CFD simulation and experiments of abrasive water jet polishing for micropores

-

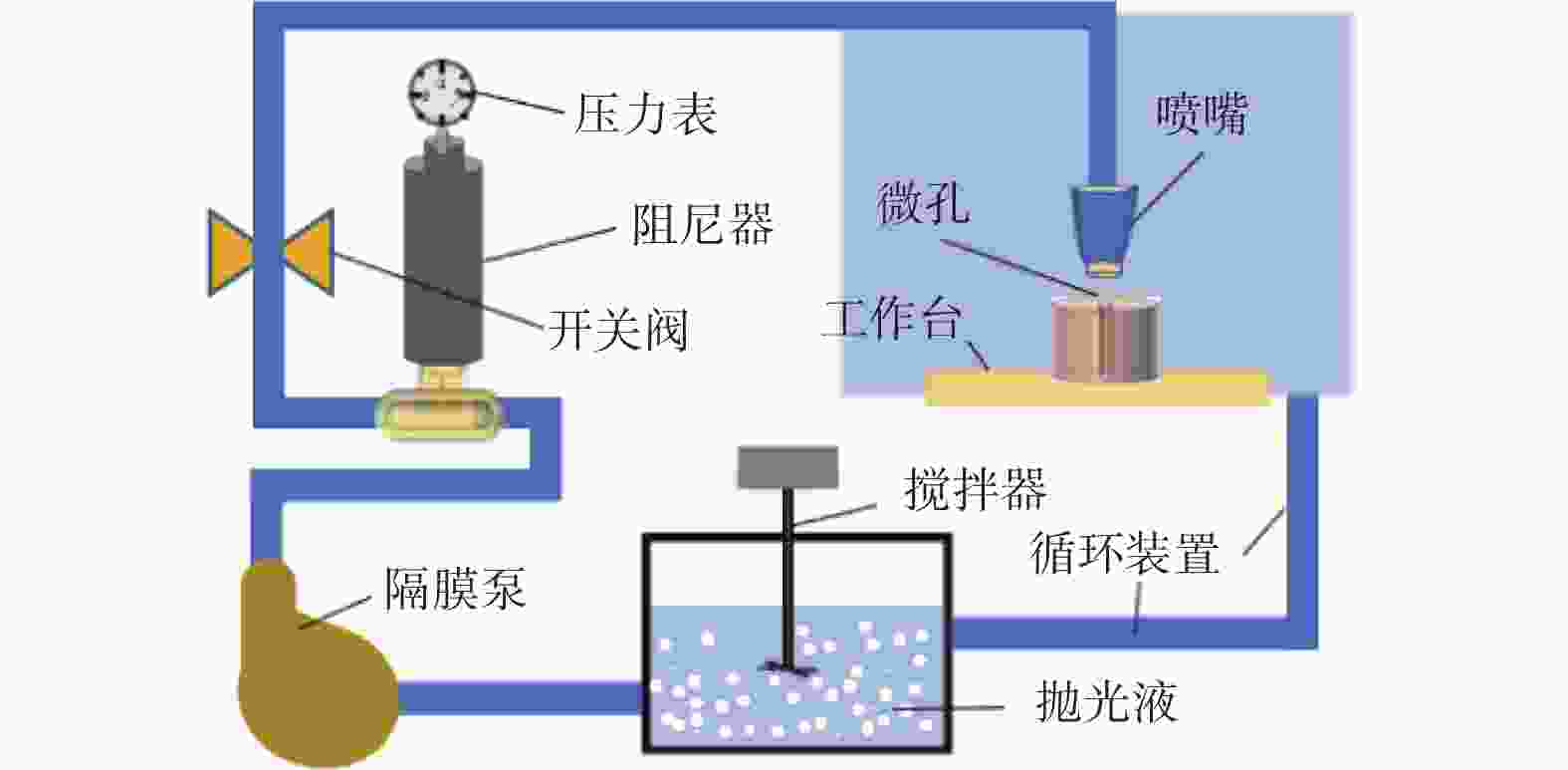

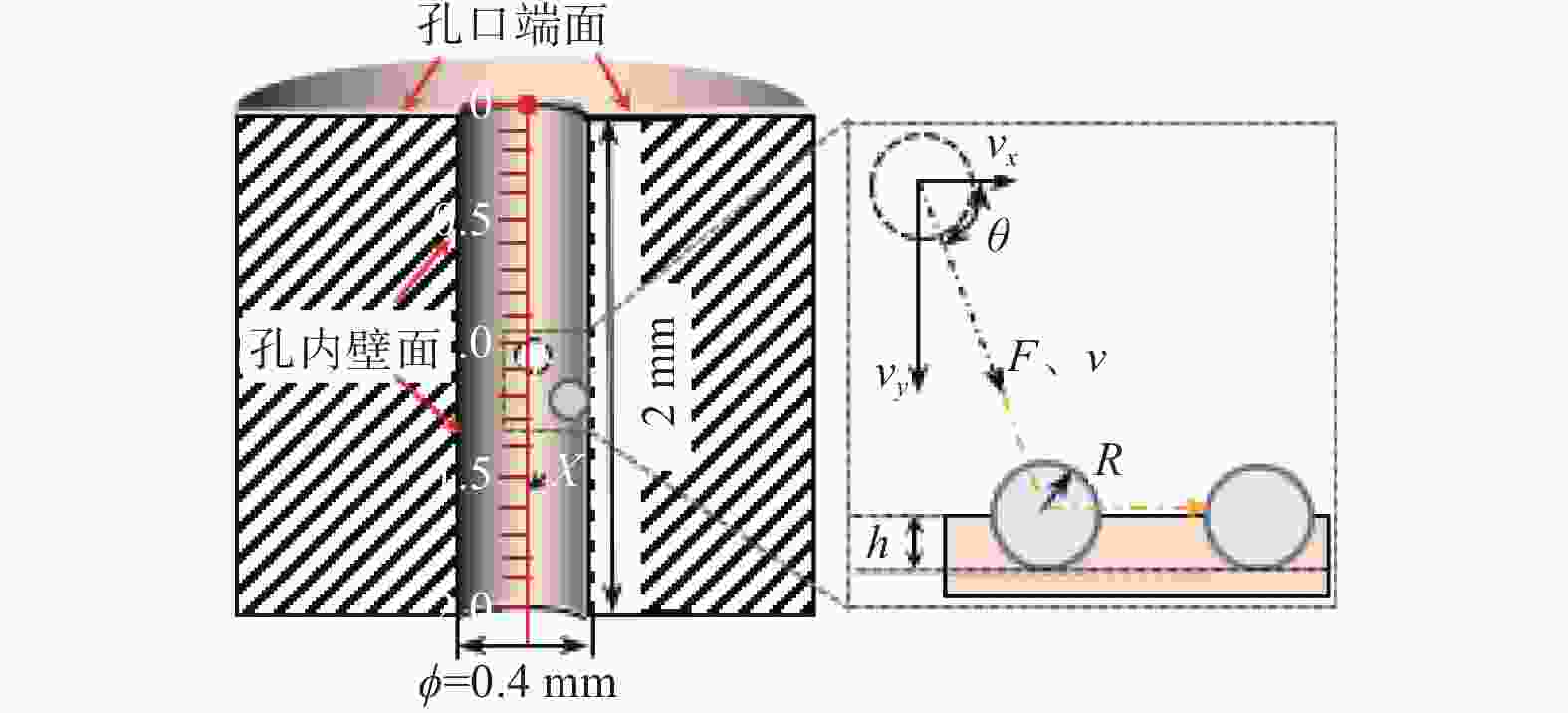

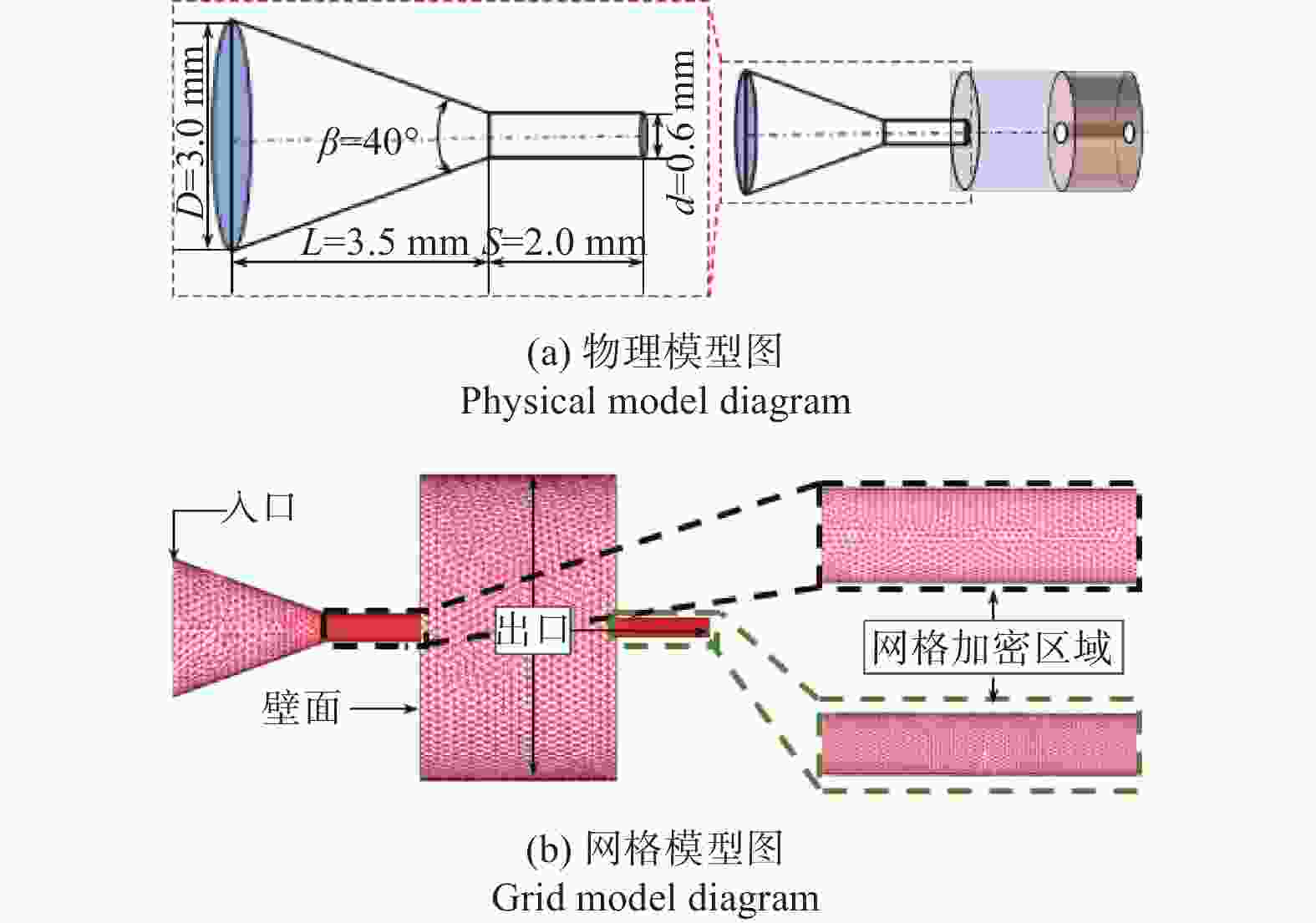

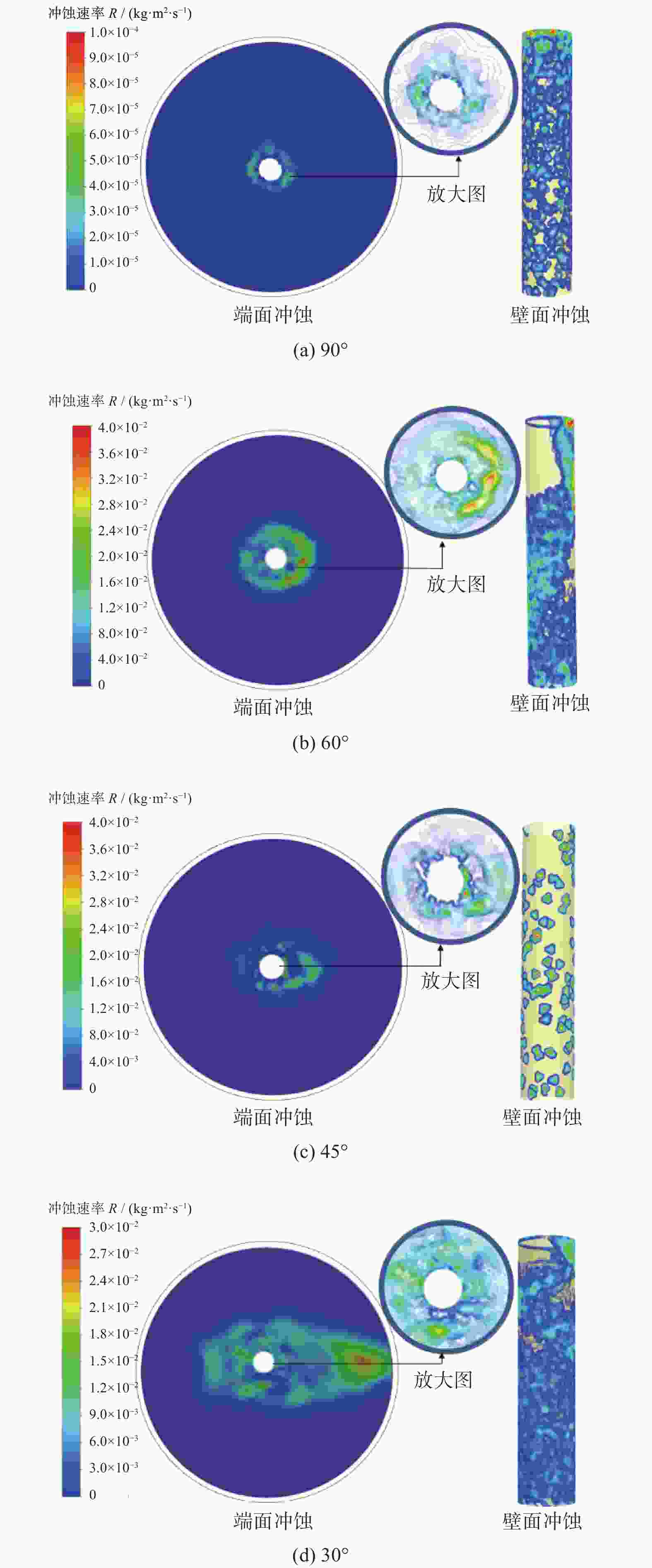

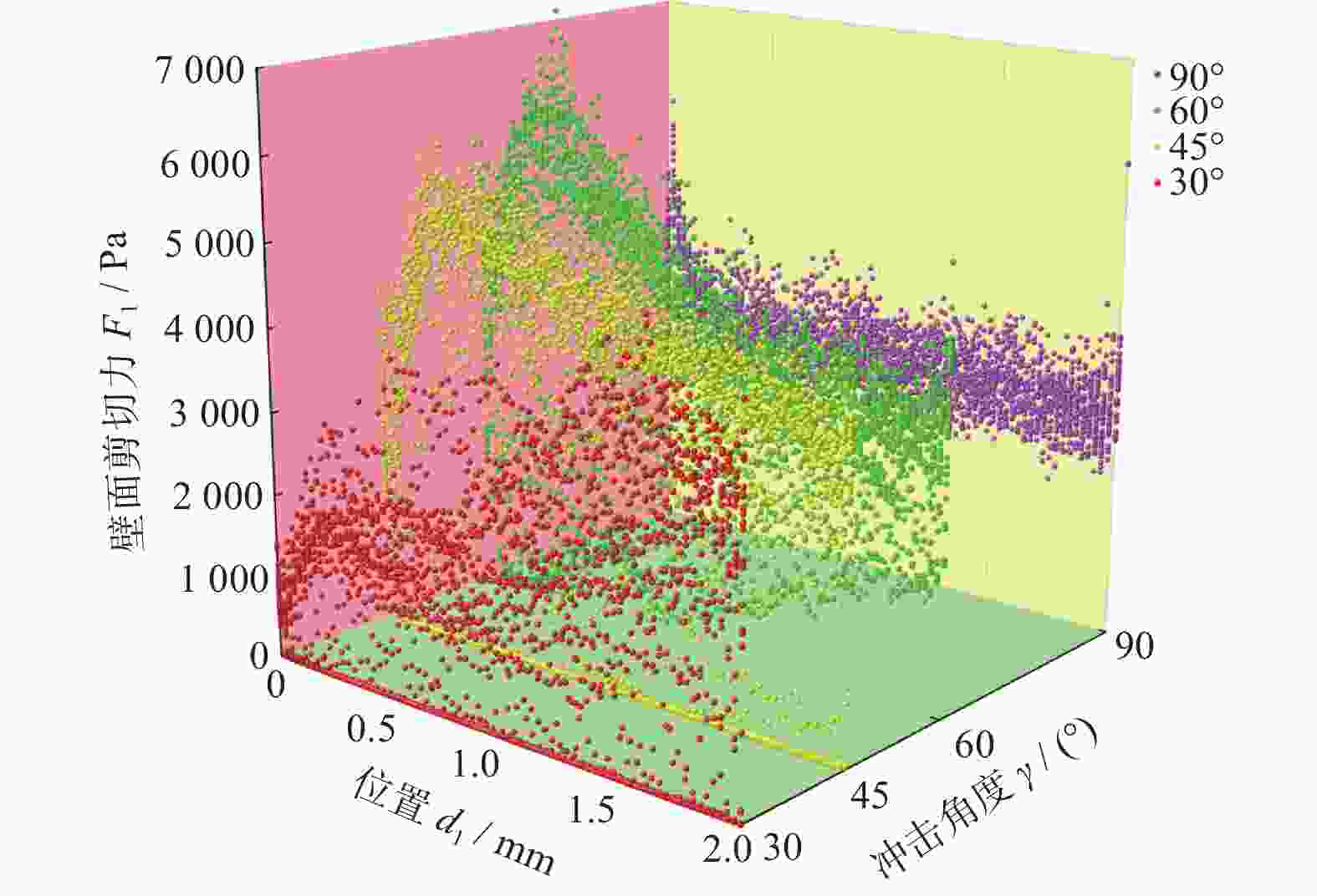

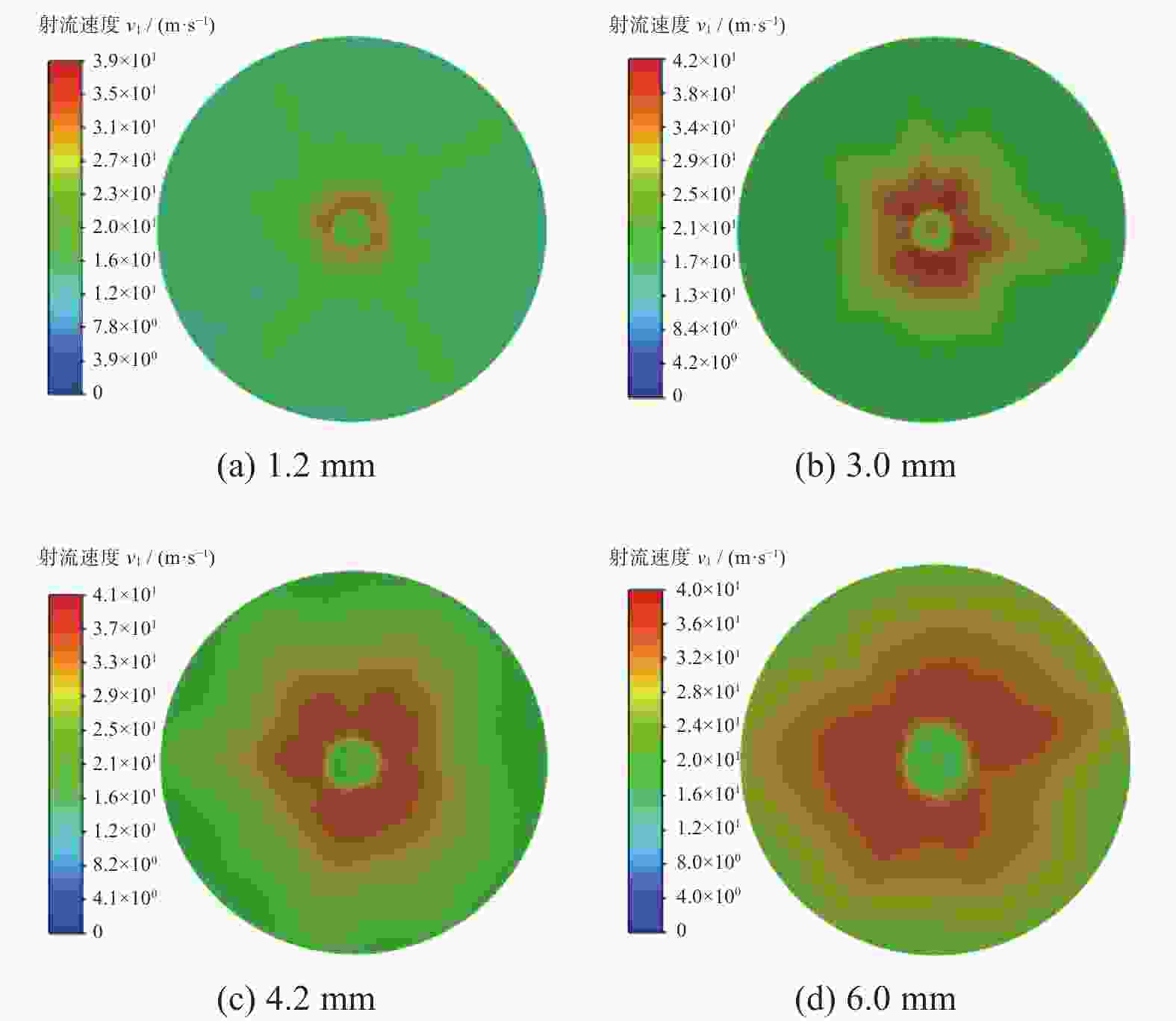

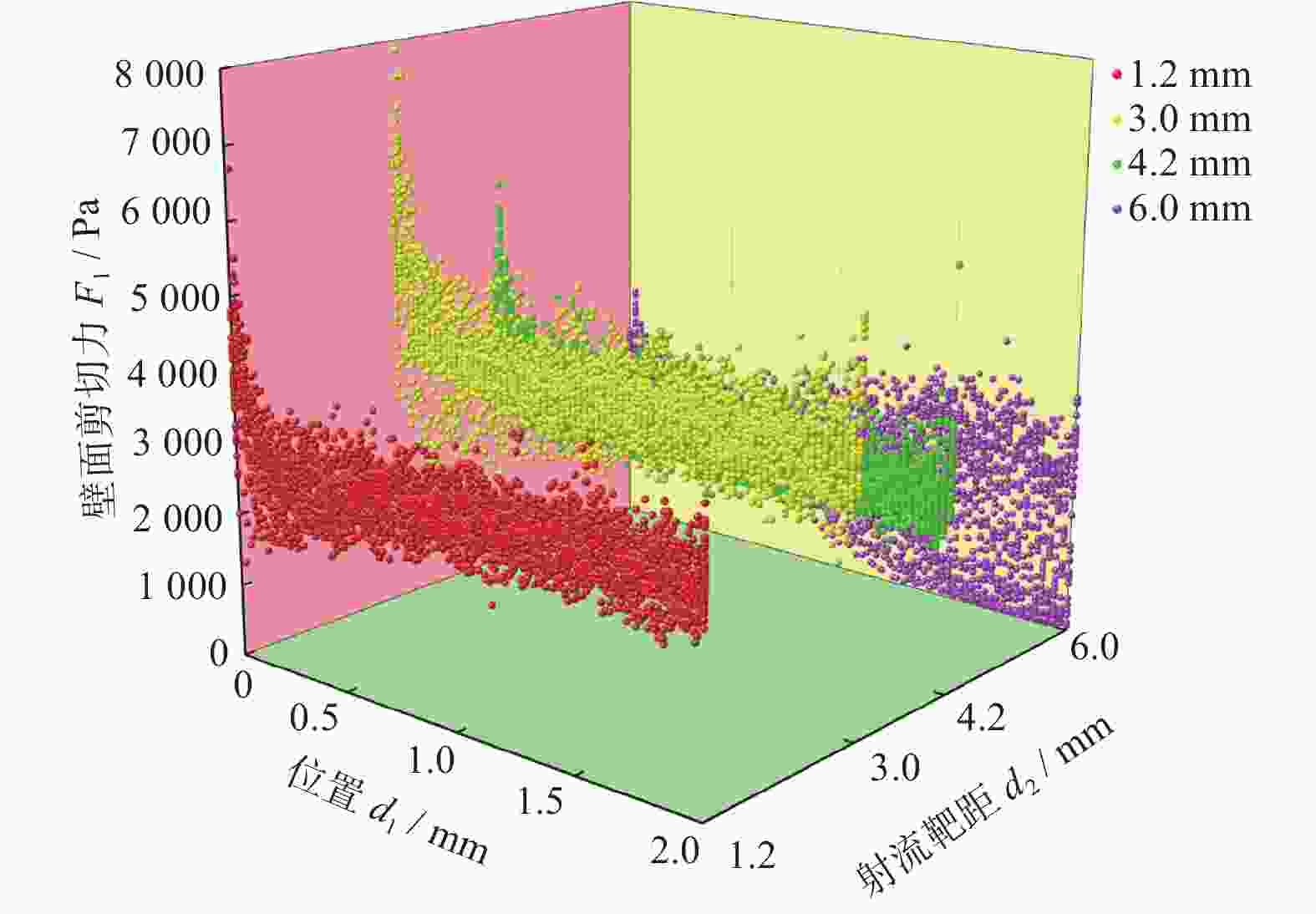

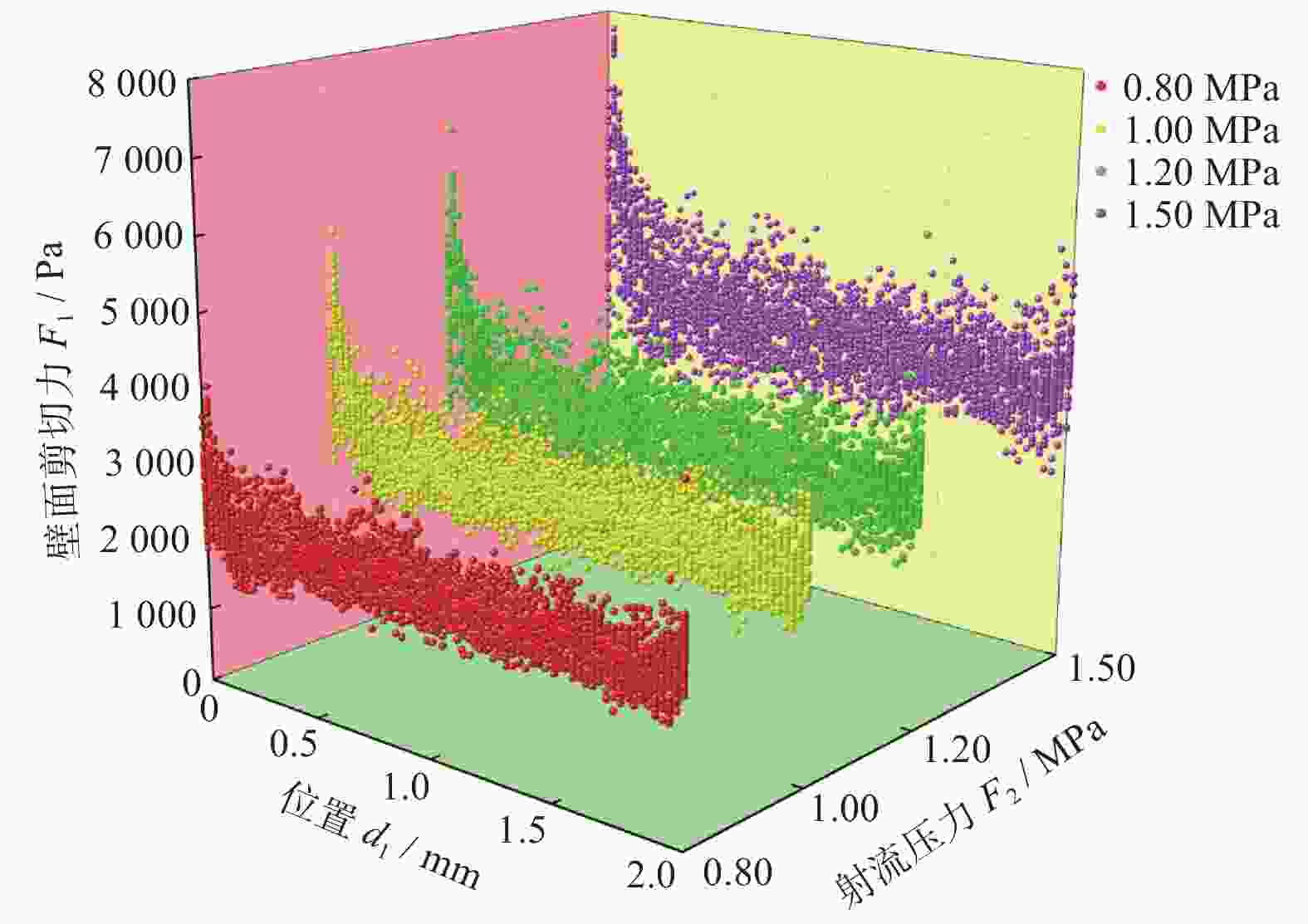

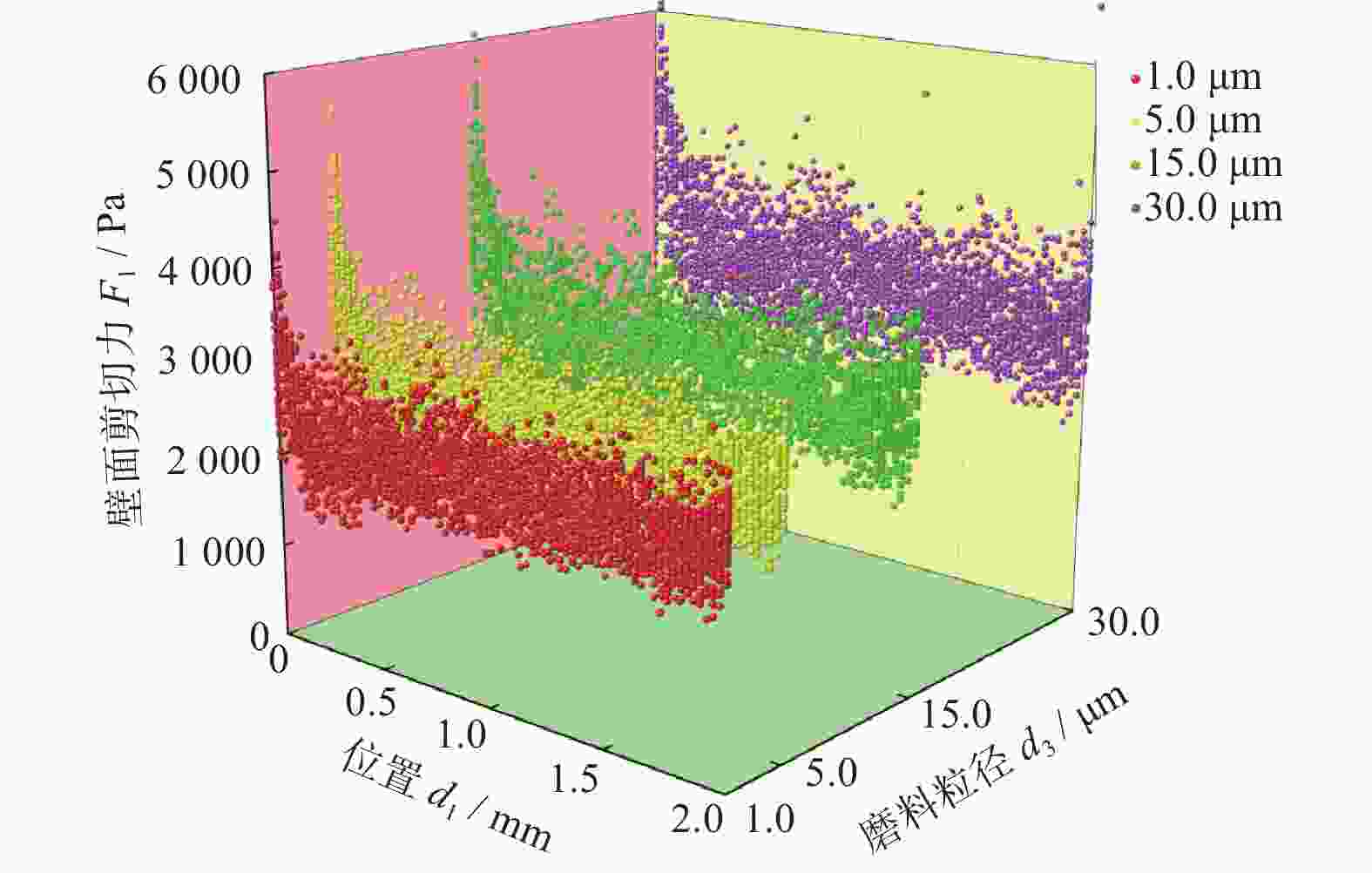

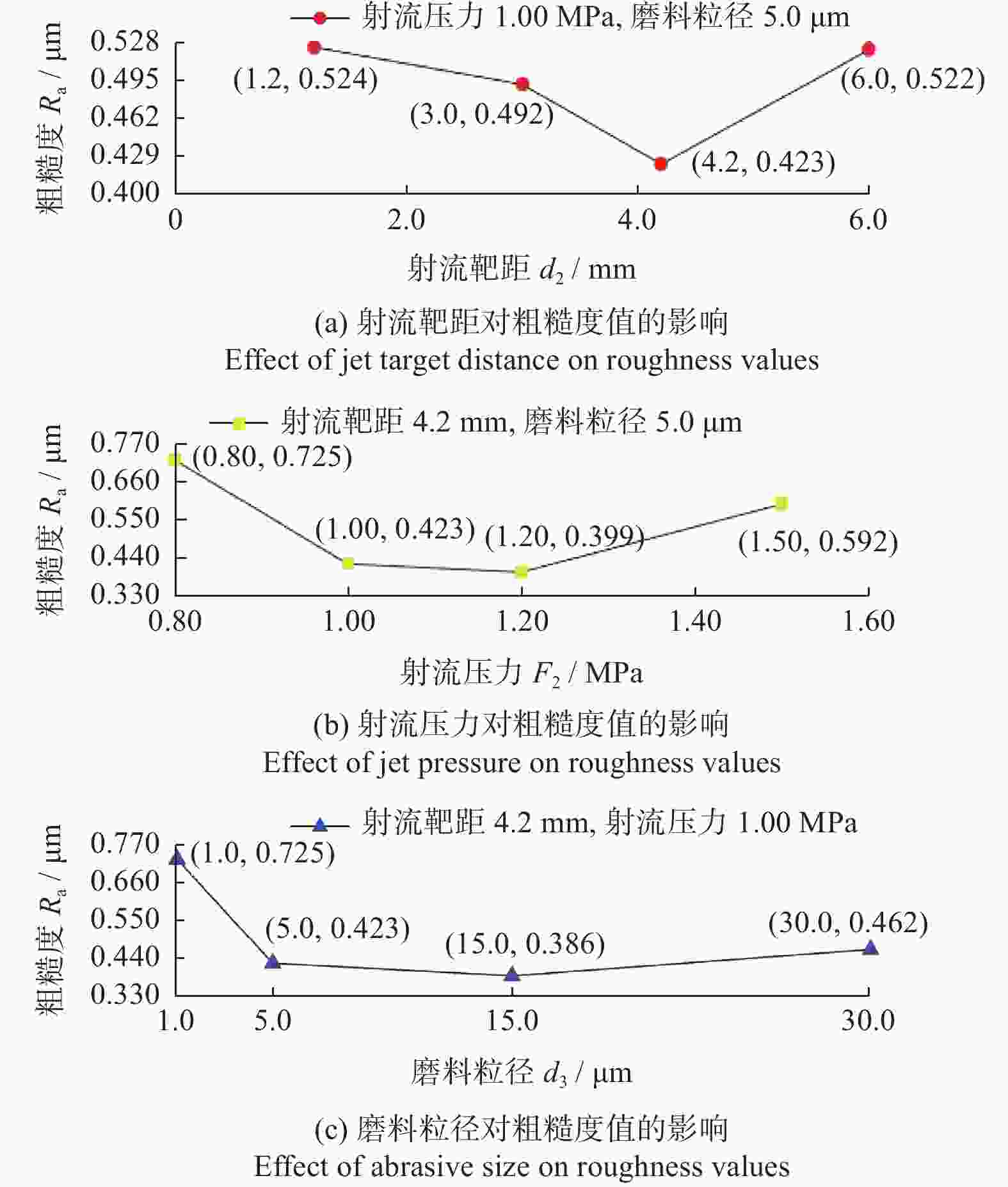

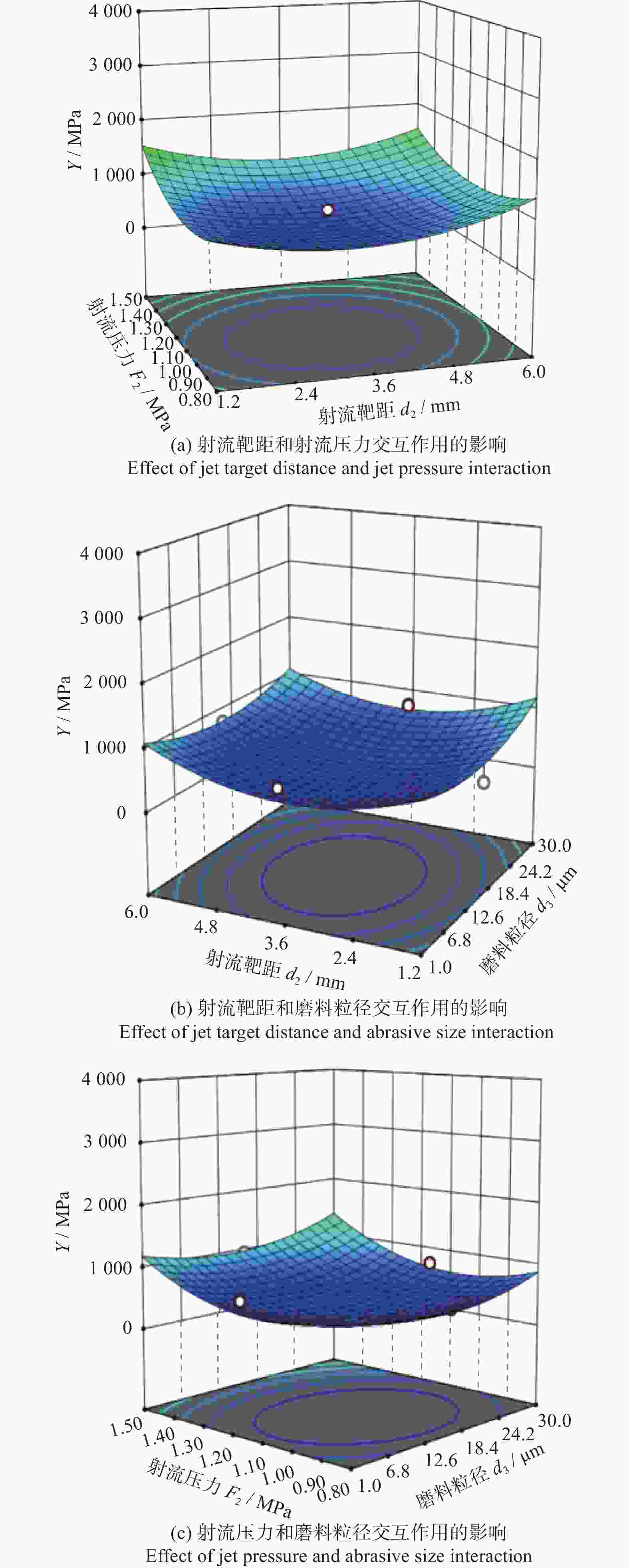

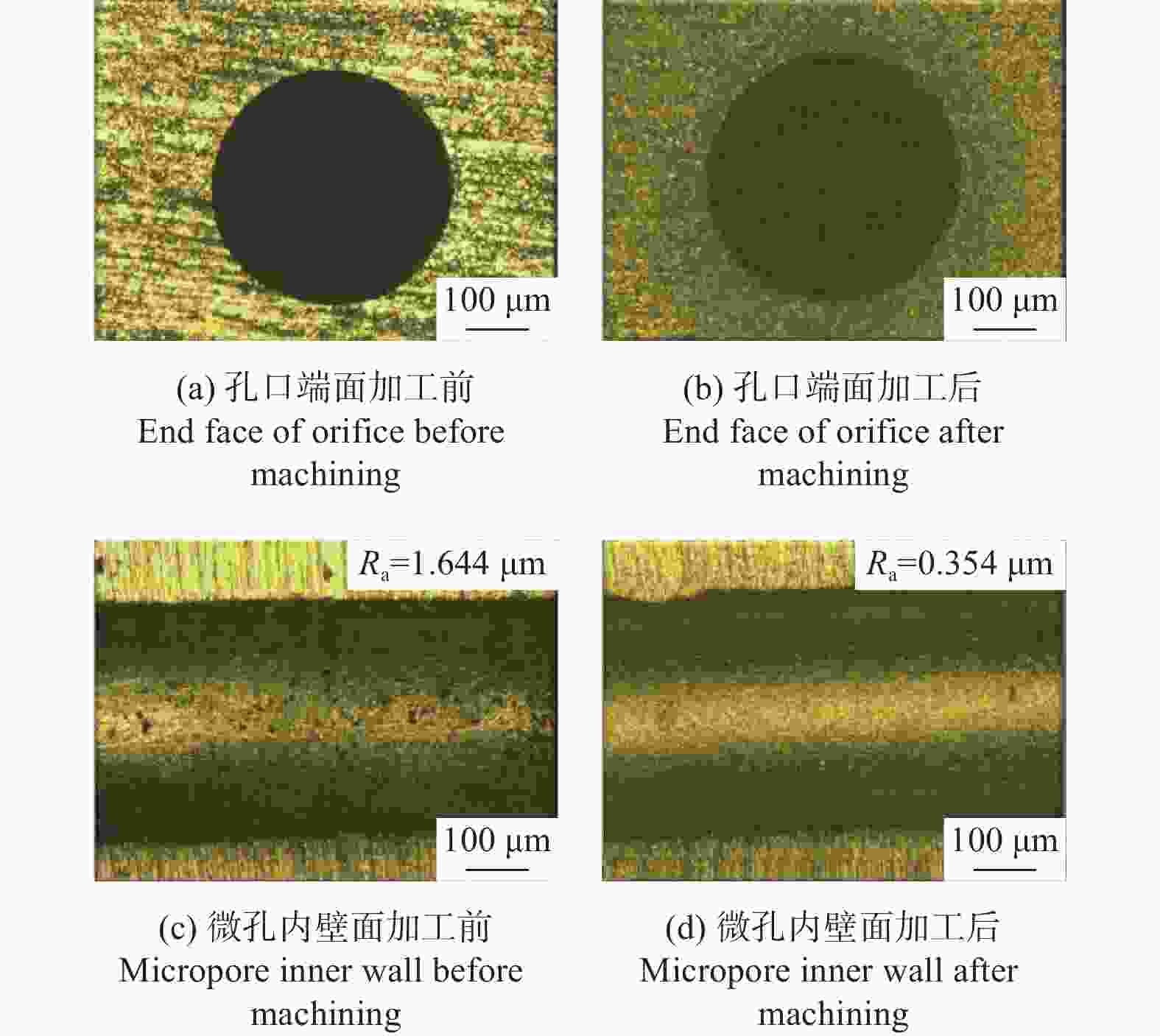

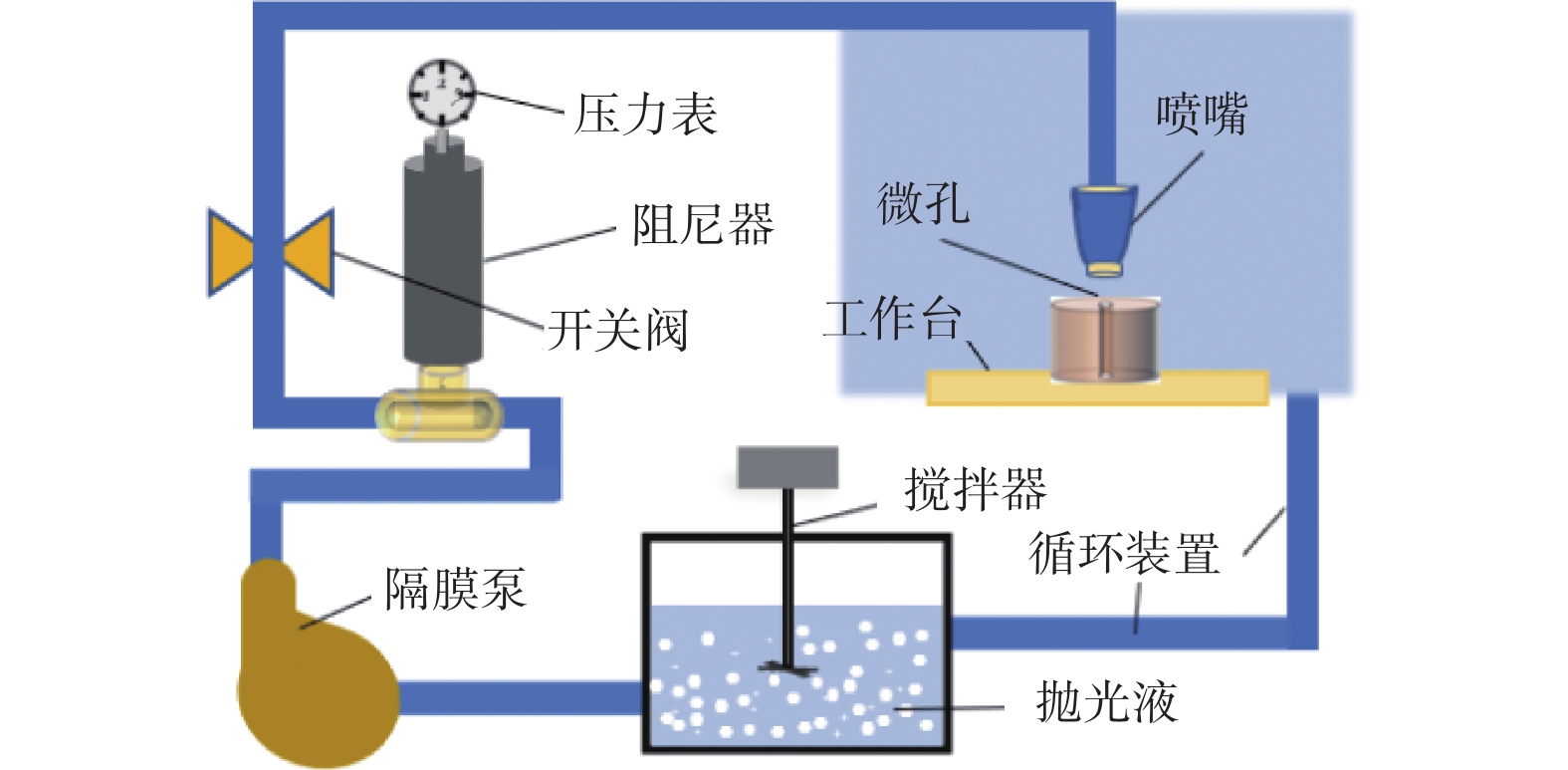

摘要: 为解决飞秒激光微孔难以抛光的问题,结合磨料水射流去除函数稳定、自适应性强等特点,采用磨料水射流抛光方法提高飞秒激光微孔质量。利用Fluent软件对不同工艺参数下的磨料水射流微孔抛光过程进行计算流体力学(computational fluid dynamics,CFD)模拟,分析不同参数下的流场分布、侵蚀速率及壁面剪切力作用规律;然后通过响应面法对射流靶距、射流压力及磨料粒径等3因素进行优化试验,以微孔内壁面剪切力均方差为响应值,建立其响应面方程,获得最佳抛光参数组合并进行试验验证。结果表明:射流压力对微孔内壁面剪切力的影响最大,当射流压力从0.80 MPa增至1.50 MPa时,微孔内壁面剪切力增大2倍以上。射流的不同结构段因性质不同可适用于不同工况。利用响应面法分析得到水射流微孔抛光的最佳工艺参数组合是:射流冲击角,90°;射流靶距,3.5 mm;射流压力,1.10 MPa;磨料粒径,15.0 μm。在该条件下抛光微孔内壁面的表面粗糙度Ra降至0.354 µm。磨料水射流抛光可显著改善微孔壁面质量,且响应面法预测的数据模型有较高准确性。Abstract: Objectives: Femtosecond laser technology has become the primary method for micropore processing due to its high precision and low energy consumption. However, during the process, it is easy to cause microcracks and burrs in the micropores. Additionally, due to the small size, low structural stability and weak wear resistance of the micropores, conventional methods are ineffective in polishing them. To address the challenge of polishing femtosecond laser-processed micropores, the abrasive water jet polishing method is employed. This method leverages the stable removal function and strong adaptability of the abrasive water jet to improve the quality of femtosecond laser-processed micropores. Methods: Computational fluid dynamics (CFD) simulations of the abrasive water jet micropore polishing process under different process parameters were carried out by using Fluent software. A finite element model of abrasive water jet polishing for femtosecond laser-processed micropores was established under various working conditions. The flow field distribution, the erosion rate and the wall shear force under different parameters were analyzed. Corresponding experiments were conducted for each variable discussed in the Fluent simulation, and the variation patterns of micropore inner wall roughness were summarized. Subsequently, optimization experiments were conducted on the three factors, namely jet target distance, jet pressure and abrasive particle size, using the response surface method. The mean square error of shear force on the inner wall of the hole was taken as the response value Y, and the response surface equation was established. The optimal polishing parameter combination was obtained through the response surface equation and experimentally verified. Results: A jet impact angle of 90° is suitable for polishing the inner wall of the micropore, as wall erosion is uniform and the shear force distribution is concentrated at this angle. At a target distance of 4.2 to 6.0 mm, the jet on the end face enters the deceleration stage, and the jet velocity decreases as the target distance increases. The shear force increases with increasing jet pressure. When the jet pressure is 0.80 MPa, the shear force is the smallest, concentrated in the range of 1 500 to 3 500 Pa. At a jet pressure of 1.50 MPa, the shear force is the largest, concentrated in the range of 3 500 to 5 500 Pa. When jet pressure increases from 0.80 to 1.50 MPa, the shear force on the inner wall of the hole increases more than twice. The effects of abrasive particle size and jet pressure on wall shear force are similar. When the abrasive particle size is 1.0 μm, the shear force is the smallest, concentrated in the range of 1 000 to 2 500 Pa. At an abrasive particle size of 30.0 μm, the shear force reaches its maximum, concentrated between 3 000 and 5 500 Pa. Corresponding tests are carried out for each variable discussed in the simulation, and the minimum roughness Ra of the inner wall of the micropore was 0.386 μm. The optimal process parameter combination obtained through response surface analysis is as follows: jet impact angle of 90°, jet target distance of 3.5 mm, jet pressure of 1.10 MPa, and abrasive particle size of 15.0 μm. Under the optimal parameter combination, with an abrasive mass fraction of 5% and a polishing time of 5.0 minutes, the surface roughness Ra of the polished micropore inner wall surface was reduced to 0.354 µm, which is better than the minimum roughness of 0.386 µm observed in the simulation. Polishing efficiency is improved by about 3%, and the quality of the micropore inner wall surface is further enhanced. Conclusions: When the impact angle is constant, the shear force on the inner wall of the hole increases with increasing jet pressure and abrasive particle size. It increases first and then decreases with the increase in jet target distance, with jet pressure having the greatest influence on the wall shear force. Different structural segments of the jet can be applied to different working conditions due to different properties. Additionally, the simulation and experimental results are in good agreement, and the improvement in roughness is significant. This indicates that abrasive water jet polishing significantly enhances the quality of micropore walls, and the data model for response surface prediction has high accuracy.

-

表 1 试验设计的因子及水平

Table 1. Factors and levels of experimental design

水平 因素 射流靶距

d2 / mm

A射流压力

F2 / MPa

B磨料粒径

d3 / μm

C−1 1.2 0.80 1.0 0 3.6 1.15 15.5 1 6.0 1.50 30.0 -

[1] 成健, 孔维畅, 杨震, 等. 液体辅助激光微孔加工研究进展 [J]. 表面技术,2023,52(2):183-195.CHENG Jian, KONG Weichang, YANG Zhen, et al. Research progress of liquid-assisted laser micro-hole processing [J]. Surface Technology,2023,52(2):183-195. [2] 马国庆, 肖强. 飞秒激光微孔加工发展综述 [J]. 激光与红外,2020,50(6):651-657.MA Guoqing, XIAO Qiang. Research progress of femtosecond laser micropore processing [J]. Laser & Infrared,2020,50(6):651-657. [3] 庞继伟, 李升, 郭明波, 等. C/SiC复合材料微孔的电镀金刚石钻头钻削加工 [J]. 金刚石与磨料磨具工程,2023,43(1):90-95.PANG Jiwei, LI Sheng, Guo Mingbo, et al. Drilling of C/SiC composite micro holes with electroplated diamond bits [J]. Diamond & Abrasives Engineering,2023,43(1):90-95. [4] LI F, FENG G, YANG X, et al. Research on microhole processing technology based on the femtosecond-laser spiral trepanning method [J]. Applied Sciences,2020,10(21):7508. doi: 10.3390/app10217508 [5] 曹凤国, 黄建宇. 金刚石拉丝模激光微细加工技术 [J]. 电加工与模具,1995(2):2-4.CAO Fengguo, HUANG Jianyu. Diamond drawing die laser microfabrication technology [J]. Electromachining & Mould,1995(2):2-4. [6] 董敏, 路家斌, 潘继生, 等. 磁流变微结构动压平面抛光试验研究 [J]. 金刚石与磨料磨具工程,2018,38(1):82-88.DONG Min, LU Jiabin, PAN Jisheng, et al. Experimental study on magnetorheological dynamic plane polishing with microstructure polishing disk [J]. Diamond & Abrasives Engineering,2018,38(1):82-88. [7] YUNG K C, ZHANG S S, DUAN L, et al. Laser polishing of additive manufactured tool steel components using pulsed or continuous-wave lasers [J]. The International Journal of Advanced Manufacturing Technology,2019,105(1/2/3/4):425-440. doi: 10.1007/s00170-019-04205-z [8] 刘勇, 魏志远, 邓世辉, 等. 高质量玻璃微孔电化学放电加工模型及试验 [J]. 光学精密工程,2018,26(7):1653-1660. doi: 10.3788/OPE.20182607.1653LIU Yong, WEI Zhiyuan, DENG Shihui, et al. Electrochemical discharge maching of glass micro-holes with high-quality [J]. Optics and Precision Engineering,2018,26(7):1653-1660. doi: 10.3788/OPE.20182607.1653 [9] 李孟楠, 董志国, 郑志鑫, 等. 喷油嘴喷孔流道磨料流光整特性仿真与试验 [J]. 金刚石与磨料磨具工程,2023,43(2):265-271.LI Mengnan, DONG Zhiguo, ZHENG Zhixin, et al. Simulation and experiment of abrasive flow finishing characteristics of nozzle jetting hole runner [J]. Diamond & Abrasives Engineering,2023,43(2):265-271. [10] 朱慧宁, 马小刚, 程海东, 等. 磁针磁力研磨工艺对发动机涡轮叶片表面质量的试验研究 [J]. 航空制造技术,2021,64(18):62-68.ZHU Huining, MA Xiaogang, CHENG Haidong, et al. Experimental study on surface quality of engine turbine blade by magnetic needle magnetic abrasive technology [J]. Aeronautical Manufacturing Technology,2021,64(18):62-68. [11] 陈逢军, 唐宇, 苗想亮, 等. 磨料射流表面抛光研究综述 [J]. 表面技术,2015,44(11):119-127.CHEN Fengjun, TANG Yu, MIAO Xiangliang, et al. Review on the abrasive jet surface polishing technology [J]. Surface Technology,2015,44(11):119-127. [12] 王军, 王惠宇, 赵连松. 高压磨料水射流切割效率与表面粗糙度的试验研究 [J]. 制造技术与机床,2017(7):149-152, 156.WANG Jun, WANG Huiyu, ZHAO Liansong. Experimental study on efficiency and surface roughness of high-pressure abrasive-waterjet cutting [J]. Manufacturing Technology & Machine Tool,2017(7):149-152, 156. [13] 彭文强, 尹韶辉. 基于狭缝射流抛光的去除函数优化 [J]. 航空精密制造技术,2019,55(6):1-4.PENG Wenqiang, YIN Shaohui. Material removal optimization of jet polishing based on slit nozzle [J]. Aviation Precision Manufacturing Technology,2019,55(6):1-4. [14] 彭文强, 尹韶辉. 基于颗粒水射流的异型不锈钢元件确定性加工 [J]. 航空精密制造技术,2019,55(4):1-4, 9. doi: 10.3969/j.issn.1003-5451.2019.04.001PENG Wenqiang YIN Shaohui. Deterministic polishing of shaped stainless-steel workpiece based on particlewater jet polishing [J]. Aviation Precision Manufacturing Technology,2019,55(4):1-4, 9. doi: 10.3969/j.issn.1003-5451.2019.04.001 [15] 邓乾发, 汪杨笑, 袁巨龙, 等. 基于流体自激的磨料水射流加工仿真与实验 [J]. 中国机械工程,2022,33(3):279-289.DENG Qianfa, WANG Yangxiao, YUAN Julong, et al. Simulations and experiments on abrasive water jet machining based on fluid self-excitation [J]. China Mechanical Engineering,2022,33(3):279-289. [16] BALASUBRAMANIAM R, KRISHNAN J, RAMAKRISHNAN N. A study on the shape of the surface generated by abrasive jet machining [J]. Journal of Materials Processing Technology,2002,121(1):102-106. doi: 10.1016/S0924-0136(01)01209-2 [17] MATSUMURA T, MURAMATSU T, FUEKI S. Abrasive water jet machining of glass with stagnation effect [J]. CIRP Annals,2011,60(1):355-358. doi: 10.1016/j.cirp.2011.03.118 [18] KOWSARI K, NOURAEI H, JAMES D F, et al. Abrasive slurry Jet micro-machining of holes in brittle and ductile materials [J]. Journal of Materials Processing Technology,2014,214(9):1909-1920. doi: 10.1016/j.jmatprotec.2014.04.008 [19] 张文超, 武美萍, 宋磊. 磨料射流铣削工艺参数优化 [J]. 表面技术,2017,46(11):190-197.ZHANG Wenchao, WU Meiping, SONG Lei. Process parameters optimization for abrasive jet milling [J]. Surface Technology,2017,46(11):190-197. [20] 黄璐云, 陈正寿, 倪路新, 等. 靶距与冲击角对超高压水射流喷嘴水动力学性能影响的研究 [J]. 振动与冲击,2022,41(15):169-178, 223.HUANG Luyun, CHEN Zhengshou, NI Luxin, et al. Effects of target distance and impact angle on hydrodynamic performance of ultra-high pressure water jet nozzle [J]. Journal of Vibration and Shock,2022,41(15):169-178, 223. [21] 陈逢军, 尹业青, 胡天. 仿形喷嘴磨料射流抛光微结构仿真及试验研究 [J]. 机械工程学报,2022,58(15):177-187. doi: 10.3901/JME.2022.15.177CHEN Fengjun, YIN Yeqing, HU Tian. Simulation and experimental research on polishing microstrcture by using abrasive water jet with profiling nozzle [J]. Journal of Mechanical Engineering,2022,58(15):177-187. doi: 10.3901/JME.2022.15.177 [22] FINNIE I. Erosion of surfaces by solid particles [J]. Wear,1960,3(2):87-103. doi: 10.1016/0043-1648(60)90055-7 [23] 李佳音, 姜晨, 王璐璐, 等. 十二烷基苯磺酸钠对磁性复合流体分散性及抛光质量的影响 [J]. 表面技术,2021,50(8):389-395.LI Jiayin, JIANG Chen, WANG Lulu, et al. Effect of sodium dodecyl benzene sulfonate on dispersion and polishing quality of magnetic compound fluid [J]. Surface Technology,2021,50(8):389-395. [24] 卞达, 宋恩敏, 倪自丰, 等. 基于响应面法的单晶硅CMP抛光工艺参数优化 [J]. 金刚石与磨料磨具工程,2022,42(6):745-752.BIAN Da, SONG Enmin, NI Zifeng, et al. Optimization of CMP processing parameters for Si based on response surface method [J]. Diamond & Abrasives Engineering,2022,42(6):745-752. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS