Research progress of 3D printing PDC and PDC bit

-

摘要: PDC钻头已成为油气勘探领域的首选钻头类型,日益提升的PDC钻头性能要求特别是钻进效率要求给钻头制造带来较大挑战。钻头工作面结构改进是PDC钻头实现高效破岩的关键,但这给PDC钻头制造带来难题。3D打印技术是一种新型的快速成形技术,具有制造任意复杂形状结构、个性化定制和创意设计的优点,将3D打印工艺应用于PDC及其钻头的生产是未来发展的必然趋势。本文中介绍了目前用于制备PDC及其钻头的3D打印技术的基本原理,包括光固化成形技术(SLA)、熔融沉积技术(FDM)、激光选区烧结(SLS)、激光选区熔化技术(SLM)和喷墨粘粉式(3DP)等;总结了现有3D打印技术在PDC及其钻头制造方面的研究进展,并对未来3D打印PDC钻头的发展进行了展望。Abstract: PDC bit has become the preferred type of drill bits in the field of oil and gas exploration. The ever-increasing performance requirements of PDC bits, especially the drilling efficiency, have brought great challenges to the drill bits. The improvement of the drill bit working face structure is crucial to the efficient rock breaking of PDC bits. However, this brings great difficulties to the manufacture of drill bits. 3D printing technology is a new type of rapid prototyping technology which has the advantages of manufacturing any complex shape structures, personalized customization and creative design. It is an inevitable trend to apply 3D printing technology to the production of PDC bits. This paper focuses on the basic principles of 3D printing technologies currently used to prepare PDC bits, including photolithography (SLA), fused deposition (FDM), selective laser sintering (SLS), selective laser melting (SLM) and three dimensional printing (3DP), etc. And then it summarizes the research progress of the existing 3D printing technology in the manufacture of PDC and PDC bits, and gives an outlook on the development of 3D printing PDC and PDC bits in the future.

-

Key words:

- 3D printing /

- polycrystalline diamond compacts /

- PDC bit /

- mould forming /

- complex structure

-

表 1 用于制造PDC及其钻头的3D打印技术及其特点[15-21]

Table 1. 3D printing technologies and their characteristics for manufacturing PDC and PDC bits[15-21]

工艺 材料类型 物理形态 几何单元 作用形式 坐标运动 光固化成型(SLA) 光敏树脂 液态

(层厚可小

至16 μm)光斑点(100~200 μm) 紫外激光辐射,光斑范围内树脂发生光子聚合物而固化,激光功率3~5 W 激光束X、Y向,工作台Z向 熔融沉积技术(FDM) 低熔点线材 固态 熔融丝线 喷头电阻加热模块使线材熔化并在挤出喷头后迅速固化 激光束X、Y向,工作台Z向(常见) 激光选区烧结(SLS) 粉末材料 固态

(粒径为

50~100 μm)粉末点 红外激光照射,光斑范围内低熔点粉末发生熔化并在激光束离开后迅速固化,激光功率≥400 W 激光束X、Y向,工作台Z向 激光选区熔化(SLM) 粉末材料 固态

(粒径为

50~100 μm)粉末点 红外激光照射,光斑范围内粉末完全熔化并在激光束离开后迅速固化,激光功率< 1000 W 激光束X、Y向,工作台Z向 喷墨粘粉式(3DP) 粉末材料

(粒径为

50~100 μm)粉末点 利用喷头按指定路径将粘结剂喷在预先铺好的粉层特定区域,完成一个层面的建造 激光束X、Y向,工作台Z向 工艺 获得累积 后处理 优点 缺点 光固化成型(SLA) 液态树脂浸没一层,刮板保证平整,层间内树脂同样发生光子聚合物而固化,并使层间粘结在一起 滤干、烘干、去支撑、再固化等 精度高,表面质量好,原材料利用率高 成形材料少,成本高,且固化过程易收缩形变 熔融沉积技术(FDM) 熔融丝线继续被喷头挤出而沉积,发生固化的同时与上层粘结在一起 去支撑、表面磨抛 技术成熟,成本低,多色彩打印 精度较低,产品具有台阶效应 激光选区烧结(SLS) 粉末材料铺展一层,展辊保证平整,层间内低熔点粉末同样被激光熔化、激光束离开后迅速固化并使层间粘结在一起 吹掉余粉、孔隙致密 成形速度快,成形结构复杂 力学性能差,表面精度差 激光选区熔化(SLM) 粉末材料铺展一层,展辊保证平整,层间内粉末同样被激光完全熔化、激光束离开后迅速固化并使层间粘结在一起 致密提升 表面质量、性能俱佳,成形结构复杂 尺寸有限,力学性能差,表面精度差 喷墨粘粉式(3DP) 粘结剂继续被喷头喷射出而沉积,发生固化的同时与上层粘结在一起 补强处理 成形快,无需支撑材料,可全彩打印 实体强度低,精细度差等 表 2 不同材料质量比和工艺参数条件下的复合材料性能对比

Table 2. Comparisons of performance of composite materials with different raw material ratios at different parameters

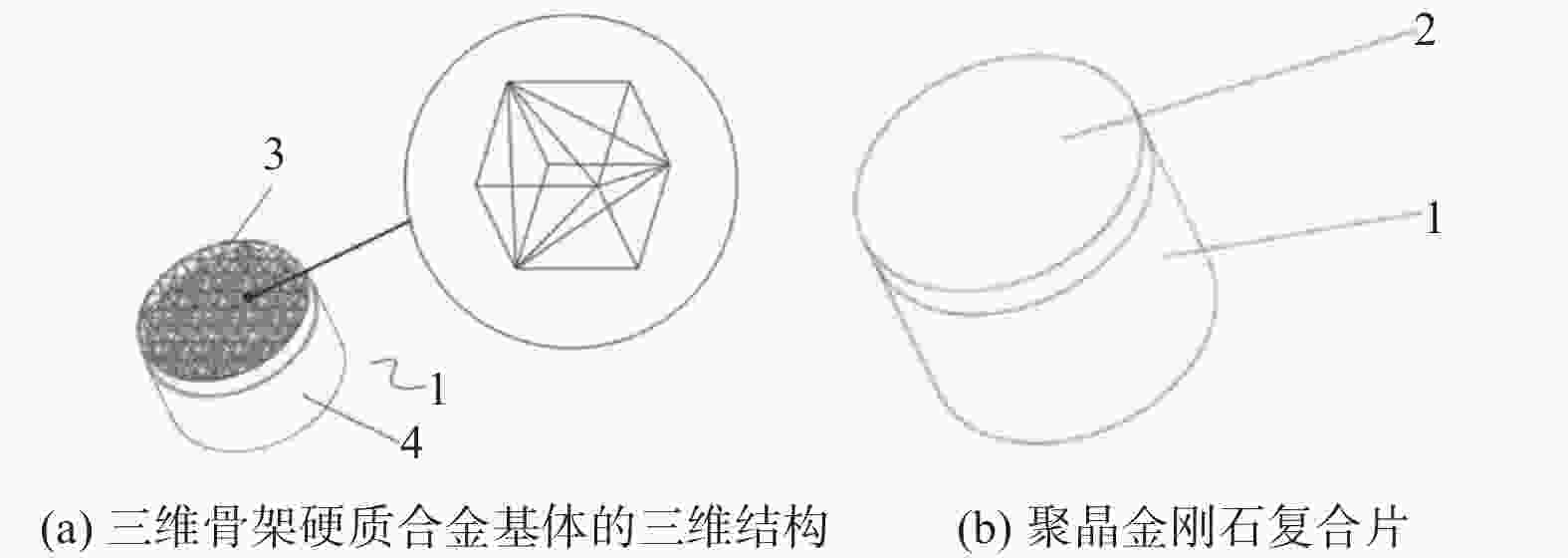

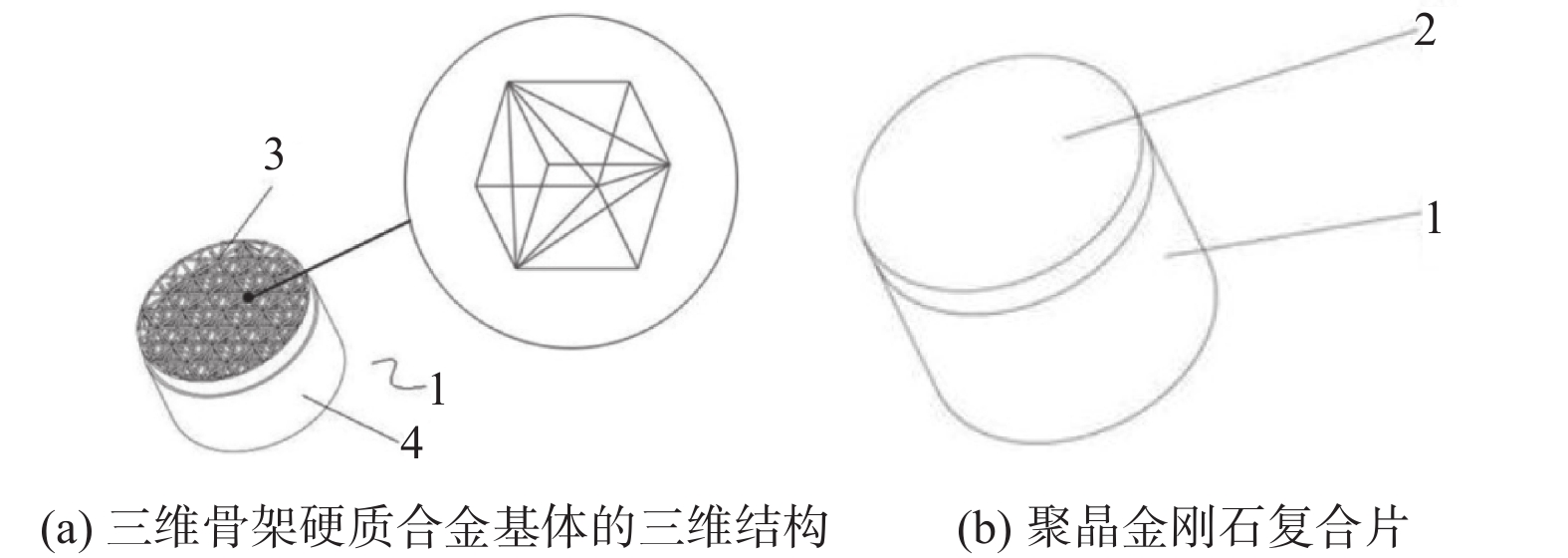

序号 硬质合金 金刚石 复合材料 质量

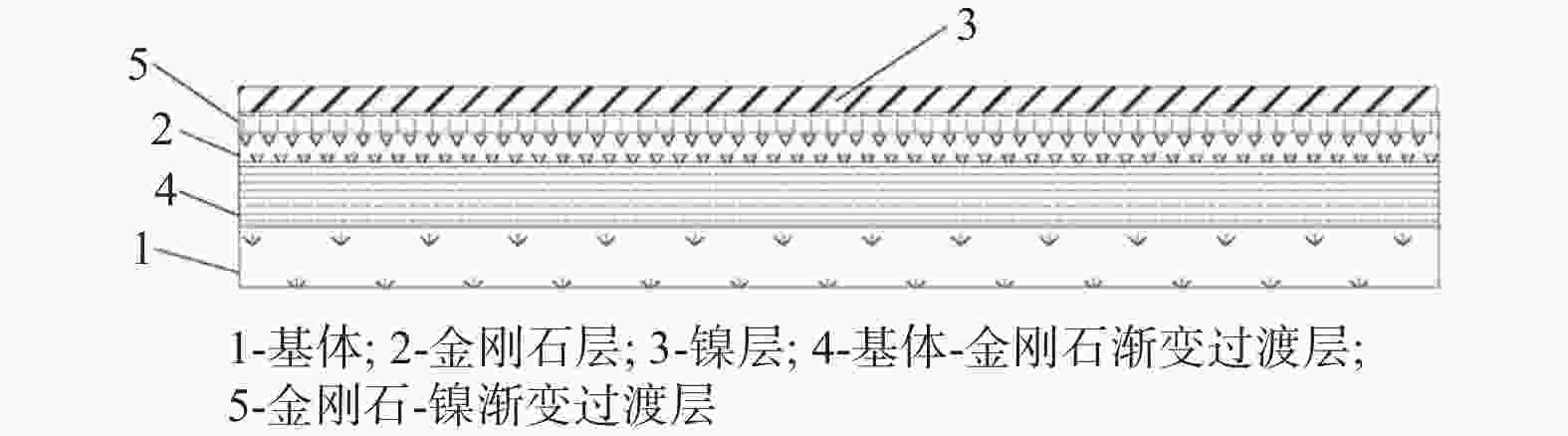

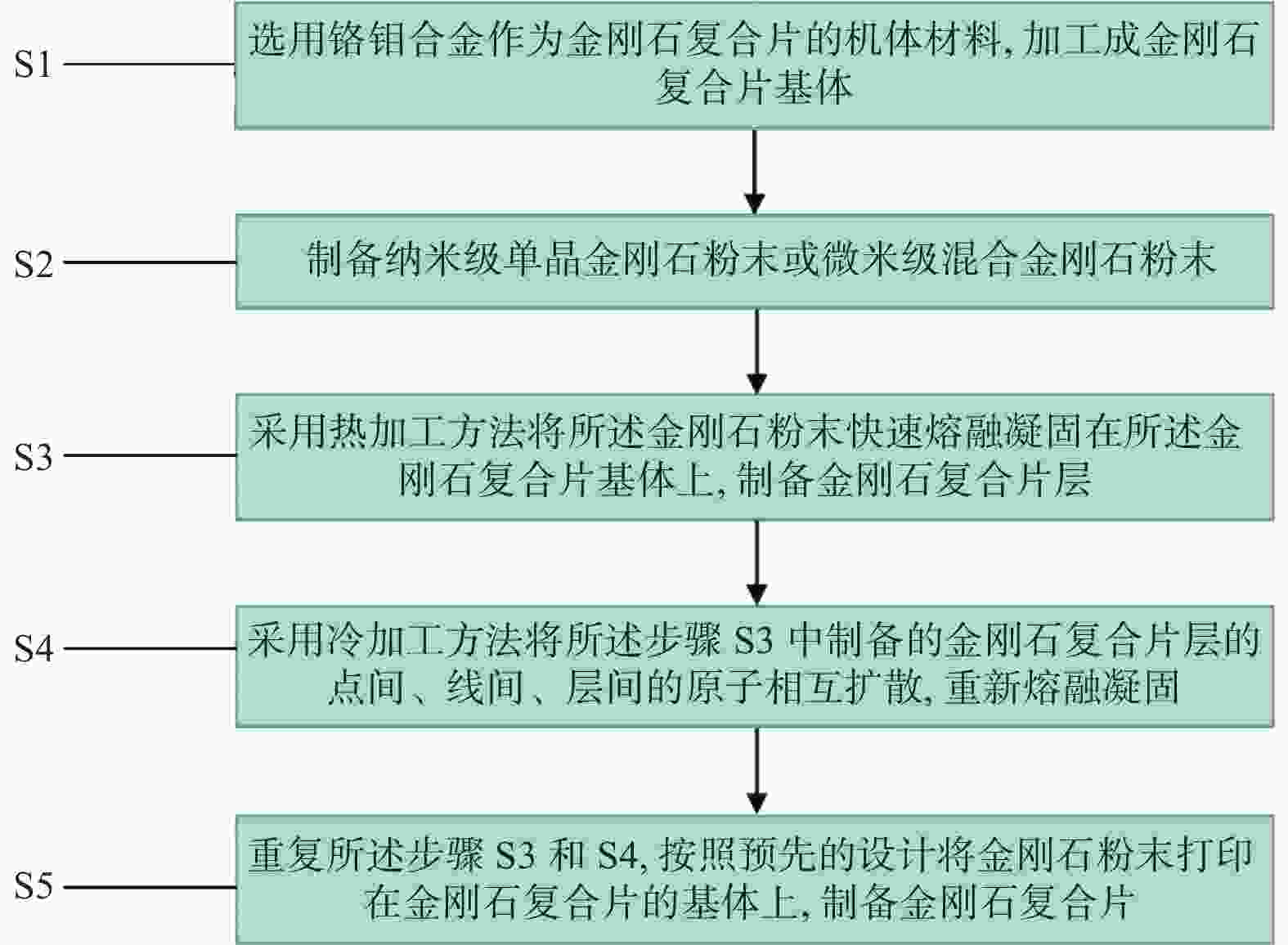

m1

g扫描速率

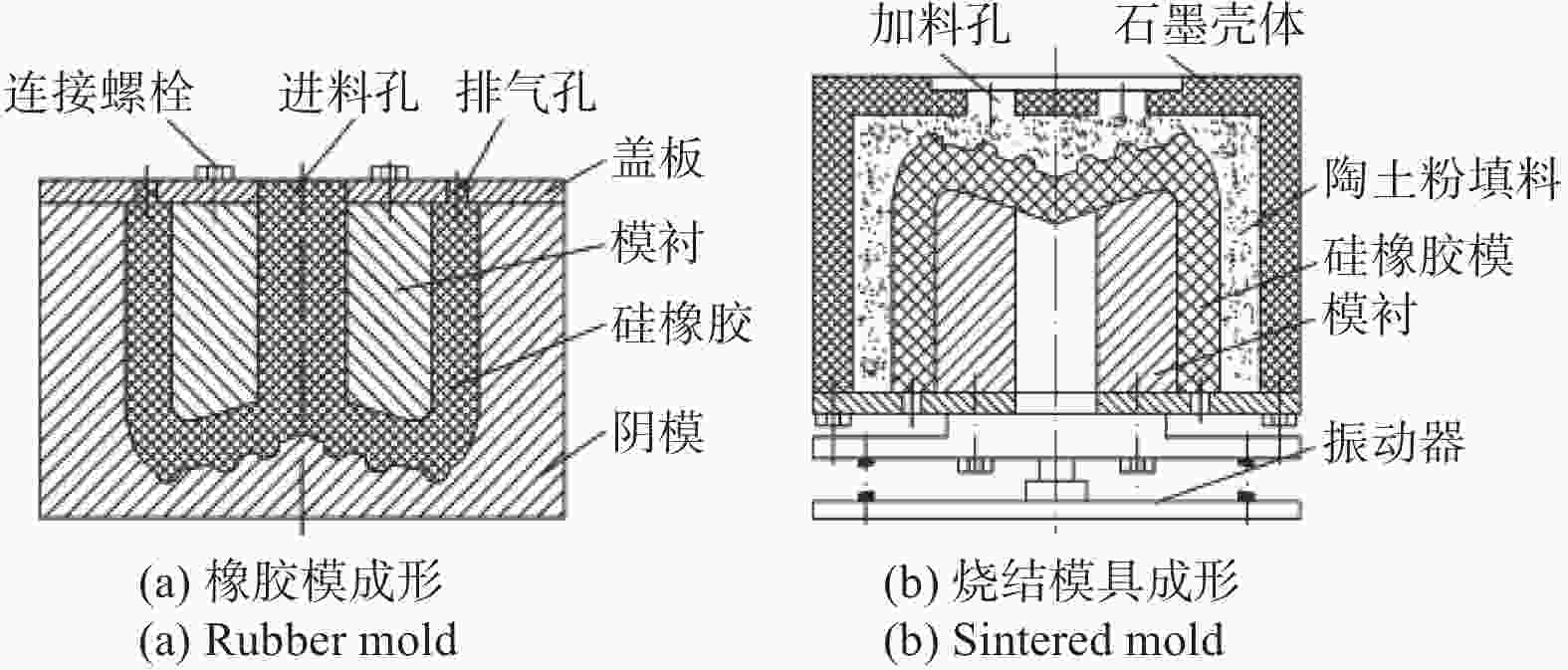

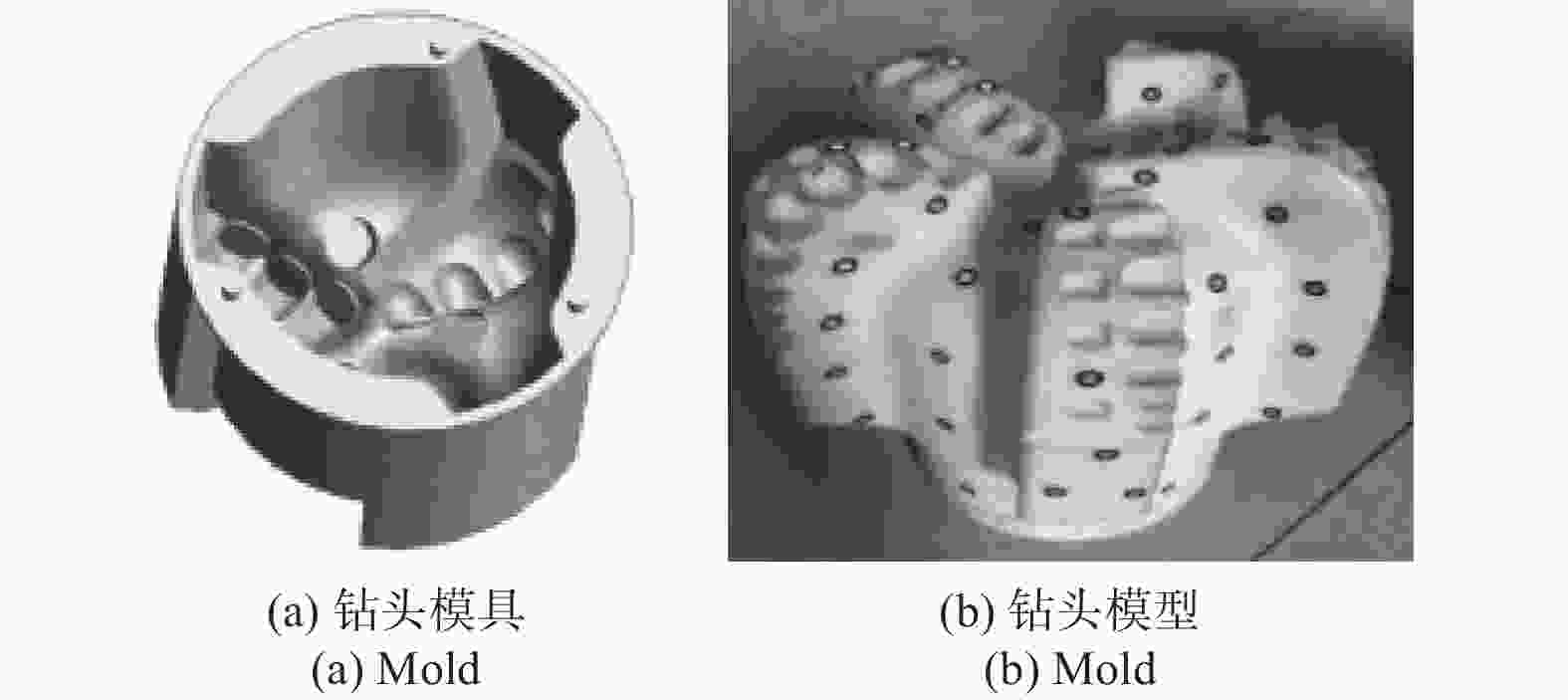

v1

mm·s−1扫描电流

I1

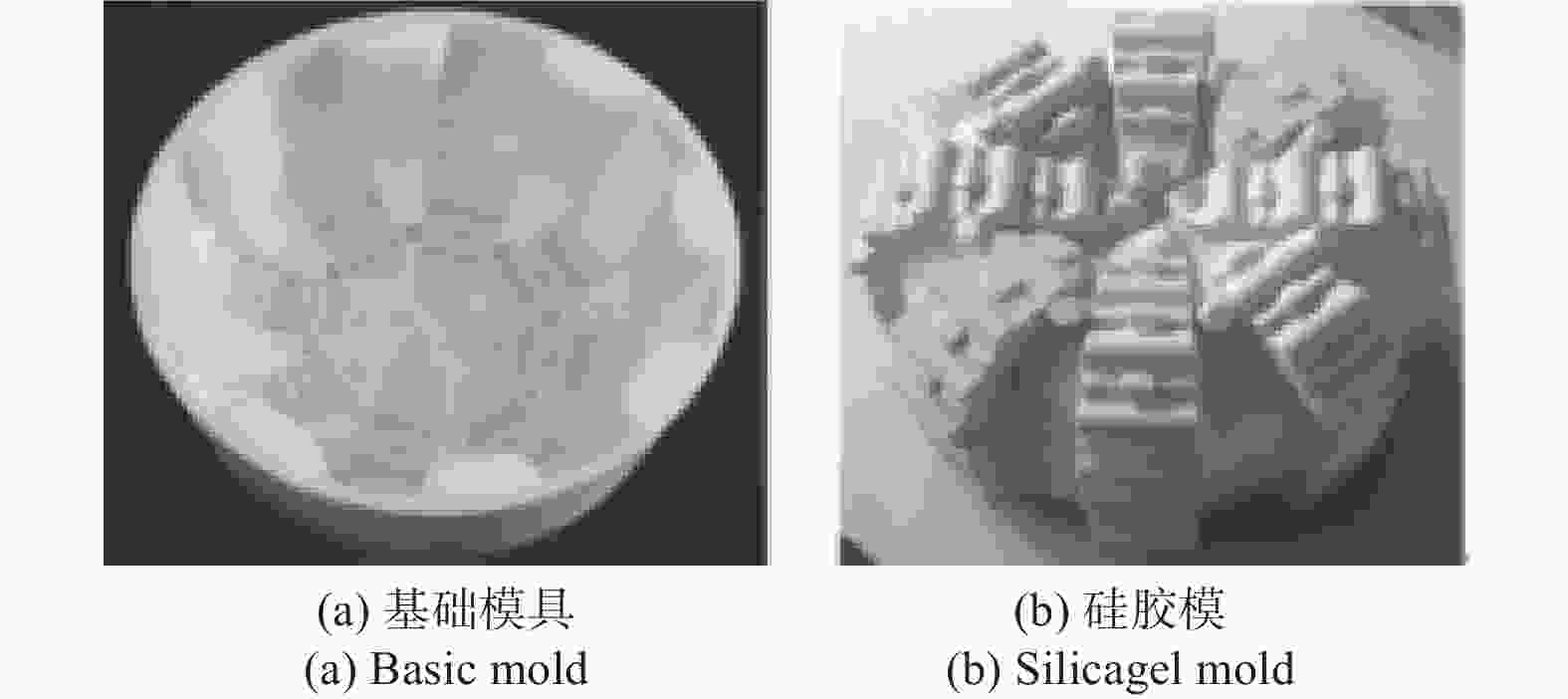

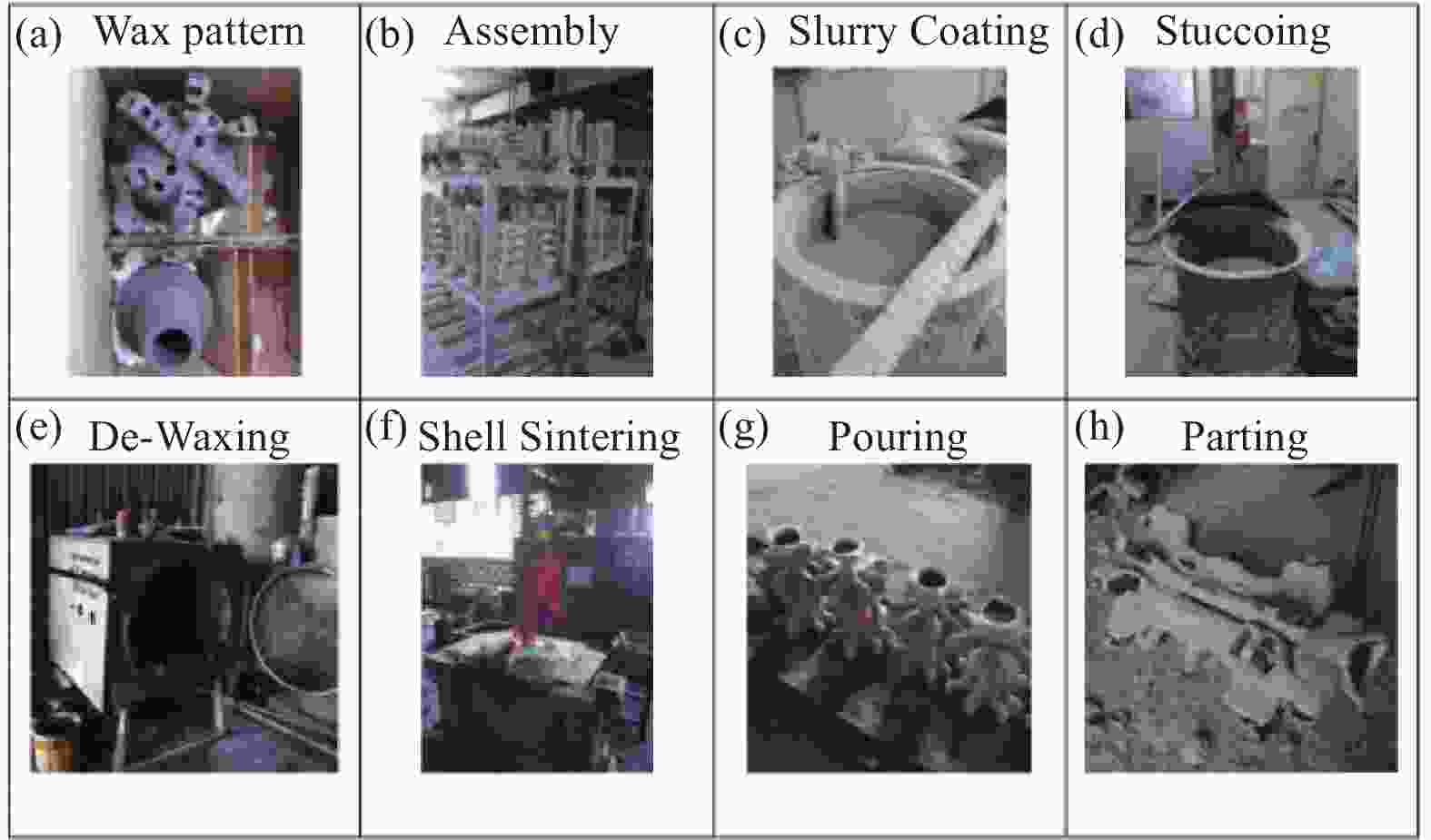

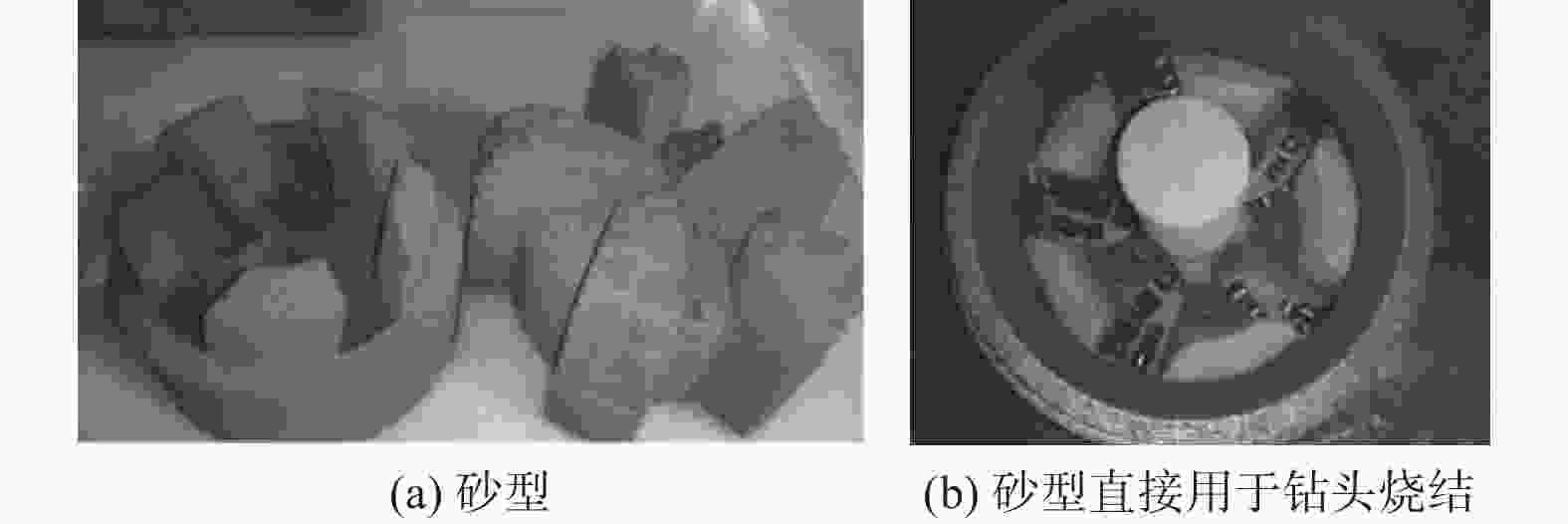

mA融化温度

t1

℃质量

m2

g扫描速率

v2

mm·s−1扫描电流

I2

mA融化温度

t2

℃导热系数

α

W·m−1K−1摩擦系数

f

热膨胀系数

λ

℃−1硬度值

HV冲击韧性

T

J1 858 1.0×104 10 1380 7.0 1.0×104 6 1450 550 0.5 1.18×10−6 5000 300 2 854 6.0×104 10 1400 6.4 6.0×104 2 1460 530 0.4 1.00×10−6 4800 320 3 850 1.0×104 10 1380 6.0 1.0×104 6 1450 500 0.3 0.90×10−6 4900 310 表 3 不同骨架材料和成形工艺条件下的复合片的平均落球冲击次数

Table 3. Average numbers of falling ball impacts on composites with different bones under different parameters

案例 骨架材料 三维骨架基体成形工艺 金刚石微粉填充方法 平均落球冲击次数 案例1 Co-Cr-Mo SLM 过凝胶挤入法 20.6 案例2 Ti6Al4V SLM 过凝胶挤入法 24.8 案例3 Mo SLM 过凝胶挤入法 35.4 案例4 W SLM 过凝胶挤入法 38.2 案例5 WC-Co + Ti6Al4V SLM 过凝胶挤入法 50.4 案例6 WC-Co SLM 过凝胶挤入法 57.6 案例7 WC-Co SLM 振动法 56.8 案例8 WC-Co SLM 溶剂沉积法 57.4 案例9 WC-Co 3DP 溶剂沉积法 55.8 对比例 无骨价 粉末冶金液相 粉末冶金液相烧结 + 高温高压烧结 6.8 -

[1] 左汝强. 国际油气井钻头进展概述(三)—PDC钻头发展进程及当今态势(上) [J]. 探矿工程-岩土钻掘工程,2016,43(3):1-8.ZUO Ruqiang. International advancement of drilling bits for oil and gas well (3)—PDC bits progress and present trend (Ⅰ) [J]. Explortion Engineering (Rock & Soil Drilling and Tunneling),2016,43(3):1-8. [2] 谭凯文. PDC钻头破岩机理实验研究 [D]. 北京: 中国石油大学(北京), 2017.TAN Kaiwen. Study on the rock fragmentation mechanism of PDC bit [D]. Beijing: China University of Petroleum(Beijing), 2017. [3] 黄鹏. PDC钻头切削齿在砾岩层中磨损规律研究 [D]. 荆州: 长江大学, 20211.HUANG Peng. Research on the wear law of PDC bit cutting teeth in conglomerate layer [D]. Jingzhou: Yangtze University, 2021. [4] 张涛, 韩成, 刘贤玉, 等. 油钻井PDC钻头技术应用现状与展望 [J]. 化学工程与装备,2021(12):104-105. doi: 10.19566/j.cnki.cn35-1285/tq.2021.12.045ZHAN Tao, HAN Cheng, LIU Xianyu, et al. Application status and prospect of PDC bit technology in oil drilling [J]. Chemical Engneering & Equipment,2021(12):104-105. doi: 10.19566/j.cnki.cn35-1285/tq.2021.12.045 [5] 谭小红. 一种3D打印制备PDC钻头的工艺: CN111761059A [P]. 2020-10-13.TAN Xiaohong. A 3D printing process for preparing PDC drill bits: CN111761059A [P]. 2020-10-13. [6] 冷静, 沈家伟, 陈林, 等. 基于3D打印技术的复合钻头加工方法研究 [J]. 内江科技,2017,38(1):45-46.LENG Jing, SHEN Jiawei, CHEN Lin, et al. Research on processing method of composite drill based on 3D printing technology [J]. Nei Jiang Science & Technology,2017,38(1):45-46. [7] 张云鹤, 黄景銮, 宋运运, 等. 3D打印金刚石工具的研究进展 [J]. 金刚石与磨料磨具工程,2021,41(3):40-47. doi: 10.13394/j.cnki.jgszz.2021.3.0006ZHANG Yunhe, HUANG Jingluan, SONG Yunyun, et al. Research progress of 3D printing diamond tools[7] [J]. Diamond & Abrasives Engineering,2021,41(3):40-47. doi: 10.13394/j.cnki.jgszz.2021.3.0006 [8] 黄伯云, 韦伟峰, 李松林, 等. 现代粉末冶金材料与技术进展 [J]. 中国有色金属学报,2019,29(9):1917-1933. doi: 10.19476/j.ysxb.1004.0609.2019.09.08HUANG Boyun, WEI Weifeng, LI Songlin, et al. Development of modern powder metallurgy materials and technology [J]. The Chinese Journal of Nonferrous Metals,2019,29(9):1917-1933. doi: 10.19476/j.ysxb.1004.0609.2019.09.08 [9] 朱艳青, 史继富, 王雷雷, 等. 3D打印技术发展现状 [J]. 制造技术与机床,2015(12):50-57. doi: 10.3969/j.issn.1005-2402.2015.12.018ZHU Yanqing, SHI Jifu, WANG Leilei, et al. Current status of the three-dimentional printing technology [J]. Manufacturing Technology & Machine Tool,2015(12):50-57. doi: 10.3969/j.issn.1005-2402.2015.12.018 [10] 张绍和, 唐健, 周侯, 等. 3D打印技术在金刚石工具制造中的应用探讨 [J]. 金刚石与磨料磨具工程,2018,38(2):51-56. doi: 10.13394/j.cnki.jgszz.2018.2.0011ZHANG Shaohe, TANG Jian, ZHOU Hou, et al. Three-dimentional printing in the application of diamond tools manufacturing [J]. Diamond & Abrasives Engineering,2018,38(2):51-56. doi: 10.13394/j.cnki.jgszz.2018.2.0011 [11] STRIUKOVA L, RAYNA T. Adaptivity and rapid prototyping: How 3D printing is changing business model innovation [M]. //VAN DEN BERG B, VAN DEN HOF S, KOSTA E. 3D Printing. Hague: T. M. C. Asser Press, 2016: 167-182. [12] 王忠宏, 李扬帆, 张曼茵. 中国3D打印产业的现状及发展思路 [J]. 经济纵横,2013(1):90-93. doi: 10.16528/j.cnki.22-1054/f.2013.01.019WANG Zhonghong, LI Yangfan, ZHANG Manyin. Current situation and development ideas of China's 3D printing industry [J]. Economic Review,2013(1):90-93. doi: 10.16528/j.cnki.22-1054/f.2013.01.019 [13] URBONAITE G, KIBIRKSTIS E, MILIUNAS V. 3D print technologies analysis [C]// Proceedings of 18th International Conference. Lithuania: Mechanika, 2013: 244-247. [14] 达昱岐, 吕骞. 国务院专题讲座讨论 3D 打印—四类相关概念股再迎发展机遇[EB/OL]. 2015-08-25 [2022-05-22]. http://finance.people.com.cn/stock/n/2015/0825/c67815-27511953.html.DA Yuqi, LYU Qian. State Council lecture discusses 3D printing—Four types of related concept stocks welcome development opportunities[EB/OL]. (2015-08-25) [2022-05-22]. http://finance.people.com.cn/stock/n/2015/0825/c67815-27511953.html. [15] 刘智, 赵永强. 3D打印技术设备的现状与发展 [J]. 锻压装备与制造技术,2020,55(6):7-13. doi: 10.16316/j.issn.1672-0121.2020.06.001LIU Zhi, ZHAO Yongqiang. The current situation and development of 3D printing technology equipment [J]. China Metal Forming Equipment & Manufacturing Technology,2020,55(6):7-13. doi: 10.16316/j.issn.1672-0121.2020.06.001 [16] 孔祥忠. SLA光固化3D打印成型技术研究 [J]. 中国设备工程,2021(11):207-208. doi: 10.3969/j.issn.1671-0711.2021.11.128KONG Xiangzhong. Research on the 3D printing technology—Stereo lithography appearance [J]. China Plant Engineering,2021(11):207-208. doi: 10.3969/j.issn.1671-0711.2021.11.128 [17] 王建宇, 黄国钦. 金刚石磨粒工具增材制造技术现状及展望 [J]. 金刚石与磨料磨具工程,2022,24(3):307-316. doi: 10.13394/j.cnki.jgszz.2022.0007WANG Jianyu, HUANG Guoqin. Review on manufacturing diamond abrasiv tools by additive manufacturing technology [J]. Diamond & Abrasives Engineering,2022,24(3):307-316. doi: 10.13394/j.cnki.jgszz.2022.0007 [18] 王静蕴. 试析国内熔融沉积快速成型技术的发展滞因及未来发展趋势 [J]. 科技经济市场,2020(1):124-126.WANG Jingyun. Analysis of the development delay and future development trend of domestic fused deposition rapid prototyping technology [J]. Science & Technology Ecnony Market,2020(1):124-126. [19] 杨申波. 基于SLS的快速树脂模具技术研究 [D]. 沈阳: 沈阳理工大学, 2013.YANG Shenbo. SLS-based rapid resin mold technology [D]. Shenyang: Shenyang Ligong University, 2013. [20] 蒋浩, 潘涛, 吴文征. 选区激光熔化技术特性及其研究现状 [J]. 科学技术创新,2021(9):9-12. doi: 10.3969/j.issn.1673-1328.2021.09.004JIANG Hao, PAN Tao, WU Wenzheng. Characteristics and research status of selective laser melting technology [J]. Scientific and Technologica Innovation,2021(9):9-12. doi: 10.3969/j.issn.1673-1328.2021.09.004 [21] 王延庆, 沈竞兴, 吴海全. 3D打印材料应用和研究现状 [J]. 航空材料学报,2016,36(4):89-98. doi: 10.11868/j.issn.1005-5053.2016.4.013WANG Yanqing, SHEN Jingxing, WU Haiquan. Application and research status of alternative materials for 3D-printing technology [J]. Journal of Aeronautical Materials,2016,36(4):89-98. doi: 10.11868/j.issn.1005-5053.2016.4.013 [22] 刘丹. 一种硬质合金-金刚石复合材料及其制备方法: CN110042292A [P]. 2019-07-23.LIU Dan. A kind of cemented carbide-diamond composite material and its preparation method: CN110042292A [P]. 2019-07-23. [23] 倪培燊, 邓欣, 赵哲, 等. 带有三维骨架硬质合金基体的聚晶金刚石复合片制备方法: CN109954883A [P]. 2019-07-02.NI Peishen, DENG Xin, ZHAO Zhe, et al. Preparation method of polycrystalline diamond composite sheet with three-dimensional skeleton cemented carbide matrix: CN109954883A [P]. 2019-07-02. [24] 梁家昌, 郑震, 李涛. 一种金刚石复合片及其3D打印方法: CN110374516A [P]. 2019-10-25LIANG Jiachang, ZHENG Zhen, LI Tao. A kind of diamond compact and its 3D printing method: CN110374516A [P]. 2019-10-25. [25] 梁家昌, 郑震, 李涛. 一种高品质金刚石复合片及其制备方法: CN110143021A [P]. 2019-10-25.LIANG Jiachang, ZHENG Zhen, LI Tao. A kind of high-quality diamond composite and its preparation method: CN110374516A [P]. 2019-10-25. [26] 李锁智. 3D打印技术在PDC钻头模具成型中的应用 [J]. 煤矿机械,2015,36(8):277-280. doi: 10.13436/j.mkjx.201508108LI Suozhi. Application of 3D printing technology in molding of PDC drill bit [J]. Coal Mine Machinery,2015,36(8):277-280. doi: 10.13436/j.mkjx.201508108 [27] SOUTHLAND S G . Rapid manufacturing of molds for forming drill bits: US6353771B1 [P]. 1996-07-22. [28] 游娜, 樊春明, 段树军, 等. 增材制造技术在井下工具中应用及问题分析 [J]. 石油矿场机械,2021,50(1):62-68. doi: 10.3969/j.issn.1001-3482.2021.01.009YOU Na, FAN Chunming, DUAN Shujun, et al. Application and problem analysis of additive manufacturing in downhole tools [J]. Oil Field Equipment,2021,50(1):62-68. doi: 10.3969/j.issn.1001-3482.2021.01.009 [29] 周龙昌. 胎体PDC钻头烧结模具快速成型新工艺 [J]. 石油机械,2005,33(2):27-28. doi: 10.3969/j.issn.1001-4578.2005.02.009ZHOU Longchang. A new manufacture process of the mould for matrix PDC bits [J]. China Petroleum Machinery,2005,33(2):27-28. doi: 10.3969/j.issn.1001-4578.2005.02.009 [30] 周龙昌, 于凤兰. 激光快速成型技术在胎体PDC钻头制造中的应用 [J]. 石油钻探技术,2005,33(2):44-45. doi: 10.3969/j.issn.1001-0890.2005.02.013ZHOU Longchang, YU Fenglan. Appliction of rapid laser shaping technique to making PDC bits with matrix body [J]. Petroleum Drilling Techniques,2005,33(2):44-45. doi: 10.3969/j.issn.1001-0890.2005.02.013 [31] 梅筱琴, 殷国富, 徐进, 等. 基于FDM工艺的胎体式PDC钻头基础母模快速成型技术 [J]. 钻采工艺,2012,35(2):57-59. doi: 10.3969/J.ISSN.1006-768X.2012.02.18MEI Xiaoqin, YIN Guofu, XU Jin, et al. Rapid manufacturing of the master models of PDC bit based on FDM technology [J]. Drilling & Production Technology,2012,35(2):57-59. doi: 10.3969/J.ISSN.1006-768X.2012.02.18 [32] 贺子延, 杨凤申, 刘坤, 等. 物探钻头快速设计制造平台的探索 [J]. 物探装备,2014,24(3):160-163.HE Ziyan, YANG Fengshen, LIU Kun, et al. A platform for rapidly developing and of producing seismic exploration drilling bit [J]. Quipment for Geophysical Prospecting,2014,24(3):160-163. [33] CHOU Z J. Prototype manufacturability of PDC drill bit body using sacrificial patterns with wax materials and using 3D printing technology [D]. Malaysia: Universiti Teknologi Petronas, 2014. [34] 姚建林, 李勇, 冯明, 等. PDC钻头模具3D打印制作方法: CN106735192A [P]. 2017-05-31.YAO Jianlin, LI Yong, FENG Ming, et al. A 3D printing production method for PDC bit mold: CN106735192A [P]. 2017-05-31. [35] 王秋涛, 杨恬恬, 屈晨光. 一种PDC钻头模具及其制备方法: CN 112876250A [P]. 2021-06-01.WANG Qiutao, YANG Tiantian, QU Chenguang. A kind of PDC bit mould and its preparation method: CN 112876250A [P]. 2021-06-01. [36] 贺波, 赵润琦, 于振忠, 等. 一种3d打印技术PDC钻头及其制造方法: CN111456641A [P]. 2020-07-28.HE Bo, ZHAO Runqi, YU Zhenzhong, et al. A PDC drill bit and its 3D printing manufacturing method: CN111456641A [P]. 2020-07-28. [37] 石一先. 一种PDC钻头体的3D打印制造方法 : CN107498050A [P]. 2017-12-22.SHI Yixian. A 3D printing manufacturing method for the PDC drill body: CN107498050A [P], 2017-12-22. [38] 亓东霞. 3D打印技术用于PDC钻头设计制造 [J]. 石油钻探技术,2014,42(3):1.QI Dongxia. 3D printing technology for the design and manufacture of PDC drill bits [J]. Petroleum Drilling Techniques,2014,42(3):1. [39] 杨金华, 郭晓霞. PDC钻头技术发展现状与展望 [J]. 石油科技论坛,2018,37(1):33-38. doi: 10.3969/j.issn.1002-302x.2018.01.008YANG Jinhua, GUO Xiaoxia. The present status and outlook of PDC bit technology [J]. Petroleum Science and Technology Forum,2018,37(1):33-38. doi: 10.3969/j.issn.1002-302x.2018.01.008 [40] ASM International. Digital drill bit for 3D printing modeled [EB /OL]. (2014-01-03)[2022-05-22]. https://www.asminternational.org/news/industry/-/journal_content/56/10180/16266943,2014. [41] 徐跃华, 王巍雄. 一种3D打印PDC胎体钻头的接头结构: CN209324263U [P]. 2019-08-30.XU Yuehua, WANG Weixiong. A joint structure of a 3D printed PDC matrix drill bit: CN209324263U [P]. 2019-08-30. [42] Q/SEED-CBAX005-2019.3D打印PDC金刚石钻头 [S]. 株洲: 西迪技术股份有限公司, 2019.Seed Technologies Corp. , Ltd. Enterprise Standard of Seed Technologies Corp. , Ltd: 3D Printing PDC Diamond Bits: Q/SEED-CBAX005-2019. [S]. Zhuzhou: Seed Technologies Corp. , Ltd. 2020: 1. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS