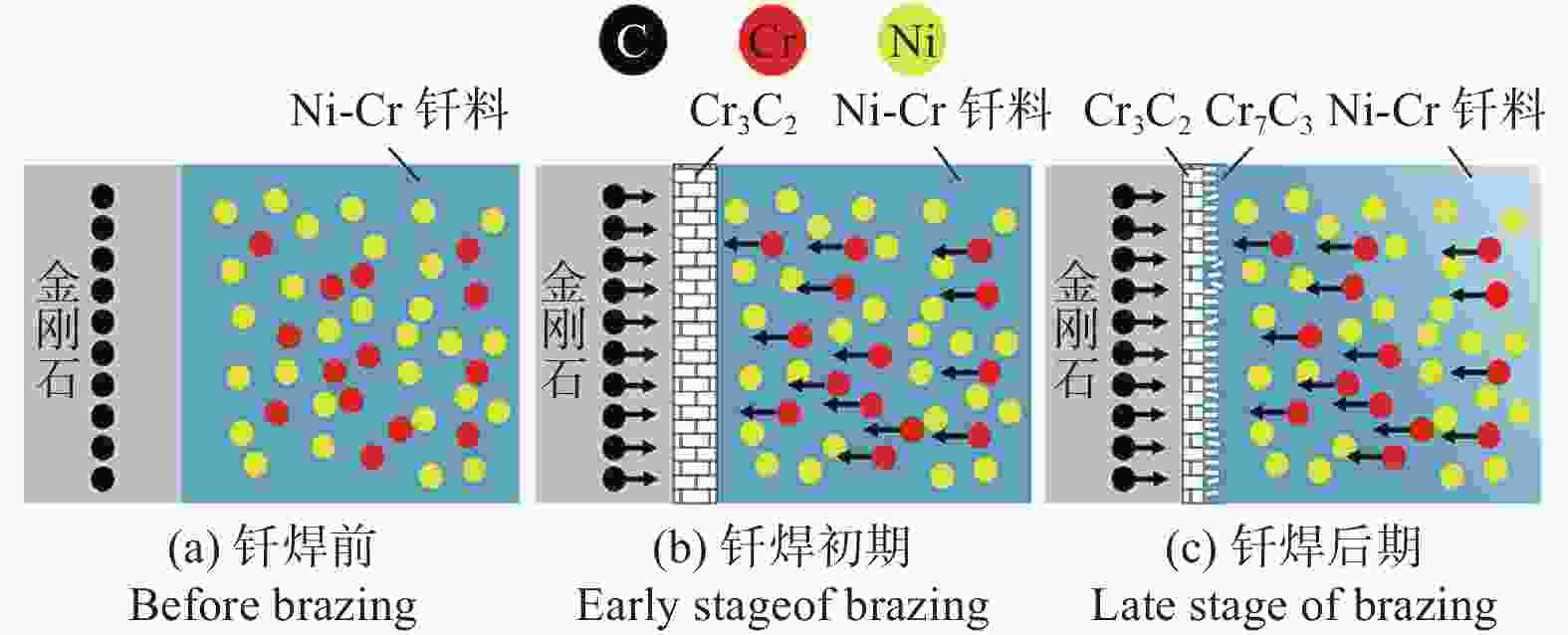

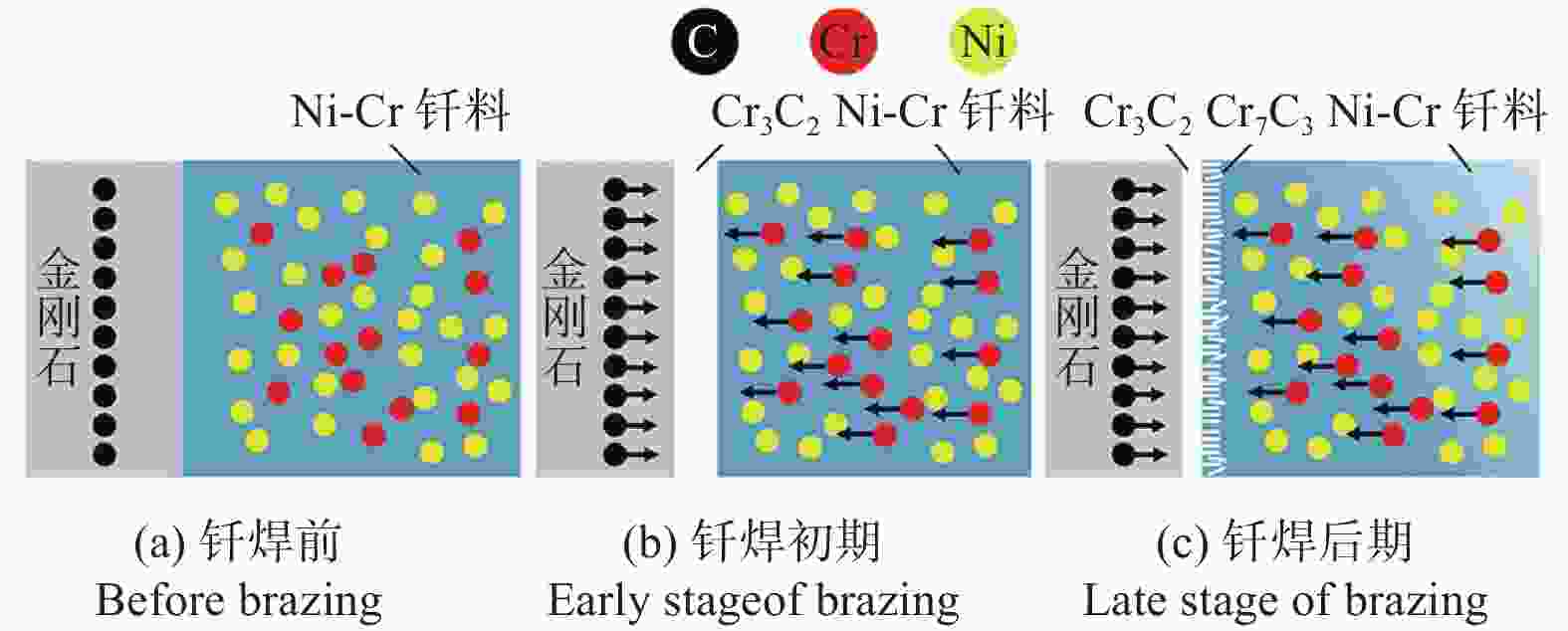

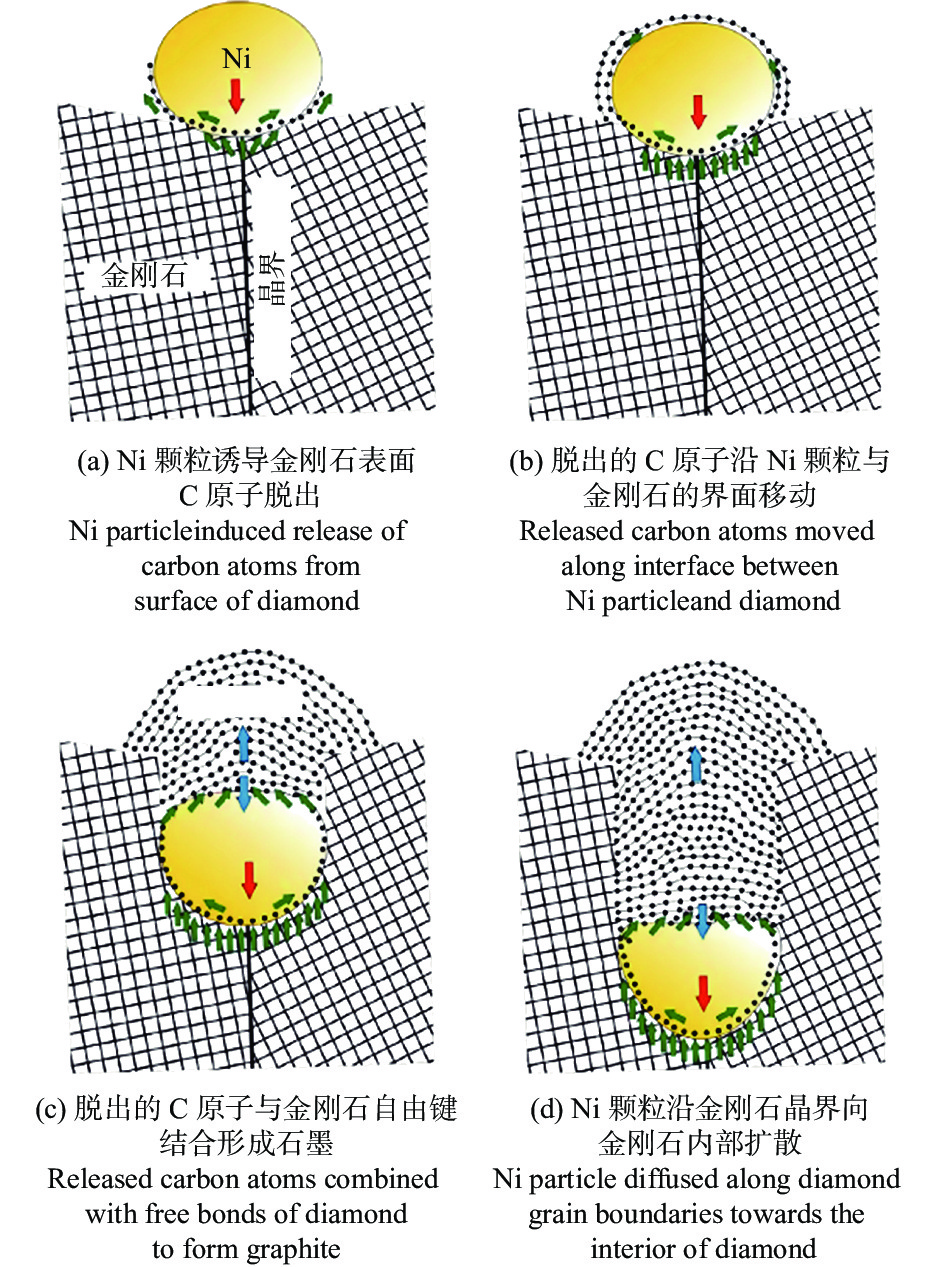

卢金斌, 汤峰, 孟普, 等. Ni-Cr合金真空钎焊金刚石的热损伤分析 [J]. 焊接学报,2010,31(8):25-28,114.LU Jinbin, TANG Feng, MENG Pu, et al. Thermal damage analysis of vacuum brazing diamond with Ni-Cr alloy [J]. Transactions of the China Welding Institution,2010,31(8):25-28,114.

|

| [3] |

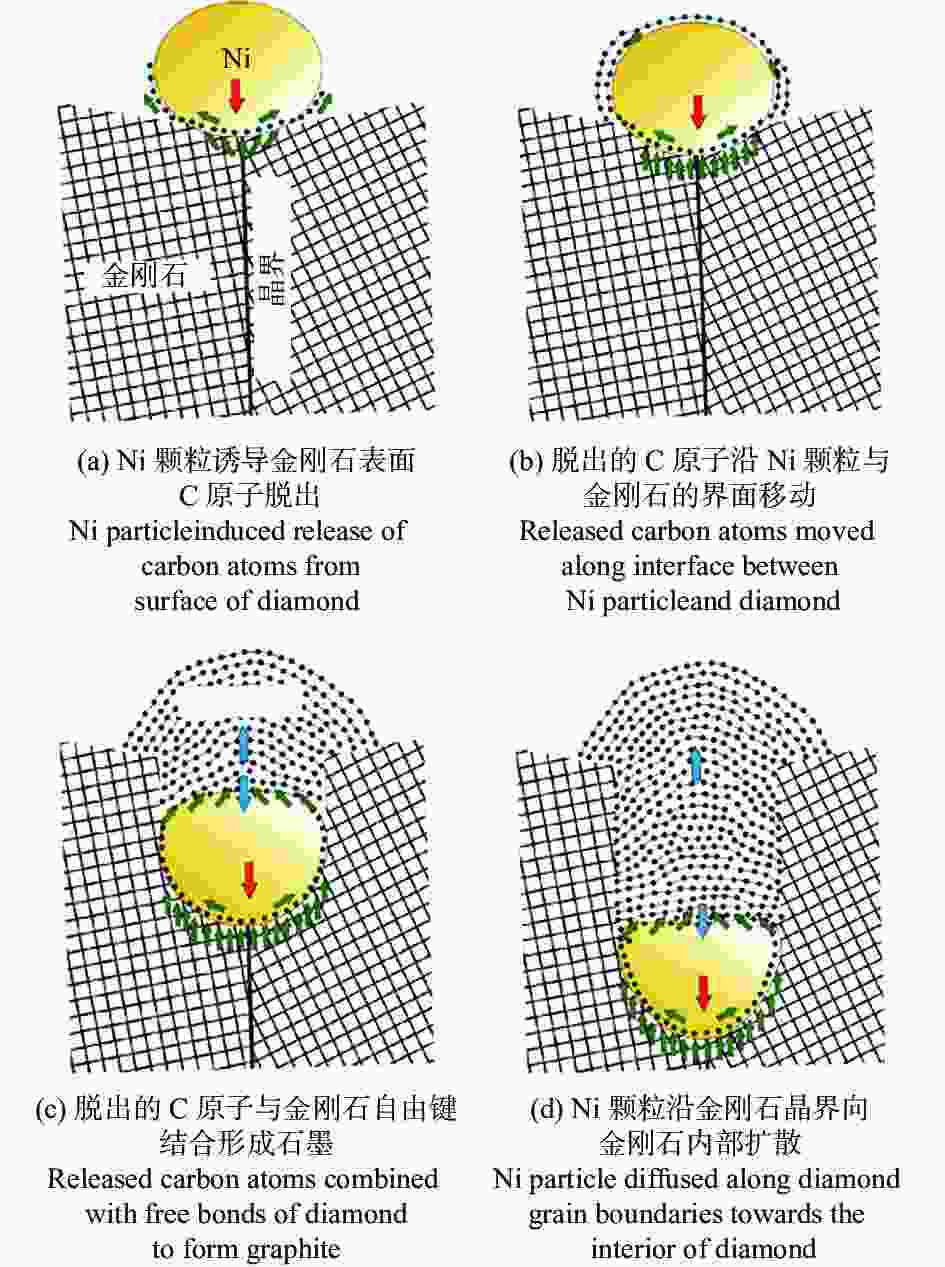

郭晓光, 翟昌恒, 金洙吉, 等. 铁基作用下的金刚石石墨化研究 [J]. 机械工程学报,2015,51(17):162-168. doi: 10.3901/JME.2015.17.162GUO Xiaoguang, ZHAI Changheng, JIN Zhuji, et al. The study of diamond graphitization under the action of iron-based catalyst [J]. Journal of Mechanical Engineering,2015,51(17):162-168. doi: 10.3901/JME.2015.17.162

|

| [4] |

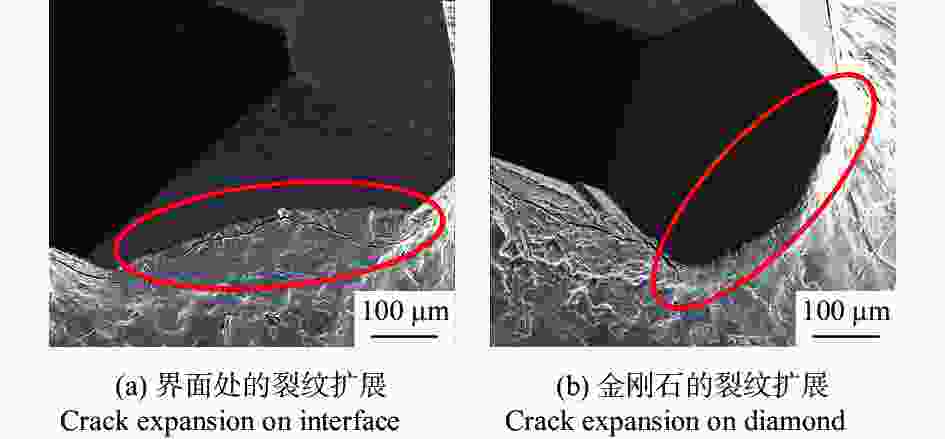

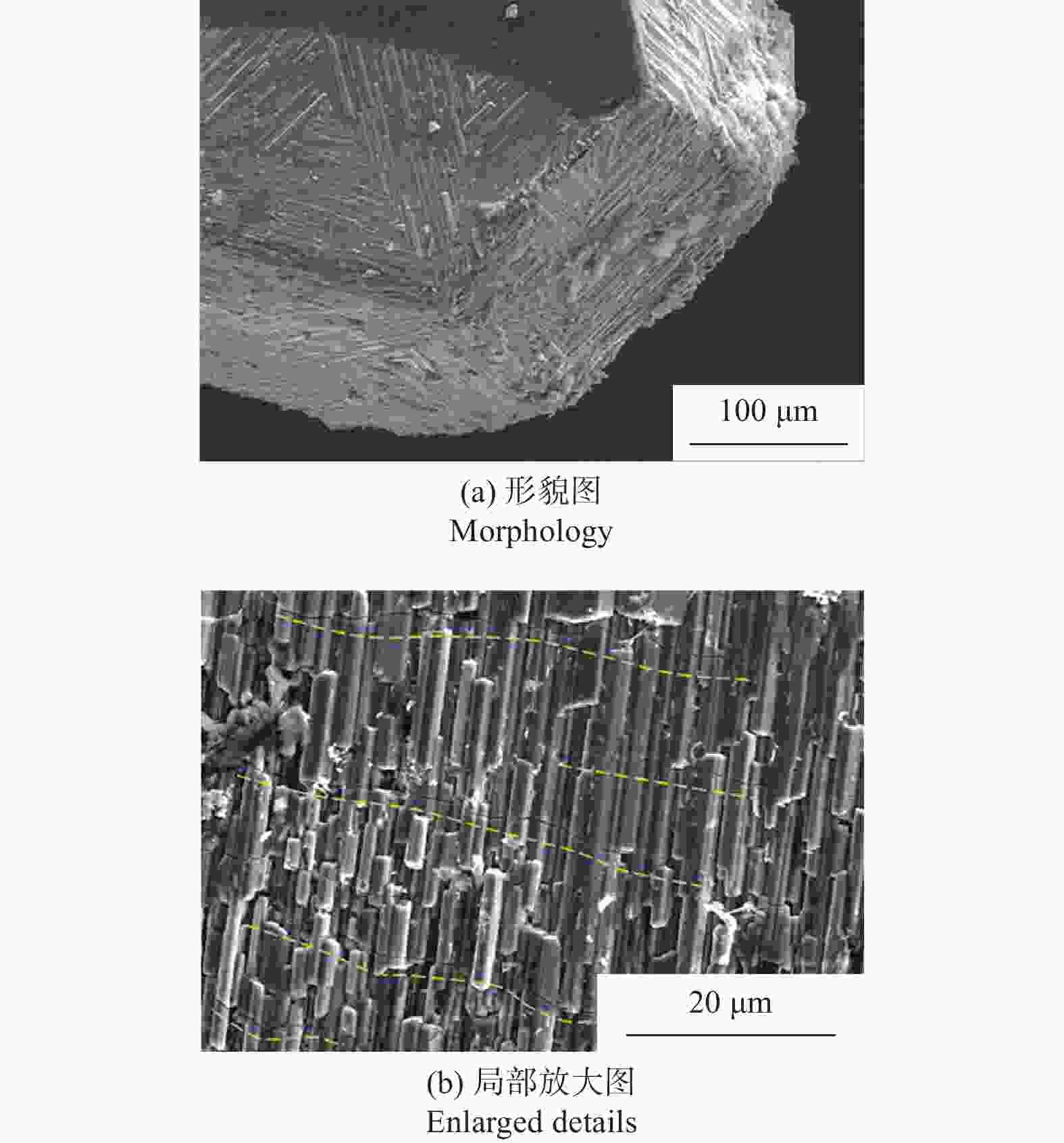

吕祎强, 张振宇, 刘冬冬, 等. 金刚石损伤的原位扫描电镜研究 [J]. 硬质合金,2022,39(2):85-93. doi: 10.3969/j.issn.1003-7292.2022.02.002LV Yiqiang, ZHANG Zhenyu, LIU Dongdong, et al. Research on in-situ scanning electron microscope of diamond damage [J]. Cemented Carbides,2022,39(2):85-93. doi: 10.3969/j.issn.1003-7292.2022.02.002

|

| [5] |

TULIC S, WAITZ T, CAPLOVICOVA M, et al. Catalytic graphitization of single-crystal diamond [J]. Carbon,2021,185:300-313. doi: 10.1016/j.carbon.2021.08.082

|

| [6] |

程伟. 金刚石磨粒与Ni-Cr合金固态反应的实验与仿真研究 [D]. 厦门: 华侨大学, 2022.CHENG Wei. Experimental and simulation study on solid-state reaction between diamond abrasives and Ni-Cr binary alloy [D]. Xiamen: Huaqiao University. 2022.

|

| [7] |

COOIL S P, WELLS J W, HU D, et al. Controlling the growth of epitaxial graphene on metalized diamond (111) surface [J]. Applied Physics Letters,2015,107:181603. doi: 10.1063/1.4935073

|

| [8] |

CUI Z P, LI G, ZONG W J. A polishing method for single crystal diamond (100) plane based on nano silica and nano nickel powder [J]. Diamond and Related Materials,2019,95:141-153. doi: 10.1016/j.diamond.2019.04.016

|

| [9] |

杨亚楠, 王海阔, 侯志强, 等. 金刚石-WC-Co复合材料的高温高压合成 [J]. 金刚石与磨料磨具工程,2021,41(2):53-58. doi: 10.13394/j.cnki.jgszz.2021.2.0009YANG Yanan, WANG Haikuo, HOU Zhiqiang, et al. Fabrication of diamond-WC-Co composites at high temperature and high pressure [J]. Diamond & Abrasives Engineering,2021,41(2):53-58. doi: 10.13394/j.cnki.jgszz.2021.2.0009

|

| [10] |

UEDA K, AICHI S, ASANO H. Direct formation of graphene layers on diamond by high-temperature annealing with a Cu catalyst [J]. Diamond and Related Materials,2016,63:148-152. doi: 10.1016/j.diamond.2015.10.021

|

| [11] |

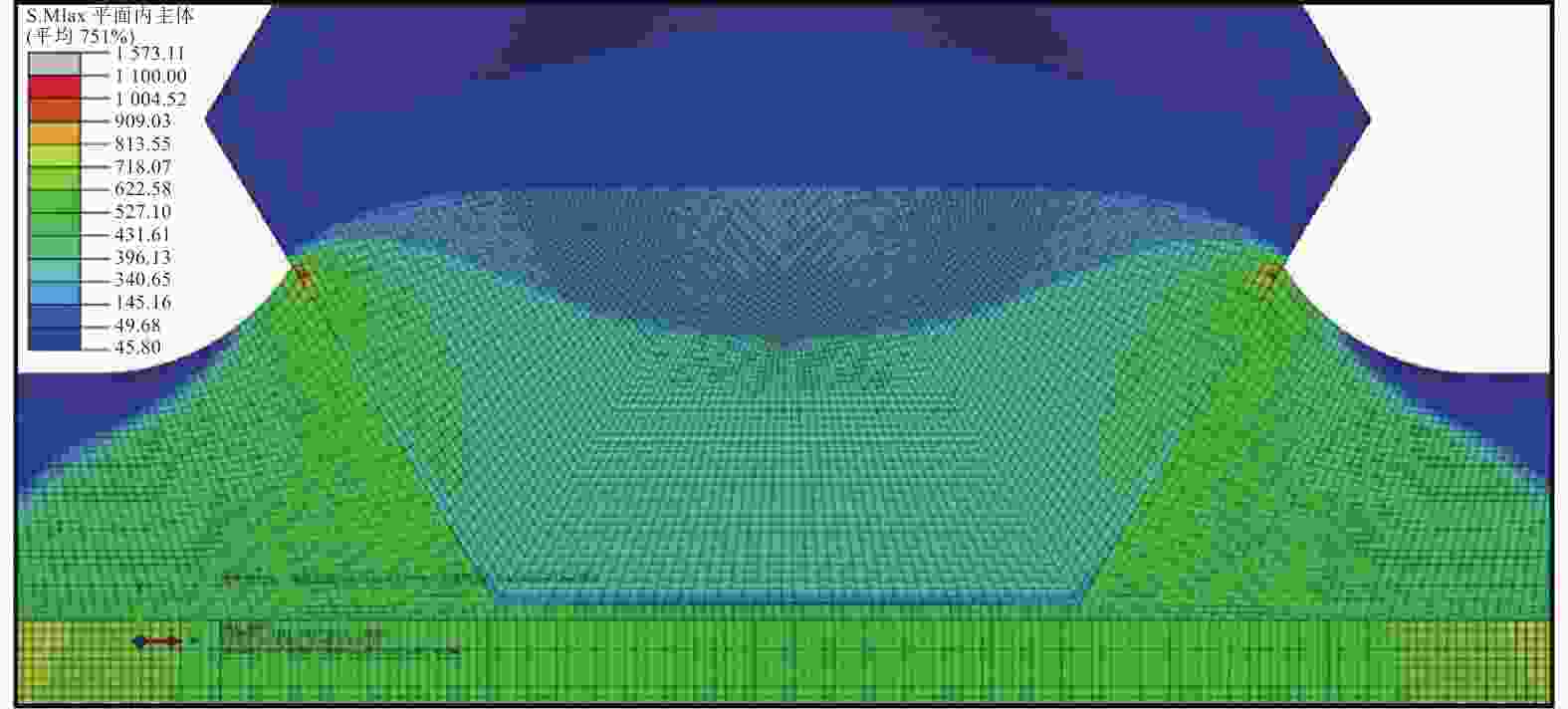

孟普. Ni-Cr合金钎焊金刚石接头残余应力分析 [J]. 金刚石与磨料磨具工程,2013,33(5):57-60,66. doi: 10.13394/j.cnki.jgszz.2013.05.008MENG Pu. Residual stress analysis of diamond joint brazed with Ni-Cr alloy [J]. Diamond & Abrasives Engineering,2013,33(5):57-60,66. doi: 10.13394/j.cnki.jgszz.2013.05.008

|

| [12] |

BUHL S, LEINENBACH C, SPOLENAK R, et al. Influence of the brazing parameters on microstructure, residual stresses and shear strength of diamond–metal joints [J]. Journal of Materials Science,2010,45:4358-4368. doi: 10.1007/s10853-010-4260-7

|

| [13] |

MUKHOPADHYAY P, SIMHAN D R, GHOSH A. Challenges in brazing large synthetic diamond grit by Ni-based filler alloy [J]. Journal of Materials Processing Technology,2017,250:390-400. doi: 10.1016/j.jmatprotec.2017.08.004

|

| [14] |

WANG S Y, XIAO B, SU S C, et al. Interfacial characteristics and thermal damage of brazed W-coated diamond with Ni- based filler alloy [J]. Diamond and Related Materials,2021,116:108401. doi: 10.1016/j.diamond.2021.108401

|

| [15] |

FENG H, YU J K, TAN W. Microstructure and thermal properties of diamond/aluminum composites with TiC coating on diamond particles [J]. Materials Chemistry and Physics,2010,124:851-855. doi: 10.1016/j.matchemphys.2010.08.003

|

| [16] |

徐俊. 金刚石盐浴镀钛对金刚石/铝复合材料组织及性能的影响 [D]. 南京: 东南大学, 2019.XU Jun. Effect of salt bath plating Ti on diamond particles on the microstructure and properties of diamond/Al composites [D]. Nanjing:Southeast University. 2019.

|

| [17] |

王艳辉. 金刚石磨料表面镀钛层的制备、结构、性能及应用 [D]. 秦皇岛: 燕山大学, 2003.WANG Yanhui. Preparation, structure, properties and applications of titanium coating on diamond abrasive [D]. Qinhuangdao: Yanshan University, 2003.

|

| [18] |

BHOWMICK S, BANERJI A, ALPAS A T. Friction reduction mechanisms in multilayer graphene sliding against hydrogenated diamond-like carbon [J]. Carbon,2016,109:795-804. doi: 10.1016/j.carbon.2016.08.036

|

| [19] |

HONG S M, AKAISHI M, KANDA H, et al. Behaviour of cobalt infiltration and abnormal grain growth during sintering of diamond on cobalt substrate [J]. Journal of Materials Science,1988,23(11):3821-3826. doi: 10.1007/BF01106798

|

| [20] |

冒爱琴, 何宜柱, 郑翠红, 等. 金刚石表面金属化的研究现状 [J]. 材料导报,2005(2):31-33. doi: 10.3321/j.issn:1005-023X.2005.02.009MAO Aiqin, HE Yizhu, ZHENG Cuihong, et al. Development of cladding on diamond [J]. Materials Reports,2005(2):31-33. doi: 10.3321/j.issn:1005-023X.2005.02.009

|

| [21] |

栗晓龙. 金刚石表面镀覆层对金属结合剂金刚石工具性能影响 [D]. 郑州: 河南工业大学, 2018.LI Xiaolong. Effect of the coating layer on the diamond surface on the properties of metal bonded diamond tools [D]. Zhengzhou: Henan University of Technology, 2018.

|

| [22] |

刘婷婷. 金刚石颗粒的表面镀镍及其在固结磨料研磨中的应用[D]. 南京: 南京航空航天大学, 2014.LIU Tingting. Surface nickel plating of diamond particles and its application in fixed abrasive lapping [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2014.

|

| [23] |

张一翔, 沈志刚. 磁控溅射金刚石微粉表面镀镍及其在电镀金刚石线锯上的应用 [J]. 中国粉体技术,2017,23(3):21-25. doi: 10.13732/j.issn.1008-5548.2017.03.004ZHANG Yixiang, SHEN Zhigang. Ni coating on surface of diamond microparticles by magnetron sputtering method for enhanced performance of diamond wire [J]. China Powder Science and Technology,2017,23(3):21-25. doi: 10.13732/j.issn.1008-5548.2017.03.004

|

| [24] |

栗晓龙, 肖长江, 栗正新. 金刚石镀镍和钛对其金属烧结制品强度的影响 [J]. 山东化工,2017,46(17):51-52. doi: 10.3969/j.issn.1008-021X.2017.17.020LI Xiaolong, XIAO Changjiang, LI Zhengxin. Study of diamond coated ni and ti influencing on strength of the metal powder sintering products [J]. Shandong Chemical Industry,2017,46(17):51-52. doi: 10.3969/j.issn.1008-021X.2017.17.020

|

| [25] |

方莉俐, 薛丽沙. 金刚石粒度对金刚石镀镍的影响 [J]. 电镀与涂饰,2015,34(23):1351-1354. doi: 10.3969/j.issn.1004-227X.2015.23.005FANG Lili, XUE Lisha. Effect of size of diamond particles on nickel plating of diamond [J]. Electroplating & Finishing,2015,34(23):1351-1354. doi: 10.3969/j.issn.1004-227X.2015.23.005

|

| [26] |

LI A , SHI L , ZHANG W, et al. A simple way to fabricate Ti6Al4V matrix composites reinforced by graphene with exceptional mechanical properties [J]. Materials Letters,2019,257:126750. doi: 10.1016/j.matlet.2019.126750

|

| [27] |

韩金江, 陈冰威, 路朋献, 等. 金刚石/铜(银、碳化钛)界面性质的第一性原理计算 [J]. 金刚石与磨料磨具工程,2022,42(5):535-542. doi: 10.13394/j.cnki.jgszz.2022.5002HAN Jinjiang, CHEN Bingwei, LU Pengxian, et al. First-principles calculations of diamond/copper (silver, titanium carbide) interface properties [J]. Diamond & Abrasives Engineering,2022,42(5):535-542. doi: 10.13394/j.cnki.jgszz.2022.5002

|

| [28] |

WEI C L, XU X , WEI B Z, et al. Titanium coating on the surface of diamond particles by a novel rapid low-temperature salt bath plating method [J]. Chemical Physics Letters,2020,761:138091. doi: 10.1016/j.cplett.2020.138091

|

| [29] |

武玺旺, 皇甫战彪, 刘雪坤, 等. 熔盐法合成Ti和TiC镀覆层对金刚石热稳定性的影响 [J]. 金刚石与磨料磨具工程,2023,43(2):196-201. doi: 10.13394/j.cnki.jgszz.2022.0054WU Xiwang, HUANGFU Zhanbiao, LIU Xuekun, et al. Effect of Ti and TiC coating on the thermal stability of diamond [J]. Diamond & Abrasives Engineering,2023,43(2):196-201. doi: 10.13394/j.cnki.jgszz.2022.0054

|

| [30] |

郭梦华, 张鹏, 栗正新, 等. 利用表面镀钛及掺杂氧化镧改善金刚石/铜复合材料性能的研究 [J/OL]. 中国稀土学报, 1-17 [2024-09-30]. http://kns.cnki.net/kcms/detail/11.2365.TG.20230627.1232.008.html.GUO Menghua, ZHANG Peng, LI Zhengxin, et al. Improving the properties of diamond/Cu composites by coating Titanium on diamond surface and doping La2O3[J/OL]. Journal of the Chinese Society of Rare Earths, 1-17[2024-09-30]. http://kns.cnki.net/kcms/detail/11.2365.TG.20230627.1232.008.html

|

| [31] |

SHA X H, YUE W, ZHANG H C, et al. Enhanced oxidation and graphitization resistance of polycrystalline diamond sintered with Ti-coated diamond powders [J]. Journal of Materials Science & Technology,2020,43(8):64-73. doi: 10.1016/j.jmst.2020.01.031

|

| [32] |

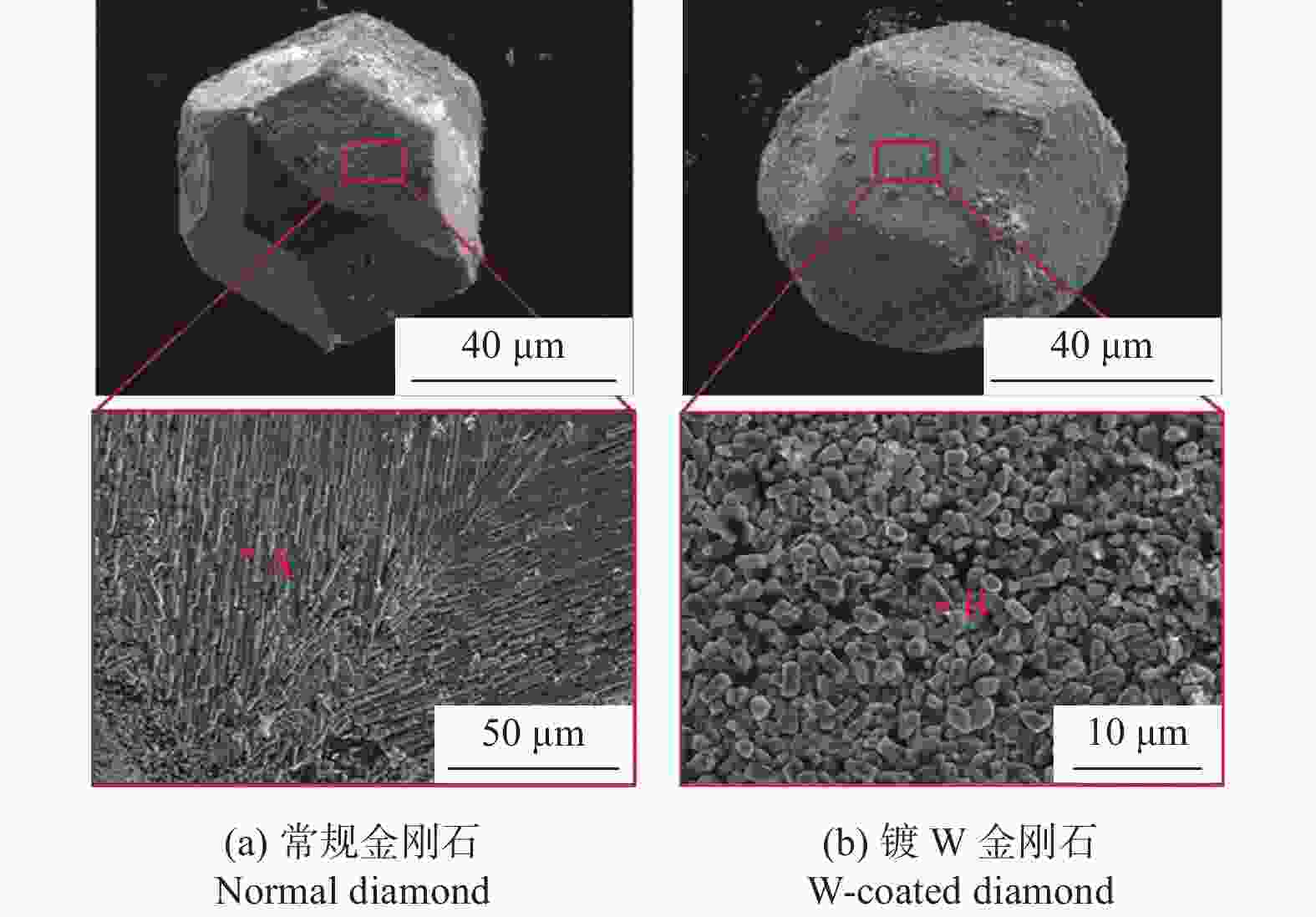

王树义, 肖冰, 肖皓中, 等. 镍基钎料真空钎焊镀钨金刚石的研究 [J]. 金刚石与磨料磨具工程,2023,43(2):202-209. doi: 10.13394/j.cnki.jgszz.2022.0134WANG Shuyi, XIAO Bing, XIAO Haozhong, et al. Research on vacuum brazing of W-coated diamond with Ni-based filler alloy [J]. Diamond & Abrasives Engineering,2023,43(2):202-209. doi: 10.13394/j.cnki.jgszz.2022.0134

|

| [33] |

李建伟, 张海龙, 张少明, 等. 金刚石表面镀钨对铜/金刚石复合材料热导率的影响 [J]. 功能材料,2016,47(1):1034-1037. doi: 10.3969/j.issn.1001-9731.2016.01.007LI Jianwei, ZHANG Hailong, ZHANG Shaoming, et al. On the thermal conductivity of Cu/diamond composite of diamond particles with tungsten coating [J]. Journal of Functional Materials,2016,47(1):1034-1037. doi: 10.3969/j.issn.1001-9731.2016.01.007

|

| [34] |

郭嘉鹏. 金刚石增强铜基复合材料的制备及性能研究 [D]. 兰州: 兰州理工大学, 2022.GUO Jiapeng. Preparation and properties of diamond reinforced copper matrix composites [D]. Lanzhou: Lanzhou University of Technology, 2022.

|

| [35] |

李文杰, 肖冰, 段端志, 等. 铜基预钎焊金刚石锯片的界面分析及其性能研究 [J]. 金刚石与磨料磨具工程,2014,34(2):44-47. doi: 10.13394/j.cnki.jgszz.2014.2.0010LI Wenjie, XIAO Bing, DUAN Duanzhi, et al. Interface analysis and performance evaluation of the Cu-based pre-brazed diamond saw blade [J]. Diamond & Abrasives Engineering,2014,34(2):44-47. doi: 10.13394/j.cnki.jgszz.2014.2.0010

|

| [36] |

DUAN D Z , XIAO B, WANG W, et al. Interface characteristics and performance of pre-brazed diamond grains with Ni–Cr composite alloy [J]. Journal of Alloys and Compounds,2015,644:626-631. doi: 10.1016/j.jallcom.2015.03.269

|

| [37] |

龙涛, 董应虎, 张瑞卿, 等. 金刚石表面金属化可控Cr层的形成机制及性能 [J]. 材料热处理学报,2015,36(1):132-137. doi: 10.13289/j.issn.1009-6264.2015.01.026LONG Tao, DONG Yinghu, ZHANG Ruiqing, et al. Formation mechanism and properties of controllable Cr layer on diamond surface by salt bath plating [J]. Transactions of Materials and Heat Treatment,2015,36(1):132-137. doi: 10.13289/j.issn.1009-6264.2015.01.026

|

| [38] |

张洪迪. 表面金属化金刚石/铜复合材料导热模型、界面结构与热变形行为研究 [D]. 上海: 上海交通大学, 2018.ZHANG Hongdi. Theoretical model of thermal conductivity, interfacial structure and hot deformation behavior of surface metallized diamond/copper composites [D]. Shanghai: Shanghai Jiao Tong University, 2018.

|

| [39] |

谢吉, 甄春刚, 覃光明, 等. 金刚石镀覆及热处理在金刚石工具中的应用 [J]. 超硬材料工程,2020,32(3):1-7. doi: 10.3969/j.issn.1673-1433.2020.03.001XIE Ji, ZHEN Chungang, QIN Guangming, et al. Application of diamond coating and heat treatment on diamond tools [J]. Superhard Material Engineering,2020,32(3):1-7. doi: 10.3969/j.issn.1673-1433.2020.03.001

|

| [40] |

SHA X H, YUE W, ZHANG H C, et al. Thermal stability of polycrystalline diamond compact sintered with boron-coated diamond particles [J]. Diamond and Related Materials,2020,104:107753. doi: 10.1016/j.diamond.2020.107753

|

| [41] |

马洪兵, 白华, 薛晨, 等. 镀硼金刚石-金属基复合材料的制备及其性能研究 [J]. 硬质合金,2017,34(5):314-319. doi: 10.3969/j.issn.1003-7292.2017.05.004MA Hongbing, BAI Hua, XUE Cheng, et al. Research on preparation and properties of boron-coated diamond-metal matrix composite [J]. Cemented Carbides,2017,34(5):314-319. doi: 10.3969/j.issn.1003-7292.2017.05.004

|

| [42] |

SUN Y, MENG Q, QIAN M,et al. Enhancement of oxidation resistance via a self-healing boron carbide coating on diamond particles [J]. Scientific Reports,2016(6):20198. doi: 10.1038/srep20198

|

| [43] |

MENG D, YAN G, YUE W, et al. Thermal damage mechanisms of Si-coated diamond powder based polycrystalline diamond [J]. Journal of the European Ceramic Society,2018,38(13):4338-4345. doi: 10.1016/j.jeurceramsoc.2018.05.017

|

| [44] |

LU J, WANG Y H , QI X H , et al. Structure and characteristics of Si-coated diamond grits [J]. 金刚石与磨料磨具工程,2005(6):13-15. doi: 10.13394/j.cnki.jgszz.2005.06.004

|

| [45] |

ZHU C X , WANG C , LANG J, et al. Si-coated diamond particles reinforced copper composites fabricated by spark plasma sintering process [J]. Materials and Manufacturing Processes,2013,28(1/2/3):143-147. doi: 10.1080/10426914.2012.746789

|

| [46] |

高先哲, 肖冰, 管海军, 等. Cu-Sn-Ti钎料的改性设计及性能分析 [J]. 金刚石与磨料磨具工程,2018,38(1):32-36,40. doi: 10.13394/j.cnki.jgszz.2018.1.0005GAO Xianzhe, XIAO Bing, GUAN Haijun, et al. Modification design and performance analysis of Cu-Sn-Ti solder [J]. Diamond & Abrasives Engineering,2018,38(1):32-36,40. doi: 10.13394/j.cnki.jgszz.2018.1.0005

|

| [47] |

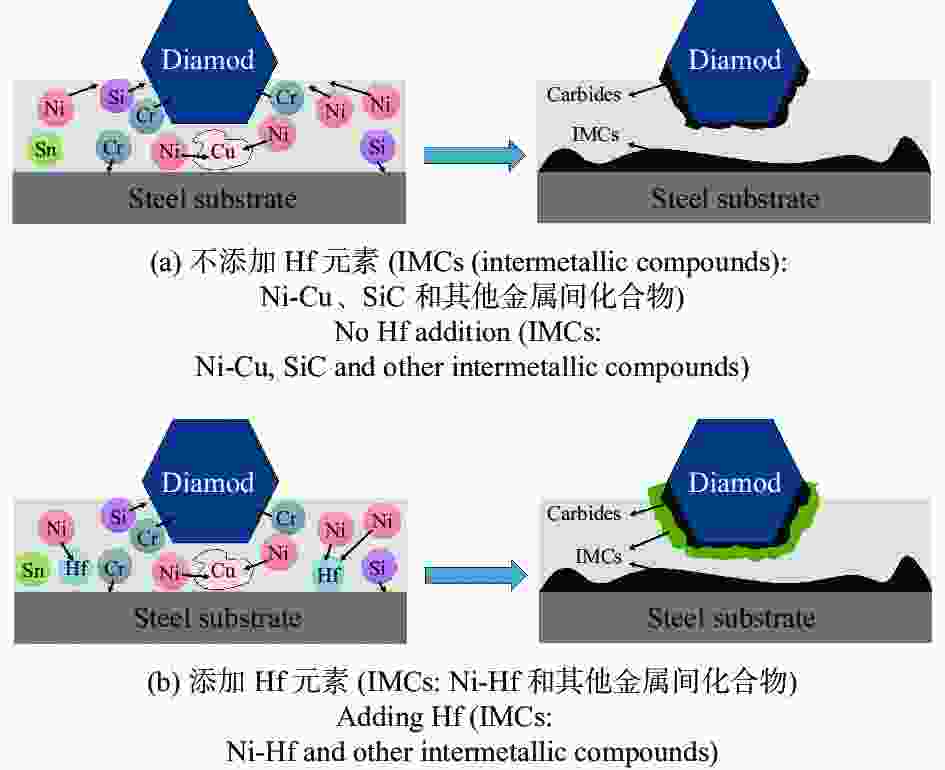

SI S H , DING Z C , ZUO R Z , et al. Adding Hf element to improve the strength and wear resistance of diamond brazed with Ni-based boron-free brazing filler metal [J]. Diamond and Related Materials,2022,121:108723. doi: 10.1016/j.diamond.2021.108723

|

| [48] |

CUI B, WANG P B, ZHAO W X, et al. Adding Zr element to improve the strength and mechanical properties of diamond vacuum-brazed with Ni-Cr boron-free filler alloy [J]. Diamond and Related Materials,2023,133:109722. doi: 10.1016/j.diamond.2023.109722

|

| [49] |

李力, 李小强, 胡可, 等. 真空钎焊TiAl基合金用Ti-Zr-Cu-Ni-Co-Mo钎料的钎焊性能 [J]. 中国有色金属学报(英文版),2019,29(4):754-763. doi: 10.1016/S1003-6326(19)64985-XLI Li, LI Xiaoqiang, HU Ke, et al. Brazeability evaluation of Ti-Zr-Cu-Ni-Co-Mo filler for vacuum brazing TiAl-based alloy [J]. Transactions of Nonferrous Metals Society of China,2019,29(4):754-763. doi: 10.1016/S1003-6326(19)64985-X

|

| [50] |

马伯江, 王镇, 王超. 非晶Ni基合金感应钎焊微粉金刚石的研究 [J]. 硬质合金,2020,37(6):417-422. doi: 10.3969/j.issn.1003-7292.2020.06.002MA Bojiang, WANG Zhen, WANG Chao. Study on induction brazing of micro-powder diamond with an amorphous ni-based alloy [J]. Cemented Carbide,2020,37(6):417-422. doi: 10.3969/j.issn.1003-7292.2020.06.002

|

| [51] |

王超. 非晶Ni基合金阻焊金刚石磨粒的研究 [D]. 青岛: 青岛科技大学, 2022.WANG Chao. Research on resistance welding of diamond grits using amorphous nickel-based alloys [D]. Qingdao: Qingdao University of Science Technology. 2022.

|

| [52] |

DING W F , XU J H,CHEN Z Z, et al. A study on effects of TiB2 contents on reactive products and compressive strength of brazed CBN grains [J]. Surface and Interface Analysis,2009,41:238-243. doi: 10.1002/sia.3013

|

| [53] |

YIN X H, XU F, MIN C Y, et al. Promoting the bonding strength and abrasion resistance of brazed diamond using Cu–Sn–Ti composite alloys reinforced with tungsten carbide [J]. Diamond and Related Materials,2021,112:108239. doi: 10.1016/j.diamond.2021.108239

|

| [54] |

尹孝辉, 徐凡, 徐东, 等. 添加ZrC增强相的Cu-Sn-Ti钎料真空钎焊金刚石的微观结构和磨削性能的研究 [J]. 机械工程学报,2021,57(18):182-189. doi: 10.3901/JME.2021.18.182YIN Xiaohui, XU Fan, XU Dong, et al. Research on microstructure and grinding performance of vacuum brazed diamond with zrc reinforced cu-sn-ti composite alloys [J]. Journal of mechanical engineering,2021,57(18):182-189. doi: 10.3901/JME.2021.18.182

|

| [55] |

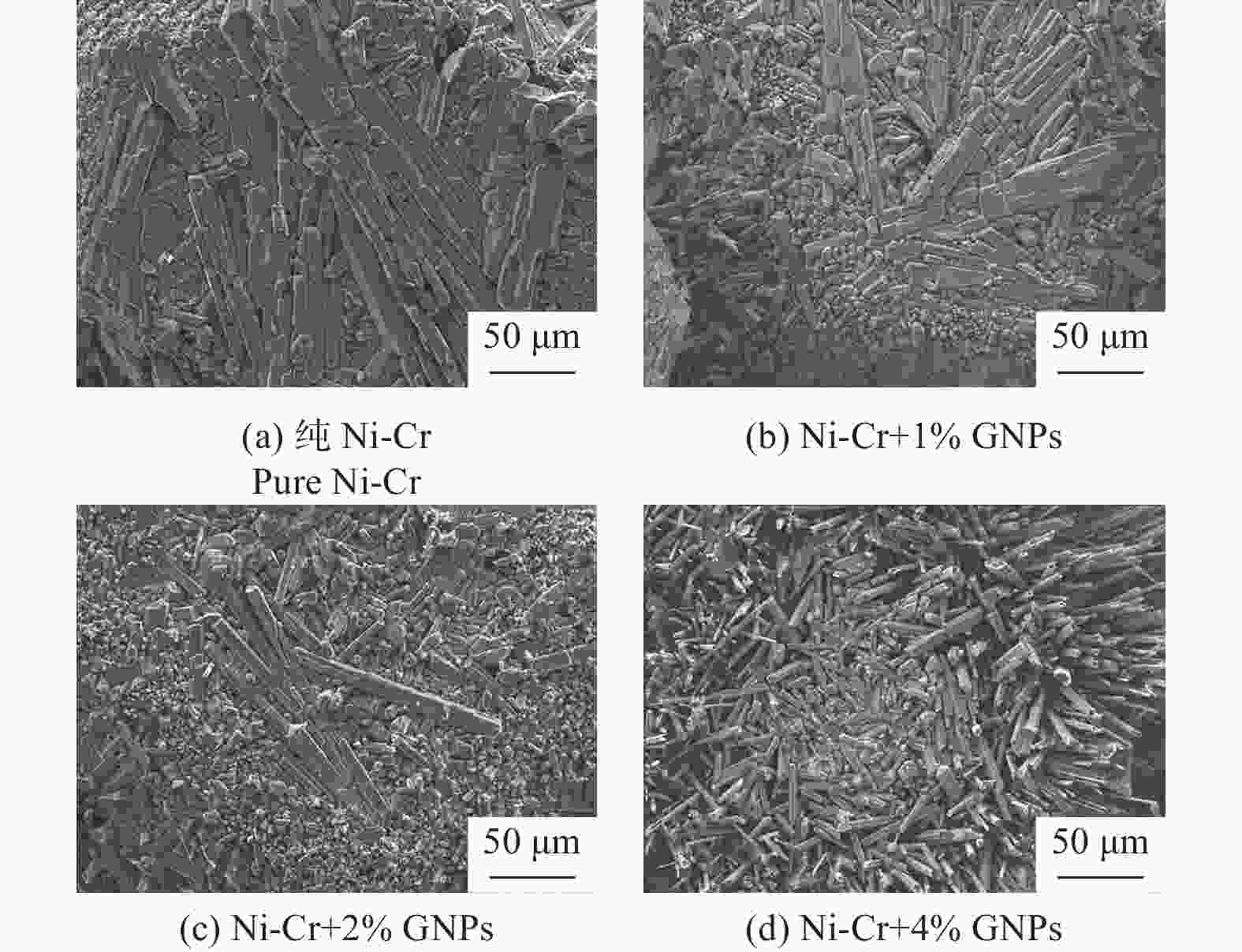

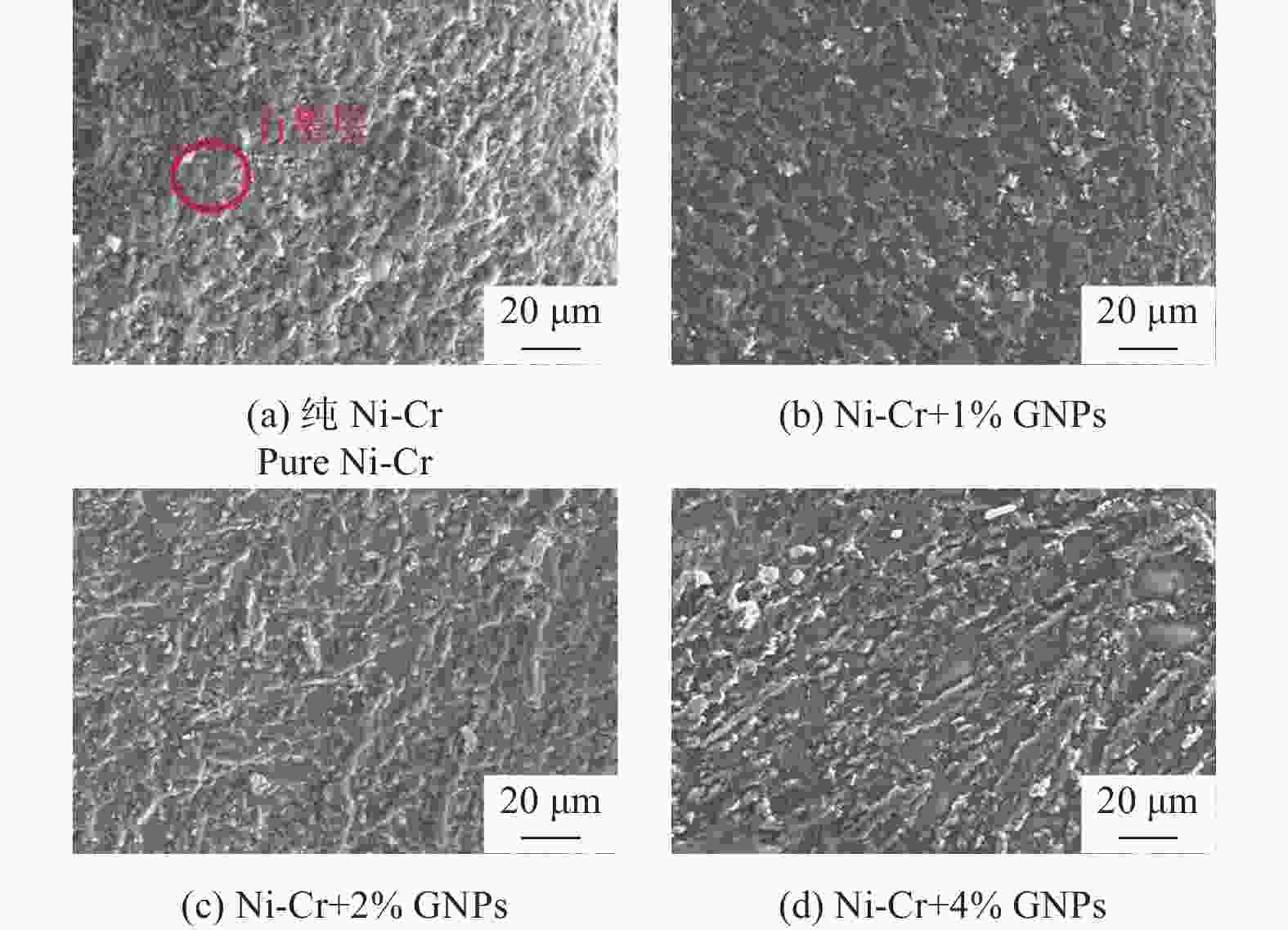

ZHAO J, GUO M, HU S P, et al. Brazing of large synthetic diamond grits using graphene nanoplatelets reinforced Ni-Cr composite fillers [J]. Diamond and Related Materials,2020,109:108004. doi: 10.1016/j.diamond.2020.108004

|

| [56] |

郭民. 石墨烯增强Ni-Cr复合钎料钎焊金刚石工艺及机理研究 [D].上海: 上海工程技术大学, 2021.GUO Min. Research on process and mechanism of diamond brazing with gnps-reinforced ni-cr composite filler [D]. Shanghai: Shanghai University of Engineering Science, 2021.

|

| [57] |

杨理清, 骆颖, 罗文来. 烧结保温时间对金刚石工具产品性能的影响 [J]. 超硬材料工程,2016,28(6):10-14. doi: 10.3969/j.issn.1673-1433.2016.06.004YANG Liqing, LUO Ying, LUO Wenlai. The influence of sintering holding time on the performance of diamond tools product [J]. Superhard Material Engineering,2016,28(6):10-14. doi: 10.3969/j.issn.1673-1433.2016.06.004

|

| [58] |

甄春刚, 覃光明, 谢吉, 等. 预烧结对钴基胎体性能的影响 [J]. 超硬材料工程,2019,31(5):33-36. doi: 10.3969/j.issn.1673-1433.2019.05.008ZHEN Chungang, QIN Guangming, XIE Ji, et al. Effect of pre-sintered process on the properties of Co-based matrix [J]. Superhard Material Engineering,2019,31(5):33-36. doi: 10.3969/j.issn.1673-1433.2019.05.008

|

| [59] |

YANG L, HONG F D, WEN S L. Effects of sintering temperature on the properties of Cu-Co-based alloys matrix [J]. Advanced Materials Research,2011,1169(201/202/203):1757-1762. doi: 10.4028/www.scientific.net/AMR.201-203.1757

|

| [60] |

徐强, 刘一波, 杨志威. 热压烧结工艺参数对金刚石工具胎体力学性能的影响 [J]. 超硬材料工程,2020,32(6):9-14. doi: 10.3969/j.issn.1673-1433.2020.06.002XU Qiang, LIU Yibo, YANG Zhiwei. Influence of hot press sintering technical parameters on mechanical properties of diamond tools matrix [J]. Superhard Material Engineering,2020,32(6):9-14. doi: 10.3969/j.issn.1673-1433.2020.06.002

|

| [61] |

郭洪凯. 金刚石工具用高熵合金结合剂的研究 [D]. 秦皇岛: 燕山大学, 2016.GUO Hongkai. Research for the high entropyalloys bond of diamond abrasive tools [D]. Qinhuangdao: Yanshan University, 2016.

|

| [62] |

张毓隽, 童震松, 沈卓身. SPS工艺对铜/金刚石复合材料性能的影响 [J]. 电子元件与材料,2009,28(10):37-40. doi: 10.3969/j.issn.1001-2028.2009.10.012ZHANG Yujun, TONG Zhensong, SHEN Zhuoshen. Effect of spark plasma sintering process on the properties of Cu/diamond composite material [J]. Electronic Components and Materials,2009,28(10):37-40. doi: 10.3969/j.issn.1001-2028.2009.10.012

|

| [63] |

武美玲, 尹育航, 丁冬海, 等. 自蔓延高温合成法制备金刚石工具材料研究现状 [J]. 材料热处理学报,2023,44(5):1-15. doi: 10.13289/j.issn.1009-6264.2022-0500WU Meiling, YIN Yuhang, DING Donghai, et al. Research status of diamond tool materials prepared by self-propagating high-temperature synthesis [J]. Transactions of Materials and Heat Treatment,2023,44(5):1-15. doi: 10.13289/j.issn.1009-6264.2022-0500

|

| [64] |

PENG J W, ZHANG F L, HUANG Y J, et al. Preparation a nickel-aluminide bonded diamond tool by self-propagating high-temperature synthesis and strengthening by nickel-chromium-phosphorus alloy and copper [J]. International Journal of Refractory Metals and Hard Materials,2019,82:100-109. doi: 10.1016/j.ijrmhm.2019.04.002

|

| [65] |

吴益雄, 陈欣宏, 彭家万, 等. 基于Fe-Al自蔓延反应的金刚石工具制备及性能研究 [J]. 超硬材料工程,2021,33(2):1-6. doi: 10.3969/j.issn.1673-1433.2021.02.001WU Yixiong, CHEN Xinhong, PENG Jiawan, et al. Study on preparation and performance of diamond tools based on Fe-Al self-propagating reaction [J]. Superhard Material Engineering,2021,33(2):1-6. doi: 10.3969/j.issn.1673-1433.2021.02.001

|

| [66] |

王光祖, 方占江. 钎焊金刚石工具的研究综述 [J]. 超硬材料工程,2022,34(1):32-36. doi: 10.3969/j.issn.1673-1433.2022.01.007WANG Guangzu, FANG Zhanjiang. Review of research progress on brazed diamond tools [J]. Superhard Material Engineering,2022,34(1):32-36. doi: 10.3969/j.issn.1673-1433.2022.01.007

|

| [67] |

吴其亮, 于爱兵, 孙磊, 等. 聚晶金刚石与高速钢的真空钎焊工艺研究 [J]. 材料保护,2021,54(7):112-116,121. doi: 10.16577/j.cnki.42-1215/tb.2021.07.020WU Qiliang, YU Aibing, SUN Lei, et al. Study on vacuum brazing technology of polycrystalline diamond and high speed steel [J]. Materials Protection,2021,54(7):112-116,121. doi: 10.16577/j.cnki.42-1215/tb.2021.07.020

|

| [68] |

王志军. 激光钎焊金刚石颗粒界面结合特征及磨损性能研究 [D]. 长沙: 长沙理工大学, 2020.WANG Zhijun. Research on interfacial bonding characteristics and wear properties of laser brazed diamond particles [D]. Changsha: Changsha University of Science & Technology, 2020.

|

| [69] |

姚鹏, 余旭东, 钟素娟, 等. 细粒度金刚石/45钢基体的激光钎焊工艺研究 [J]. 超硬材料工程,2020,32(5):13-17. doi: 10.3969/j.issn.1673-1433.2020.05.004YAO Peng, YU Xudong, ZHONG Sujuan, et al. Study on brazing fine-grained diamonds onto 45 steel by laser heating [J]. Superhard Material Engineering,2020,32(5):13-17. doi: 10.3969/j.issn.1673-1433.2020.05.004

|

| [70] |

张俊涛, 黄淼俊, 胡子健, 等. 选区激光熔化制备金刚石/TC4复合材料的成型工艺及性能分析 [J]. 机电信息,2021(15):46-49. doi: 10.3969/j.issn.1671-0797.2021.15.019ZHANG Juntao, HUANG Miaojun, HU Zijian, et al. Forming process and performance analysis of diamond/TC4 composite materials prepared by selective laser melting [J]. Mechanical and Electrical Information,2021(15):46-49. doi: 10.3969/j.issn.1671-0797.2021.15.019

|

| [71] |

张绍和, 苏舟, 刘磊磊, 等. SLS和FDMS制造超薄金刚石锯片对比研究 [J]. 金刚石与磨料磨具工程,2021,41(1):38-43. doi: 10.13394/j.cnki.jgszz.2021.1.0007ZHANG Shaohe, SU Zhou, LIU Leilei, et al. Comparative study on ultra-thin diamond saw blades made by SLS and FDMS [J]. Diamond & Abrasives Engineering,2021,41(1):38-43. doi: 10.13394/j.cnki.jgszz.2021.1.0007

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS