Precision pressing technology of four-column press

-

摘要:

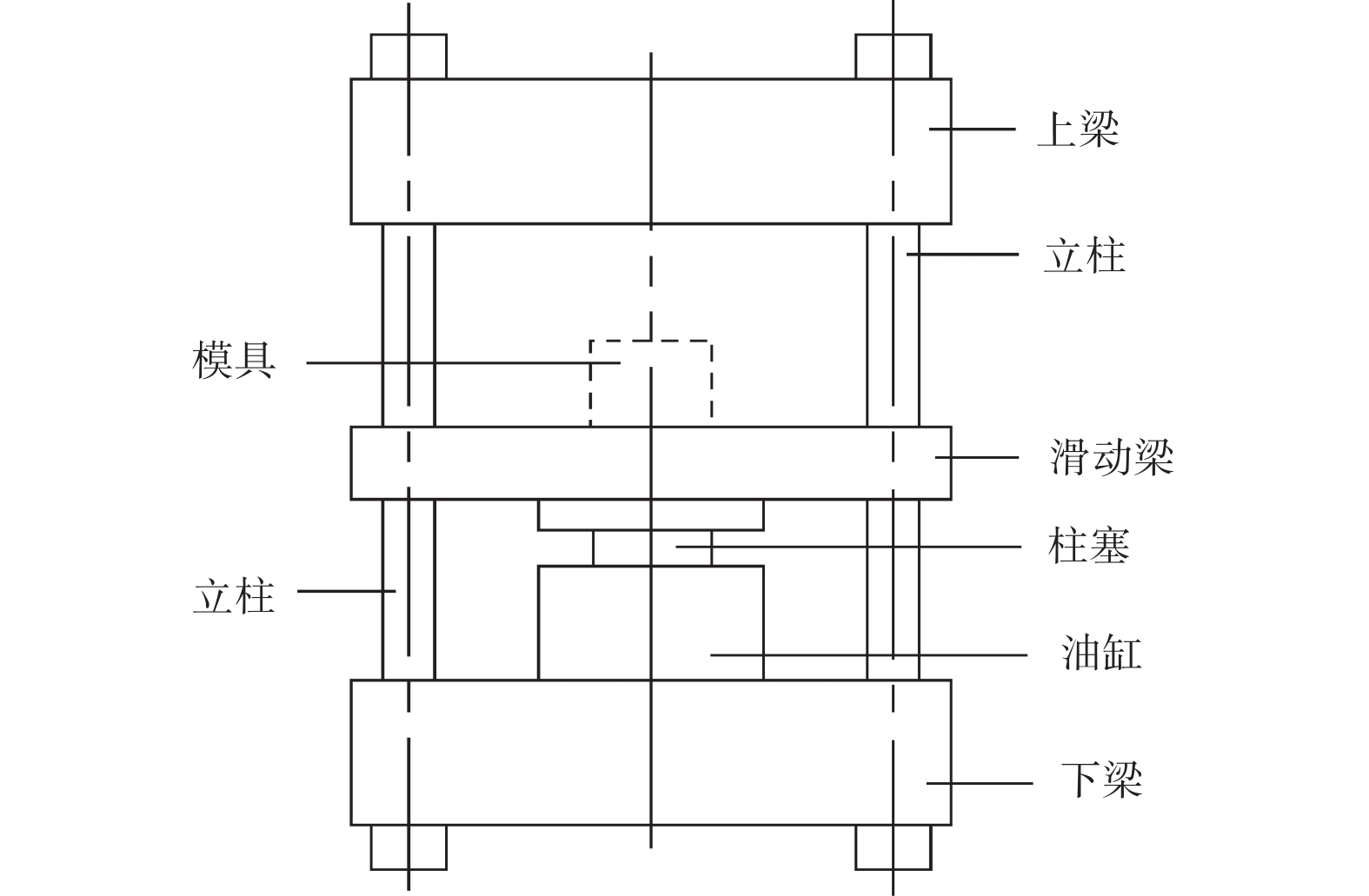

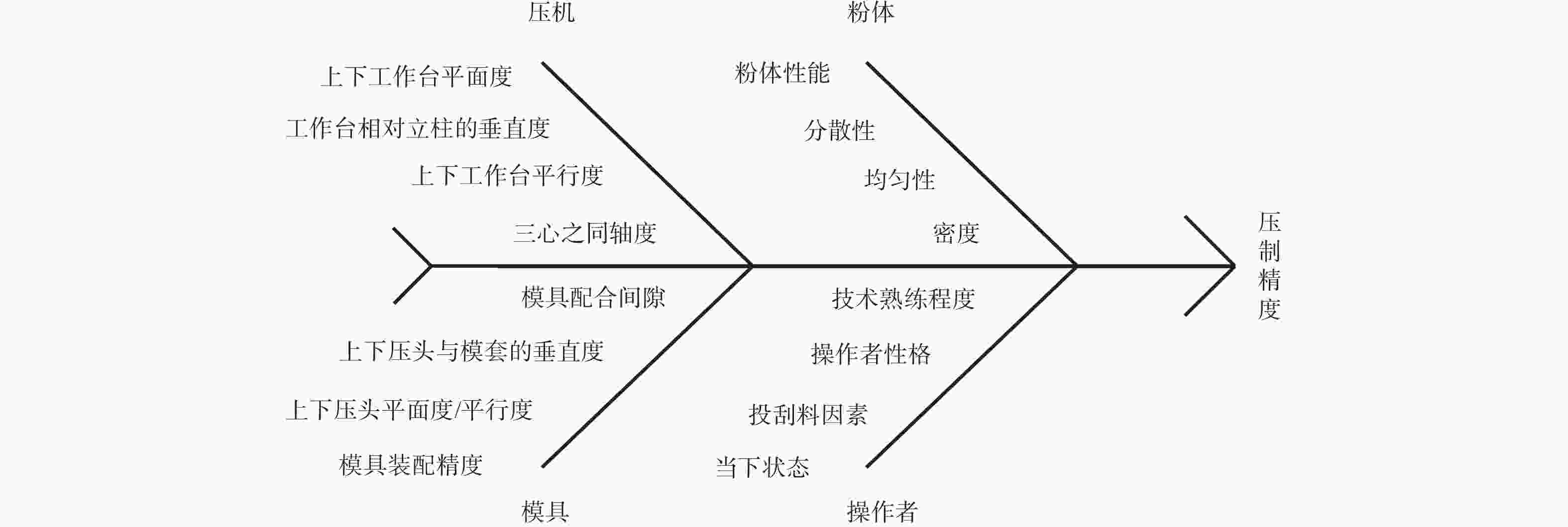

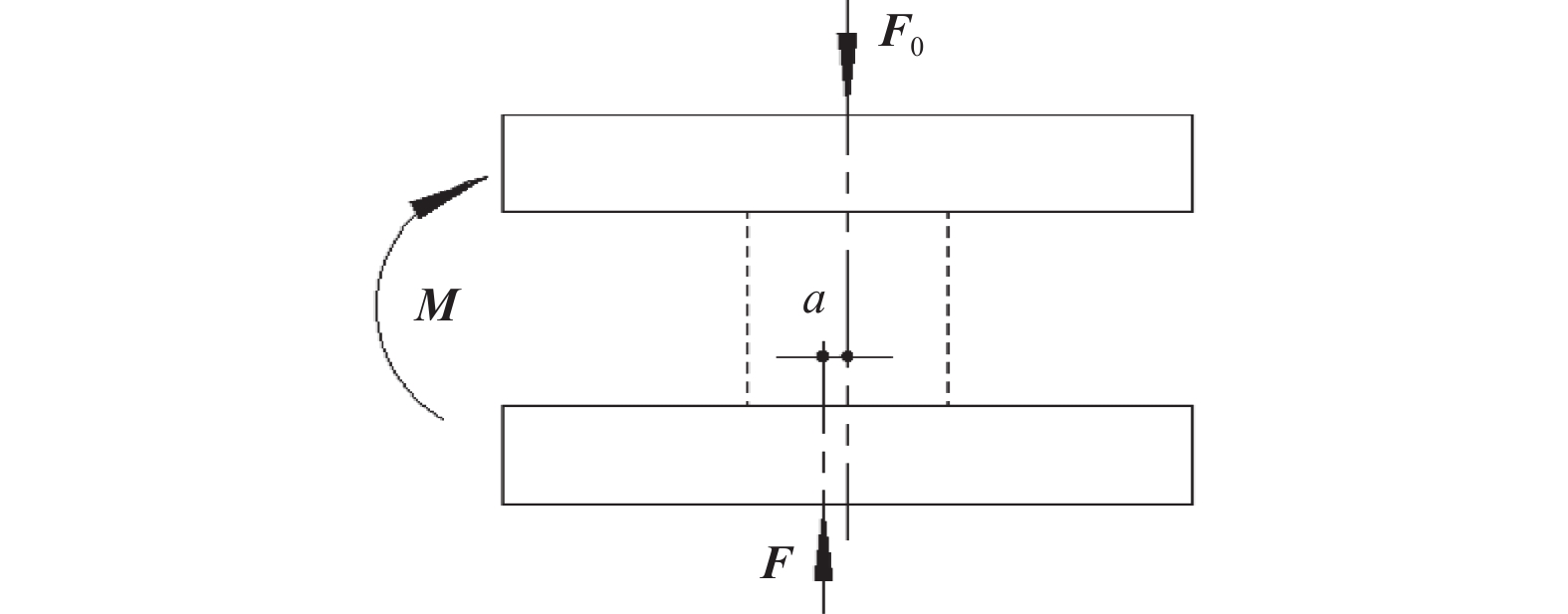

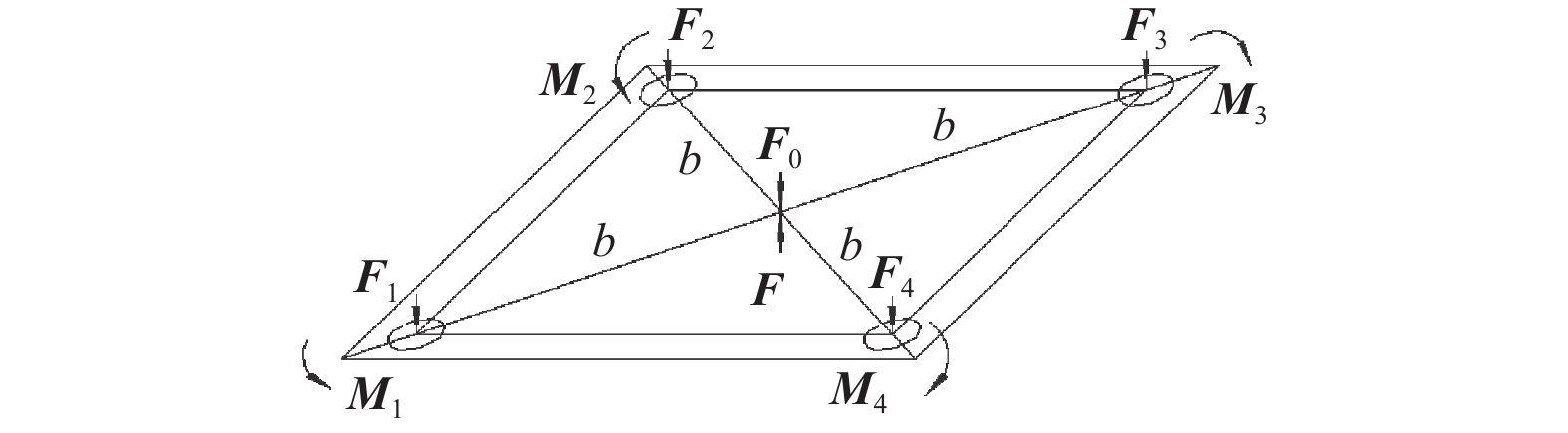

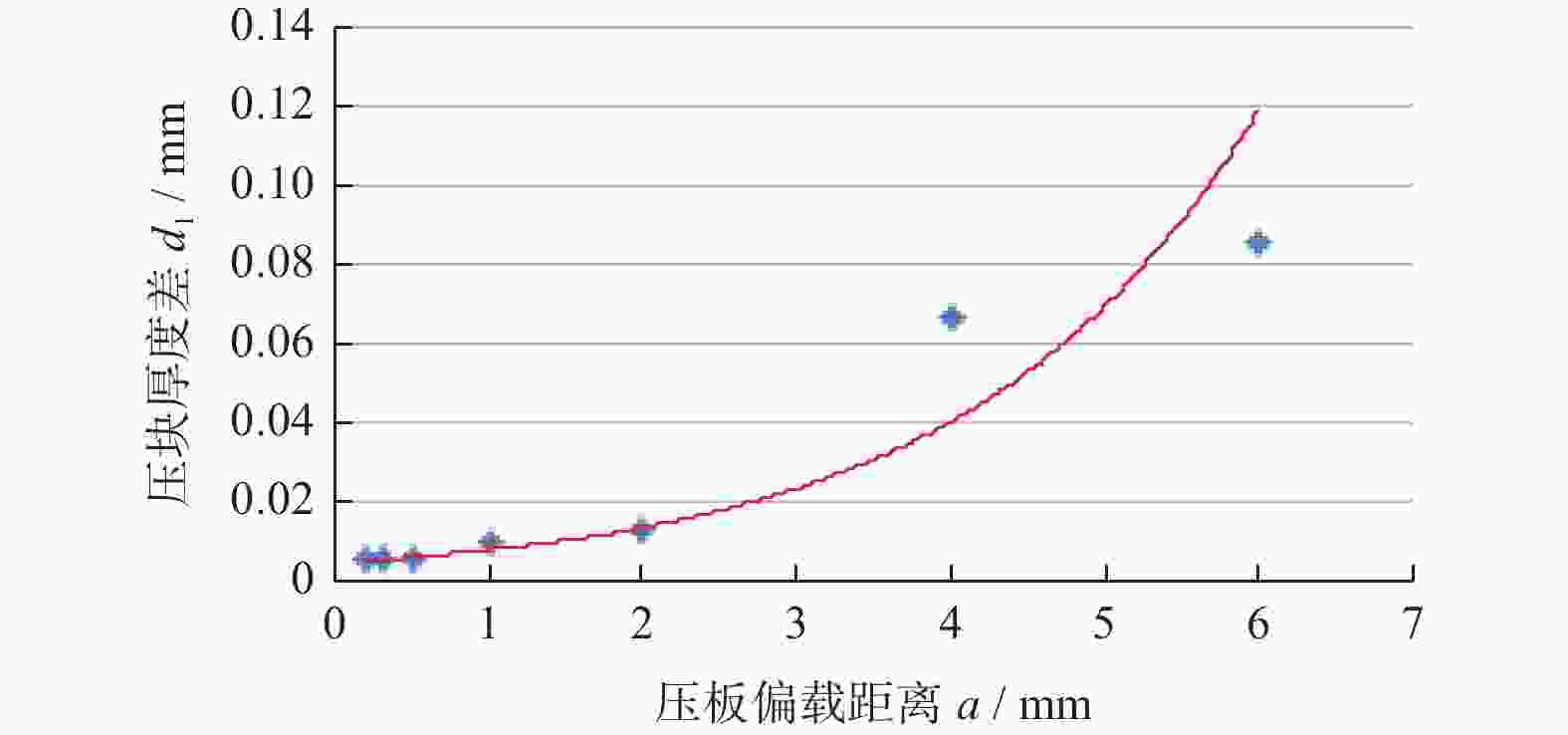

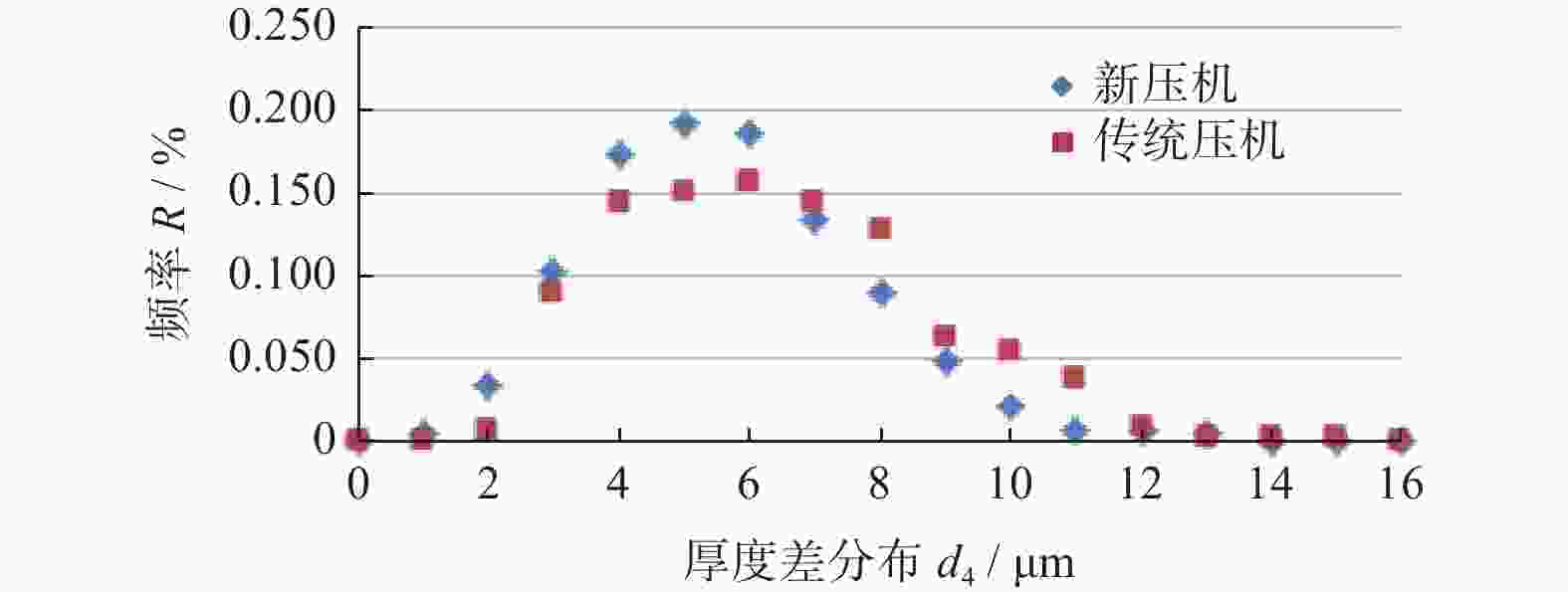

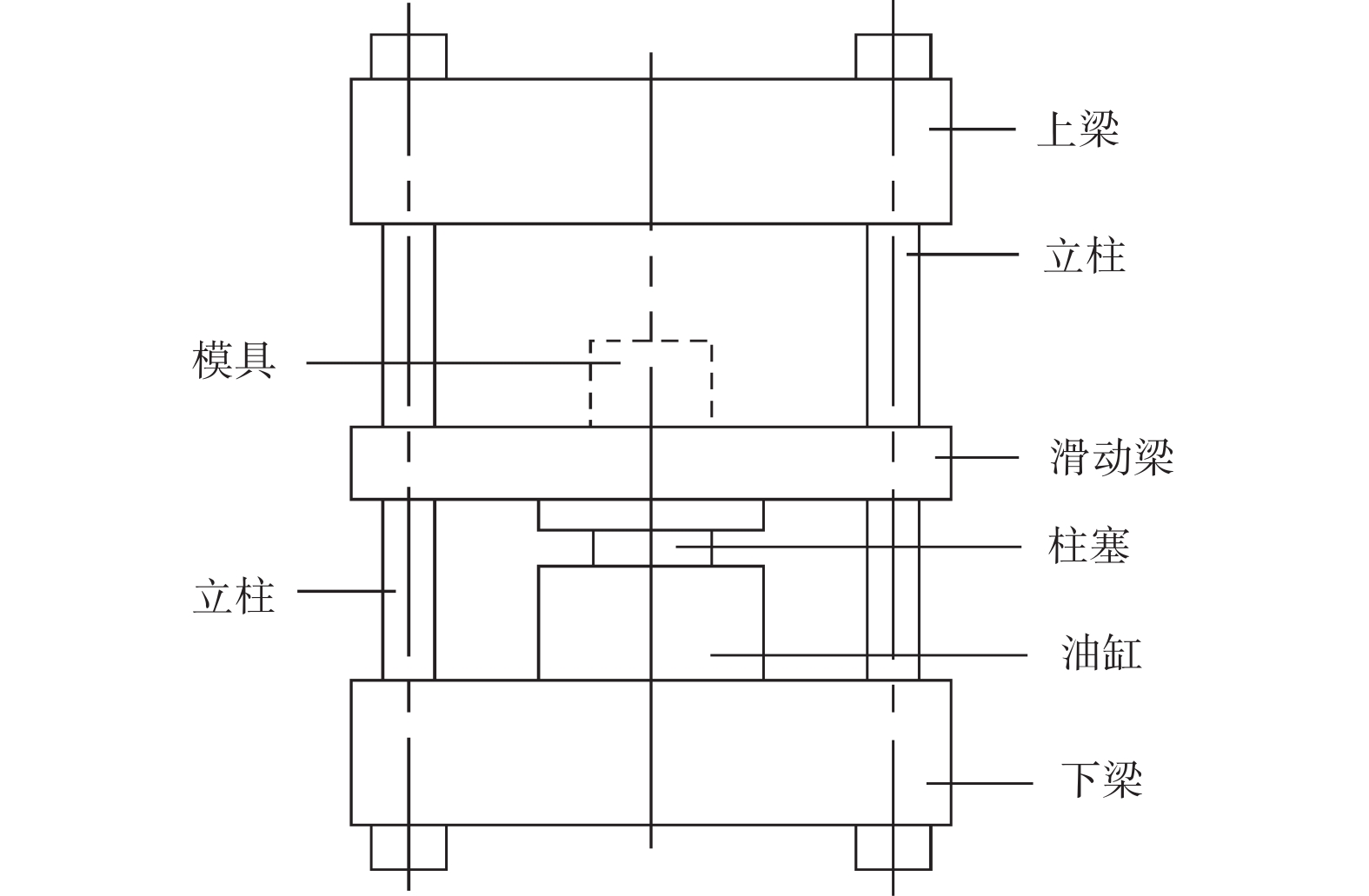

为提高砂轮成形精度,对其用四柱压机的压制方式进行调研、检测、梳理、分析,发现传统压机压制时普遍存在三心不同轴、压力易偏载、导向不均匀现象。对此,基于力的直线传递原理,提出力心压制新方案,制作新式试验压机并进行压制试验。新压机去除了四柱导向功能,提高了系统刚性,重新确定了力心位置等,且全面消除了所有附加力矩的干涉。砂轮批量成型试验结果发现:砂轮毛坯厚度差降低了10.3%~16.5%;力心压制方式明显优于传统压机压制方式,适于小尺寸制品的近净尺寸成形。

Abstract:In order to improve the forming accuracy of grinding wheel, the pressing method of the four-column press for grinding wheel was investigated, tested, carded and analyzed. It was found that the traditional press generally had the phenomena of three centers with different shafts, easy unbalance loading pressure and uneven guidance during pressing. Based on the principle of linear transmission of force, a new scheme of pressure-center pressing was proposed, and a new test press was made and subjected to pressing tests. The new press removes the four-column guiding function, improves the system rigidity, redefines the position of the pressure-center, and completely eliminates the interference of all additional moments. The results of the batch forming test of grinding wheel show that the thickness difference of grinding wheel blank is reduced by 10.3% to 16.5%. The pressure-center pressing method is obviously superior to the traditional press pressing method, and is suitable for the near-net-size forming of small size products.

-

Key words:

- four-column press /

- pressing technology of pressure center /

- molding /

- eccentric load /

- precision

-

表 1 2种压制方式测试数据对比

Table 1. Comparison of test data of two pressing methods

序号 操作工情况 时序 新压机 传统压机 均值同比

R / %数量

n1 / 片厚度差均值

d2 / μm数量

n2 / 片厚度差均值

d3 / μm1 在岗半年员工 1 292 7.10 16 8.50 16.5 2 在岗2年员工1 1 23 5.74 62 6.76 2 81 6.02 61 6.23 3 66 5.58 58 6.12 4 66 5.98 5 66 5.83 6 71 5.41 7 63 5.35 合计 436 181 加权平均 5.72 6.38 10.3 3 在岗2年员工2 1 73 5.48 63 5.95 2 65 5.00 43 6.72 3 67 5.78 41 6.29 4 77 6.27 5 77 6.42 6 46 6.22 合计 205 347 加权平均 5.42 6.30 14.0 -

[1] 冯文, 王芳, 冯佳. DORST-15HS压机行程比对正角刀片尺寸精度的影响 [J]. 硬质合金,2021,38(2):117-122.FENG Wen, WANG Fang, FENG Jia, et al. The influence of DORST-15HS press stroke ratio on dimensional precision of positive insert [J]. Cemented Carbides,2021,38(2):117-122. [2] ZHU Y, HE Y, REN J. Structure analysis and optimization design of the base of four-pillar hydraulic testing machine [J] Journal of Physics: Conference Series, 2021, 2002: 012036. [3] SUN C, YUAN R. Adaptive robust cross-coupling position synchronization control of a hydraulic press slider-leveling [J]. Science Progress,2021,104(1):82-89. [4] LIAO S, ZHANG Z, WANG S, et al. Analysis of the upper cross beam of a forging hydraulic press: 2010 the 2nd international conference on industrial mechatronics and automation [C]. Wuhan: IEEE, 2010. [5] LIU Z. Research on rigidity of the giant forging hydraulic press on the impact of synchronization performance: Second international conference on digital manufacturing & automation [C]. Zhangjiajie: IEEE, 2011. [6] LIU Z W, LIU S J, HUANG M H. Influence factors research on control performance of synchronous control system for giant forging hydraulic press [J]. Forging & Stamping Technology,2010(5):64-68. [7] 张广庆, 徐楠, 王瑗. 粉末冶金压制成形理论与工艺综述 [J]. 热加工工艺,2017,46(19):9-14.ZHANG Guangqing, XU Nan, WANG Yuan. Review on theory and technology of powder metallurgy pressing forming [J]. Hot Working Technology,2017,46(19):9-14. [8] 卜匀. 四柱液压机主体改造研究 [J]. 机床与液压,2014,42(20):159-162. doi: 10.3969/j.issn.1001-3881.2014.20.050BU Yun. Research on the main body transformation of four column hydraulic press [J]. Machine Tools and Hydraulics,2014,42(20):159-162. doi: 10.3969/j.issn.1001-3881.2014.20.050 [9] 冯克明, 朱建辉, 杜晓旭. 基于过定位原理的砂轮精密成型试验研究 [J]. 制造业自动化,2015,37(23):20-23, 27. doi: 10.3969/j.issn.1009-0134.2015.23.06FENG Keming, ZHU Jianhui, DU Xiaoxu. Test research on grinding wheel precision molding based on the principle of over-location [J]. Manufacturing Automation,2015,37(23):20-23, 27. doi: 10.3969/j.issn.1009-0134.2015.23.06 [10] 张凯. 提高模压机主缸压制精度的研究 [J]. 科技创新与生产力,2017(8):91-93. doi: 10.3969/j.issn.1674-9146.2017.09.091ZHANG Kai. Research on pressing precision improvement of die forging hydraulic press master cylinder [J]. Technology Innovation and Productivity,2017(8):91-93. doi: 10.3969/j.issn.1674-9146.2017.09.091 [11] 沈维佳, 张年松, 贾轶杰. 粉末压机模架配合精度优化 [J]. 机械制造与自动化,2014,43(4):38-40.SHEN Weijia, ZHANG Niansong, JIA Yijie. Optimization of coordinate precision based on powder metallurgy precision molding press [J]. Machine Building & Automation,2014,43(4):38-40. [12] 郑州磨料磨具磨削研究所有限公司. 一种四轴激光定心测量装置及方法: CN113418451A [P]. 2021-09-21.Zhengzhou Research Institute for Abrasives & Grinding Co., Ltd. The invention relates to a four-axis laser centering measuring device and a method: CN113418451A [P]. 2021-09-21. [13] 彭沪新, 温证钧, 丁亚辉. 大型压机压制砖坯尺寸超差的原因及对策 [J]. 佛山陶瓷,2020,30(2):38-40.PENG Huxin, WEI Zhengjun, DING Yahui. The reason and countermeasure for the size deviation of large-scale press pressing brick blank [J]. Foshan Ceramics,2020,30(2):38-40. [14] 任胜利, 姜化雨. 提高粉末制品压制精度的机构设计 [J]. 粉末冶金工业,2005(6):37-40.REN Shengli, JIANG Huayu. A system design for heightening pressing precision of powder products [J]. Powder Metallurgy Industry,2005(6):37-40. [15] 李征, 单忠德, 孙启利, 等. 树脂渗透对砂型3D打印成型精度影响机理研究 [J]. 铸造技术,2021,42(4):247-251.LI Zheng, SHAN Zhongde, SUN Qili, et al. Influence mechanism of resin penetration on molding accuracy of sand 3D printing [J]. Foundry Technology,2021,42(4):247-251. [16] 赵丽丽, 张严, 许鹏飞, 等. 硬质合金混合料粒度分布对成型尺寸精度的影响 [J]. 硬质合金,2018,35(5):344-350.ZHAO Lili, ZHANG Yan, XU Pengfei, et al. Influence of particle size distribution of powder mixture on molding precision of cemented carbide [J]. Cemented Carbides,2018,35(5):344-350. [17] 郑学森, 朱姝, 翟国芳. SMC制件精度的影响因素 [J]. 纤维复合材料,2006(3):23-25. doi: 10.3969/j.issn.1003-6423.2006.03.007ZHENG Xuesen, ZHU Shu, ZHAI Guofang. Discussion of factors influencing precision of SMC parts [J]. Fiber Composites,2006(3):23-25. doi: 10.3969/j.issn.1003-6423.2006.03.007 [18] 马洪勇, 喻宝林, 赵志学. 闭式四点机械压力机偏载问题研究 [J]. 一重技术,2018(6):10-14.MA Hongyong, YU Baolin, ZHAO Zhixue. Study on eccentric load of four-point closed mechanical press [J]. CFHI Technology,2018(6):10-14. [19] 刘林志, 李森, 耿文轩, 等. 十六面导向模锻液压机抗偏载能力分析: 2008年中国机械工程学会年会暨甘肃省学术年会 [C]. 兰州: 机械工业出版社, 2008.LIU Linzhi, LI Sen, GENG Wenxuan, et al. Analysis of anti-eccentric load capacity of 16-face oriented die forging press: 2008 annual conference of chinese mechanical engineering and gansu academic conference [C] . Lanzhou: China Machine Press, 2008. [20] 张建民. 用于新兴复合材料成形的液压机装备—模具在偏载下的耦合分析 [D]. 天津: 天津理工大学, 2013.ZHANG Jianmin. The coupling analysis of hydraulic press equipment - die used in new composite material forming in the partial loads [D]. Tianjin: Tianjin University of Technology, 2013. [21] 张珍. 用于复合材料成形的液压机装备—模具形状不对称引起偏载的耦合分析 [D]. 天津: 天津理工大学, 2015.ZHANG Zhen. The coupling analysis of partial load due to mould shape asymmetric - used in composite materials forming hydraulic press equipment [D]. Tianjin: Tianjin University of Technology, 2015. [22] 金淼, 聂绍珉, 郭宝锋, 等. 偏载下液压机动梁与立接触状态分析: 第九届全国塑性工程学术年会论文集 [C]. 太原: 锻压技术, 2005.JIN Miao, NIE Shaomin, GUO Baofeng, et al. Analysis of the contact state between a hydraulic mechanical beam and a vertical beam under eccentric load: Proceedings of the ninth national symposium on plastic engineering [C]. Taiyuan: Forging Stamping Technology, 2005. [23] 曾金越. 四柱液压机设计分析 [D]. 合肥: 合肥工业大学, 2014.ZENG Jinyue. Design and analysis of four-column hydraulic press [D]. Hefei: Hefei University of Technology, 2014. [24] 全国锻压机械标准化技术委员会. 四柱液压机精度: GB/T 9166-2009 [S]. 北京: 中国标准出版社, 2009.National Technical Committee for Standardization of Forging Machinery. Four-column hydraulic press-testing of the accuracy: GB/T 9166-2009 [S]. Beijing: Standard Press of China, 2009. [25] 全国锻压机械标准化技术委员会. 粉末制品液压机 精度: JB/T 3819-2014 [S]. 北京: 机械工业出版社, 2014.National Technical Committee for Standardization of Forging Machinery. Powder product hydraulic press-testing of the accuracy: JB/T 3819-2014 [S]. Beijing: China Machine Press, 2014. [26] 邵俊鹏, 徐龙飞, 孙桂涛. 液压缸静压支承抗偏载特性分析 [J]. 中国机械工程,2020,31(18):2174-2180.SHAO Junpeng, XU Longfei, SUN Guitao. Analysis of anti-eccentric load characteristics of hydraulic cylinder hydrostatic supports [J]. China Mechanical Engineering,2020,31(18):2174-2180. [27] 郑州磨料磨具磨削研究所有限公司. 一种压机寻中测试方法: CN114689001A [P]. 2022-07-01.Zhengzhou Research Institute for Abrasives & Grinding Co., Ltd. The invention relates to a method for testing the centering of a press: CN114689001A [P]. 2022-07-01. [28] 王德广, 吴玉程, 焦明华, 等. 粉末成形过程中摩擦行为研究进展 [J]. 机械工程学报,2009,45(5):12-19. doi: 10.3901/JME.2009.05.012WANG Deguang, WU Yucheng, JIAO Minghua, et al. Research progress of friction behavior during powder forming [J]. Journal of Mechanical Engineering,2009,45(5):12-19. doi: 10.3901/JME.2009.05.012 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS