Particle action behavior on the tooth surface of straight cylindrical gears by spindle finishing

-

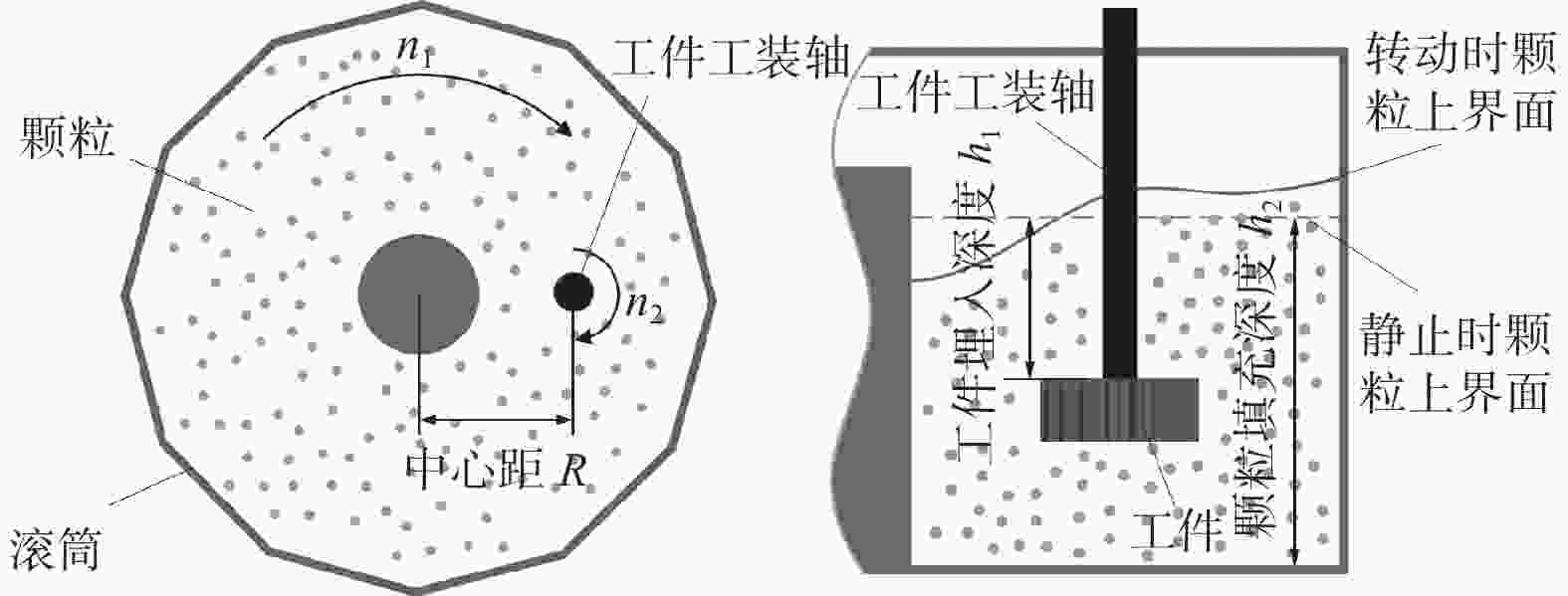

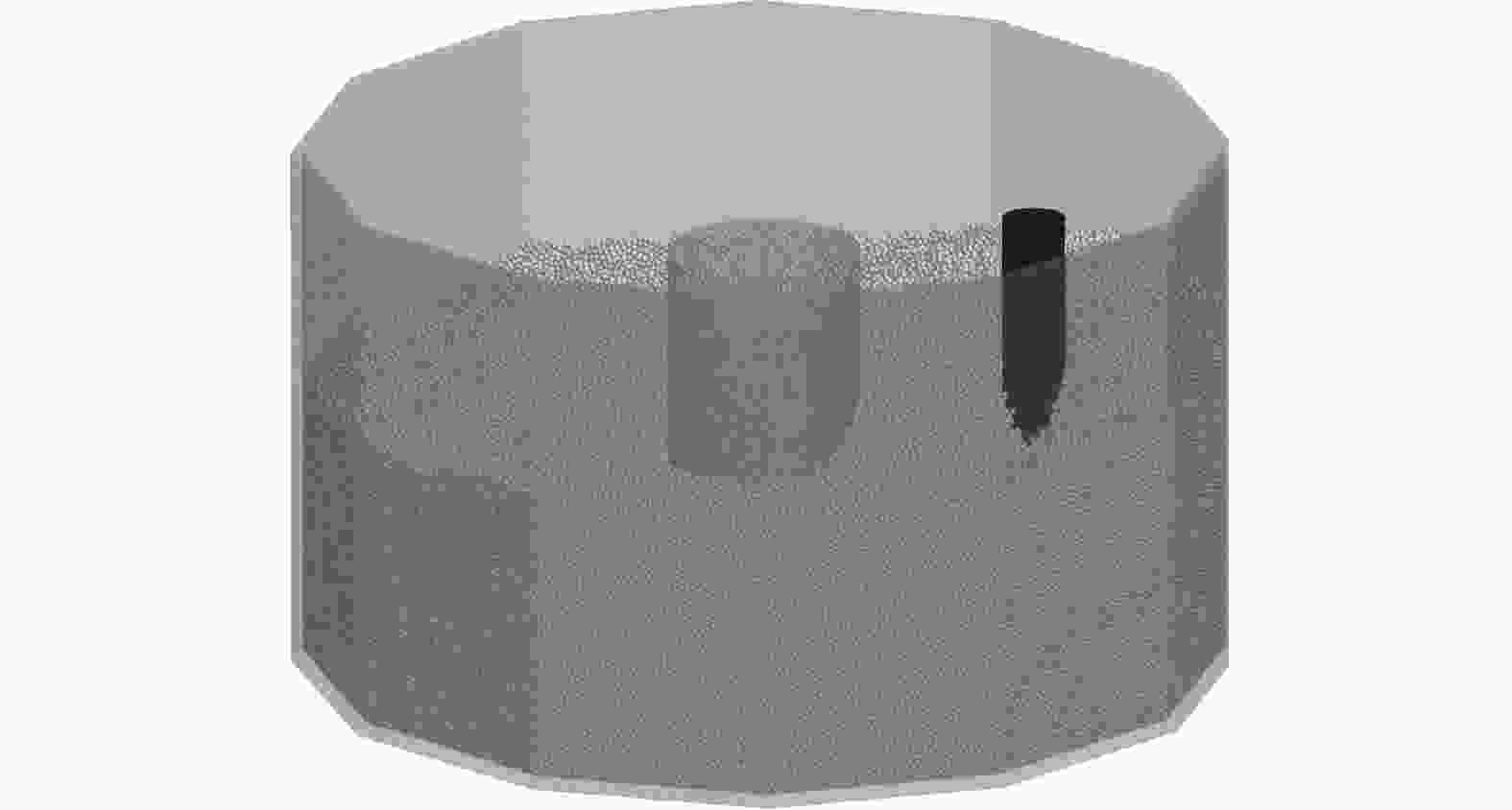

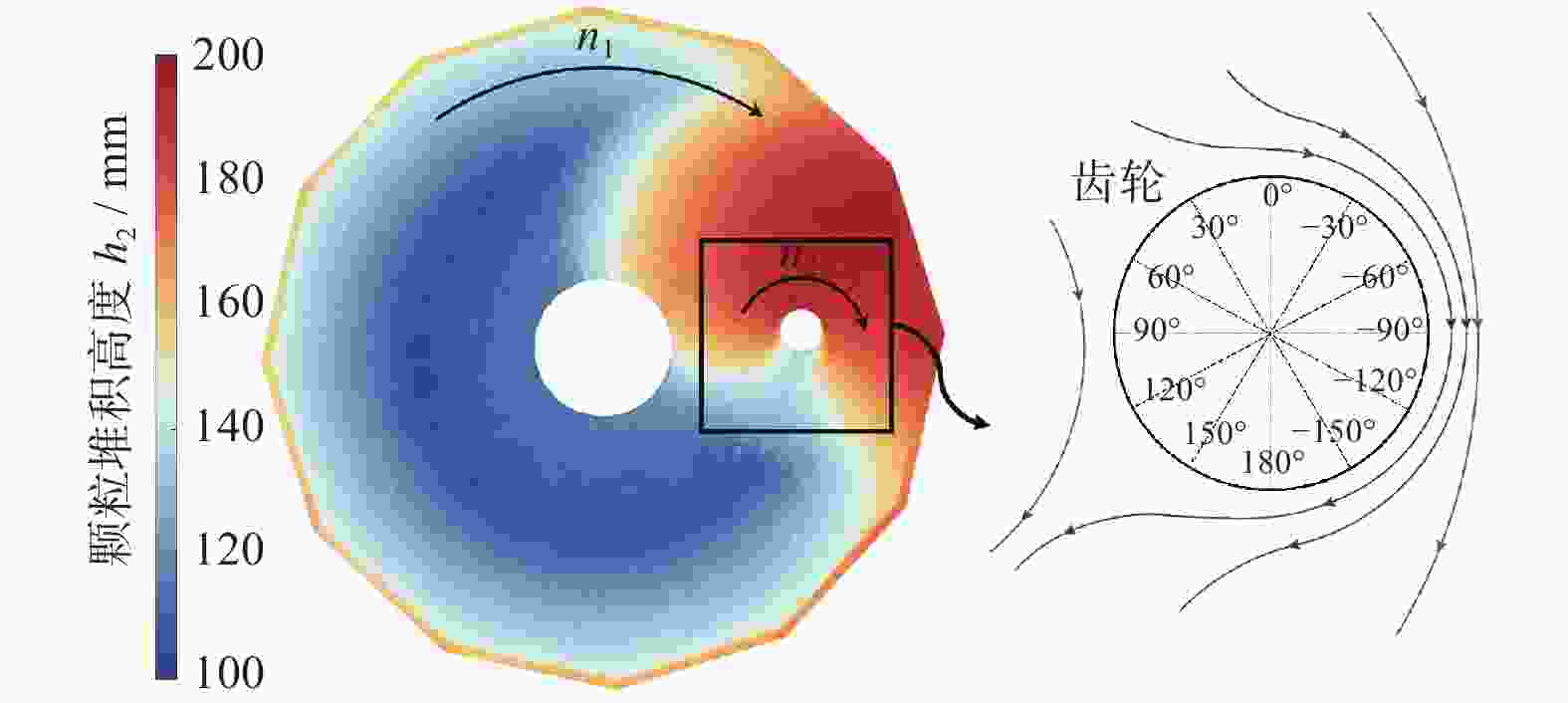

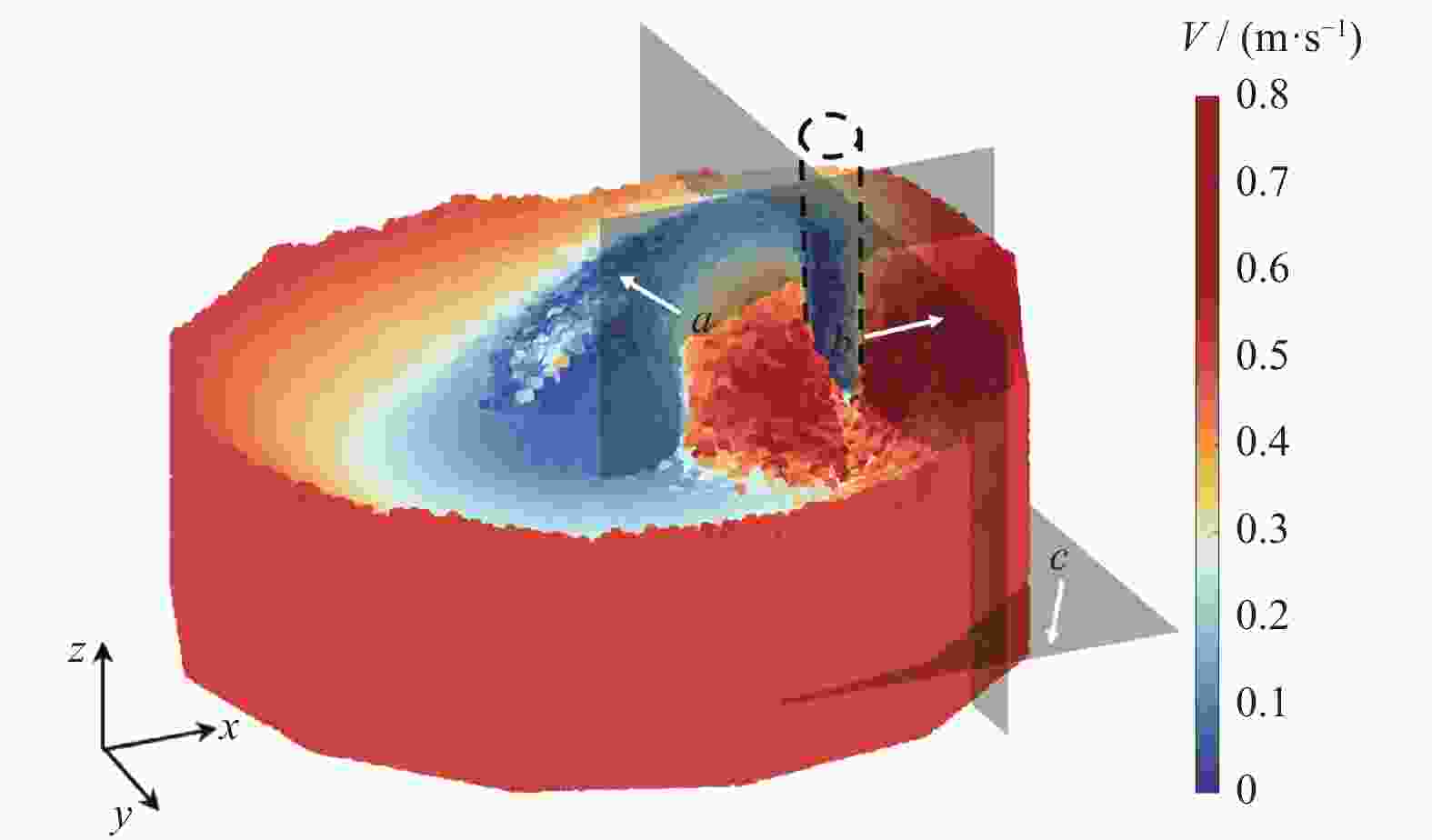

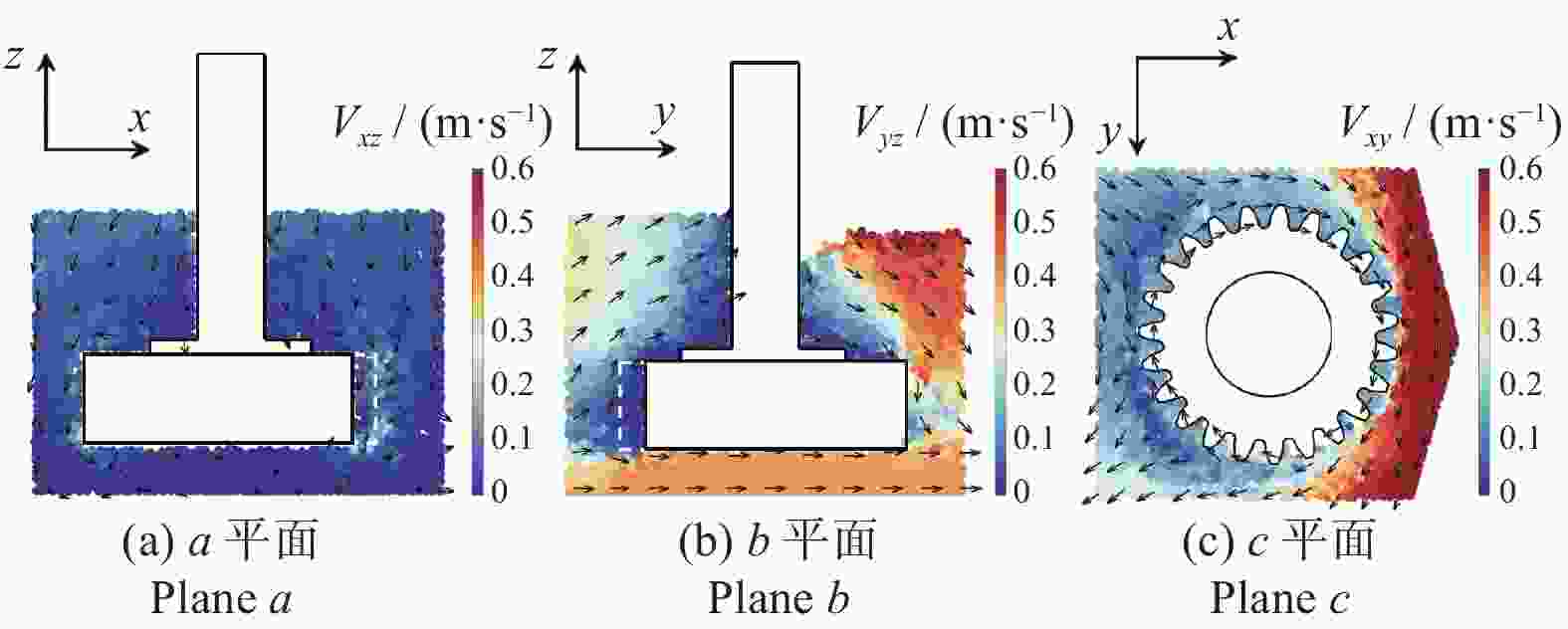

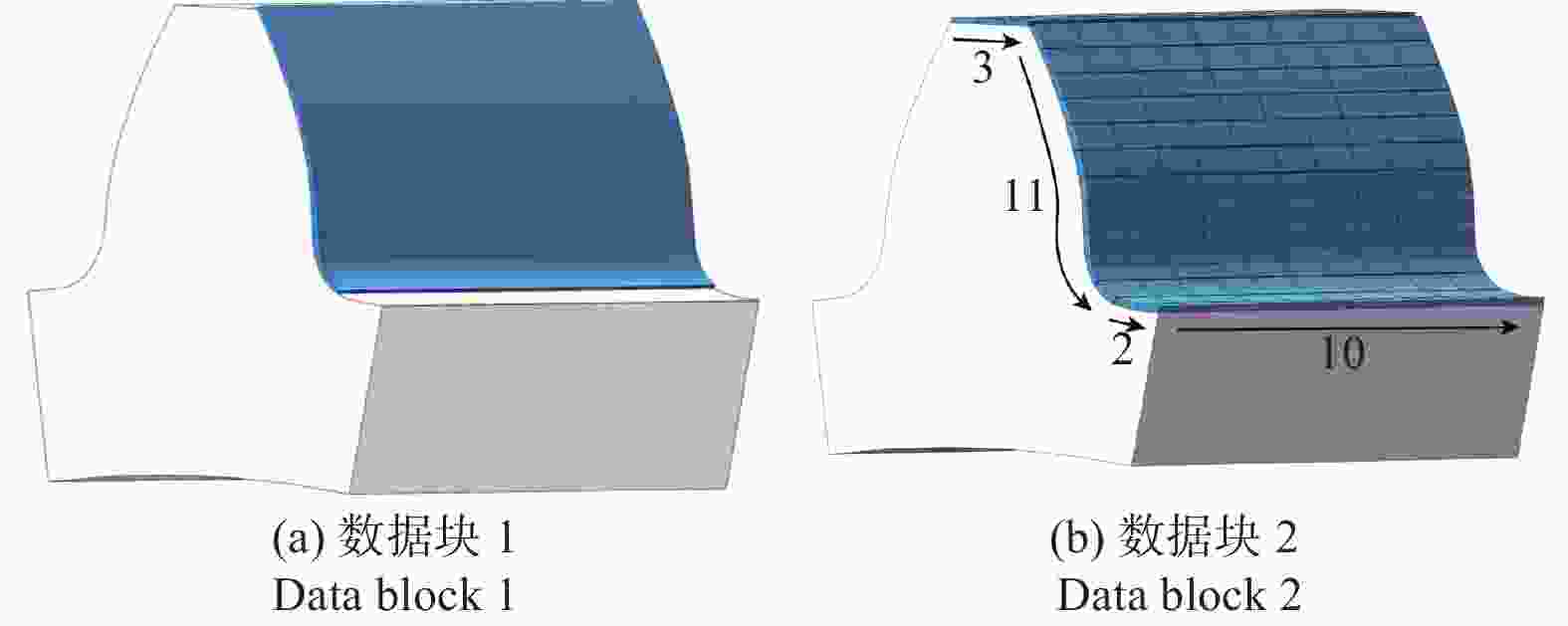

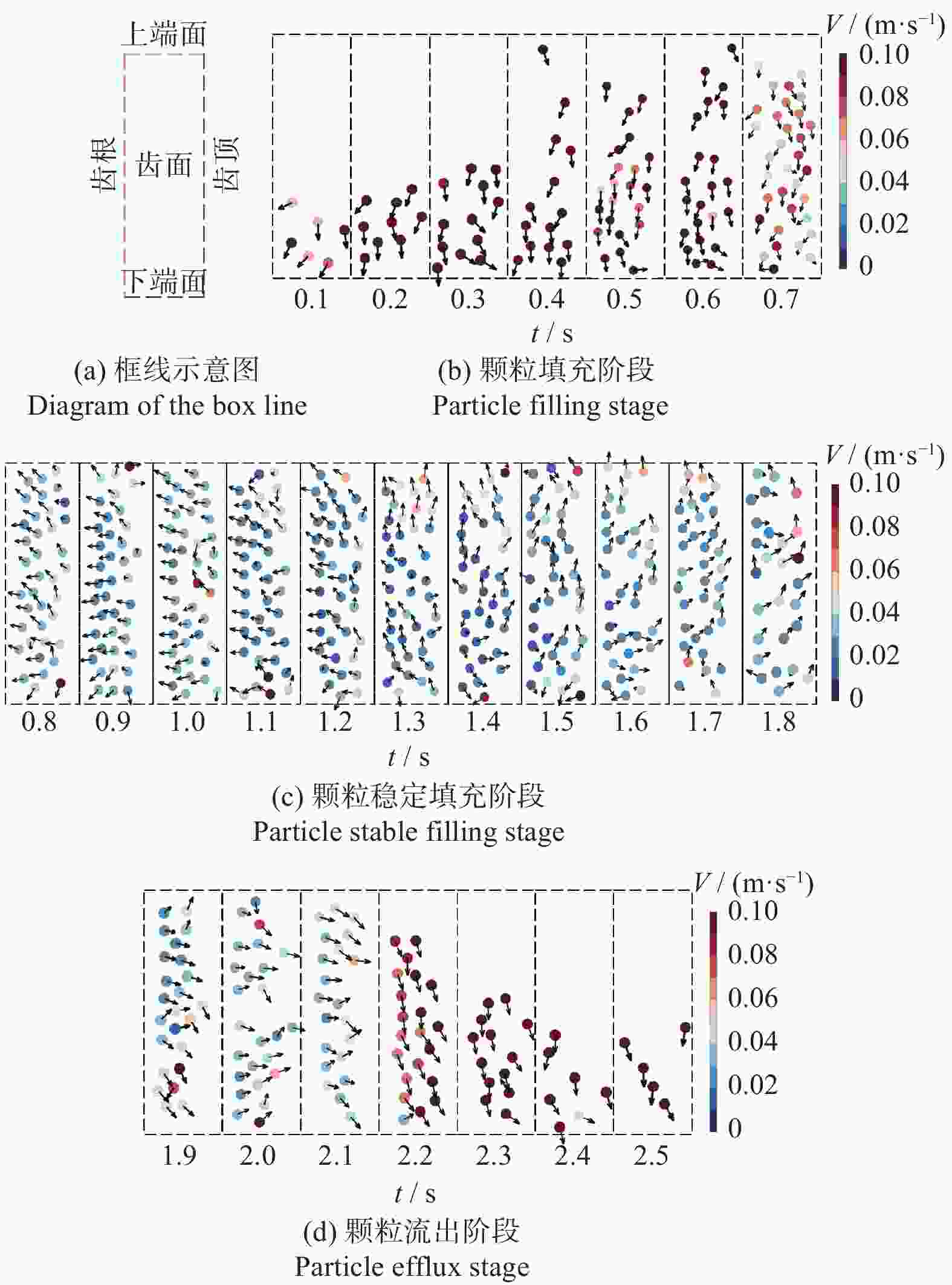

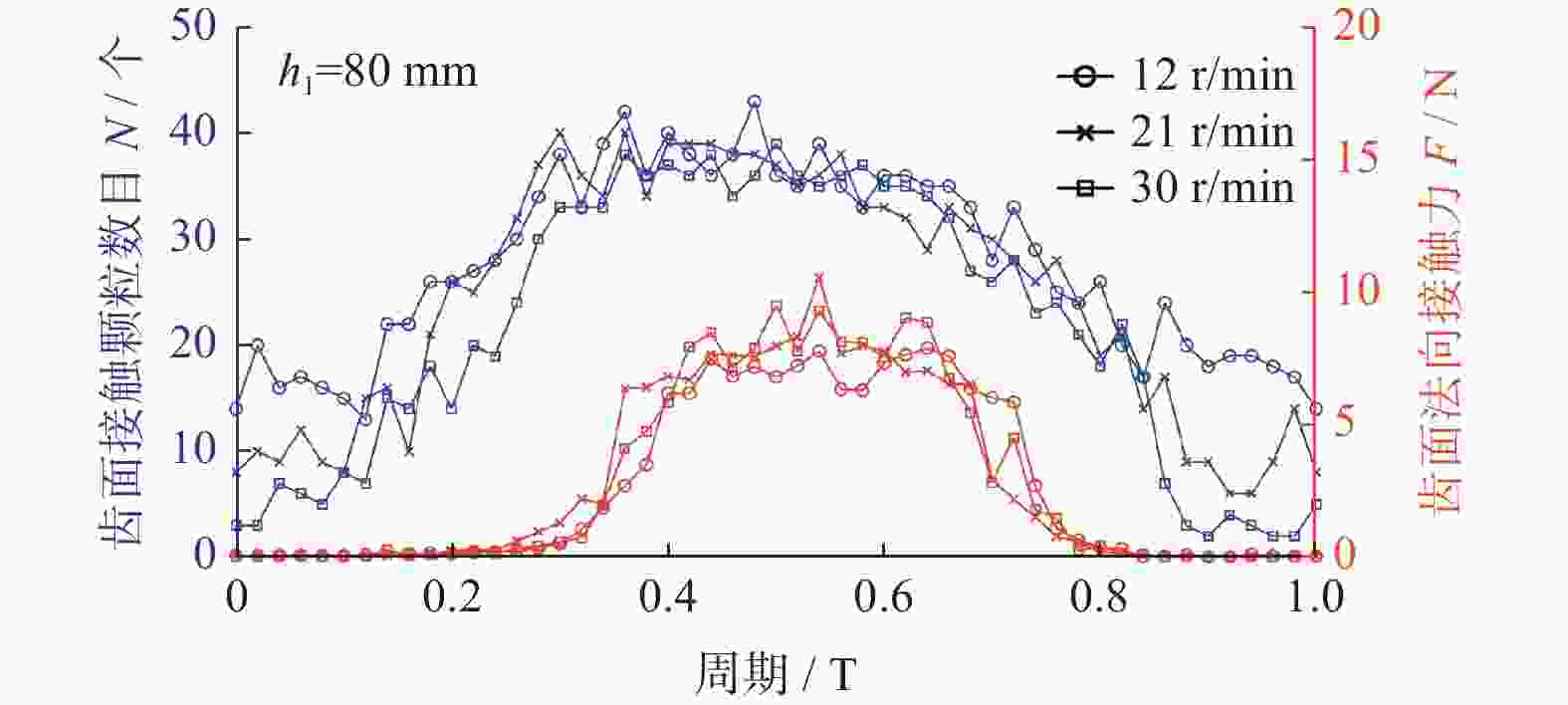

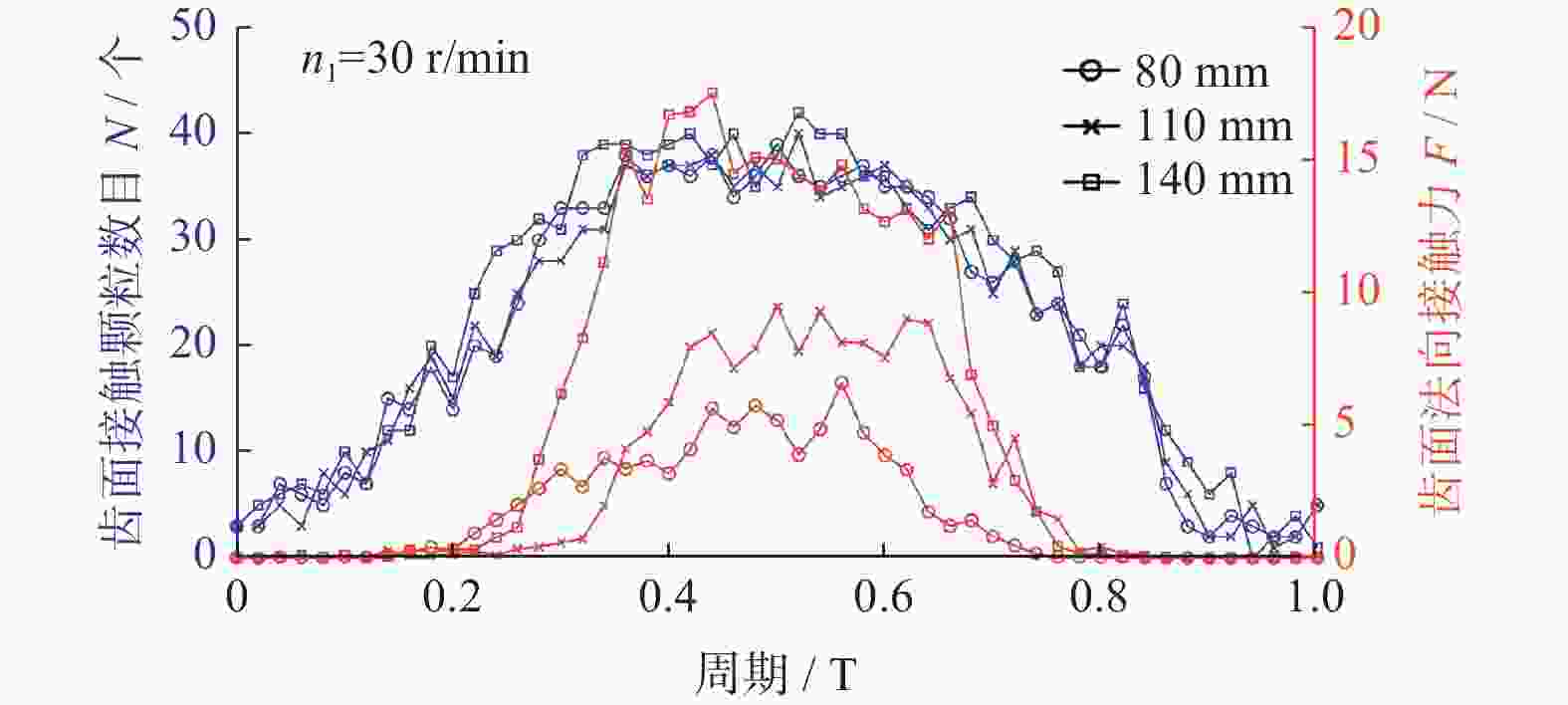

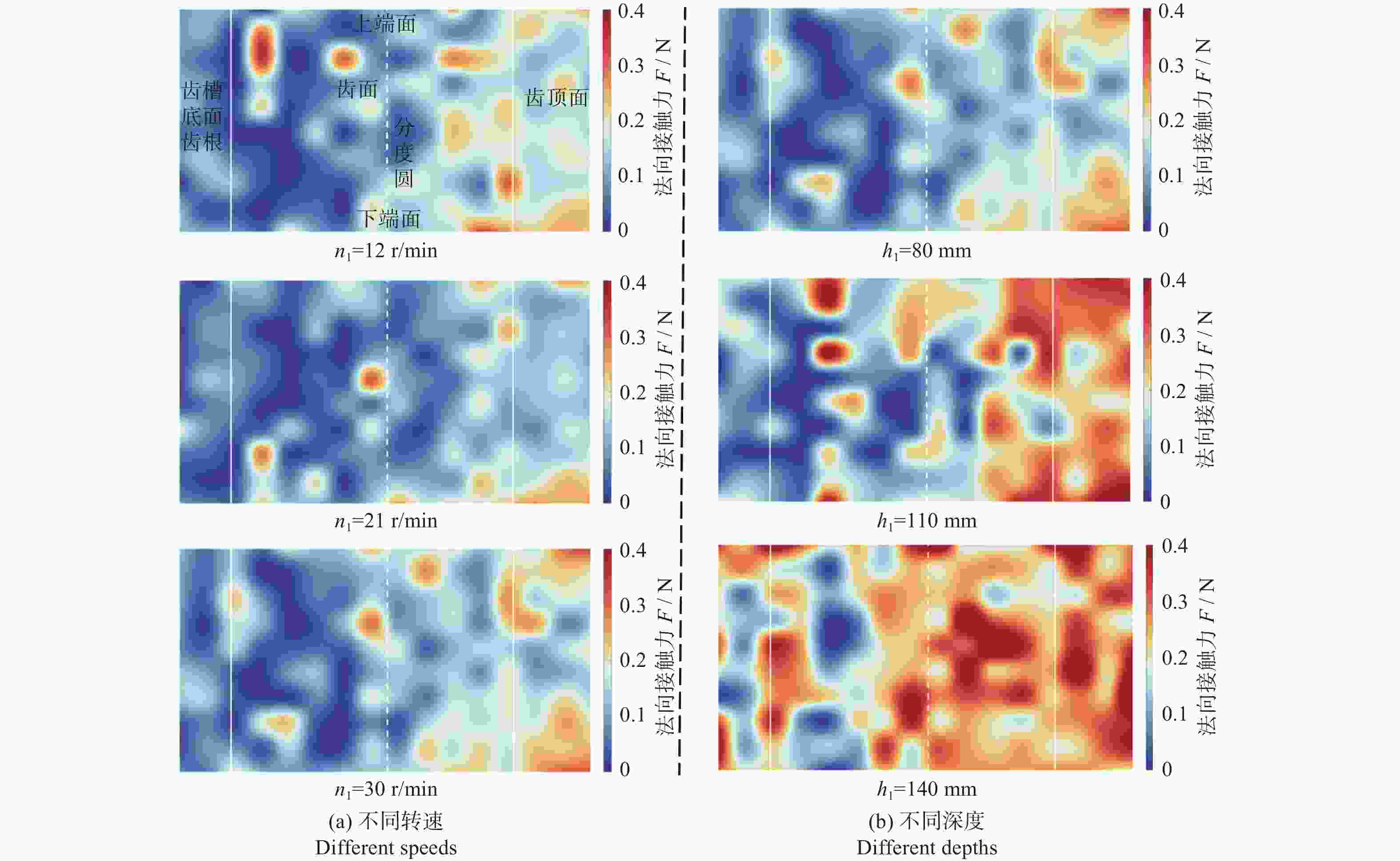

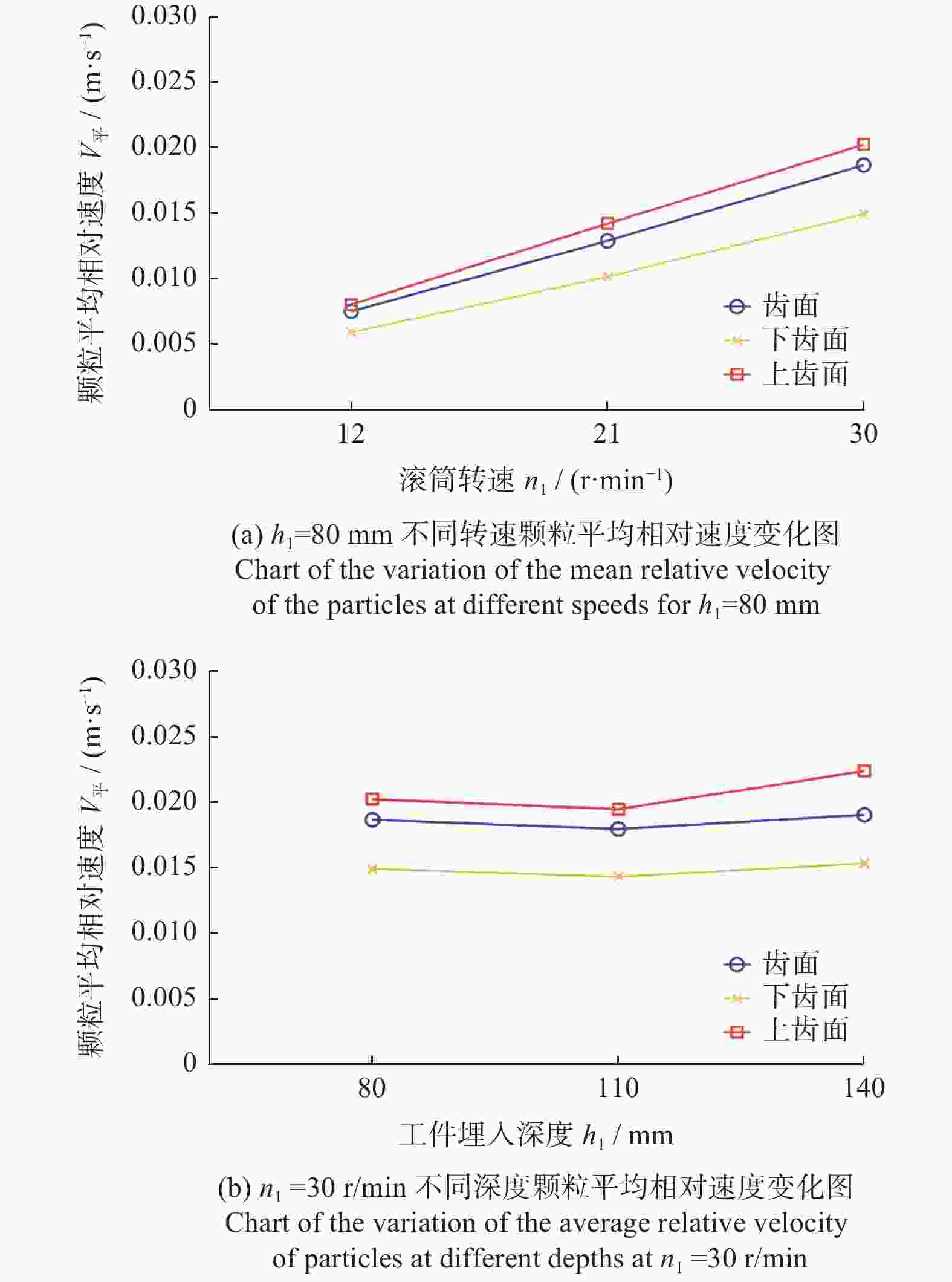

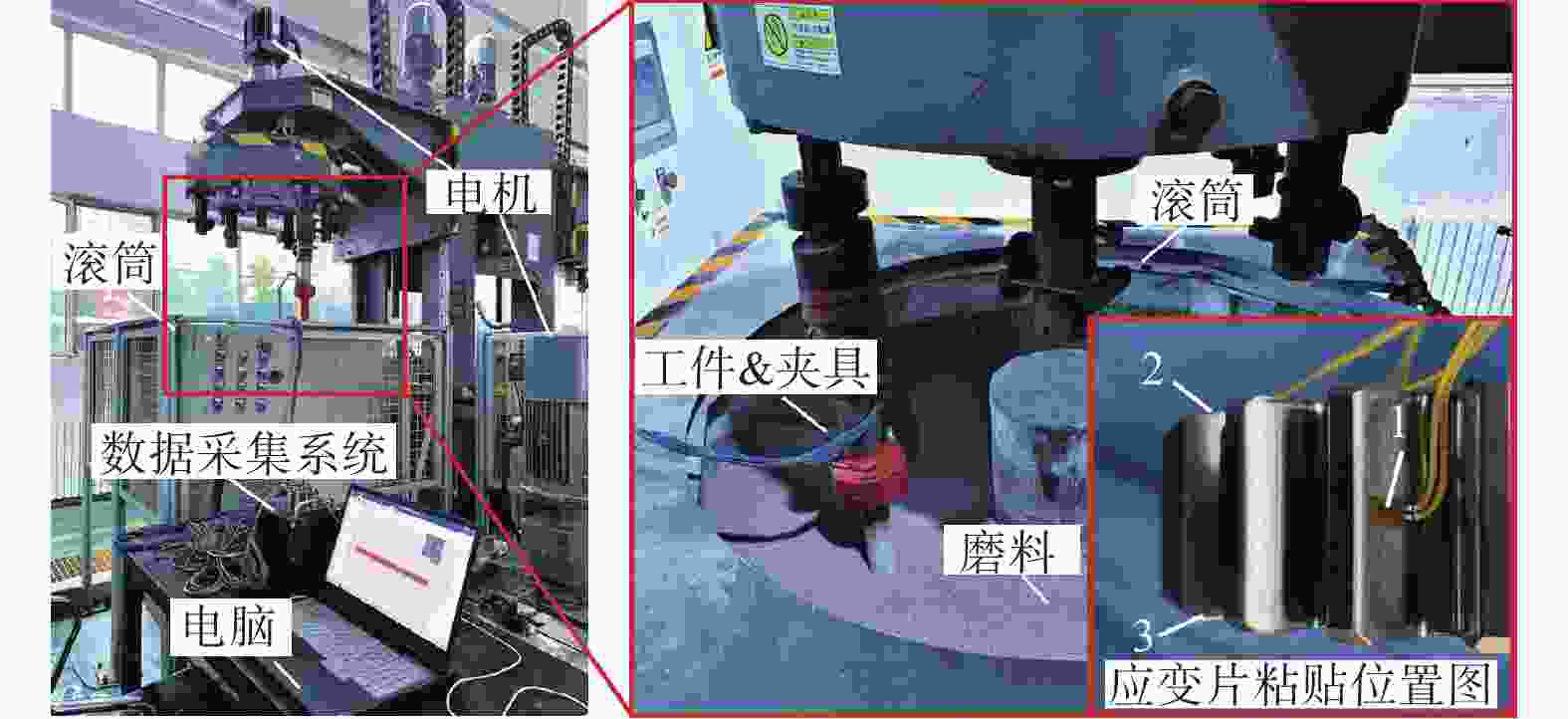

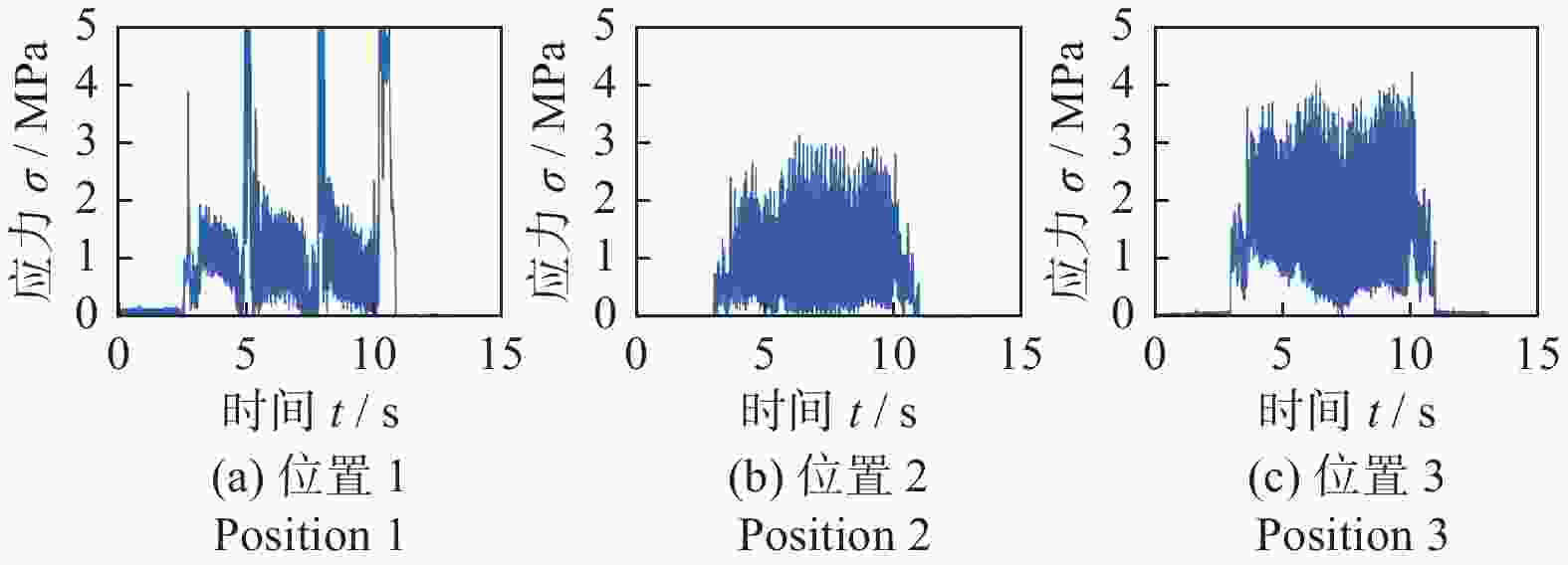

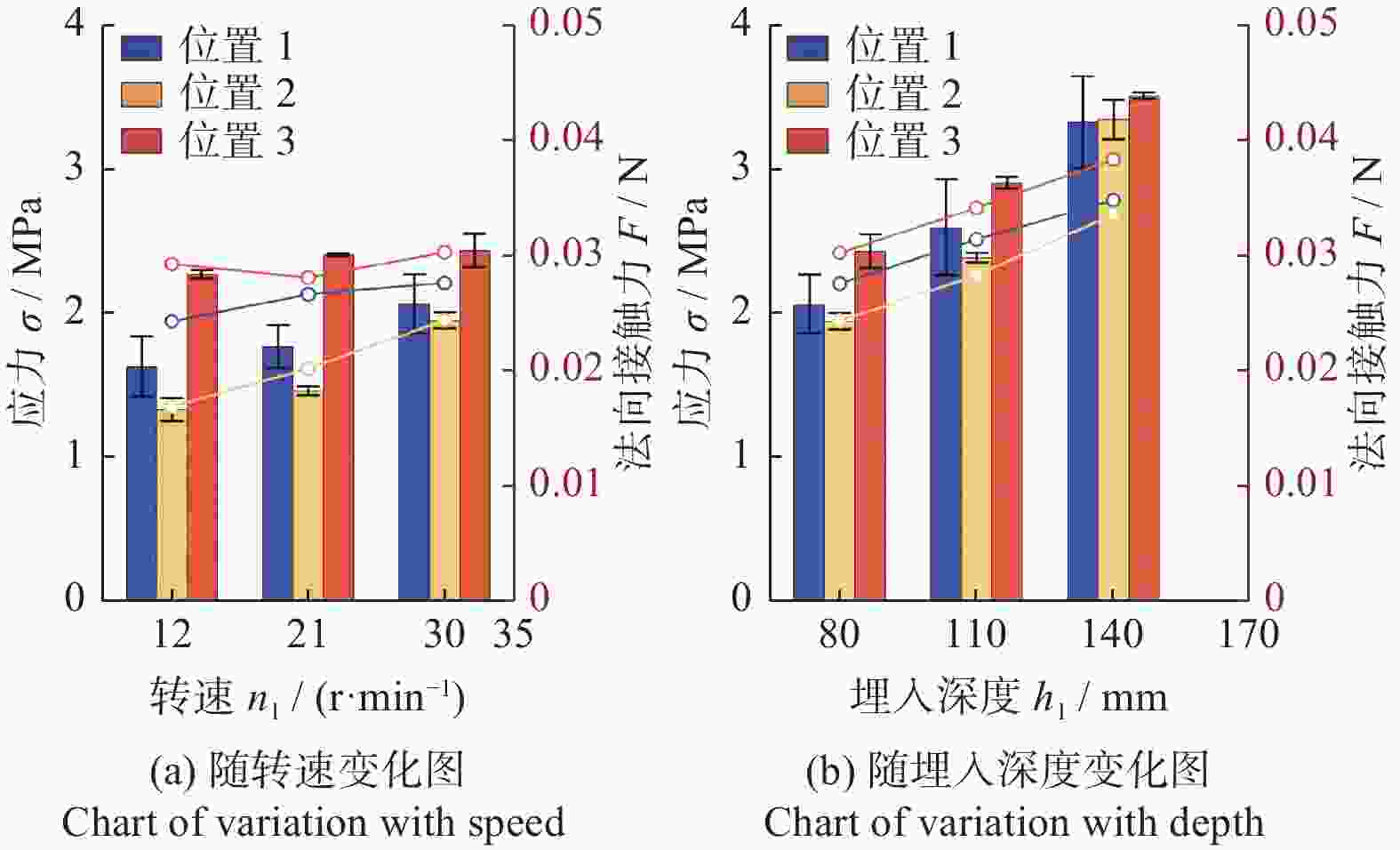

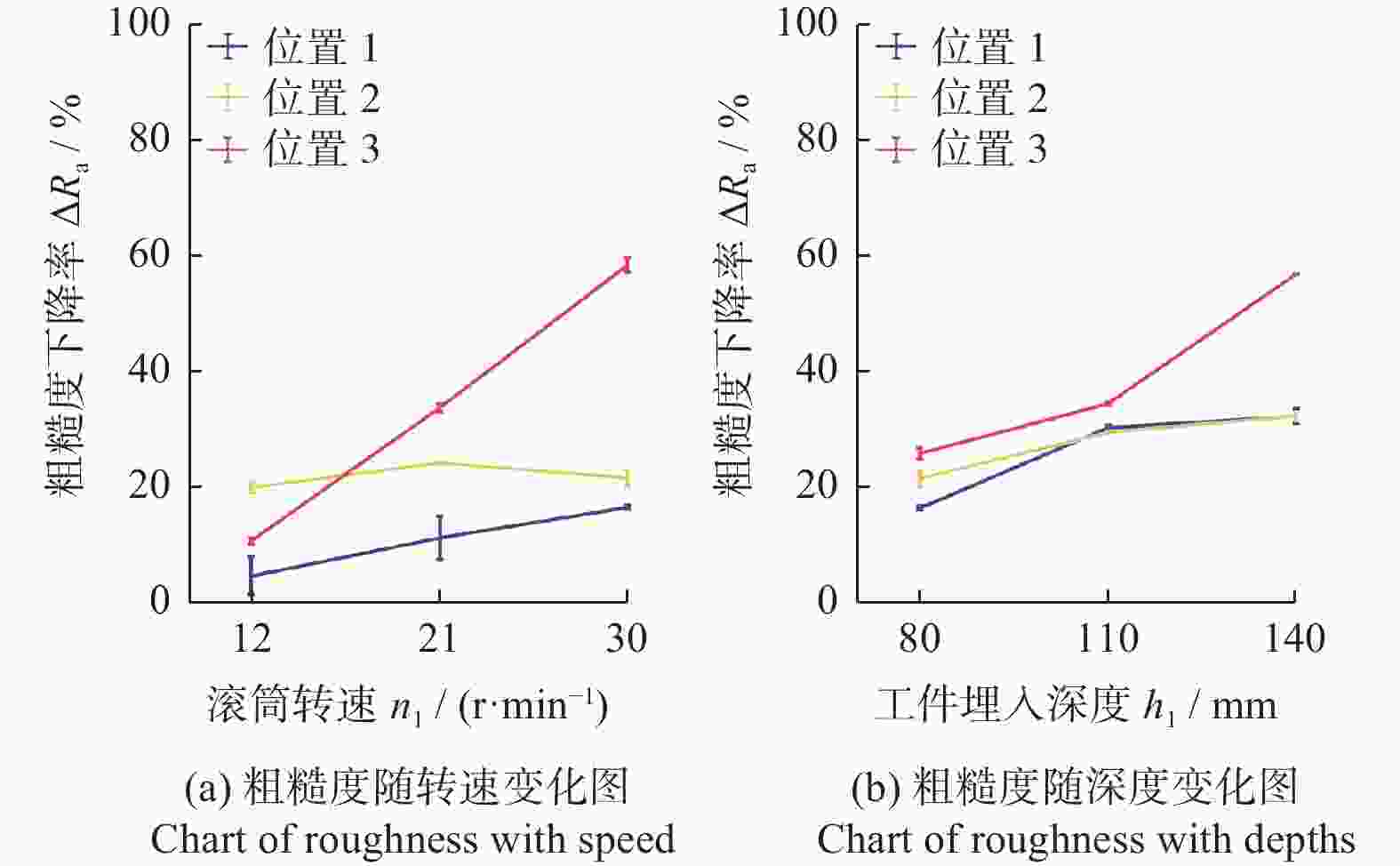

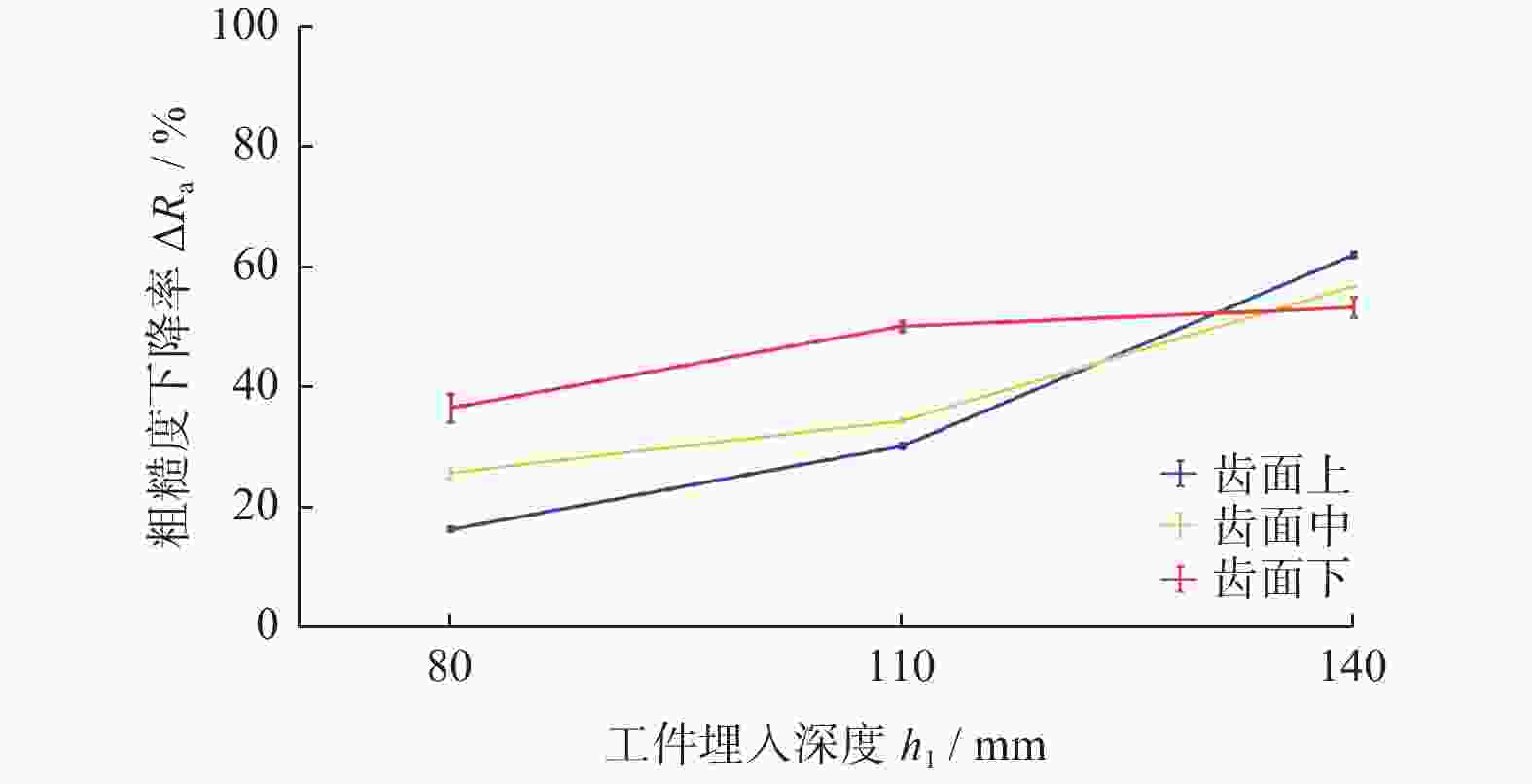

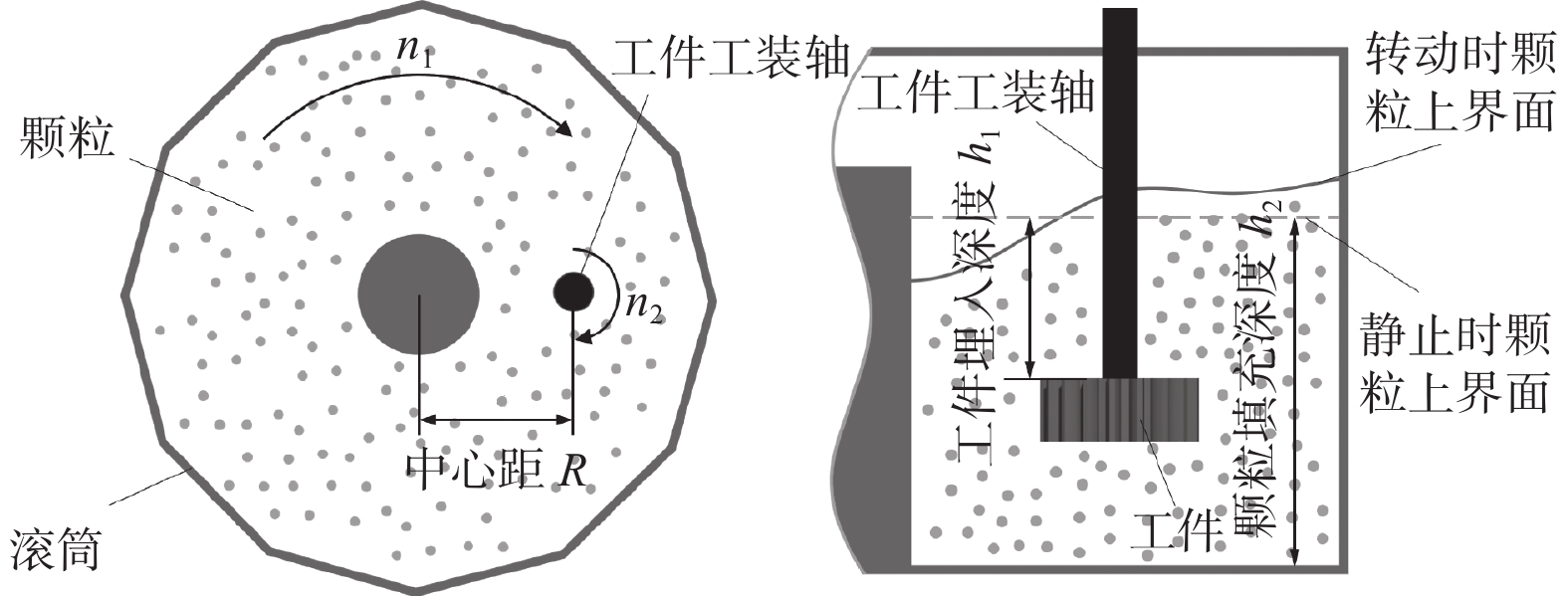

摘要: 为探究主轴式滚磨光整加工中齿轮与颗粒接触界面处的作用行为,基于离散元法(discrete element method, DEM)对主轴式滚磨光整加工进行模拟仿真。首先阐述齿轮附近及齿面接触颗粒的运动形式,然后探究齿轮埋入深度、齿轮和滚筒的转速对齿面接触颗粒相对运动速度及齿面接触力的影响,最后通过实验进行验证。结果表明:主轴式滚磨光整加工对齿轮齿面的作用具有周期性;齿轮上下齿面受力不均匀,上齿面所受接触力是下齿面的1.5~1.8倍。增加齿轮埋入深度主要影响颗粒与齿面的接触力,埋入深度增大75%,齿面接触力增大76%;提升齿轮与滚筒转速则主要影响颗粒与齿面的相对运动速度,齿轮与滚筒转速增大150%,齿面接触颗粒相对运动速度增大148%。且增加齿轮埋入深度可减小齿轮齿面沿轴向的加工差异性,埋入深度由80 mm增大到140 mm后,上下齿面沿轴向的粗糙度下降率由17%和36%变为62%和55%,而改变转速和埋入深度对沿齿廓方向的加工差异性改变不明显。Abstract: The objective of this study is to explore the mechanism of action at the contact interface between gears and particles in spindle barrel finishing, using the Discrete Element Method (DEM) for simulation. The motion of the particles in the vicinity of the gear and the contact particles on the tooth surface is first described. Then the effects of gear embedment depth, gear and roller speed on relative particle motion velocity and tooth contact force are investigated. Finally, the simulation results are verified by experiments. The results show that the action of spindle barrel finishing on the gear tooth face is cyclical in nature. Contact force on the upper and lower tooth surfaces of the gear is not uniform, and the contact force on the upper tooth surface is 1.5 to 1.8 times that on the lower tooth surface. Increasing the gear embedment depth mainly affects the contact force between the particles and the tooth surface. A 75% increase in embedment depth leads to a 76% rise in tooth surface contact force. Similarly, increasing the gear and drum speed mainly affects the relative movement speed between particles and the tooth surface. A 150% increase in gear and drum speed results in a 148% increase in the relative movement speed of particles in contact with the tooth surface. Increasing the embedment depth of the gear can reduce the processing variability of the gear tooth surface along the axial direction. After increasing the embedment depth from 80 mm to 140 mm, the roughness of the upper and lower tooth surfaces along the axial direction decreases from 17% and 36% to 62% and 55%, respectively. However, the processing variability along the tooth profile direction does not change significantly by changing the speed and embedment depth.

-

Key words:

- gear /

- barrel finishing /

- discrete element simulation /

- particle flow field /

- stress testing

-

表 1 材料本征参数[4]

Table 1. Material parameters of the model

材料参数 密度 $\rho $ / (kg·m−3) 泊松比 $\varepsilon $ 剪切模量 E / MPa 滚筒(钢) 7 850 0.300 7 940 颗粒

(棕刚玉)2 675 0.360 1 260 齿轮(40 Cr) 7 870 0.277 8 080 相互作用 碰撞恢复

系数 μ1静摩擦

系数 μ2滚动摩擦

系数 μ3颗粒-滚筒 0.50 0.35 0.10 颗粒-齿轮 0.43 0.36 0.10 颗粒-颗粒 0.46 0.39 0.10 表 3 滚磨光整加工离散元模拟设计

Table 3. Discrete element simulation design for barrel finishing

齿轮埋入深度 $ {h}_{1} $ / mm 滚筒转速 $ {n}_{1} $ / (r·min−1) 80,110,140 12,21,30 -

[1] 高玉魁, 赵振业. 齿轮的表面完整性与抗疲劳制造技术的发展趋势 [J]. 金属热处理,2014(4):1-6. doi: 10.13251/j.issn.0254-6051.2014.04.001GAO Yukui, ZHAO Zhenye. Surface integrity of gears and the development trend of fatigue-resistant manufacturing technology [J]. Metal Heat Treatment,2014(4):1-6. doi: 10.13251/j.issn.0254-6051.2014.04.001 [2] 南小侠, 翟婷婷, 韩晓光. 滚磨光整在齿轮加工中的应用技术研究 [J]. 新型工业化,2019,9(7):40-44. doi: 10.19335/j.cnki.2095-6649.2019.07.008NAN Xiaoxia, ZHAI Tingting, HAN Xiaoguang. Research on the application technology of roller grinding and finishing in gear machining [J]. New Industrialization,2019,9(7):40-44. doi: 10.19335/j.cnki.2095-6649.2019.07.008 [3] 罗丽霞, 武增宏. 光整加工对齿轮传动影响的研究 [J]. 机械工程师,2018(11):155-157, 163. doi: 10.3969/j.issn.1002-2333.2018.11.051LUO Lixia, WU Zenghong. Study on the effect of finishing machining on gear transmission [J]. Mechanical Engineer,2018(11):155-157, 163. doi: 10.3969/j.issn.1002-2333.2018.11.051 [4] WANG Na, YANG S Q, ZHAO T T, et al. Experiment and simulation analysis on the mechanism of the spindle barrel finishing [J]. The International Journal of Advanced Manufacturing Technology,2020,109(1):57-74. [5] 杨英波, 李文辉, 李东祥, 等. 齿轮类零件滚磨光整加工技术现状及发展思考 [J]. 表面技术,2021,50(12):1-16. doi: 10.16490/j.cnki.issn.1001-3660.2021.12.001YANG Yingbo, LI Wenhui, LI Dongxiang, et al. Research status and development thinking of mass finishing for gear parts [J]. Surface Technology,2021,50(12):1-16. doi: 10.16490/j.cnki.issn.1001-3660.2021.12.001 [6] BUDZISZ W, MARCINIEC A. The new gear finishing method research for highly loaded gears [J]. Aerospace, 2022, 9(131): 1-15. [7] UHLMANN E, EULITZ A, DETHLEFS A. Discrete element modelling of drag finishing [J]. Procedia Cirp,2015,31:369-374. doi: 10.1016/j.procir.2015.03.021 [8] HASHIMOTO F, CHAUDHARI R G, MELKOTE S N. Characteristics and performance of surfaces created by various finishing methods [J]. Procedia CIRP,2016,45:1-6. doi: 10.1016/j.procir.2016.02.052 [9] KACARAS A, GIBMEIER J, ZANGER F, et al. Influence of rotational speed on surface states after stream finishing [J]. Procedia CIRP,2018,71:221-226. doi: 10.1016/j.procir.2018.05.067 [10] ITOH S, HO J, TURANGAN C, et al. In situ measurement of granular pressure and velocity on component surfaces in stream finishing[C]//International Conference on Advanced Surface Enhancement. Singapore: Springer, 2019: 226-233. [11] 王娜, 杨胜强, 曹波, 等. 主轴式滚磨光整加工参数对加工效果的影响 [J]. 机械设计与制造,2020(5):206-213. doi: 10.3969/j.issn.1001-3997.2020.05.050WANG Na, YANG Shengqiang, CAO Bo, et al. Influence of spindle-type roller grinding and finishing parameters on the machining effect [J]. Machine Design and Manufacture,2020(5):206-213. doi: 10.3969/j.issn.1001-3997.2020.05.050 [12] HASHIMOTO Y, ITO T, NAKAYAMA Y, et al. Fundamental investigation of gyro finishing experimental investigation of contact force between cylindrical workpiece and abrasive media under dry condition [J]. Precision Engineering,2021,67:123-136. doi: 10.1016/j.precisioneng.2020.09.009 [13] MALKORRA I, SOULI H, CLAUDIN C, et al. Identification of interaction mechanisms during drag finishing by means of an original macroscopic numerical model [J]. International Journal of Machine Tools and Manufacture, 2021, 168(Part A): 1-18. [14] CARIAPA V, PARK H, KIM J, et al. Development of a metal removal model using spherical ceramic media in a centrifugal disk mass finishing machine [J]. The International Journal of Advanced Manufacturing Technology,2008,39(1):92-106. [15] TAN K L, NEOH E T, LIFTON J J, et al. Internal measurement of media sliding velocity in a stream finishing bowl [J]. The International Journal of Advanced Manufacturing Technology,2022,120(7):4681-4691. [16] MALKORRA I, SOULI H, SALVATORE F, et al. Numerical modelling of the drag finishing process at a macroscopic scale to optimize surface roughness improvement on additively manufactured (SLM) Inconel 718 parts [J]. Procedia CIRP, 2022, 108: 648-653. [17] 杨胜强, 李文辉, 陈红玲, 等. 表面光整加工理论与新技术[M]. 北京: 国防工业出版社, 2011.YANG Shengqiang, LI Wenhui, CHEN Hongling, et al. Theory and new technology of surface finishing [M]. Beijing: National Defense Industry Press, 2011. [18] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics,1953,24(8):981-988. doi: 10.1063/1.1721448 [19] ARCHARD J F. Friction between metal surfaces [J]. Wear,1986,113(1):3-16. doi: 10.1016/0043-1648(86)90052-9 [20] 桂长林. Archard 的磨损设计计算模型及其应用方法 [J]. 润滑与密封,1990(1):12-21.GUI Changlin. Archard's wear design calculation model and its application method [J]. Lubrication and Seals,1990(1):12-21. [21] 余将, 杨胜强, 李文辉, 等. 主轴式滚磨光整加工中滚筒转速对滚抛磨块群上界面的影响 [J]. 中国科技论文,2018,13(10):1153-1157. doi: 10.3969/j.issn.2095-2783.2018.10.011YU Jiamg, YANG Shengqiang, LI WenHui, et al. Influence of roller speed on the upper interface of roller polishing block group in spindle-type roller polishing process [J]. China Science and Technology Paper,2018,13(10):1153-1157. doi: 10.3969/j.issn.2095-2783.2018.10.011 [22] HASHIMOTO Y, NAKAYAMA Y, FURUMOTO T, et al. Improving finishing efficiency using a cover plate in gyro finishing [J]. Precision Engineering,2022,74:140-146. doi: 10.1016/j.precisioneng.2021.11.004 [23] 王程伟, 李秀红, 李文辉, 等. 主轴式滚磨光整加工中介质流场的数值模拟及作用机理分析 [J]. 表面技术,2018,47(11):251-258. doi: 10.16490/j.cnki.issn.1001-3660.2018.11.036WANG Chengwei, LI Xiuhong, LI Wenhui, et al. Numerical simulation of media flow field in spindle-type roller grinding and finishing process and analysis of the action mechanism [J]. Surface Technology,2018,47(11):251-258. doi: 10.16490/j.cnki.issn.1001-3660.2018.11.036 [24] 李盼菲. 电阻应变测量中提高精度的方法研究 [J]. 计量与测试技术,2019,46(12):62-64. doi: 10.15988/j.cnki.1004-6941.2019.12.020LI Panfei. Research on methods to improve accuracy in resistance-strain measurement [J]. Measurement and Testing Technology,2019,46(12):62-64. doi: 10.15988/j.cnki.1004-6941.2019.12.020 [25] 余航, 舒安庆, 丁克勤. 电阻应变片敏感栅栅丝尺寸对测量精度影响的研究 [J]. 中国仪器仪表,2021(4):71-75. doi: 10.3969/j.issn.1005-2852.2021.04.019YU Hang, SHU Anqing, DING Keqin. Study on the influence of the size of the sensitive grid wire on the measurement accuracy of resistance strain gauges [J]. China Instrumentation,2021(4):71-75. doi: 10.3969/j.issn.1005-2852.2021.04.019 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS