Effect of diamond particle size on thermophysical properties of diamond /Cu-B alloy composites

-

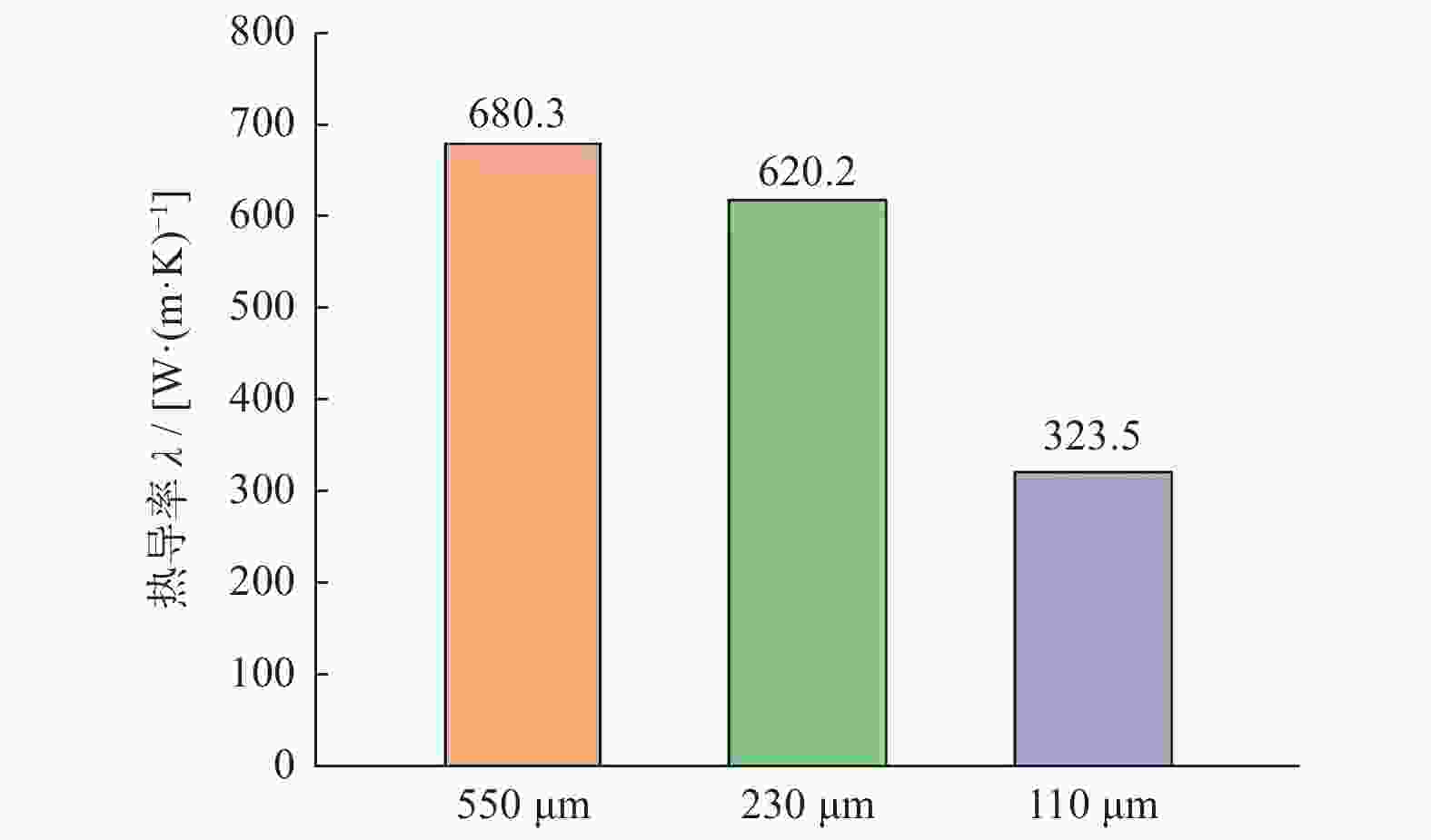

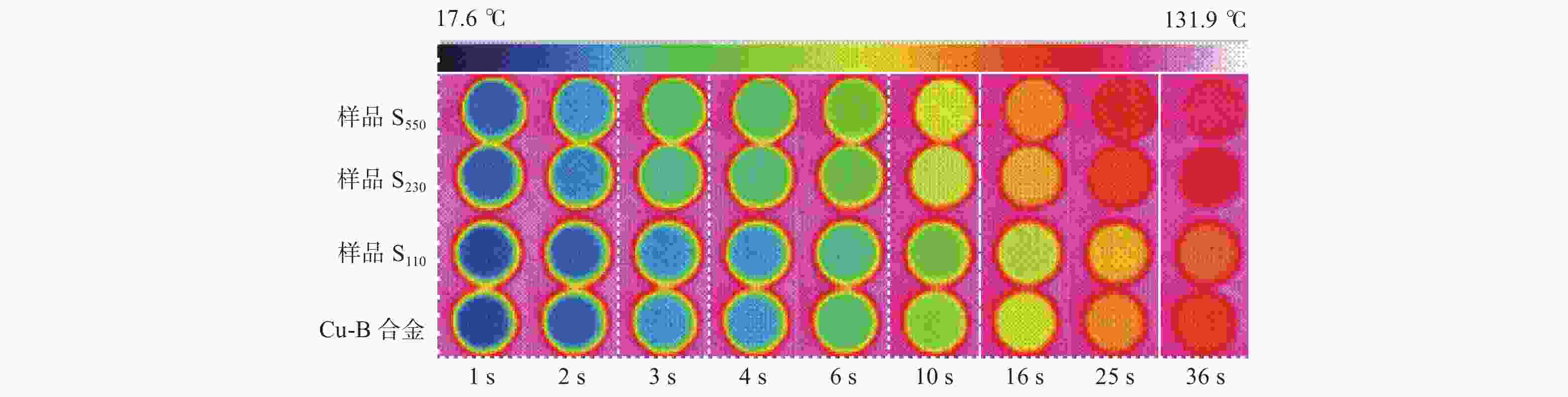

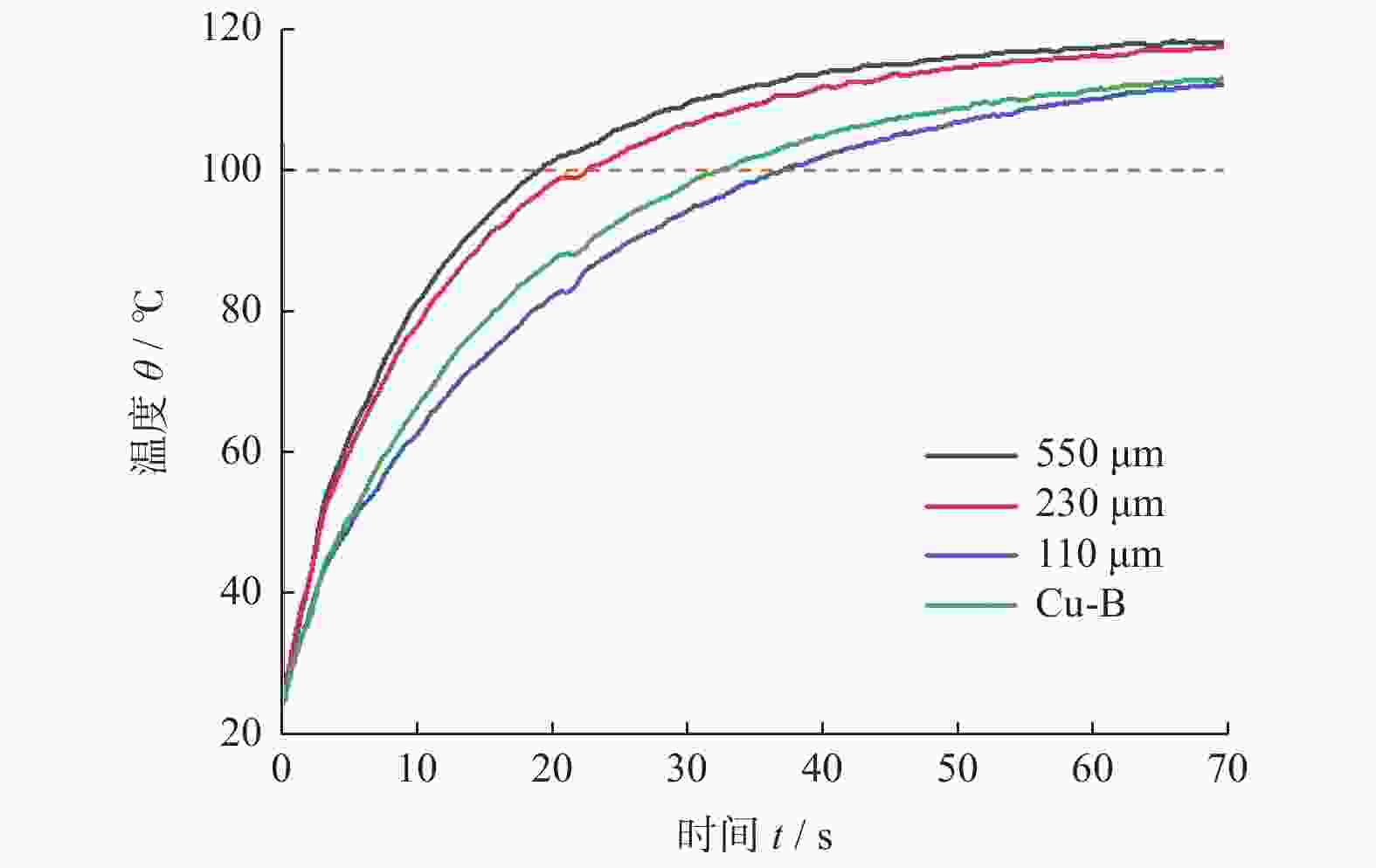

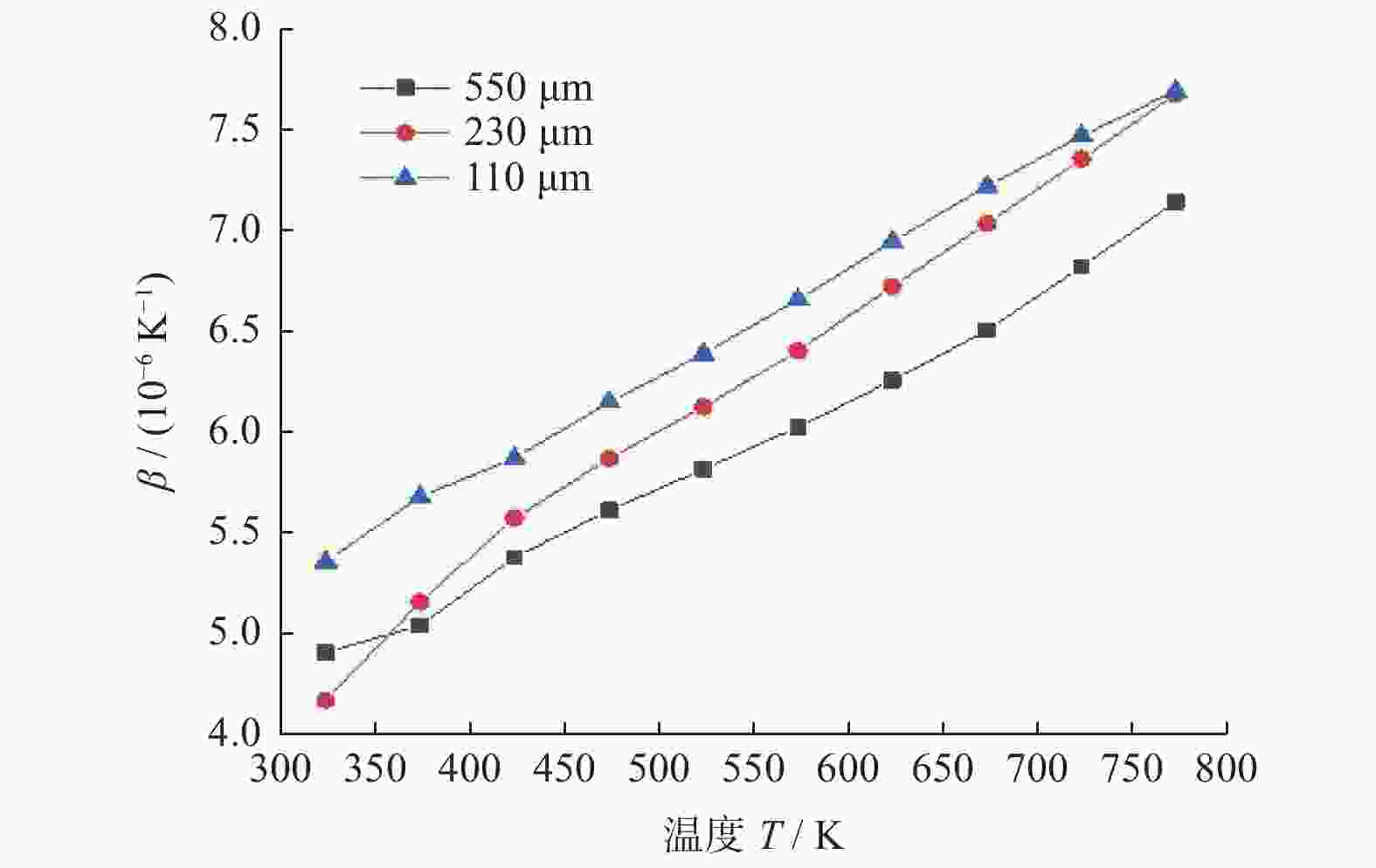

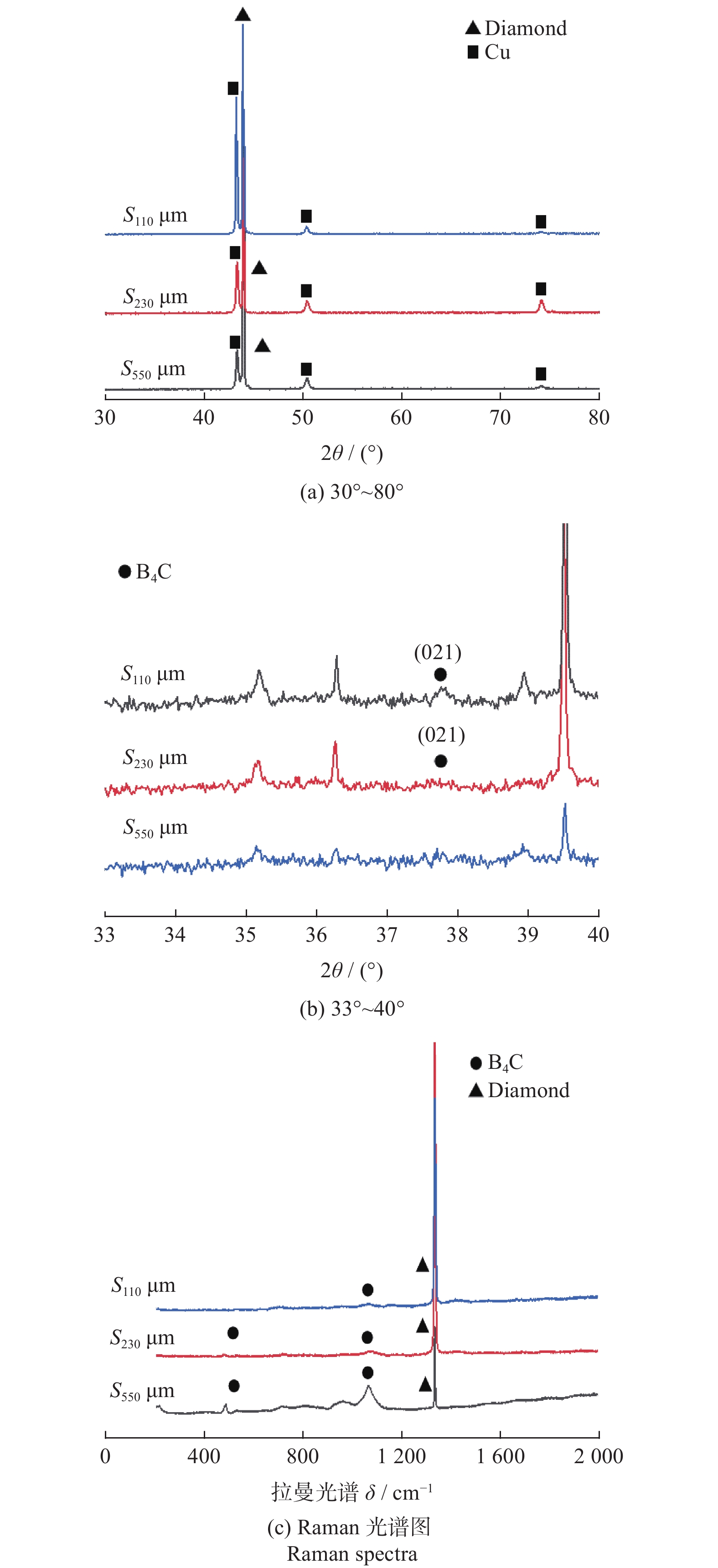

摘要: 采用Cu-B合金为基体,选用粒径分别为110、230、550 μm的金刚石颗粒作为增强体,利用气压熔渗工艺在1 100 ℃、10 MPa气体压力下制备金刚石/Cu-B合金复合材料,研究金刚石颗粒粒径对复合材料组织结构、界面相分布及热物理性能的影响。结果表明,随着金刚石粒径的增大,复合材料热导率上升,热膨胀系数减小,复合材料界面处硼碳化合物含量增加,界面结合情况得到改善。由金刚石颗粒粒径为550 μm时,复合材料热导率最高,可达680.3 W/(m·K) ,热膨胀系数最小,为4.905 × 10−6 K−1,符合高效热管理器件对金刚石/金属基复合材料的热物理性能要求,在电子产品散热器件方面具有良好的应用前景。

-

关键词:

- 热导率 /

- 金刚石粒径 /

- 气压熔渗 /

- 热膨胀系数 /

- 金刚石/Cu-B复合材料

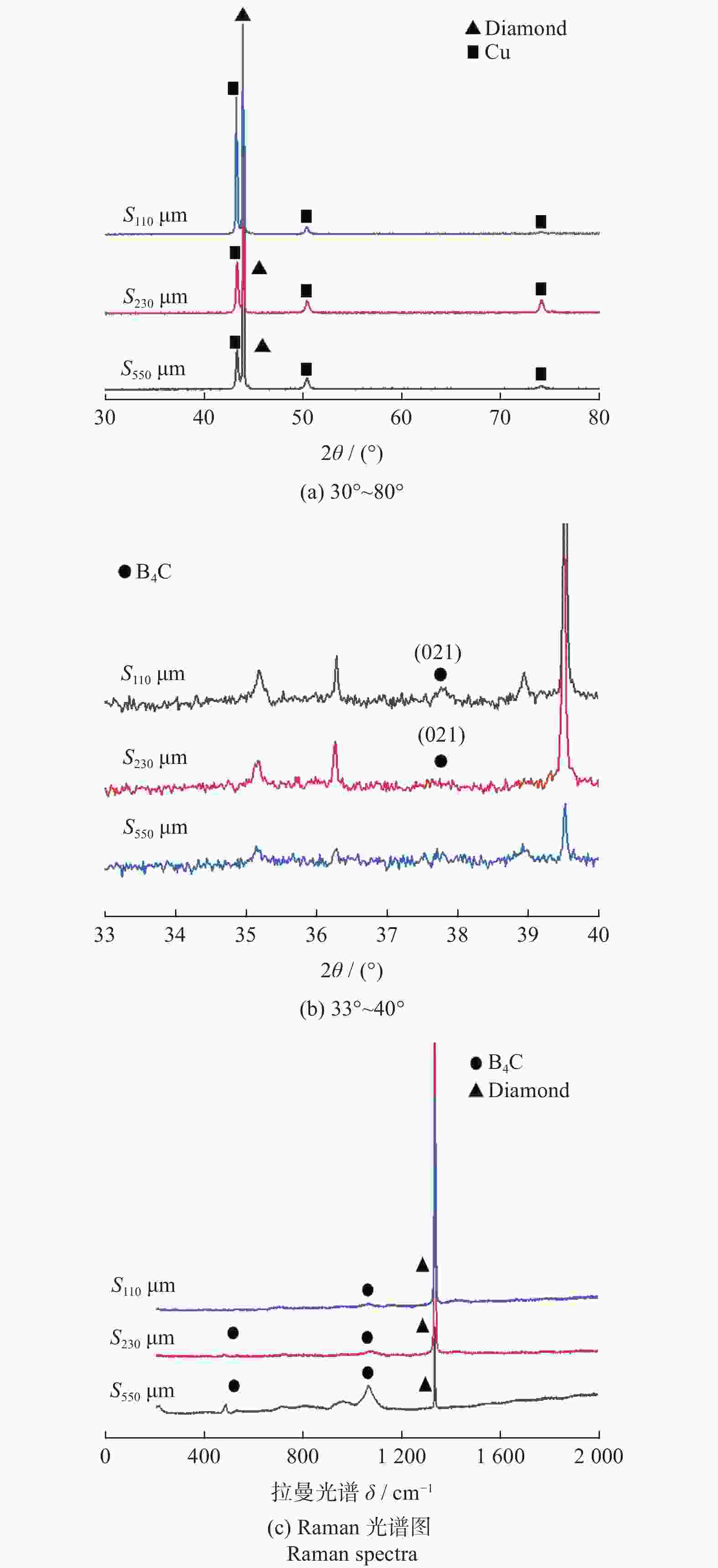

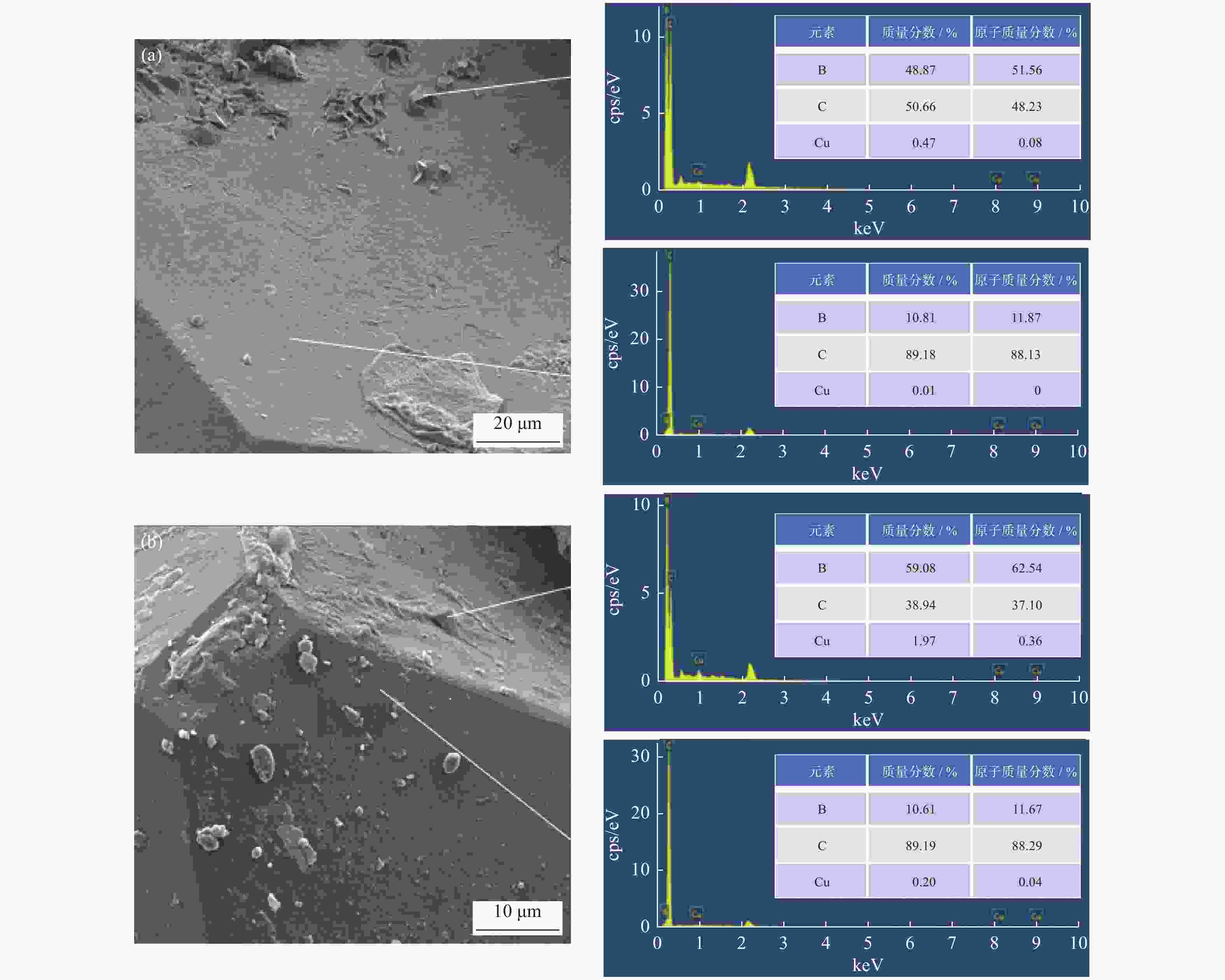

Abstract: Using copper-boron alloy as the metal matrix and different-sized diamond particles through 110 μm, 230 μm to 550 μm as reinforcement, the diamond/copper-boron alloy composites were prepared via gas pressure infiltration technology under 1100 ℃ and 10 MPa gas pressure. The influences of the size of diamond particles on the configuration, interlayer phase distribution, and thermophysical properties of the composites were investigated. The results show that with the increase of particle size, there is a benefit of better interface bonding, and the thermal conductivity of the diamond/copper-boron composite is enhanced while the thermal expansion coefficient decreases. When the diamond particle size is 500 μm, the best performance of the composite is obtained. The thermal conductivity is 680.3 W/(m·K), and the thermal expansion coefficient increases from 4.095×10−6 K−1 to 7.139×10−6 K−1. -

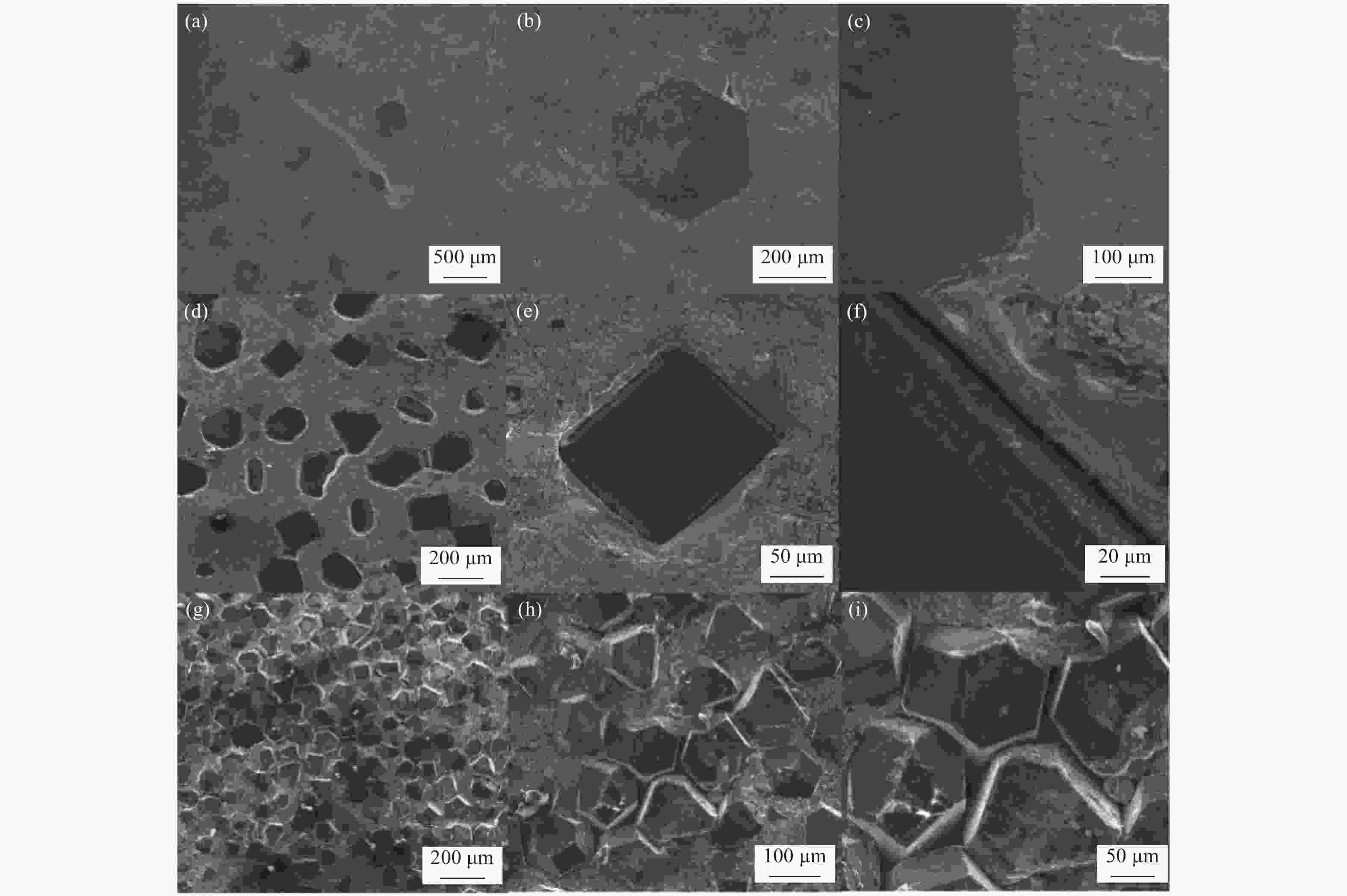

图 2 不同粒径金刚石/Cu-B合金复合材料界面结合情况:样品S550 (a) 低倍形貌 (b) 中倍形貌 (c) 高倍形貌; 样品S230 (d) 低倍形貌 (e) 中倍形貌 (f) 高倍形貌;样品S110 (g) 低倍形貌 (h) 中倍形貌 (i) 高倍形貌

Figure 2. Surface morphologies of diamond/Cu-B alloy composites: (a) Low magnification morphology (b) Middle magnification morphology (c) High magnification morphology of sample S550, (d) Low magnification morphology (e) Middle magnification morphology (f) High magnification morphology of sample S230, (g) Low magnification morphology (h) Middle magnification morphology (i) High magnification morphology of sample S110

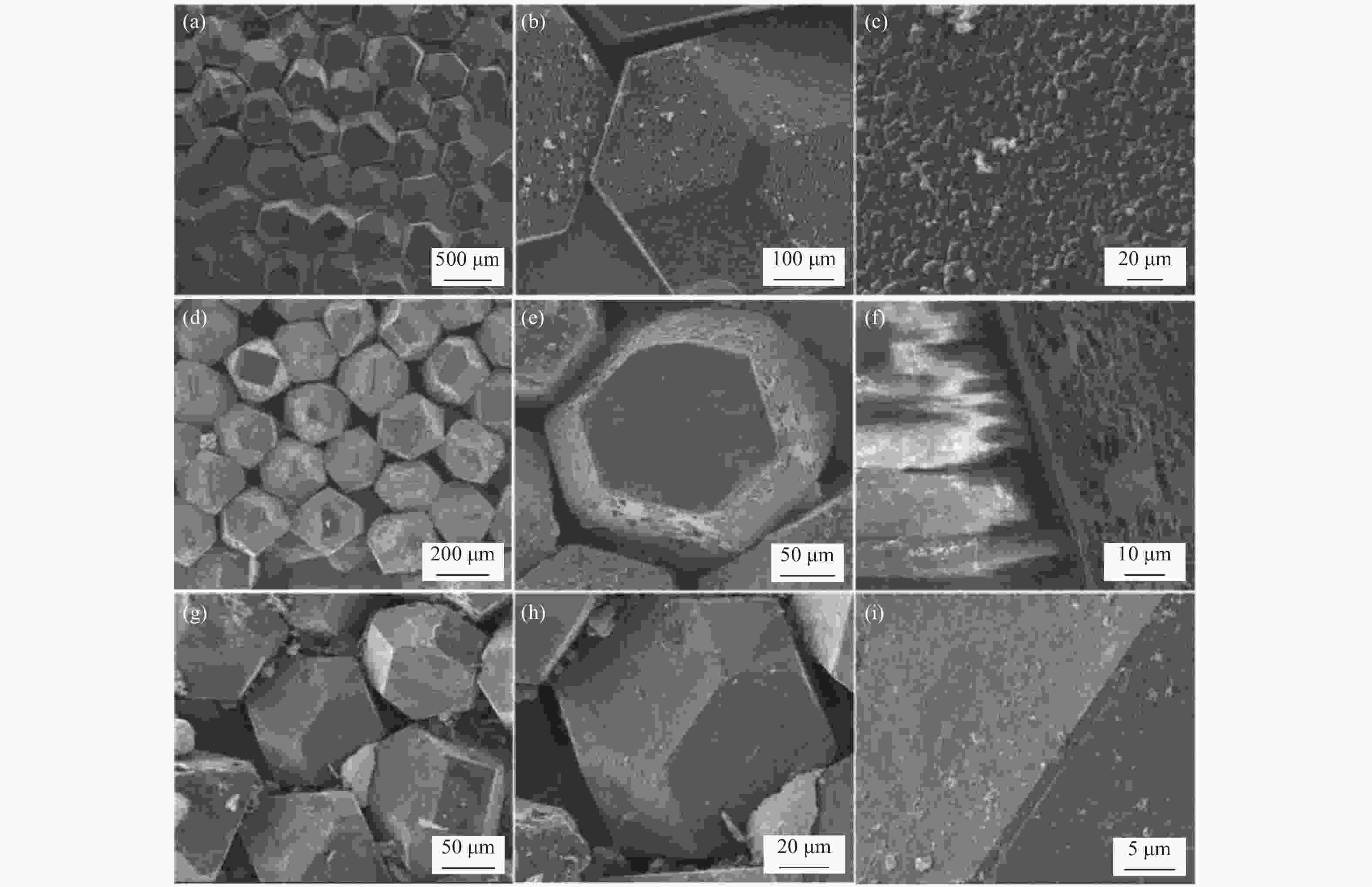

图 3 电化学腐蚀后不同粒径金刚石/Cu-B合金复合材料表面形貌

(a) 样品S550低倍形貌; (b) 样品S550中倍形貌; (c) 样品S550高倍形貌; (d)样品S230低倍形貌; (e) 样品S230中倍形貌; (f)样品S230高倍形貌; (g) 样品S110低倍形貌; (h)样品S110 中倍形貌; (i) 样品S110高倍形貌

Figure 3. Surface morphologies of diamond / copper boron alloy composites with different particle sizes after electrochemical corrosion

(a) Low magnification morphology;(b) Middle magnification morphology; (c) High magnification morphology of sample S550;(d) Low magnification morphology; (e) Middle magnification morphology ;(f) High magnification morphology of sample S230;(g) Low magnification morphology; (h) Middle magnification morphology; (i) High magnification morphology of sample S110

表 1 不同粒径复合材料的密度、致密度、金刚石体积分数、比热容及热扩散系数

Table 1. Density, densification, diamond volume fraction and thermal diffusivity of diamond/copper-boron alloy composites

样品 密度

$\rho $/(g·cm−3)金刚石体积

分数 V/%致密度

$ \rho_2 $/%比热容

c /(J·g−1·K−1)热扩散系数

$\alpha $/(mm2·s−1)S550 5.61 53.2 95.24 0.43 283.11 S230 5.37 54.1 94.91 0.44 265.04 S110 5.87 52.2 91.28 0.42 132.00 -

[1] 李广义, 张俊洪, 高键鑫. 大功率电力电子器件散热研究综述 [J]. 兵器装备工程学报,2020,41(11):8-14. doi: 10.11809/bqzbgcxb2020.11.002LI Guangyi, ZHANG Junhong, GAO Jianxin. Review on Heat Dissipation of High Power Electronic Devices [J]. Journal of Ordnance Equipment Engineering,2020,41(11):8-14. doi: 10.11809/bqzbgcxb2020.11.002 [2] BAHUN I, SUNDE V, JAKOPOVIC Z. Estimation of Insulated-gate Bipolar Transistor Operating Temperature: Simulation and Experiment [J]. Journal of Power Electronics,2013,13(4):729-736. doi: 10.6113/JPE.2013.13.4.729 [3] QIAO L, ZHOU H, FU R. Thermal conductivity of AlN ceramics sintered with CaF2 and YF3 [J]. Ceramics International,2003,29(8):893-896. doi: 10.1016/S0272-8842(03)00033-6 [4] 刘佩东, 胡晓丹, 宋诗慧, 等. 聚合物基电子封装材料的研究进展 [J]. 工程塑料应用,2022,50(7):160-167. doi: 10.3969/j.issn.1001-3539.2022.07.026LIU Peidong, HU Xiaodan, SONG Shihui, et al. Research progress of polymer-based electronic packaging materials [J]. Engineering Plastics Application,2022,50(7):160-167. doi: 10.3969/j.issn.1001-3539.2022.07.026 [5] 曾婧, 彭超群, 王日初, 等. 电子封装用金属基复合材料的研究进展 [J]. 中国有色金属学报,2015,25(12):3255-3270.ZENG Jing, PENG Chaoqun, WANG Richu, et al. Research and development of metal matrix composites for electronic packaging [J]. The Chinese Journal of Nonferrous Metals,2015,25(12):3255-3270. [6] 张晓辉, 王强. 电子封装用金属基复合材料的研究现状 [J]. 微纳电子技术,2018,55(1):18-25,44.ZHANG Xiaohui, WANG Qiang. Research State of Metal-Matrix Composites for Electronic Packaging [J]. Micronanoelectronic Technology,2018,55(1):18-25,44. [7] 张荻, 谭占秋, 熊定邦, 等. 热管理用金属基复合材料的应用现状及发展趋势 [J]. 中国材料进展,2018,37(12):47, 994-1001.ZHANG Di, TAN Zhanqiu, XIONG Dingbang, et al. Application and Prospect of Metal Matrix Composites for Thermal Management: An Overview [J]. Materials China,2018,37(12):47, 994-1001. [8] WU D, YANG L, SHI C-D, et al. Effects of rolling and annealing on microstructures and properties of Cu/Invar electronic packaging composites prepared by powder metallurgy [J]. Transactions of Nonferrous Metals Society of China,2015,25(6):1995-2002. doi: 10.1016/S1003-6326(15)63808-0 [9] HUANG F Y, CHOW H M, CHEN S L, et al. The machinability of Kovar material [J]. Journal of Materials Processing Technology,1999,87(1/2/3):112-118. doi: 10.1016/S0924-0136(98)00341-0 [10] KIM Y D, OH N L, OH S T, et al. Thermal conductivity of W-Cu composites at various temperatures [J]. MATERIALS LETTERS,2001,51(5):420-424. doi: 10.1016/S0167-577X(01)00330-5 [11] CHEN G Q, WU G H, ZHU D Z, et al. Microstructure and thermal and electric conductivities of high dense Mo/Cu composites [J]. Transactions of Nonferrous Metals Society of China,2005(15):110-114. [12] GAN J Q, HUANG Y J, WEN C, et al. Effect of Sr modification on microstructure and thermal conductivity of hypoeutectic Al-Si alloys [J]. Transactions of Nonferrous Metals Society of China,2020,30(11):2879-2890. doi: 10.1016/S1003-6326(20)65428-0 [13] LIU Q Y, WANG F, SHEN W, et al. Influence of interface thermal resistance on thermal conductivity of SiC/Al composites [J]. Ceramics International,2019,45(17):23815-23819. doi: 10.1016/j.ceramint.2019.07.358 [14] ZHANG H L, WU J H, ZHANG Y, et al. Mechanical properties of diamond/Al composites with Ti-coated diamond particles produced by gas-assisted pressure infiltration [J]. Materials Science And Engineering A-Structural Materials Properties Microstructure And Processing,2015(626):362-368. doi: 10.1016/j.msea.2014.11.077 [15] LIU D G, TIAN H, LIN L J, et al. Microstructure, mechanical and elevated temperature tribological behaviors of the diamond/Cu composites prepared by spark plasma sintering method [J]. Diamond And Related Materials,2019(91):138-143. doi: 10.1016/j.diamond.2018.10.022 [16] MA L, ZHANG L, ZHAO P, et al. A new design of composites for thermal management: Aluminium reinforced with continuous CVD diamond coated W spiral wires [J]. Materials & Design,2016(101):109-16. [17] 陈贞睿, 刘超, 谢炎崇, 等. 高导热金属基复合材料的制备与研究进展 [J]. 粉末冶金技术,2022,40(1):40-52.CHEN Zhenrun, LIU Chao, XIE Yan chong, et al. Preparation and research process of high thermal conductivity metalmatrix composites [J]. Powder Metallurgy Technology,2022,40(1):40-52. [18] 贾鑫, 魏俊俊, 黄亚博, 等. 金刚石散热衬底在GaN基功率器件中的应用进展 [J]. 表面技术,2020,49(11):111-123.JIA Xin, WEI Junjun, HUANG Yabo, et al. Application progress of diamond heat dissipation substrate in GaN-based power devices [J]. Surface Technology,2020,49(11):111-123. [19] 孟汝浩, 左宏森, 李跃, 等. 热管理用金刚石/Cu复合材料的研究进展 [J]. 超硬材料工程,2022,34(1):46-51. doi: 10.3969/j.issn.1673-1433.2022.01.010MENG Ruhao, ZUO Hongsen, LI Yue, et al. Research progress of diamond/Cu composites for thermal management [J]. Superhard Material Engineering,2022,34(1):46-51. doi: 10.3969/j.issn.1673-1433.2022.01.010 [20] 李明君, 马永, 高洁, 等. 高导热金刚石/铜复合材料研究进展 [J]. 中国表面工程, 2022, 35(4): 140-50.LI Mingjun, MA Yong, GAO Jie, et al. Research progress of diamond/Cu composites for thermal management [J]. China Surface Engineering, 2022, 35(4): 140-150. [21] DAI S G, LI J W, WANG C J. Preparation and thermal conductivity of tungsten coated diamond/copper composites [J]. Transactions of Nonferrous Metals Society of China,2022,32(9):2979-2992. doi: 10.1016/S1003-6326(22)65997-1 [22] 王元元, 马捷, 李辉, 等. 金刚石粉体表面CVD法镀钨的工艺研究 [J]. 表面技术,2017,46(2):98-102.WANG Yuanyuan, MA Jie, LI Hui, et al. Technical study of tungsten plating on surface of diamond powder by CVD [J]. Surface Technology,2017,46(2):98-102. [23] CHO H J, KIM Y J, ERB U. Thermal conductivity of copper-diamond composite materials produced by electrodeposition and the effect of TiC coatings on diamond particles [J]. Composites Part B-Engineering,2018(155):197-203. doi: 10.1016/j.compositesb.2018.08.014 [24] SHEN X Y, HE X B, REN S B, et al. Effect of molybdenum as interfacial element on the thermal conductivity of diamond/Cu composites [J]. Journal of Alloys and Compounds,2012(529):134-139. doi: 10.1016/j.jallcom.2012.03.045 [25] ZHANG H D, ZHANG J J, LIU Y, et al. Unveiling the interfacial configuration in diamond/Cu composites by using statistical analysis of metallized diamond surface [J]. Scripta Materialia,2018(152):84-88. doi: 10.1016/j.scriptamat.2018.04.021 [26] XIE Z N, GUO H, ZHANG X M, et al. Tailoring the thermal and mechanical properties of diamond/Cu composites by interface regulation of Cr alloying [J]. Diamond and Related Materials,2021,114(8):108309. [27] CHU K, JIA C C, GUO H, et al. Microstructure and thermal conductivity of Cu-B/diamond composites [J]. Journal of Composite Materials,2013,47(23):2945-2953. doi: 10.1177/0021998312460259 [28] 张晓宇, 蔺伟康, 许旻, 等. 添加稀土Nd改善金刚石/铜复合材料界面 [J]. 表面技术,2018,47(5):27-32.ZHANG Xiaoyu, LIN Weikang, XU Min, et al. Adding rare earth Nd to improve the interface of diamond/copper composites [J]. Surface Technology,2018,47(5):27-32. [29] KIDALOV S V, SHAKHOV F M. Thermal Conductivity of Diamond Composites [J]. MATERIALS,2009,2(4):2467-2495. doi: 10.3390/ma2042467 [30] CHEN C, GUO H, CHU K, et al. Thermal conductivity of diamond/copper composites with a bimodal distribution of diamond particle sizes prepared by pressure infiltration method [J]. RARE METALS,2011,30(4):408-413. doi: 10.1007/s12598-011-0405-3 [31] 胡熠闻, 傅蔡安, 于培师, 等. 铝基金刚石复合材料热性能的数值模拟与实验验证 [J]. 材料热处理学报,2022,43(3):134-141.HU Yiwen, FU Caian, YU Peishi, et al. Numerical simulation and experimental verification of thermal properties of diamond/Al composites [J]. Transactions of Materials and Heat Treatment,2022,43(3):134-141. [32] BATTABYAL M, BEFFORT O, KLEINER S, et al. Heat transport across the metal-diamond interface [J]. Diamond and Related Materials,2008,17(7/8/9/10):1438-1442. [33] 崔巍. 熔渗法制备金刚石/铜复合材料及其性能 [D]. 北京: 北京科技大学, 2016.CUI Wei . Preparation and properties of diamond/copper composite materials by infiltration method [D]. Beijing: Beijing University of Science and Technology, 2016. [34] 康翱龙, 康惠元, 焦增凯, 等. 气压熔渗法制备高导热金刚石/Cu–B合金复合材料 [J]. 金刚石与磨料磨具工程,2022,42(6):667-675.KANG Aolong, KANG Huiyuan, JIAO Zengkai, et al. Preparation f high thermal conductivity diamond/Cu–B alloy composites by gas pressure infiltration method [J]. Diamond & Abrasives Engineering,2022,42(6):667-675. [35] TAN Z Q, LI Z Q, FAN G L, et al. Fabrication of diamond/aluminum composites by vacuum hot pressing: Process optimization and thermal properties [J]. Composites Part B-Engineering,2013(47):173-180. doi: 10.1016/j.compositesb.2012.11.014 [36] TAVANGAR R, MOLINA J M, WEBER L. Assessing predictive schemes for thermal conductivity against diamond-reinforced silver matrix composites at intermediate phase contrast [J]. Scripta Materialia,2007,56(5):357-360. doi: 10.1016/j.scriptamat.2006.11.008 [37] 梁远龙, 姜国圣. 表面镀钨金刚石/铜复合材料的有限元模拟 [J]. 粉末冶金技术, 2019, 37(4): 283-287.LIANG Yuanlong, JIANG Guosheng. Finite element simulation of tungsten-coated diamond/copper composites [J]. Powder Metallurgy Technology, 2019, 37(4): 283-287. [38] 白光珠. Cu-B/diamond复合材料的制备、结构与性能 [D]. 北京: 北京科技大学, 2020.BAI Guangzhu. Preparation, structure and properties of Cu-B/diamond composites [D]. Beijing: Beijing University of Science and Technology, 2020. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS