Study on lapping performance of agglomerated diamond abrasive

-

摘要:

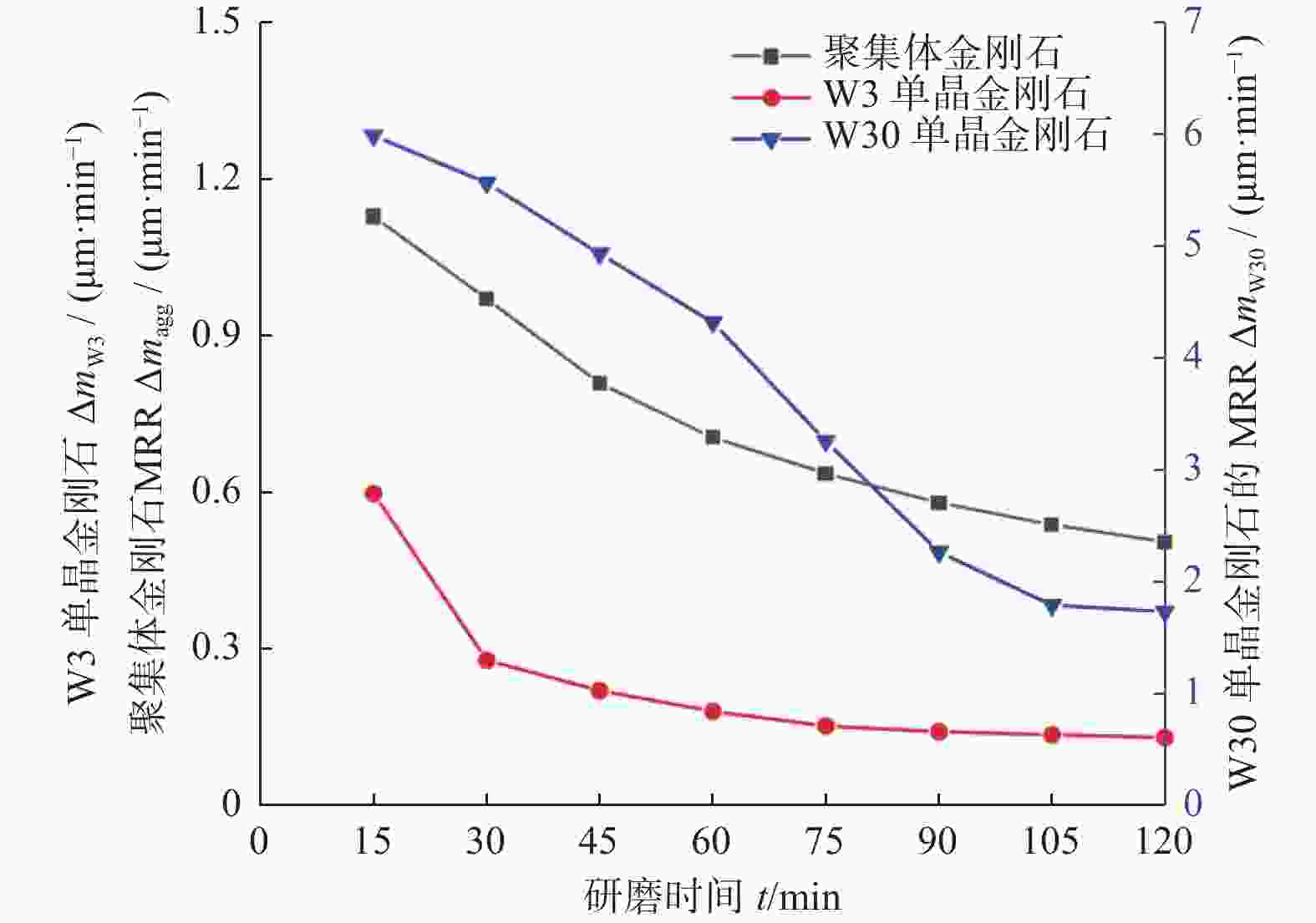

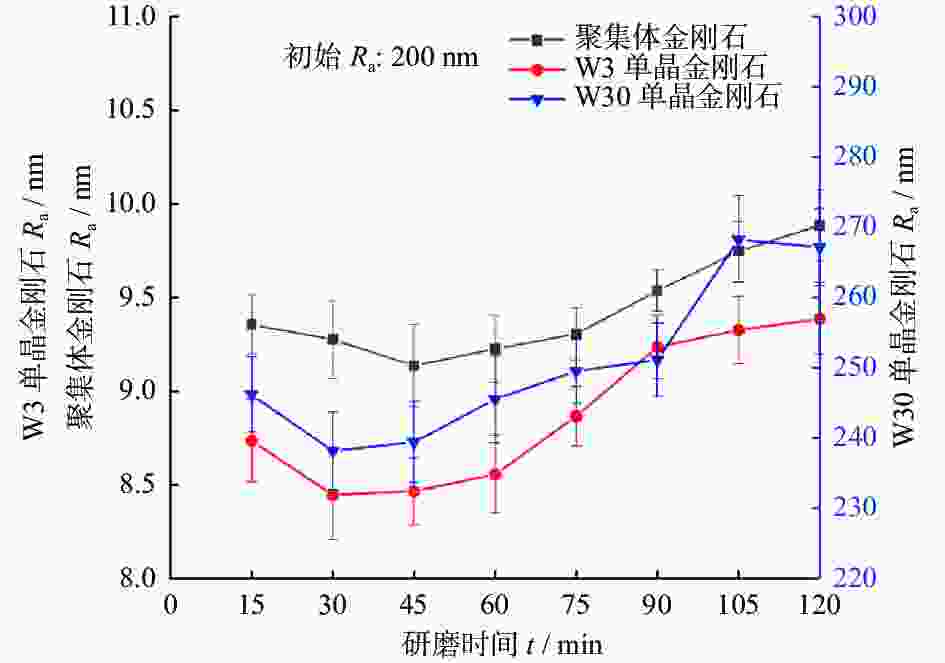

为实现蓝宝石等硬脆材料的高效率、低表面粗糙度研磨加工,提出利用陶瓷结合剂和微细金刚石磨料(粒径3 μm)烧结制成聚集体金刚石磨料(平均粒径30 μm)进行研磨加工新工艺。通过与3 μm和30 μm等2种单晶金刚石磨料对蓝宝石基片进行研磨加工对比实验,系统研究聚集体金刚石磨料的研磨性能。结果表明:聚集体金刚石磨料具有较高的材料去除率,相同条件下聚集体金刚石磨料加工15 min时材料去除率为1.127 μm/min;聚集体金刚石磨料具有较好的加工稳定性,研磨120 min时材料去除率为0.483 μm/min,相比于加工15 min时下降57.14%,而3 μm单晶金刚石磨料则下降78.02%;聚集体金刚石磨料与3 μm单晶金刚石磨料研磨蓝宝石的表面粗糙度相近,分别为Ra 9.45 nm和Ra 8.75 nm,远低于30 μm单晶金刚石磨料的Ra 246 nm。聚集体金刚石磨料能实现低加工表面粗糙度和高材料去除率的机理可以归纳为:多磨粒微刃产生去除作用可以获得低表面粗糙度,同时具有自锐性,提高材料去除效率并保证加工过程的稳定。

Abstract:[OBJECTIVES] Grinding is one of the ultraprecision machining methods for efficiently thinning and flattening hard and brittle materials such as sapphire. However, traditional grinding processes cannot meet the requirements for high material removal rates and high surface quality simultaneously. Exploring the use of aggregated diamond abrasives and their corresponding processing methods is beneficial for achieving efficient and stable high-quality grinding of hard and brittle materials.

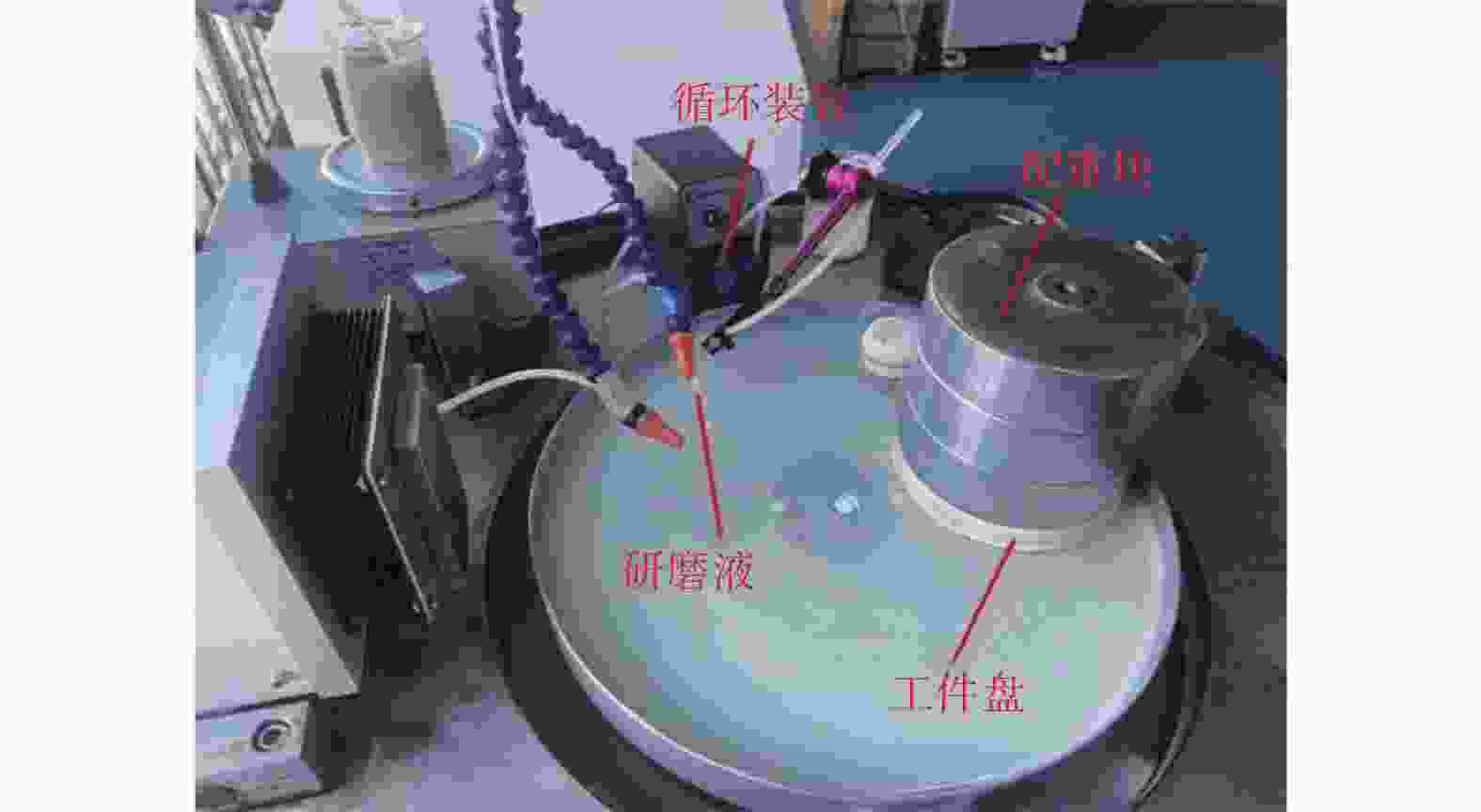

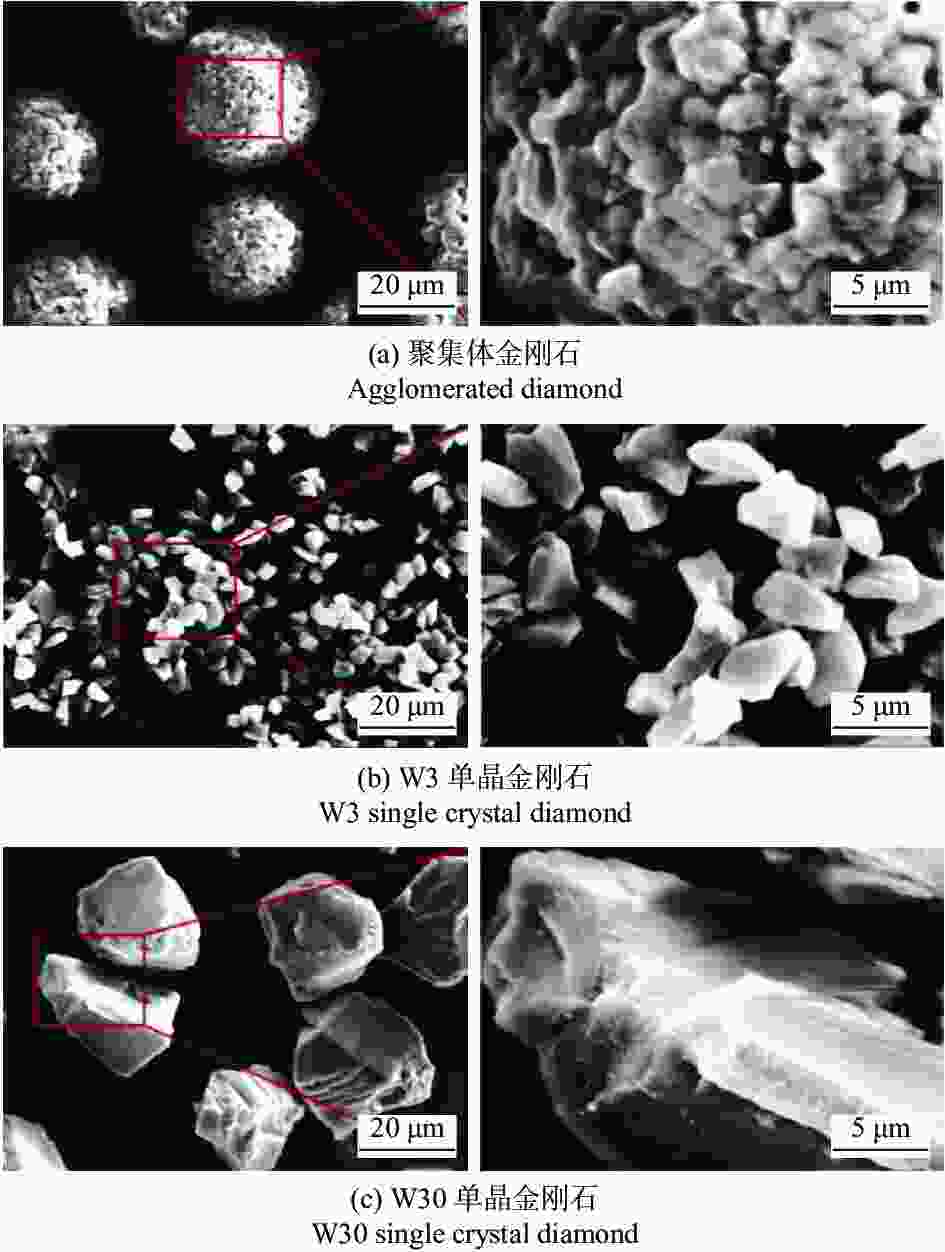

[METHODS] A novel process was proposed, using ceramic binders and fine diamond abrasives (grain size 3 μm) sintered to form aggregated diamond abrasives (average grain size 30 μm) for grinding purposes. Comparative grinding experiments were conducted on sapphire substrates using the prepared aggregated diamond abrasives and single-crystal diamond abrasives with grain sizes of 3 μm and 30 μm. The grinding performance of the aggregated diamond abrasives was systematically investigated, and a material removal model was established to further reveal the material removal mechanism during processing with these abrasives.

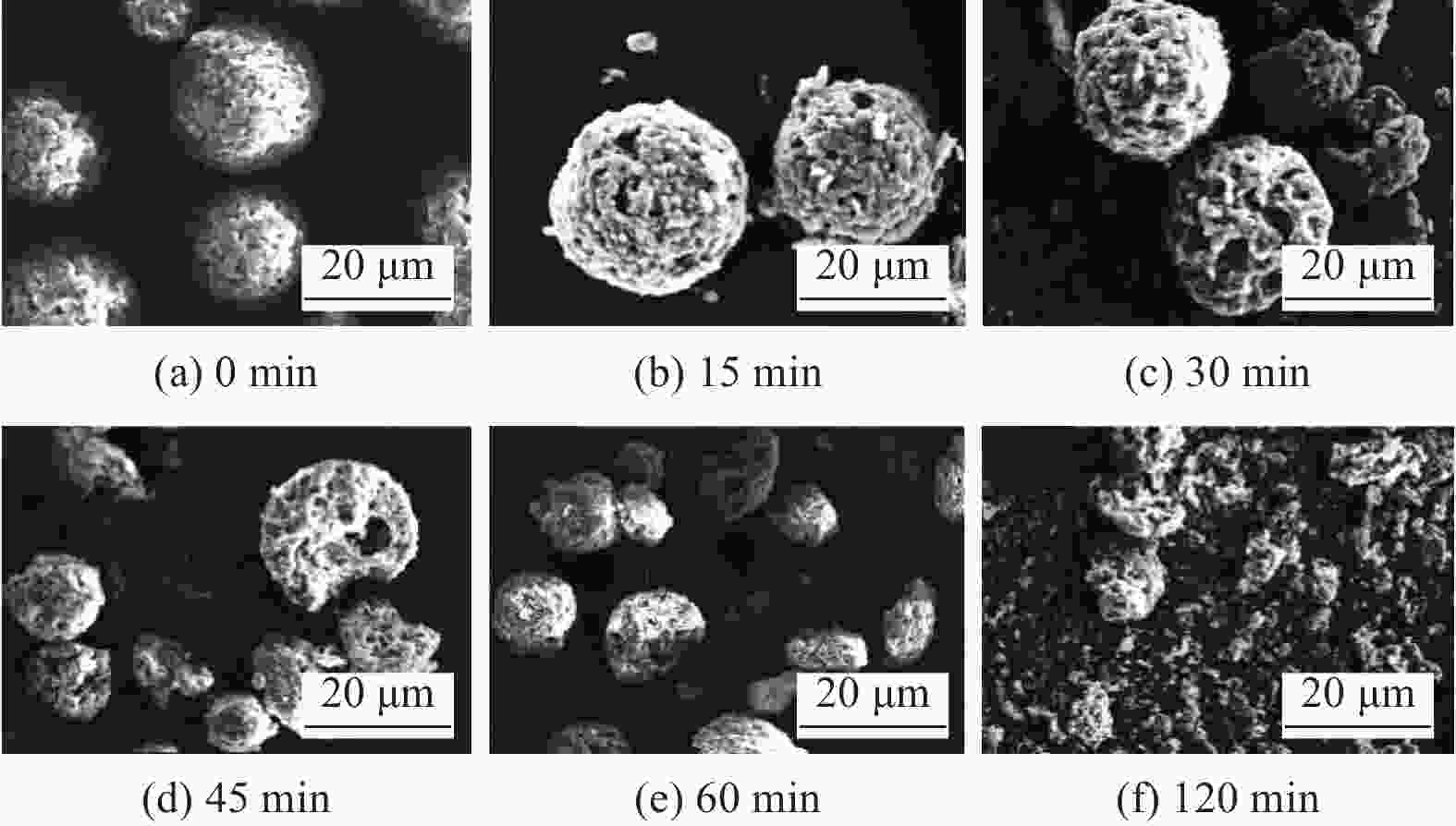

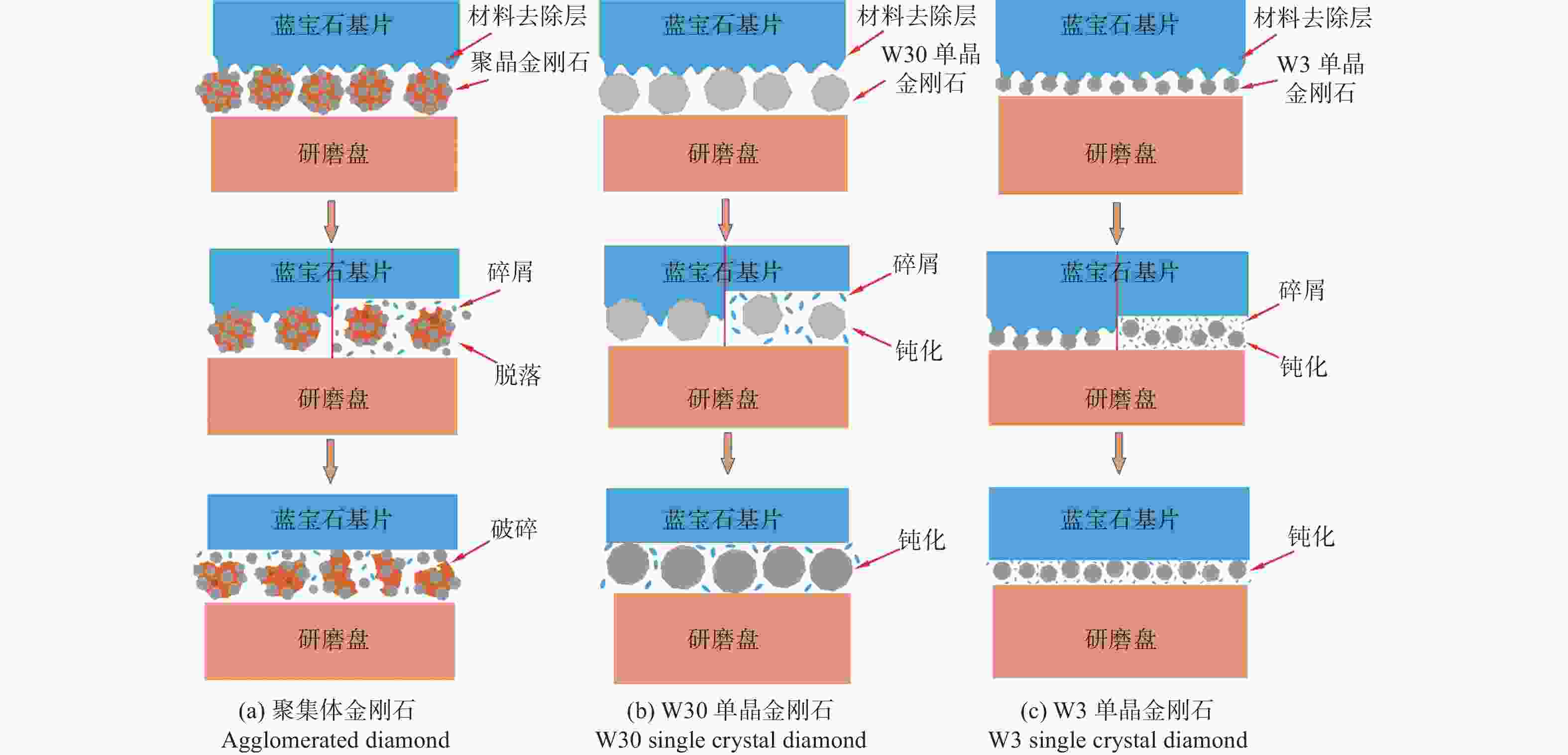

[RESULTS] (1) Aggregated diamond abrasives exhibited a higher material removal rate. Under the same conditions, grinding with aggregated diamond abrasives for 15 minutes achieved a material removal rate of 1.127 μm/min, an 89.1% increase compared to using 3 μm single-crystal diamond abrasives. (2) Aggregated diamond abrasives demonstrated superior processing stability. Over a 120-minute processing cycle, their material removal rate showed the least reduction, with a rate of 0.483 μm/min after 120 minutes, marking a 57.14% decrease from the rate at 15 minutes. In comparison, the material removal rates of 3 μm and 30 μm single-crystal diamond abrasives decreased by 78.02% and 71.2%, respectively. (3) Aggregated diamond abrasives resulted in better surface quality. The lowest surface roughness Ra after grinding with aggregated diamond abrasives and 3 μm single-crystal diamond abrasives were 9.45 nm and 8.75 nm, respectively, while using 30 μm single-crystal diamond abrasives yielded a lowest Ra of 246 nm. (4) The wear and removal patterns of aggregated abrasives during processing differed from those of single-crystal diamond abrasives. The latter’s wear was through abrasion dulling, characterized by chipping, flattening, and abrasive wear of the cutting edges. In contrast, the aggregated diamond abrasives underwent micro-fracturing, characterized by the shedding of micro-fine single-crystals from the abrasive surface and the binder network disintegration. Statistical analysis of the particle size distribution of the grinding fluid during the grinding process revealed that after 30 minutes of grinding, the particle size distribution curve of aggregated diamond abrasives shifted to the left, with a 51.5% decrease in peak volume fraction. The change in the abrasive particle size distribution curve was relatively small. At the same time, a trapezoidal peak composed of abrasion debris and detached micro-fine single-crystal abrasives formed on the left side of the curve. In contrast, a significant leftward shift was observed in the curve for 30 μm single-crystal diamond abrasives, with the peak volume fraction decreasing by 82.8%. The change in the abrasive particle size distribution curve was relatively large, forming a low peak wave on the left side of the curve. Aggregated diamond abrasives employed a multi-edge cutting method, primarily relying on multiple micro-fine single-crystal diamond grains on the surface to remove material from the workpiece. In contrast, single-crystal diamond abrasives engaged in single-edge cutting, mainly relying on the edges and corners of the abrasive for material removal.

[CONCLUSION] During the grinding process, aggregated diamond abrasives remove material from the workpiece surface through the combined action of multiple micro-fine single-crystal diamond grains on the surface layer. This ensures consistency in cutting depth and enhances surface quality. Under the impact and compression between the workpiece and the grinding disc, the aggregated diamond grains undergo abrasive wear and micro-fracturing, exposing the micro-fine diamond grains encapsulated within the binder and achievi ng cutting edge renewal and self-sharpening. This leads to higher efficiency and more stable processing capability. Therefore, the multi-edge cutting and micro-fracturing characteristics of aggregated diamond abrasives enable the efficient, stable, and high-quality grinding of sapphire substrates.

-

表 1 金刚石磨料参数

Table 1. Diamond abrasive parameters

型号 粒径范围 d / μm 种类 W3 2~4 单晶金刚石 W30 20~40 单晶金刚石 聚集体金刚石 20~40 (类)多晶金刚石 -

[1] SEO J, KIM T, LEE H. Effect of free abrasives on material removal in lap grinding of sapphire substrate [J]. Tribology and Lubricants,2018,34(6):209-216. [2] CHUNG C, KORACH C S, KAO I. Experimental study and modeling of lapping using abrasive grits with mixed sizes [J]. Journal of Manufacturing Science and Engineering,2011,133(3):031006. doi: 10.1115/1.4004137 [3] BHAGAVAT S, LIBERATO J C, CHUNG C, et al. Effects of mixed abrasive grits in slurries on free abrasive machining (FAM) processes [J]. International Journal of Machine Tools and Manufacture,2010,50(9):843-847. doi: 10.1016/j.ijmachtools.2010.04.006 [4] NIU F, WANG K, SUN T, et al. Lapping performance of mixed-size agglomerated diamond abrasives in fixed abrasives pads [J]. Diamond and Related Materials,2021,118:108499. doi: 10.1016/j.diamond.2021.108499 [5] ZHANG L, ZHU L, ZHOU T, et al. Study on the grinding characteristics of sapphire with the assistant of cerium oxide liquid [J]. Materials & Design,2022,215:110451. doi: 10.1016/j.matdes.2022.110451 [6] HU X, SONG Z, PAN Z, et al. Planarization machining of sapphire wafers with boron carbide and colloidal silica as abrasives [J]. Applied Surface Science,2009,255(19):8230-8234. doi: 10.1016/j.apsusc.2009.05.056 [7] XU Y, LU J, XU X. Study on planarization machining of sapphire wafer with soft-hard mixed abrasive through mechanical chemical polishing [J]. Applied Surface Science,2016,389:713-720. doi: 10.1016/j.apsusc.2016.07.155 [8] CHEN J, ZHU Y, PENG Y, et al. Silica-assisted fixed agglomerated diamond abrasive polishing [J]. Journal of Manufacturing Processes,2020,59:595-603. doi: 10.1016/j.jmapro.2020.09.013 [9] HUANG S, LI X, ZHAO Y, et al. A novel lapping process for single-crystal sapphire using hybrid nanoparticle suspensions [J]. International Journal of Mechanical Sciences,2021,191:106099. doi: 10.1016/j.ijmecsci.2020.106099 [10] ZHANG B, LEI H, CHEN Y. Preparation of Ag2O modified silica abrasives and their chemical mechanical polishing performances on sapphire [J]. Friction,2017,5(4):429-436. doi: 10.1007/s40544-017-0156-8 [11] CHEN J, SUN T, SU J, et al. A novel agglomerated diamond abrasive with excellent micro-cutting and self-sharpening capabilities in fixed abrasive lapping processes [J]. Wear,2021,464-465:203531. doi: 10.1016/j.wear.2020.203531 [12] 邹芹, 向刚强, 王瑶, 等. 聚晶金刚石的研究进展与展望 [J]. 金刚石与磨料磨具工程,2021,41(3):23-32. doi: 10.13394/j.cnki.jgszz.2021.3.0004ZOU Qin, XIANG Gangqiang, WANG Yao, et al. Research progress and prospect of polycrystalline diamond [J]. Diamond & Abrasives Engineering,2021,41(3):23-32. doi: 10.13394/j.cnki.jgszz.2021.3.0004 [13] 朱永伟, 沈琦, 王子琨, 等. 多晶金刚石固结磨料研磨垫精研石英玻璃的性能探索 [J]. 红外与激光工程,2016,45(10):26-31. doi: 10.3788/IRLA201645.1003003ZHU Yongwei, SHEN Qi, WANG Zikun, et al. Lapping performance on quartz glass of fixed abrasive pad embedded with multi-grain diamond grits [J]. Infrared and Laser Engineering,2016,45(10):26-31. doi: 10.3788/IRLA201645.1003003 [14] WANG Z, NIU F, ZHU Y, et al. Comparison of lapping performance between fixed agglomerated diamond pad and fixed single crystal diamond pad [J]. Wear,2019,432/433:202963. doi: 10.1016/j.wear.2019.202963 [15] SHI H, RING T A. CMP pad wear and polish-rate decay modeled by asperity population balance with fluid effect [J]. Microelectronic Engineering,2010,87(11):2368-2375. doi: 10.1016/j.mee.2010.04.010 [16] ANDERSON D, WARKENTIN A, BAUER R. Comparison of spherical and truncated cone geometries for single abrasive-grain cutting [J]. Journal of Materials Processing Technology,2012,212(9):1946-1953. doi: 10.1016/j.jmatprotec.2012.04.021 [17] BOZKAYA D, MÜFTÜ S. A material removal model for CMP based on the contact mechanics of pad, abrasives, and wafer [J]. Journal of the Electrochemical Society,2009,156(12):H890. doi: 10.1149/1.3231691 [18] CHEN J, ZHU Y, WANG J, et al. Relationship between mechanical properties and processing performance of agglomerated diamond abrasive compared with single diamond abrasive [J]. Diamond and Related Materials,2019,100:107595. doi: 10.1016/j.diamond.2019.107595 [19] MATSUO T, TOYOURA S, OSHIMA E, et al. Effect of grain shape on cutting force in superabrasive single-grit tests [J]. CIRP Annals - Manufacturing Technology,1989,38(1):323-326. doi: 10.1016/S0007-8506(07)62714-0 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS