Research on cutting burrs in high speed milling of aluminum alloy plane with diamond coated tools

-

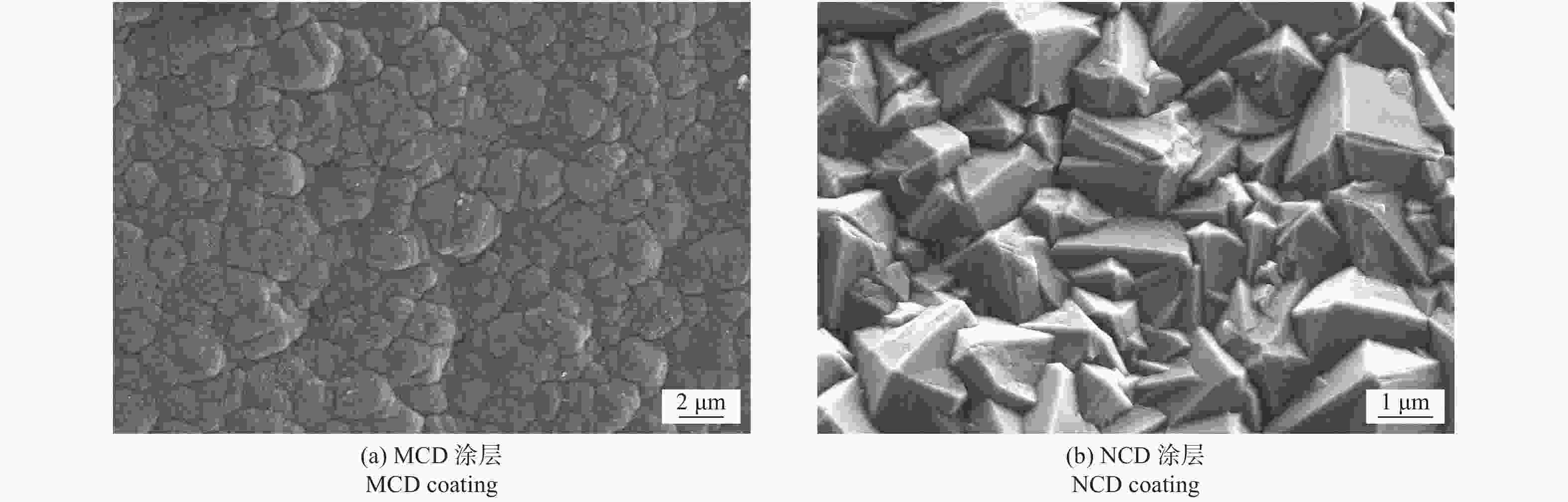

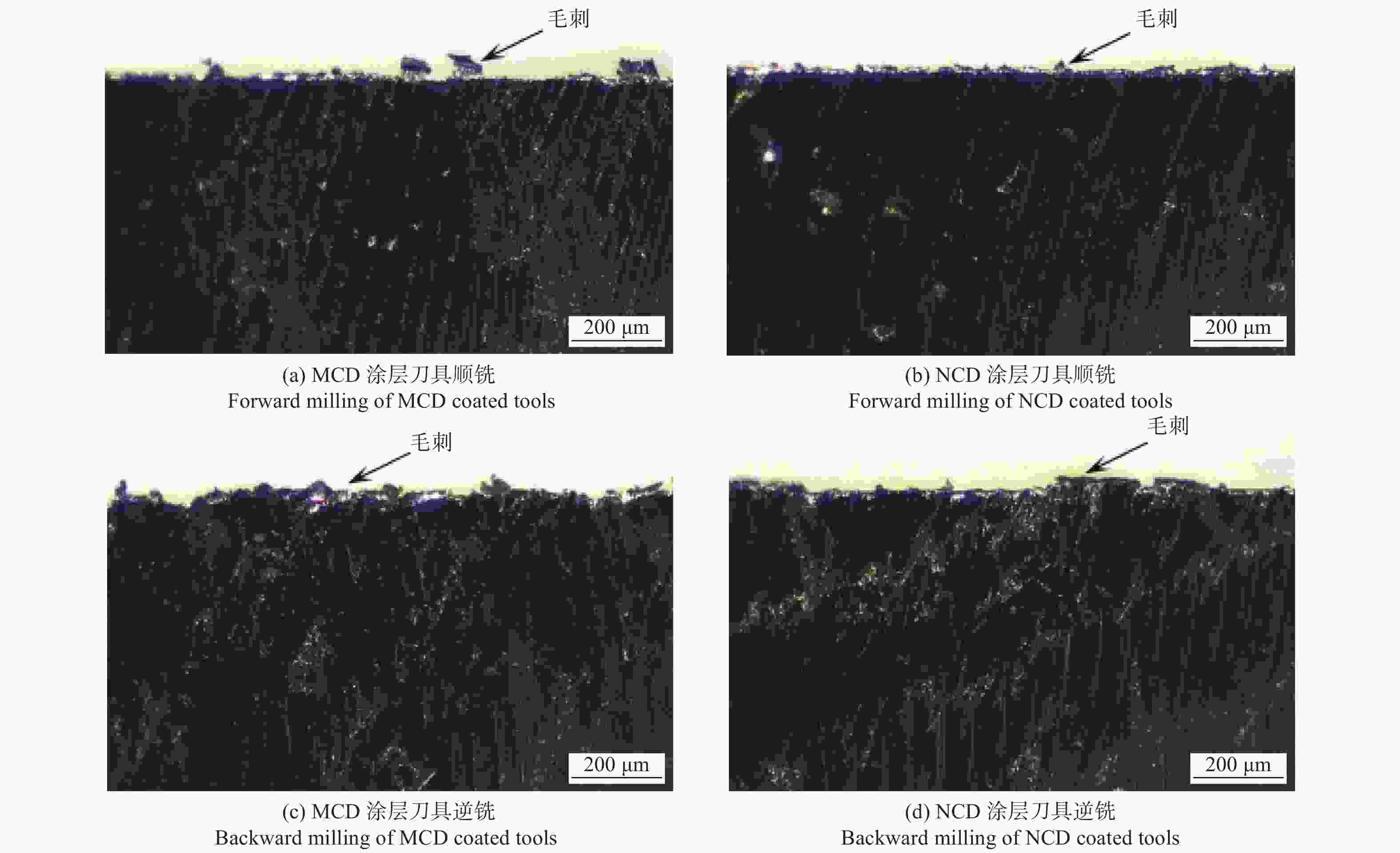

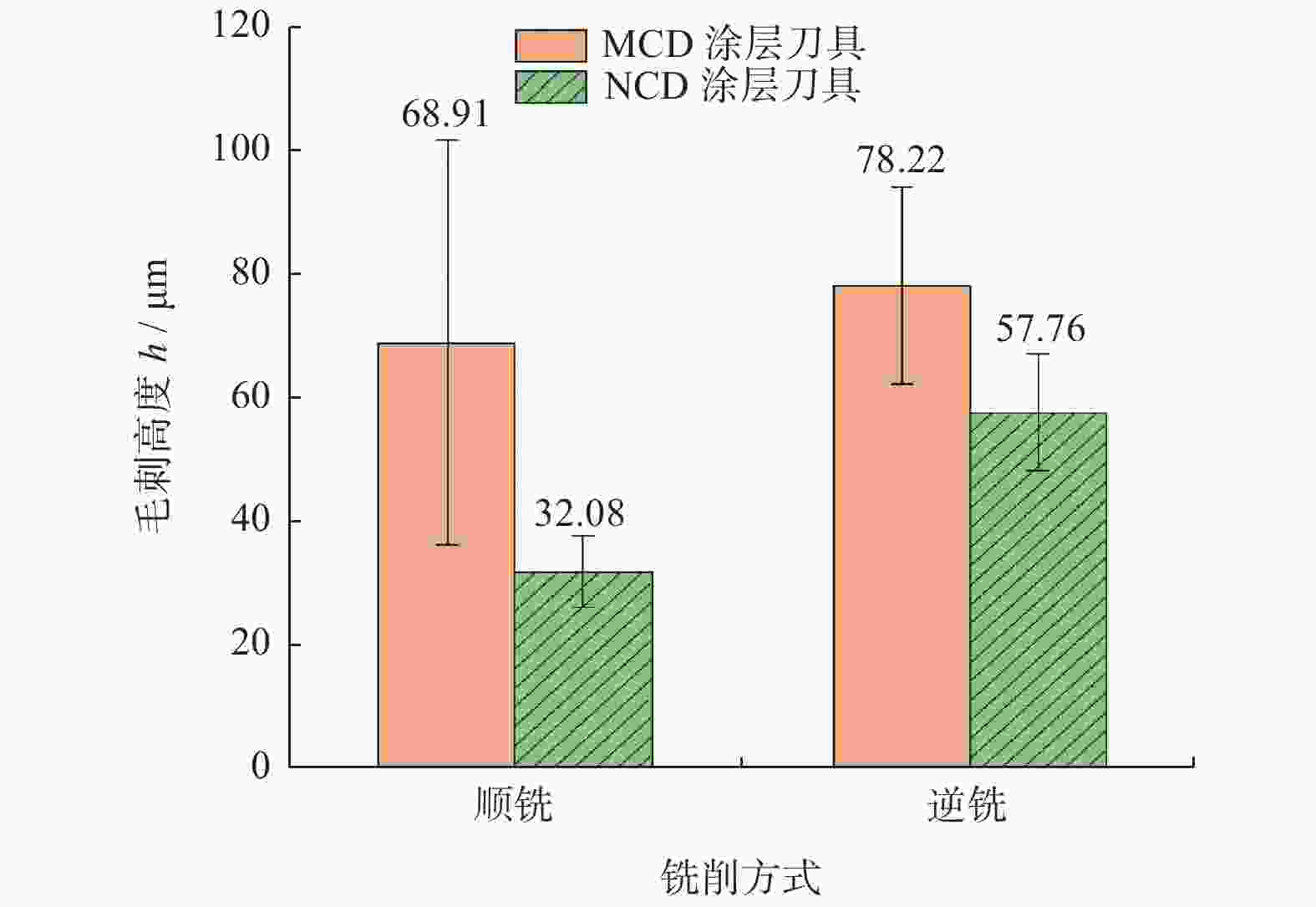

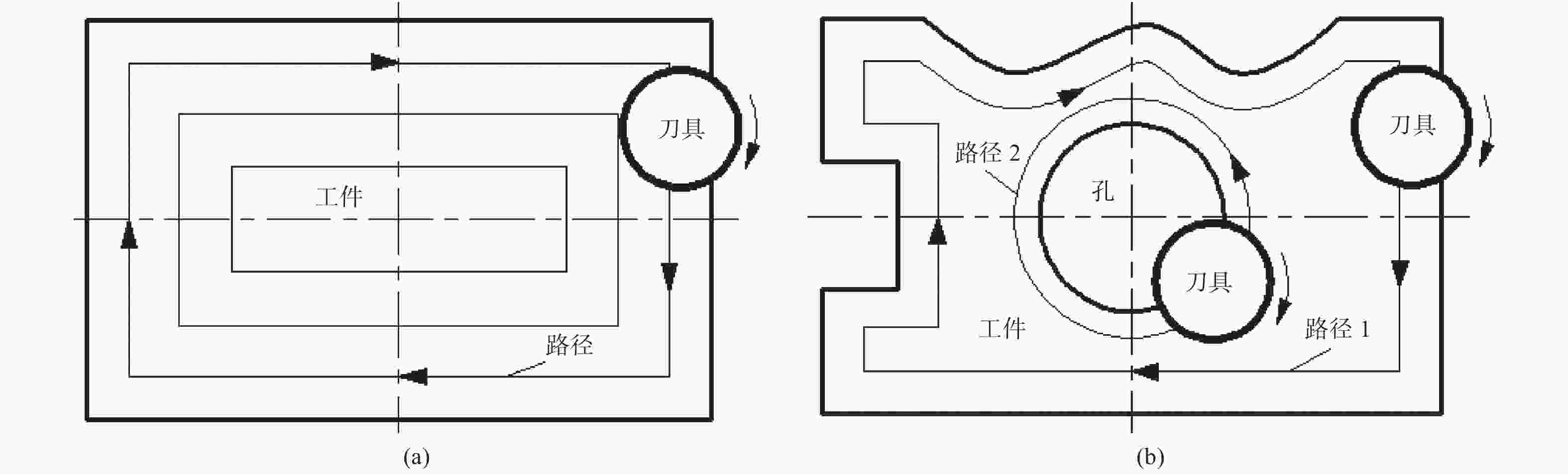

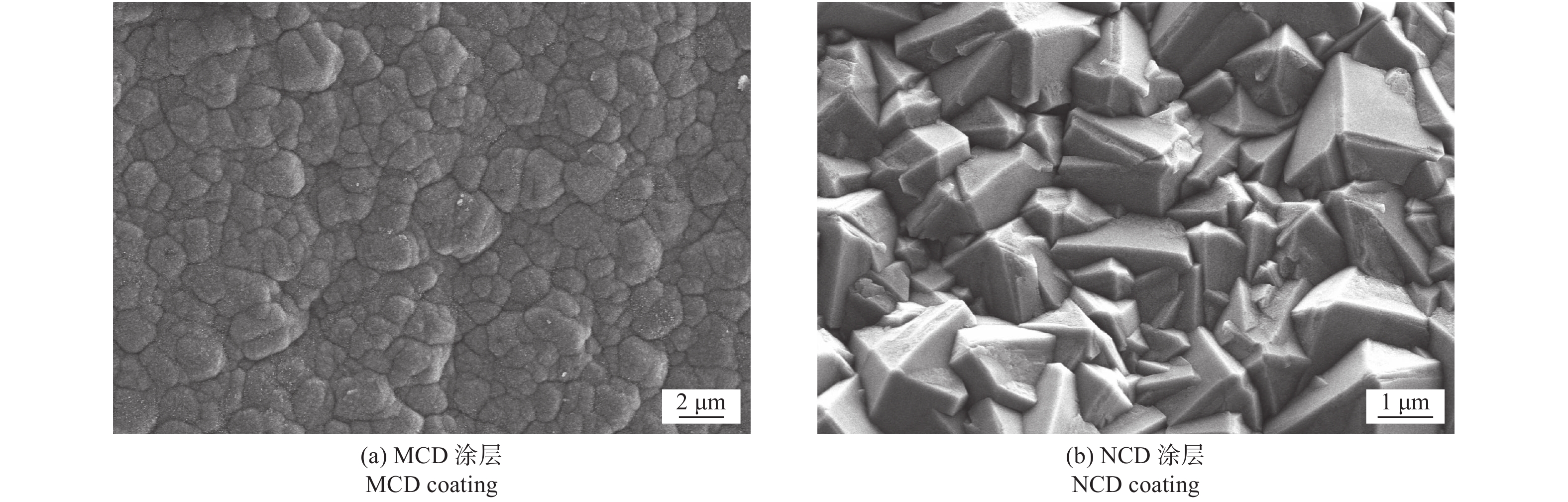

摘要: 采用热丝 CVD 法制备纳米与微米金刚石薄膜涂层刀具,利用场发射扫描电镜表征其薄膜表面形貌。用已制备的 CVD 金刚石涂层刀具,在无润滑干切条件下高速顺、逆端铣铝合金平面,研究CVD金刚石涂层刀具切削时的棱边毛刺特点与大小;并对纳米金刚石涂层刀具高速顺铣切削工艺参数进行正交试验,探究取得少无切削毛刺的切削参数与切削工艺。结果表明:工件铣削后棱边毛刺分布不均匀,顺铣毛刺稀疏,尺寸较小,其中纳米金刚石涂层刀具顺铣棱边毛刺高度平均值为32.08 μm,仅为微米金刚石涂层刀具顺铣毛刺高度的46.5%。纳米金刚石涂层刀具高速顺铣平面,对棱边毛刺影响最大的是vc,其次为vf,ae的影响最小,最优参数组合为ae=4 mm、vf=2 000 mm/min、vc=400 m/min,铣削后毛刺高度平均值为21.29 μm。当金刚石涂层刀具端铣铝合金平面时,为取得较小的棱边毛刺,优选纳米金刚石涂层刀具,采用顺铣棱边的切削方式与切削工艺,以及相应的高速切削参数。Abstract: The nano and micro diamond film coated tools were prepared by the hot wire CVD method.The surface morphology of the film was characterized by field emission scanning electron microscopy. The prepared CVD diamond coated tools were used to end mill the aluminum alloy surface forward and backward at high speed under the condition of dry cutting without lubrication. It studies the characteristics and size of edge burrs during high-speed end milling of aluminum alloy using CVD diamond coated tools. It carries out orthogonal tests on cutting process parameters to explore the cutting parameters and processes with little or no cutting burr when nano-diamonds coated tools are used for high-speed forward milling. The results show that the distribution of burrs on the edges of the workpiece is uneven after milling, and the burrs during forward milling are sparse and small in size. Among them, the average height of burrs on the edges during forward milling with nano diamond coated tools is 32.08 μm, only 46.5% of the forward milling burr height of micrometer diamond coated tools. When nano diamond coated tools are used for high-speed forward milling of flat surfaces, vc has the greatest impact on edge burrs, followed by vf, and ae has the weakest impact. The optimal parameter combination for high-speed milling is ae=4 mm, vf=2 000 mm/min, and vc=400 m/min. The average burr height after milling is 21.29 μm. When the diamond coated tool is used to end mill the aluminum alloy plane, in order to obtain a small burr, the nano diamonds coated tool is selected, the cutting method of forward milling and the corresponding high-speed cutting parameters are adopted.

-

Key words:

- diamond coated tools /

- end milling /

- edge burrs /

- cutting parameters /

- process path

-

表 1 切削毛刺正交实验因素水平表

Table 1. orthogonal experimental factors for cutting burrs

水平 因素 径向切削深度

ae/ mm

A进给速度

vf / (mm·min−1)

B切削速度

vc / (m·min−1)

C1 3 1 000 300 2 4 2 000 400 3 5 3 000 500 表 2 切削毛刺正交实验组合及结果

Table 2. Orthogonal test combination and results for cutting burrs

试验

编号参数组合 毛刺高度h / μm 毛刺平均高

度$\overline h $ / μm1 A1B1C1 104.82,84.83,48.88,80.75,97.82 83.42 2 A1B2C2 24.48,19.63,18.72,23.24,24.23 22.06 3 A1B3C3 31.71,95.31,112.04,99.39,90.55 85.80 4 A2B1C2 34.57,54.07,24.44,44.12,46.43 34.57 5 A2B2C3 29.33,24.59,26.84,34.71,28.88 28.87 6 A2B3C1 46.67,70.63,60.61,50.08,65.26 58.65 7 A3B1C3 36.72,53.08,151.54,46.54,72.32 72.04 8 A3B2C1 49.23,88.61,53.71,73.37,65.13 66.01 9 A3B3C2 48.48,65.55,60.37,51.41,61.08 57.38 表 3 各切削参数影响的毛刺高度均值以及极差R值

Table 3. The average and range R values of burr height affected by various cutting parameters

项目 取值 径向切削深度

ae / mm

A供给速度

vf / (mm·min−1)

B铣削速度

vc / (m·min−1)

C均值t1 63.76 63.34 69.36 均值t2 40.70 38.98 38.00 均值t3 65.14 67.28 62.24 极差R 24.44 28.30 31.36 -

[1] 秦艳利, 孙博慧, 张昊, 等. 选区激光熔化铝合金及其复合材料在航空航天领域的研究进展 [J]. 中国激光,2021,48(14):15-31.QIN Yanli, SUN Bohui, ZHANG Hao, et al. Development of selective laser melted aluminum alloys and aluminum matrix composites in the aerospace field [J]. Chinese Journal of Lasers,2021,48(14):15-31 [2] 陆家朋. 金属切削加工中边缘毛刺形成机理及尺寸预报理论研究[D]. 长沙: 湖南大学, 2016.LU Jiapeng. Study on the burr formation Mechanism and sizes prediction theory in Cutting metal materials[D]. Changsha: Hunan University, 2016. [3] 高可, 金成哲, 杨梓荆. 微细铣削7075铝合金的毛刺研究 [J]. 工具技术,2022,56(11):103-1077.GAO Ke, JIN Chengzhe, YANG Zijing. Research on micro milling Burr of 7075 aluminum alloy [J]. Tool Engineering,2022,56(11):103-107. [4] 张文杰, 王明娣, 潘煜, 等. 6系列铝合金零件激光去毛刺工艺实验研究 [J]. 应用激光,2019,39(4):647-651.ZHANG Wenjie, WANG Mingdi, PAN Yu, et al. Experimental research on laser deburring process for 6 series aluminum alloy parts [J]. Applied Laser,2019,39(4):647-651. [5] 陈耀峰, 李康, 明伟伟, 等. 发动机缸盖铣削毛刺形成及控制技术研究 [J]. 机械设计与制造,2021,365(7):163-165,170.CHEN Yaofeng, LI Kang, MING Weiwei, et al. Research on formation and control technology of burrs of engine cylinder head milling [J]. Machinery Design & Manufacture,2021,365(7):163-165,170. [6] XU L, HUANG C, SU R, et al. Estimation of tool life and cutting burr in high speed milling of the compacted graphite iron by DE based adaptive neuro-fuzzy inference system [J]. Mechanical Sciences,2019,10(1):243-254. [7] HASHIMURA M, CHANG Y P, DOMNFELD D. Analysis of burr formation mechanism in orthogonal cutting [J]. Journal of Manufacturing Science and Engineering,1999,121(1):1-7. doi: 10.1115/1.2830569 [8] 王贵成. 金属切削毛刺分类体系的研究及其应用 [J]. 中国机械工程,1995,(6):40-42.WANG Guicheng. Research and application of the classification system for metal cutting burrs [J]. China Mechanical Engineering,1995,(6):40-42. [9] NIKNAM S A, SONGMENE V. Analysis of friction and burr formation in slot milling[J]. Procedia Cirp, 2014. [10] 罗蒙, 刘钢, 陈明. 铝合金槽铣中毛刺形成机理与控制方法 [J]. 上海交通大学学报,2007,41(12):1905-1909.LUO Meng, LIU Gang, CHEN Ming. Mechanism of burr formation and control methods in slot milling aluminum alloy [J]. Journal of Shanghai Jiao Tong University,2007,41(12):1905-1909. [11] 雷学林. 微细刀具表面金刚石涂层的制备及其应用基础研究[D]. 上海: 上海交通大学, 2015.LEI Xuelin. Study on the fabrication and application of diamond films on micro cutting tools[D]. Shanghai: Shanghai Jiaotong University, 2015. [12] 邵伟平, 张韬. 纳米金刚石涂层刀具高速铣削7075铝合金的工艺参数优化 [J]. 金刚石与磨料磨具工程,2022,42(4):473-480.SHAO Weiping, ZHANG Tao. Process parameters optimization of high-speed milling 7075 aluminum alloy with nano-diamond coated tool [J]. Diamond and Abrasives Engineering,2022,42(4):473-480. [13] 张韬, 薛喆, 万方, 等. 微米及纳米WC-Co基BDD污水处理电极的制备研究 [J]. 人工晶体学报,2023,52(2):354-362.ZHANG Tao, XUE Zhe, WAN Fang, et al. Preparation of micro- and nano-WC-Co/BDD electrodes for wastewater treatment [J]. Journal of Synthetic Crystals,2023,52(2):354-362. [14] WANG B, LIU Z Q, SU G S, et al. Investigations of critical cutting speed and ductile-to-brittle transition mechanism for workpiece material in ultra-high speed machining [J]. International Journal of Mechanical Sciences,2015(104):44-59. doi: 10.1016/j.ijmecsci.2015.10.004 [15] WANG B, LIU Z Q. Evaluation on fracture locus of serrated chip generation with stress triaxiality in high speed machining of Ti6A14V [J]. Materials and Design,2016,(98):68-78. doi: 10.1016/j.matdes.2016.03.012 [16] RAMASUBRAMANIAN K, ARUNACHALAMN N, RAMACHANDRA R M S. Wear performance of nano-engineered boron doped graded layer CVD diamond coated cutting tool for machining of Al-SiC MMC[J]. Wear, 2018(426/427): 1536-1547. [17] KREMER A, DEVILLEZ A, Dominiak S, et al. Machinability of Al/SiC particulate metal-matrix Composites under dry conditions with CVD diamond-coated carbide tools [J]. Machining Science and Technology,2008,12(2):214-233. doi: 10.1080/10910340802067494 [18] 邓福铭, 朱灏, 王双, 等. 不同结构金刚石涂层刀具的制备及性能参数优化[J]. 人工晶体学报, 2018, 47(7): 1353-1358, 1365.DENG Fuming, ZHU Hao, WANG Shuang, et al. Preparation and properties parameter optimization of different structural diamond coated tools[J]. Journal of Synthetic Crystals, 2018, 47 (7): 1353-1358, 1365. [19] 王宜豹, 黄楠, 刘鲁生, 等. 加工7075航空铝合金用金刚石涂层刀具的制备及其切削性能 [J]. 材料研究学报,2019,33(1):15-26.WANG Yibao, HUANG Nan, LIU Lusheng, et al. Preparation and cutting performance of diamond coated hard alloy cutting tools for 7075 aviation al-alloy [J]. Chinese Journal of Materials Research,2019,33(1):15-26. [20] ZHANG Y, KANG R, DONG Z, et al. Effect of dislocation density distribution in work-hardened layer on cutting characteristics in the multi-cutting of 49Fe49Co2V alloy[J]. Journal of Manufacturing Processes, 2023(85): 1187-1196. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS