Influence of crystal anisotropy and process parameters on surface shape deviation of sapphire slicing

-

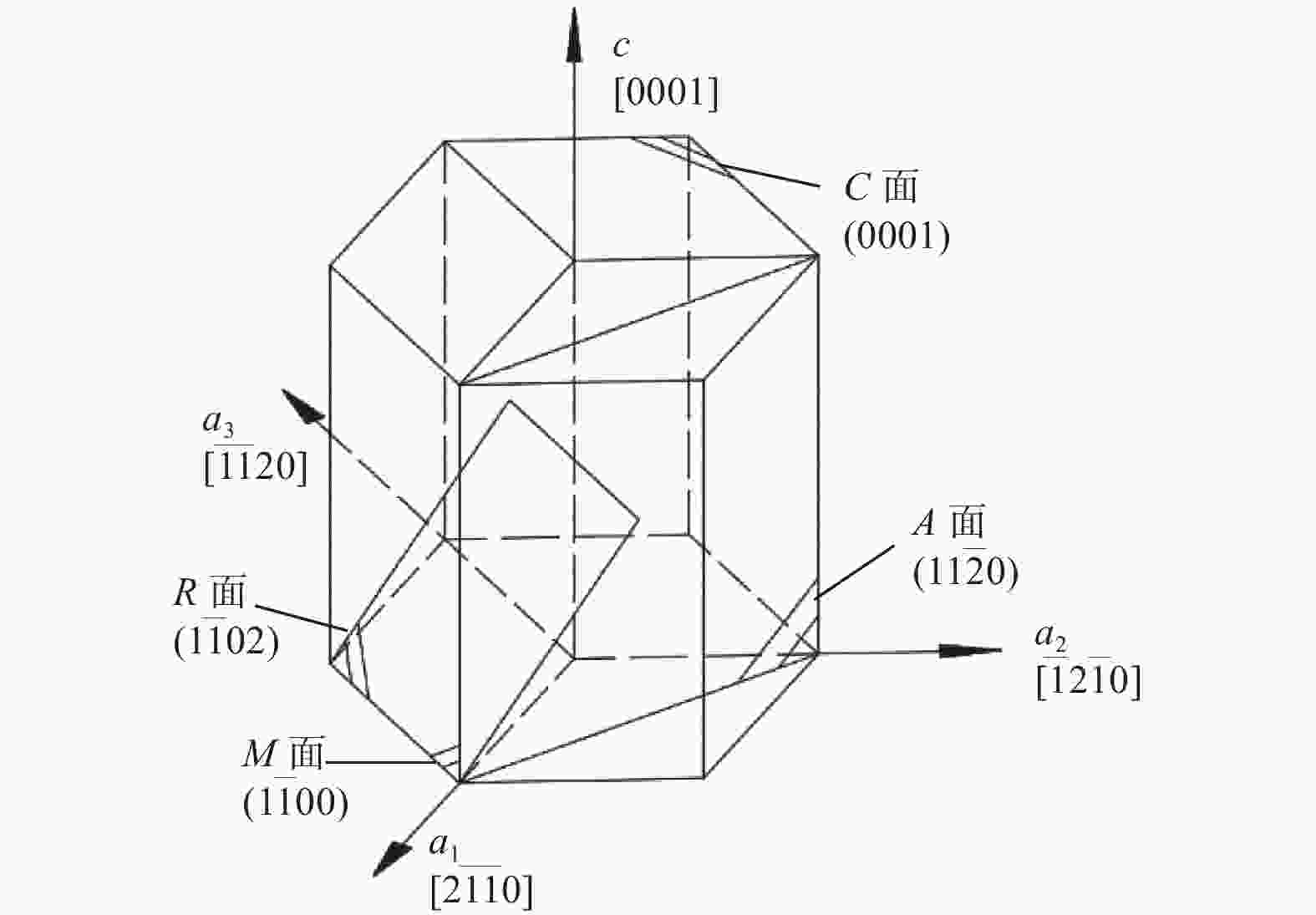

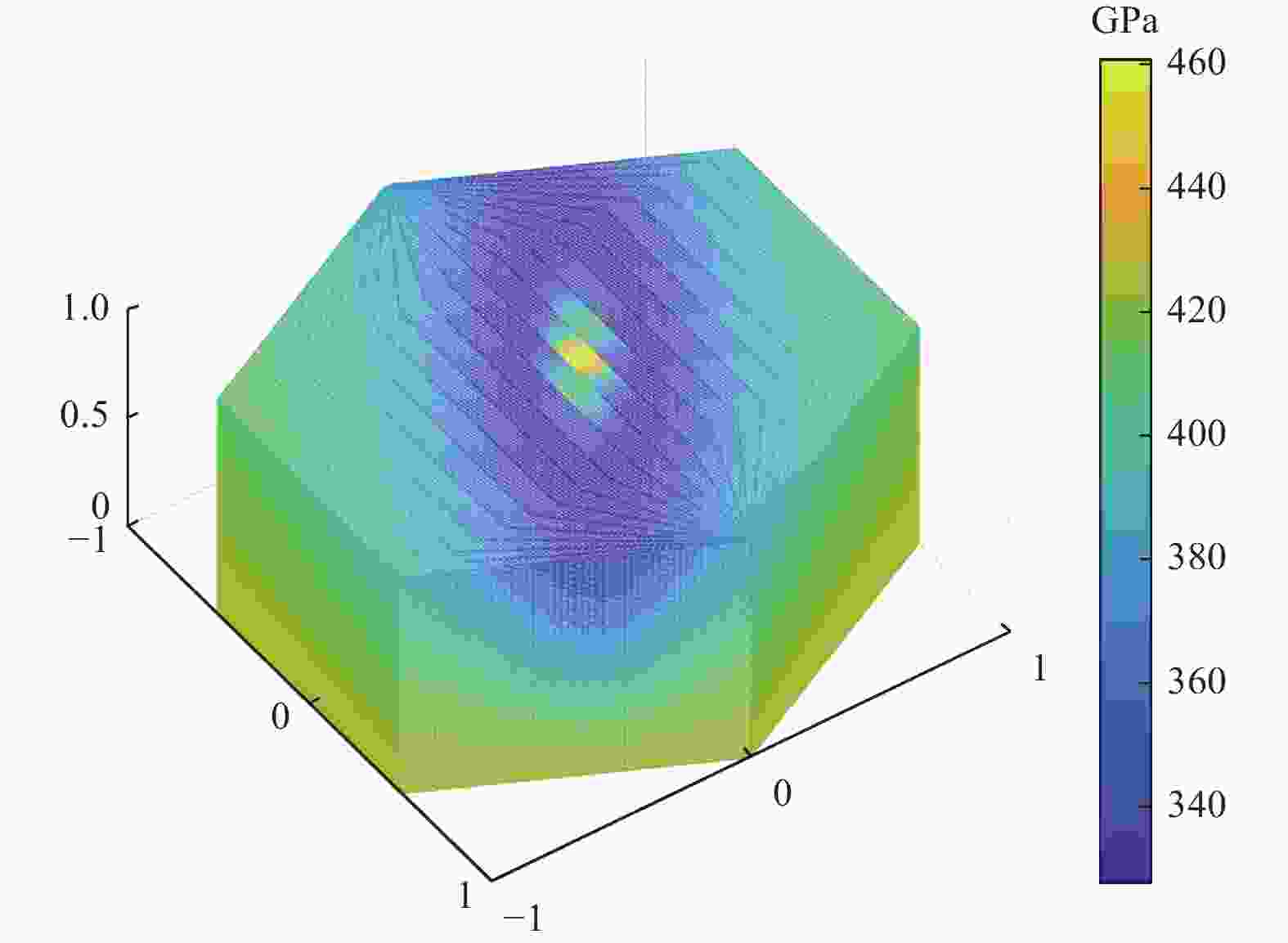

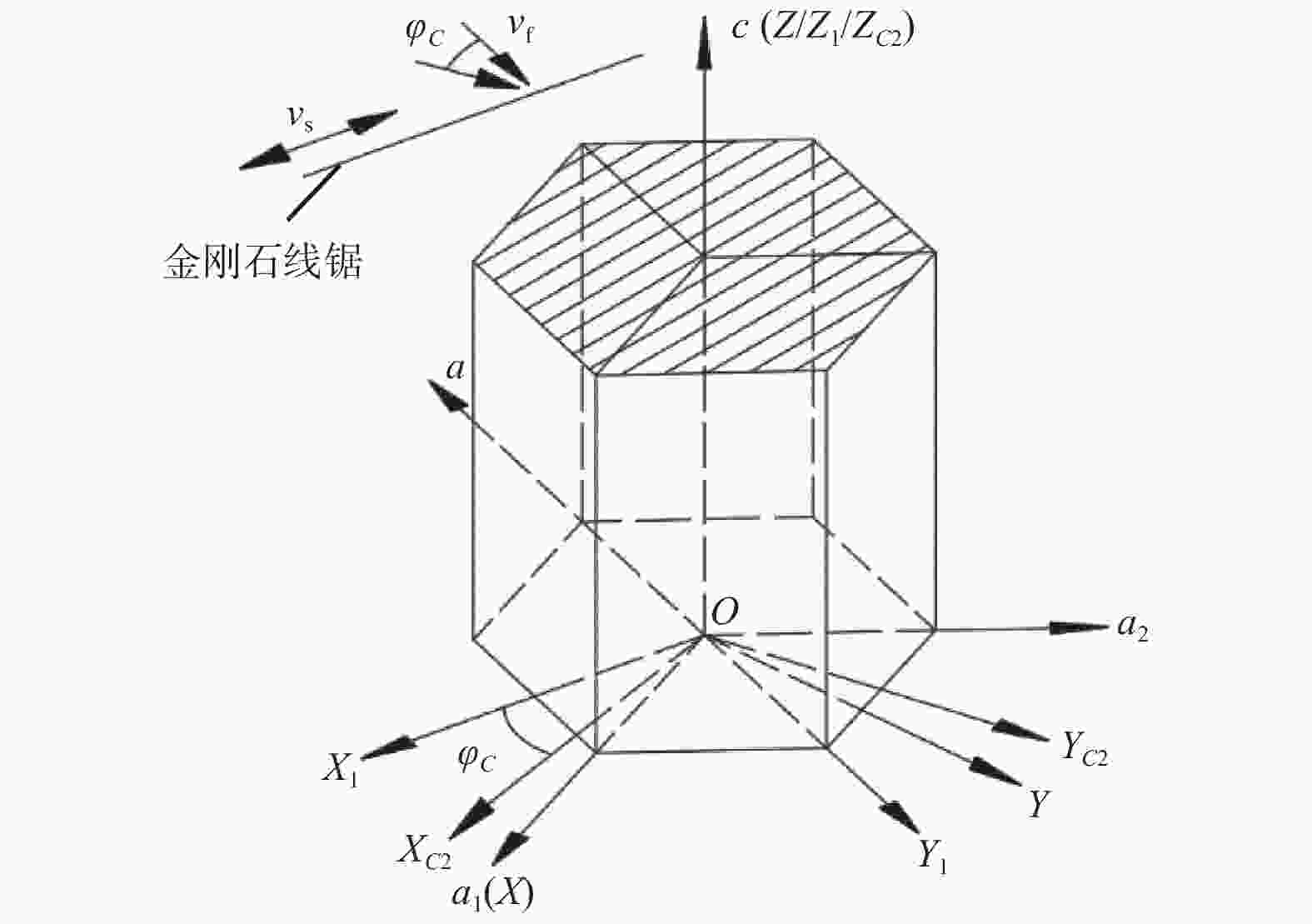

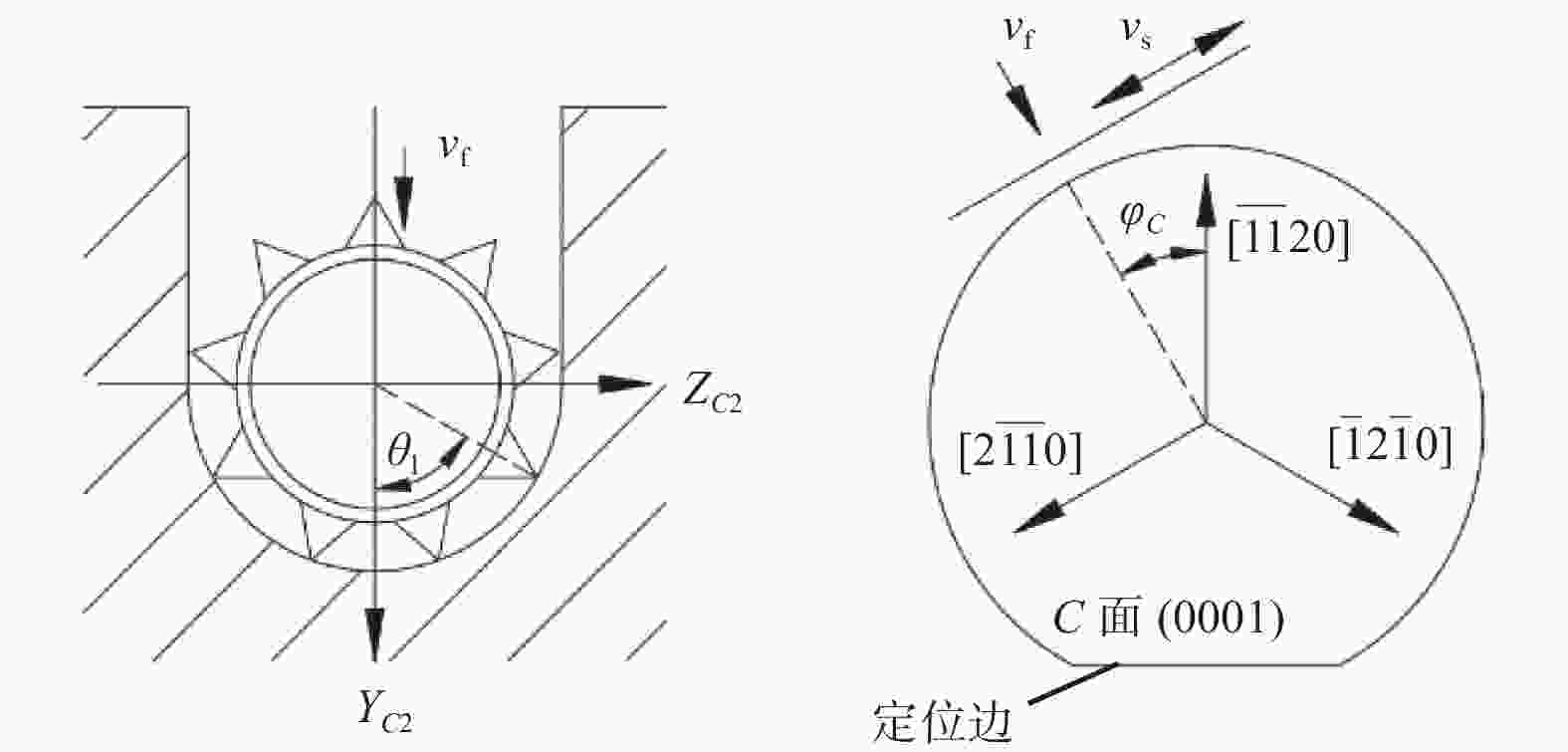

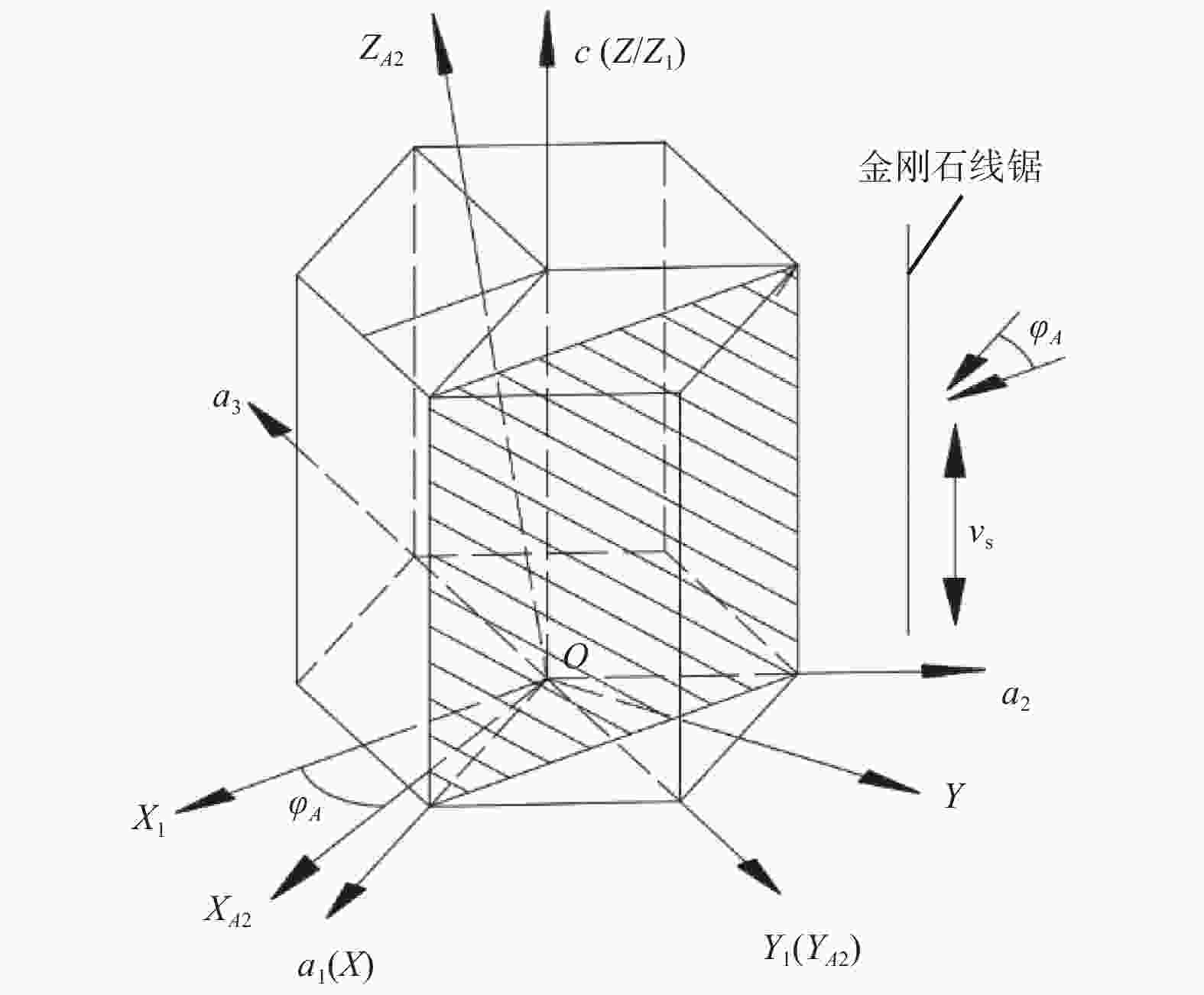

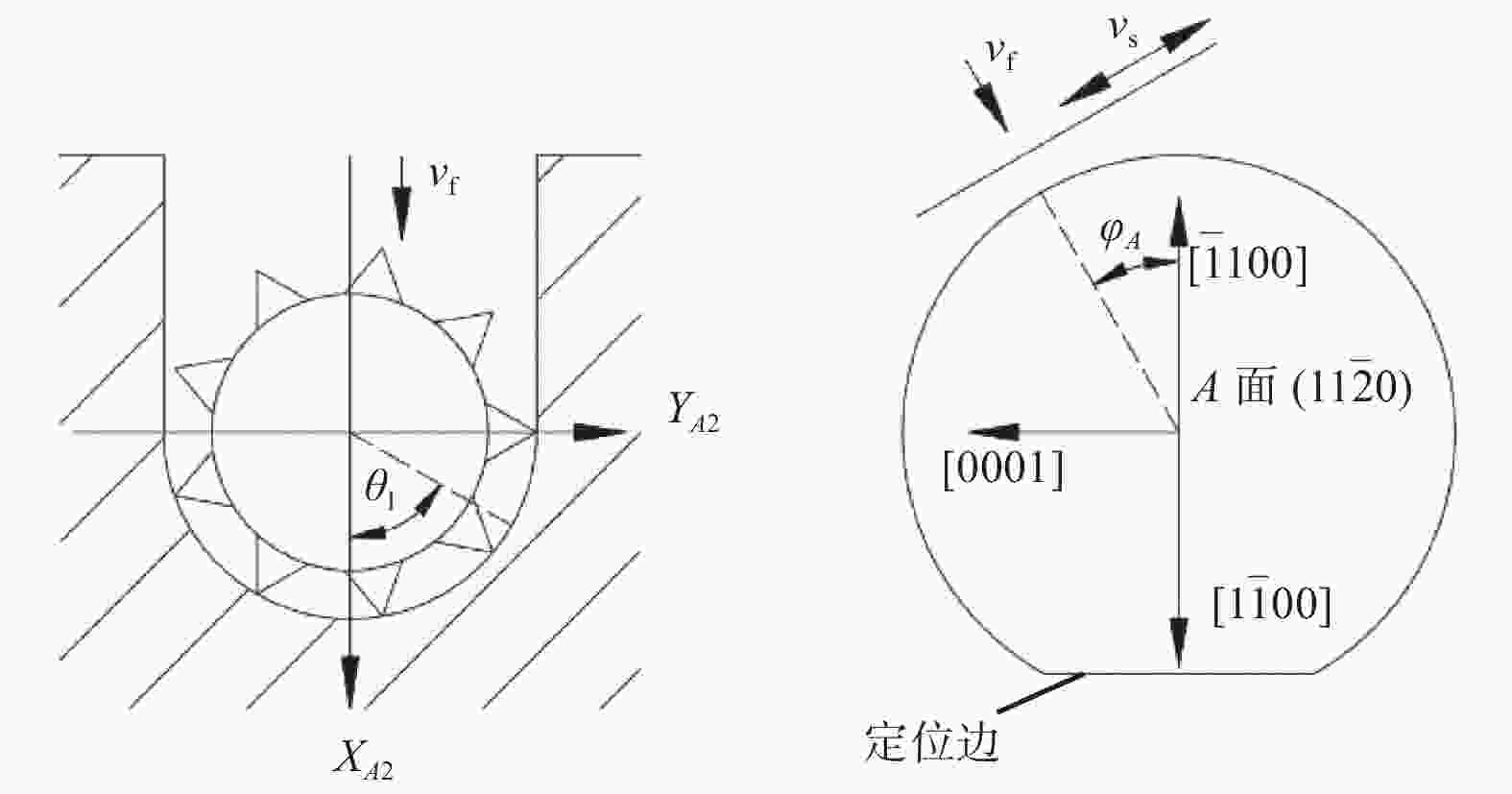

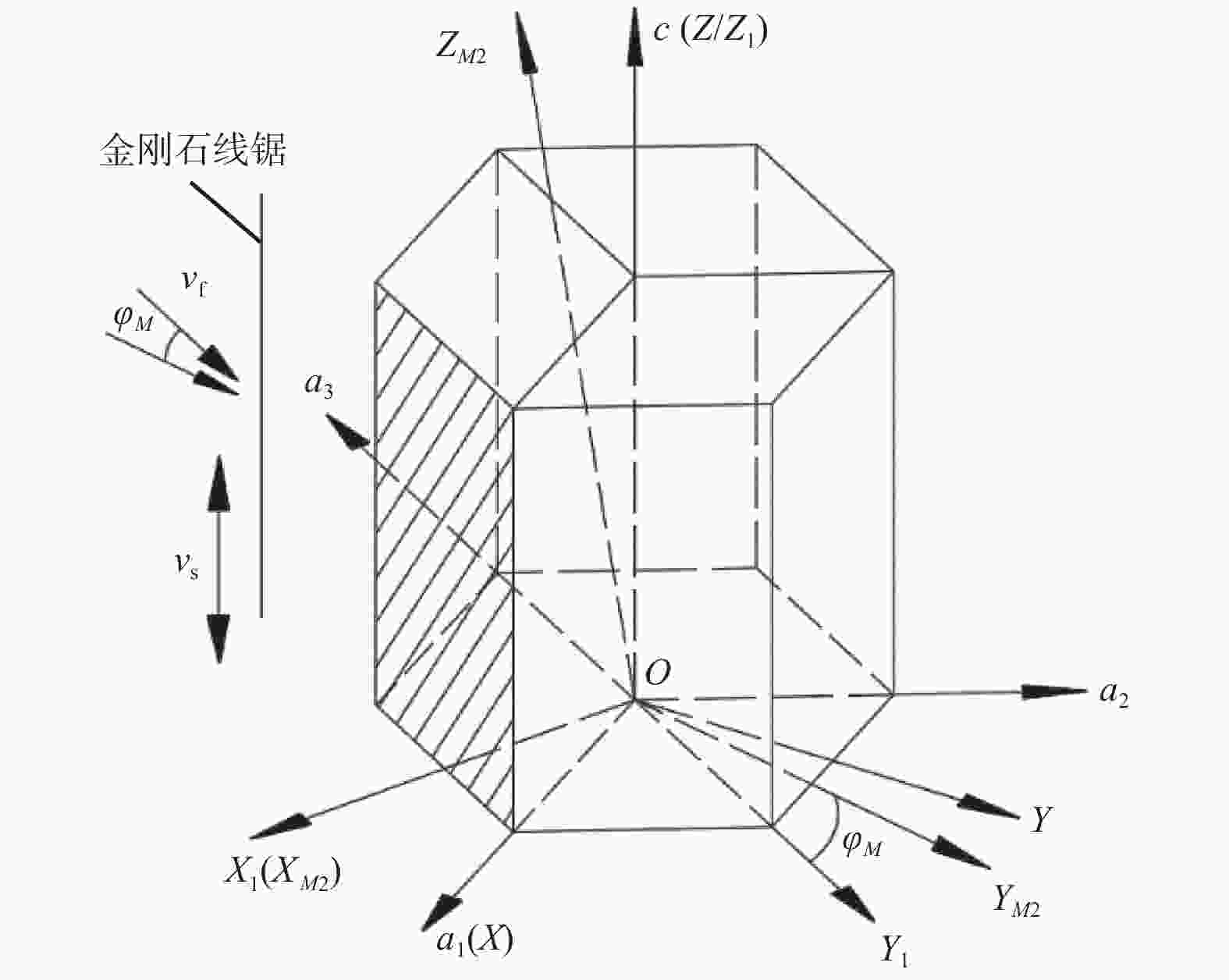

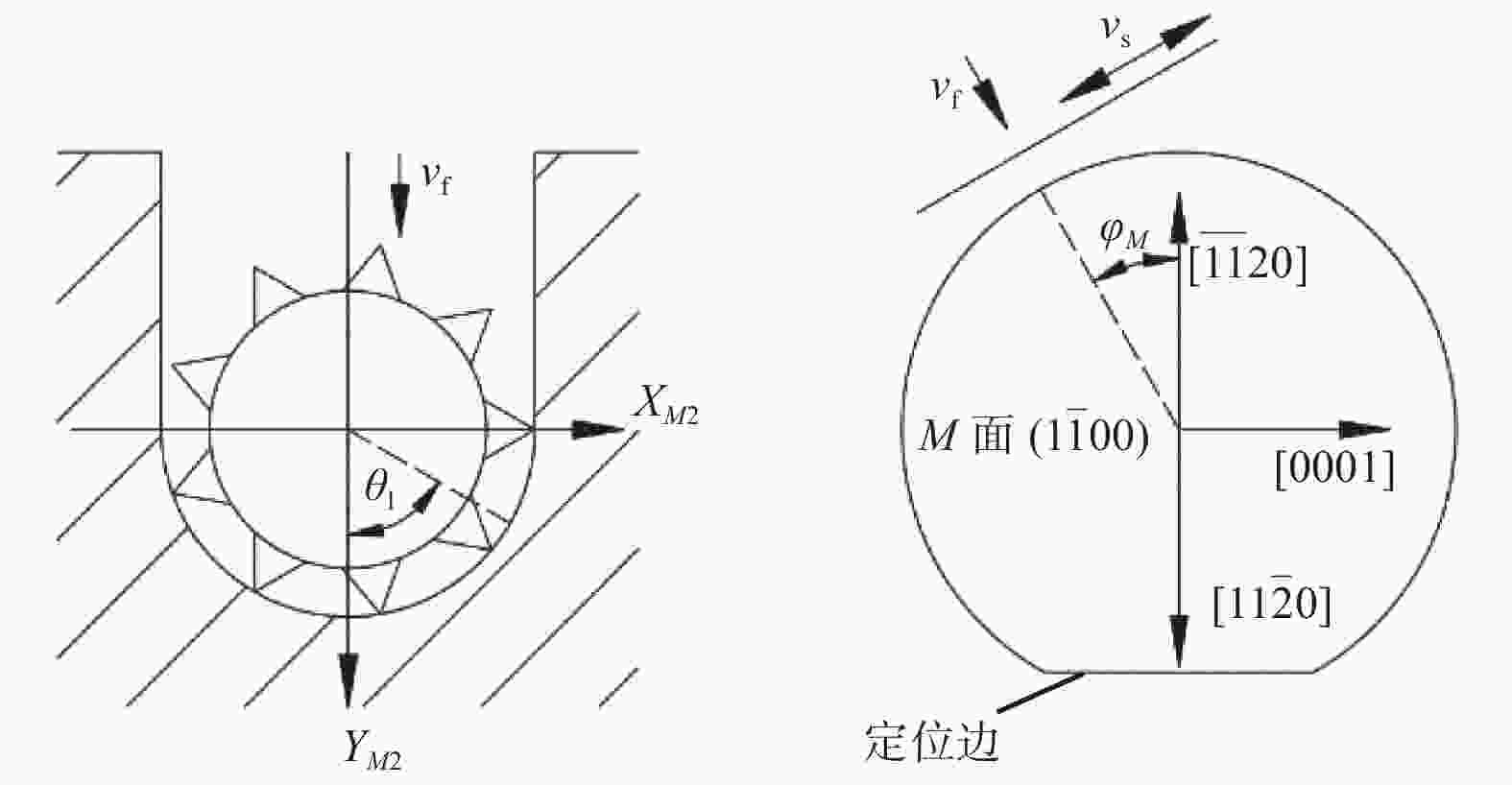

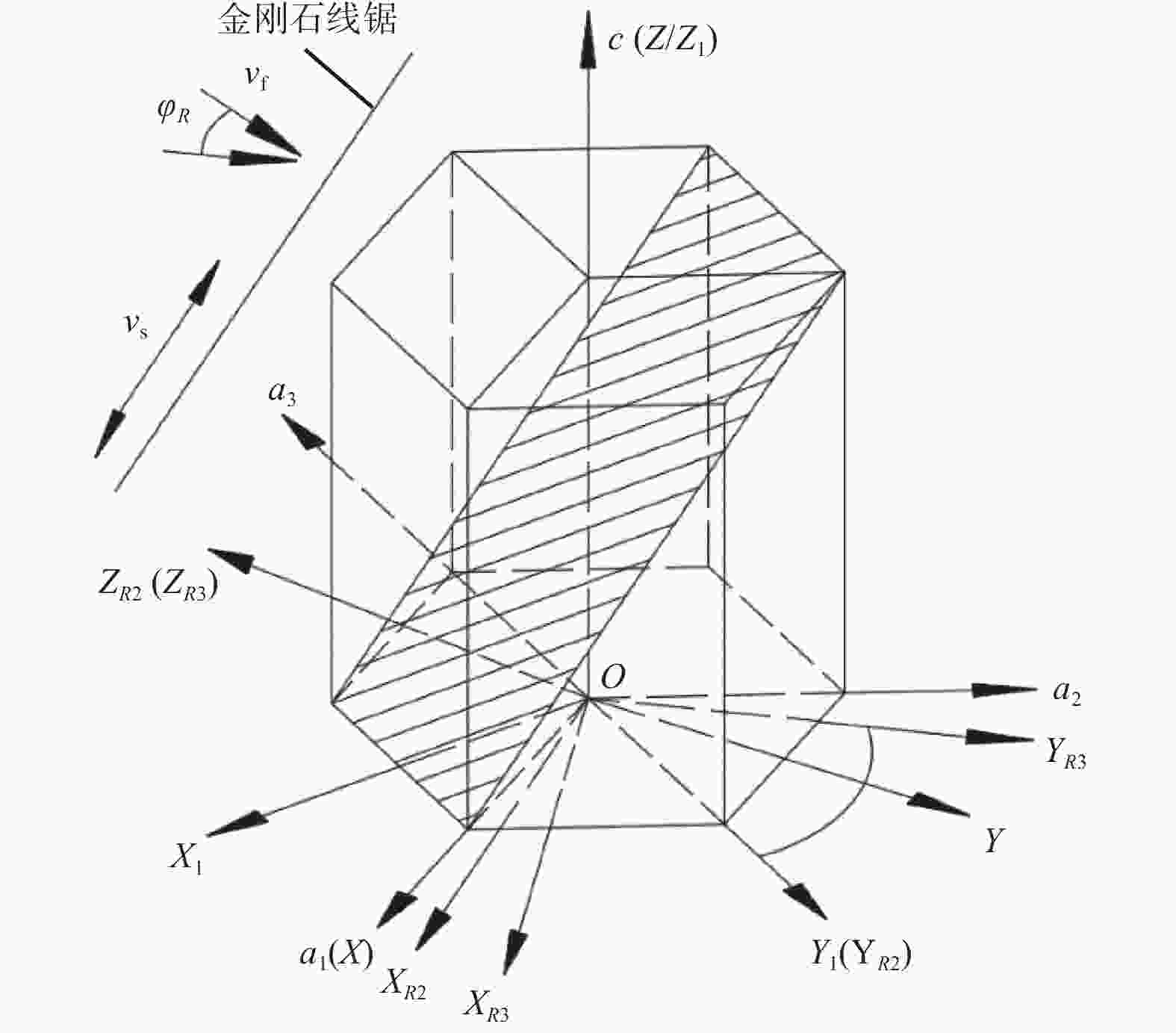

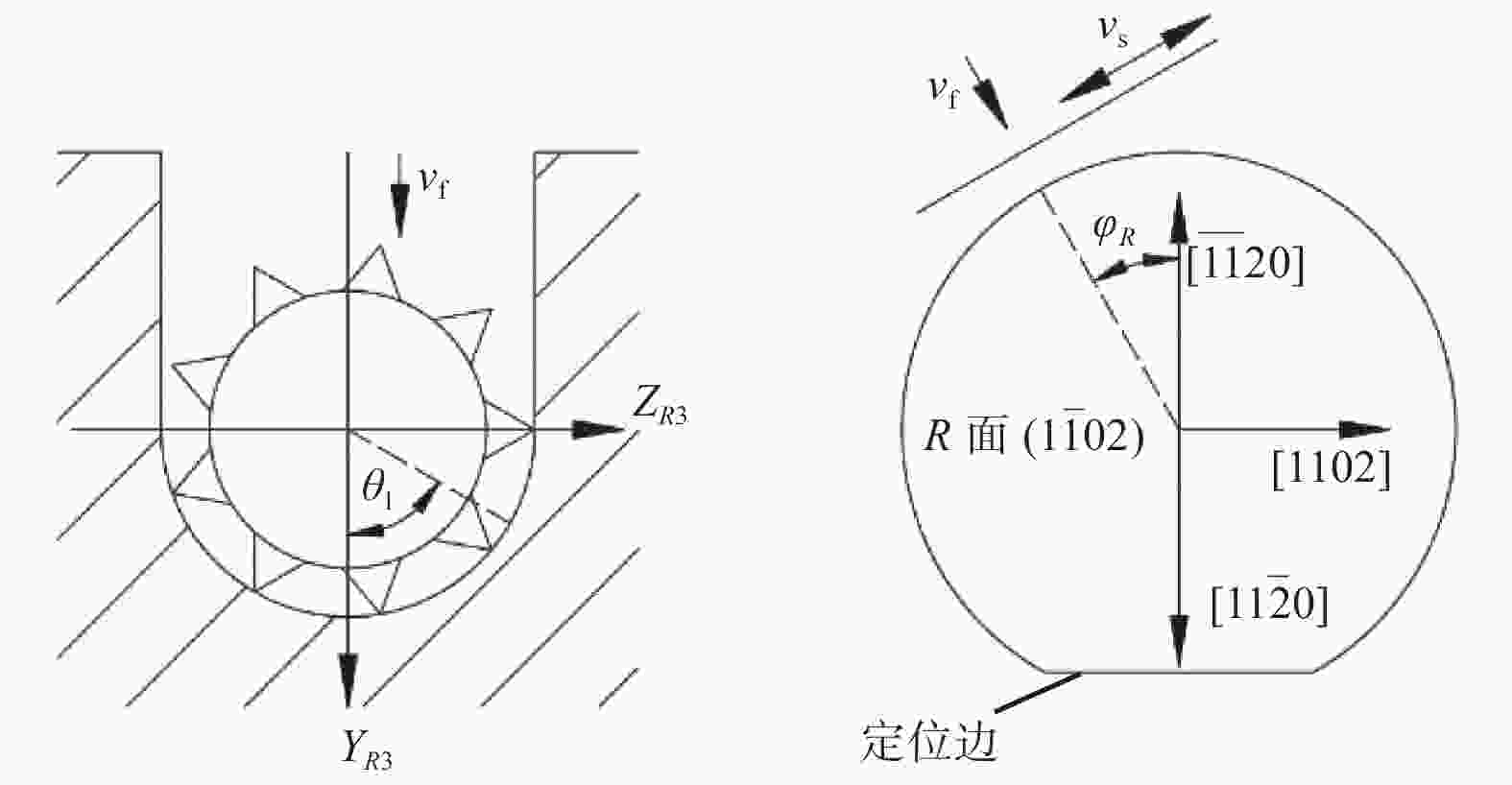

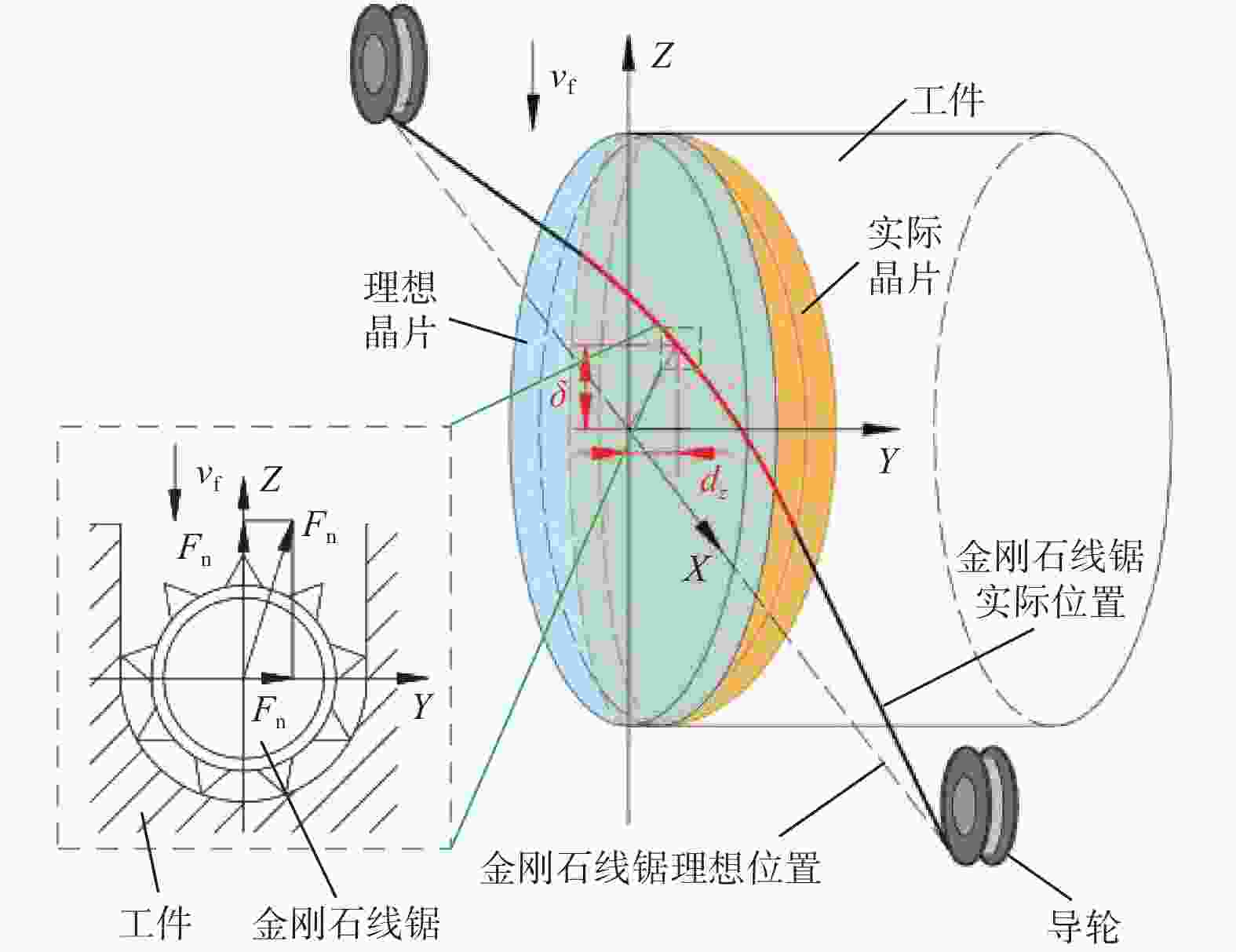

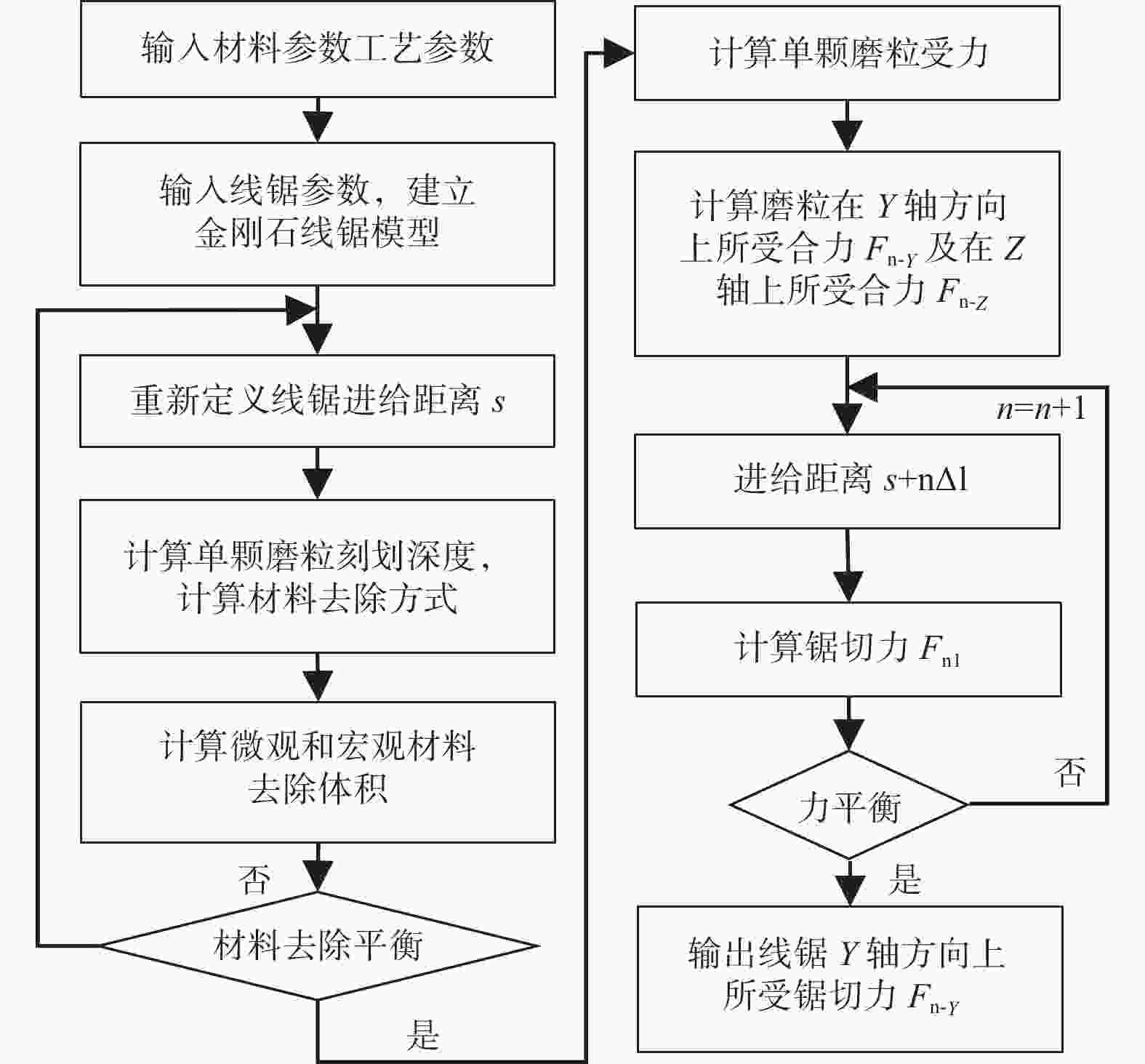

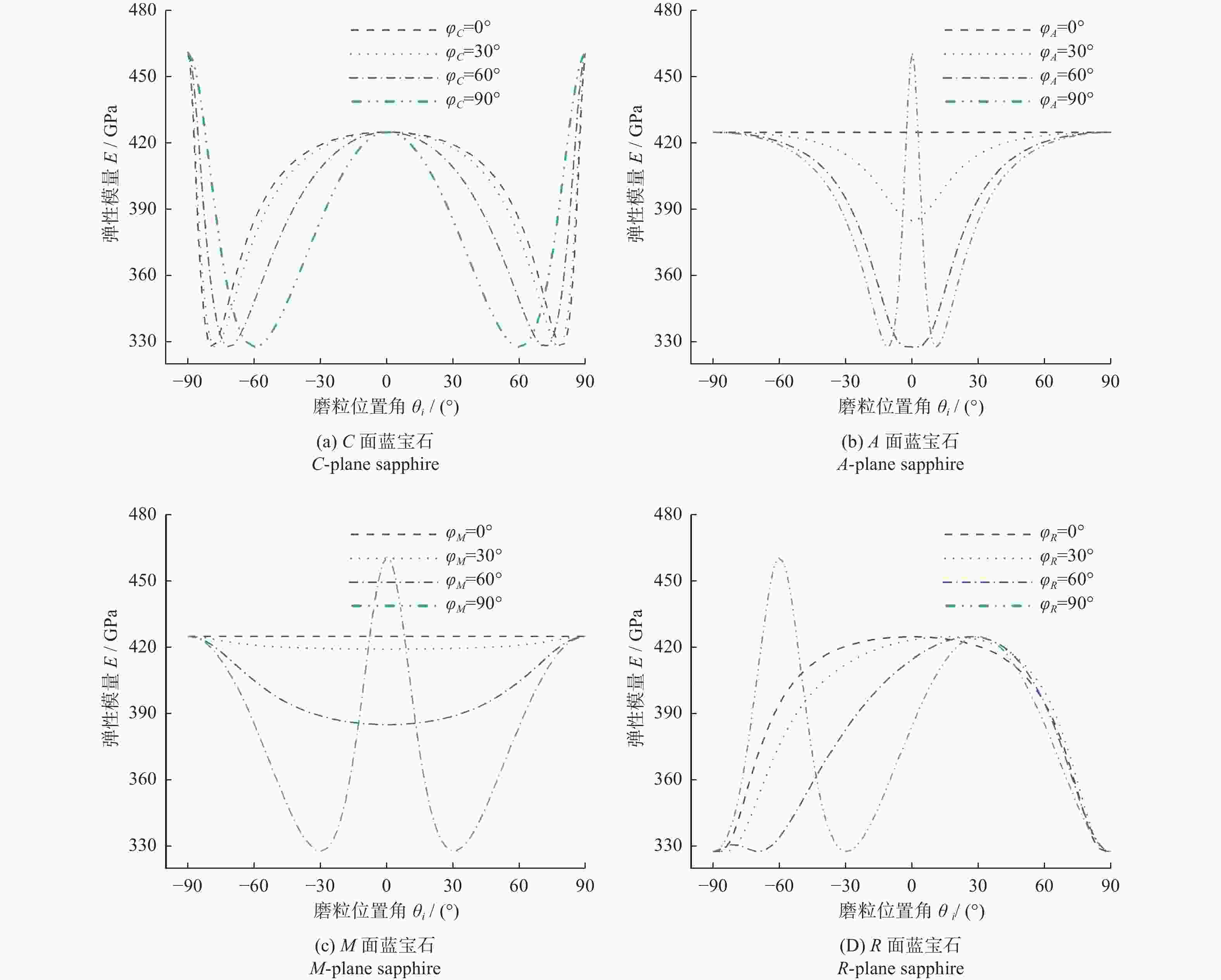

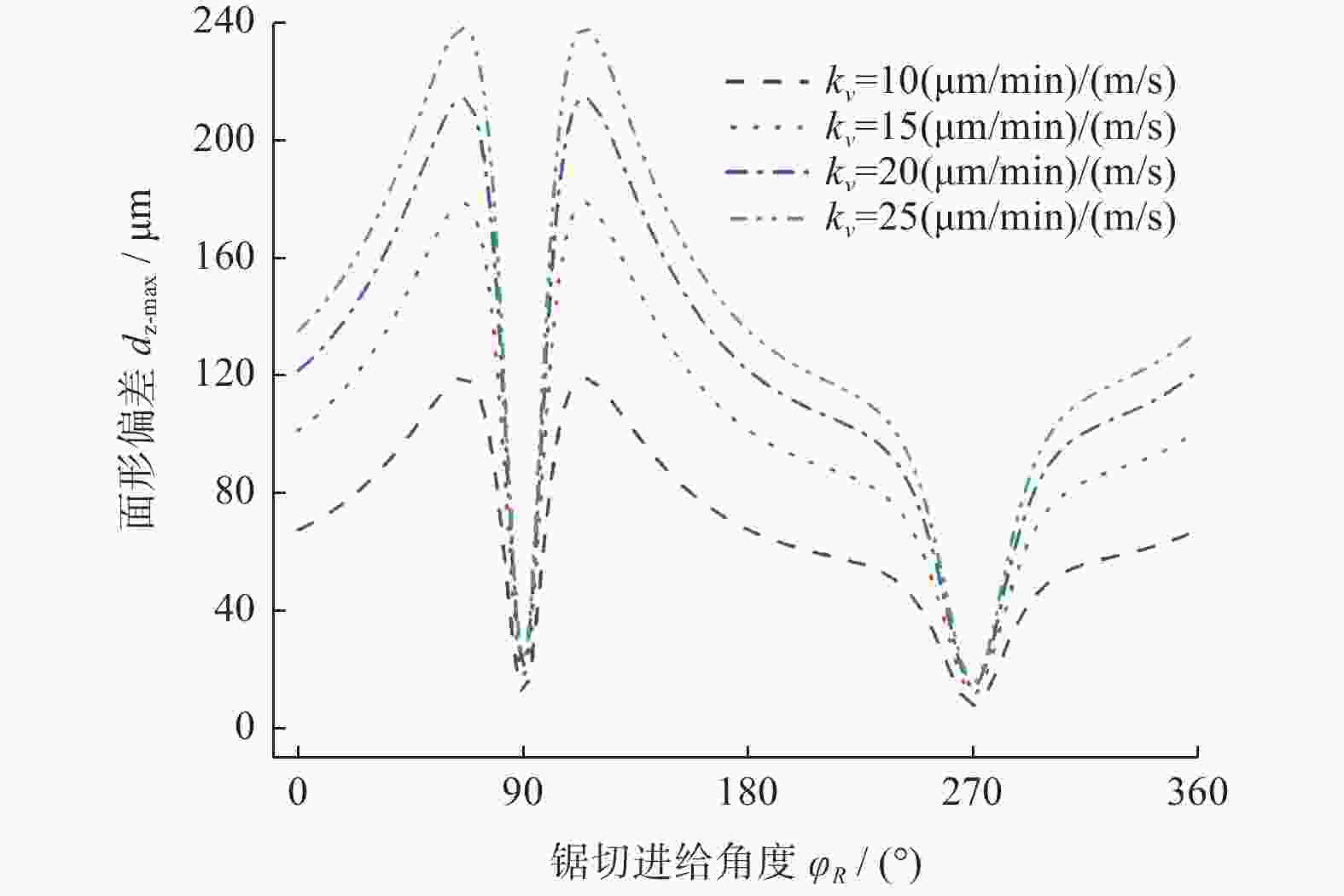

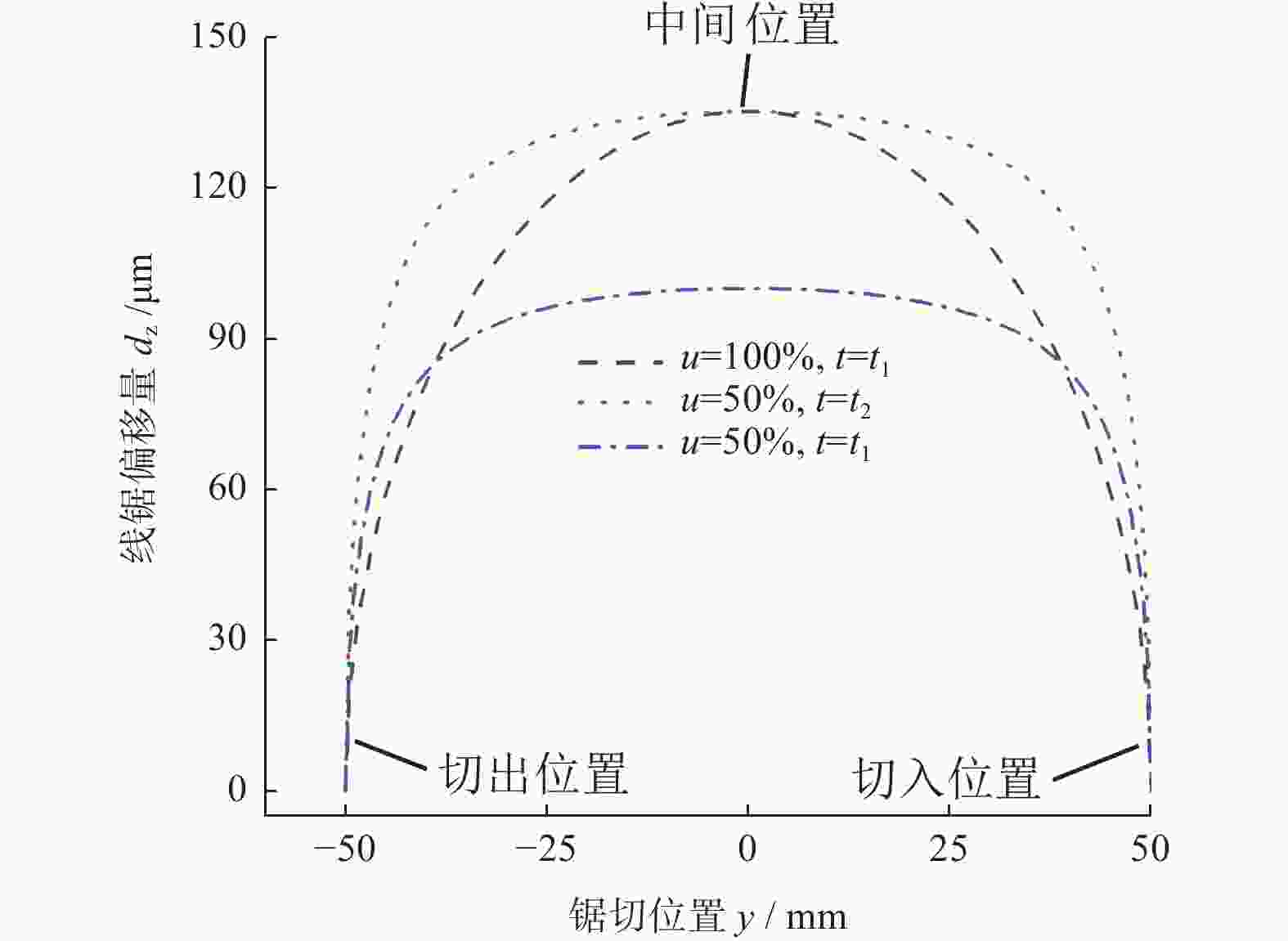

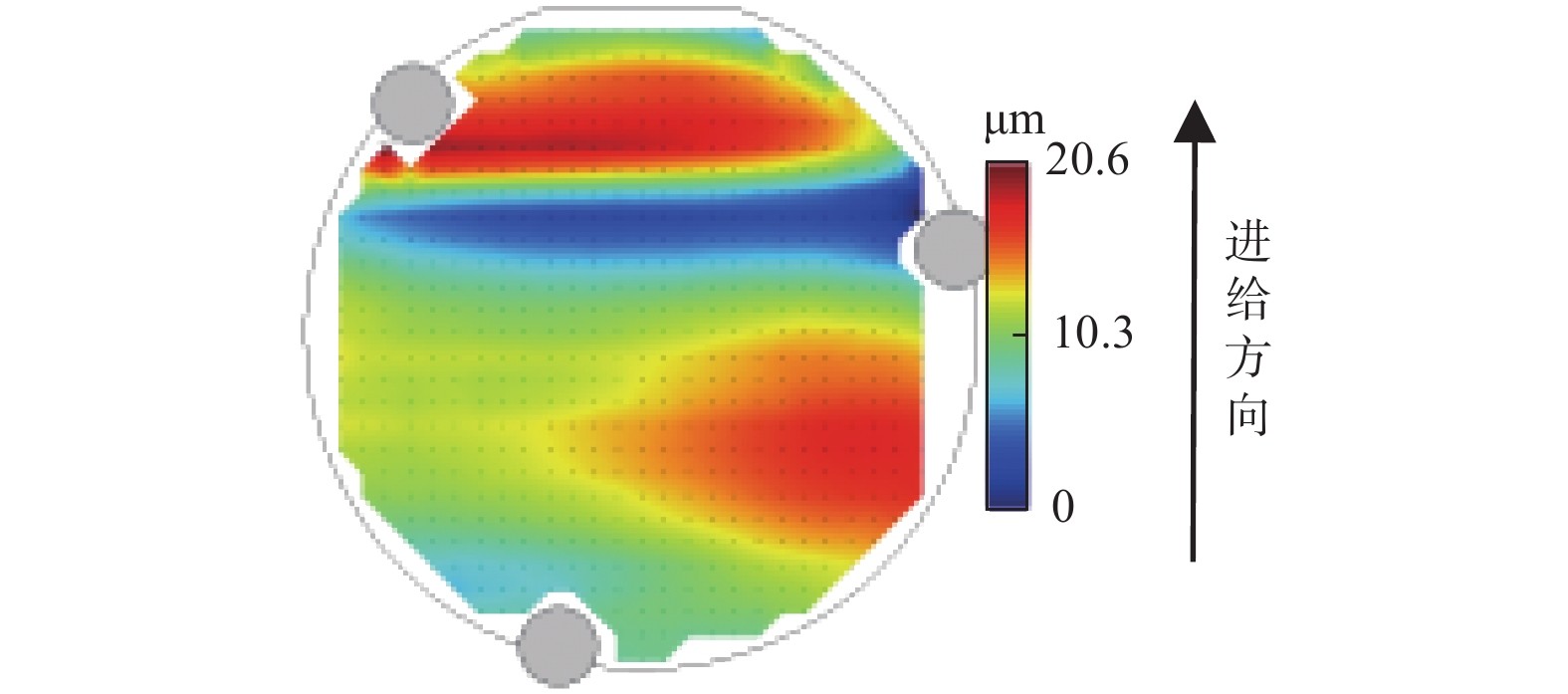

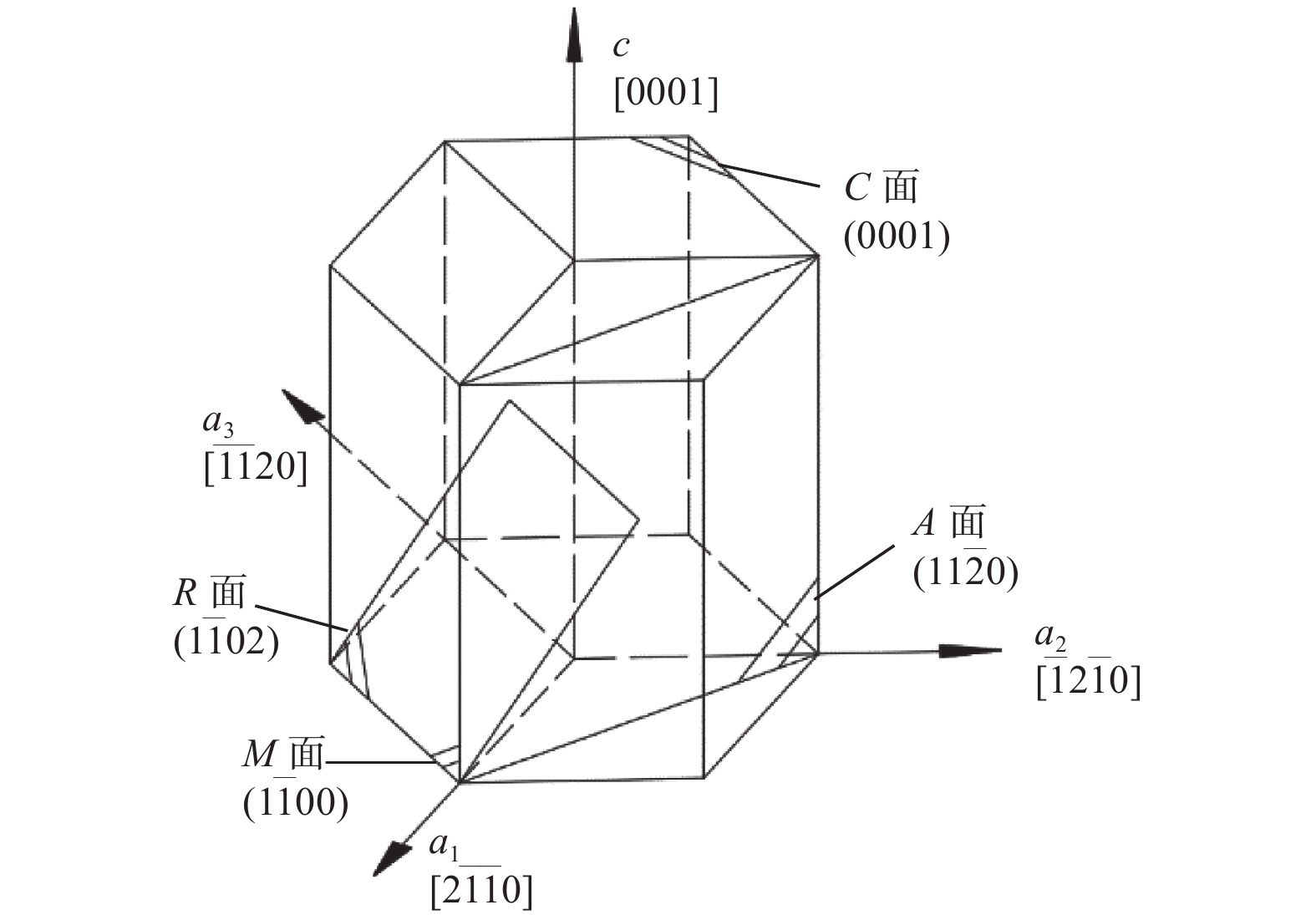

摘要: 在多线锯切片加工中,由于蓝宝石晶体材料的各向异性,不同加工位置处的力学性能不同,导致金刚石线锯在垂直进给方向上产生偏移,从而造成切片加工晶片面形偏差。为深入研究晶体各向异性对切片加工晶片面形偏差的影响机制,通过分析蓝宝石晶体材料的特性,并计算常用晶面弹性模量分布情况,结合线锯受力情况模拟,计算晶片的面形偏差,分析工艺参数对面形偏差的影响。结果表明:C面、A面和M面晶片面形偏差不受蓝宝石各向异性的影响;R面晶片切片加工时,可选择切片进给角度为90°或270°以获得较小晶片面形偏差;减小比进给速度或采用变速进给方法可降低晶片面形偏差。Abstract: Due to the anisotropy of sapphire crystal material, the mechanical properties vary in multi-wire saw slicing based on different cutting positions. This variation leads to the deviation of the diamond wire in the vertical feed direction, resulting in the surface shape deviation of the sapphire wafers. To further investigate the influence of crystal anisotropy on the surface shape deviation of the wafer, the properties of sapphire crystal material were analyzed, and the distribution of the elastic modulus of its common crystal surfaces was calculated. By simulating the sawing force, the surface shape deviation of the wafer was calculated, and the influence of process parameters on the surface shape deviation was analyzed. The results show that the surface shape deviations of wafers cut from the C-plane, A-plane, and M-plane are not affected by the anisotropy of sapphire. A feed angle of 90° or 270° can be selected to obtain a small surface shape deviation during the slicing process of the R-plane. Additionally, reducing the specific feed rate or adopting the variable speed feed method can reduce the wafer's surface shape deviation.

-

Key words:

- sapphire /

- diamond wire saw /

- crystal anisotropy /

- surface shape deviation /

- process parameter

-

表 1 蓝宝石柔性系数[5]

Table 1. Elastic constants of sapphire

序号 s11

10−11 Pa−1s13

10−11 Pa−1s33

10−11 Pa−1s44

10−11 Pa−11 0.2353 0.0364 0.2170 0.6940 表 2 仿真工艺参数

Table 2. Process parameters of simulation

参数 单位 数值 比进给速度kv (μm·min)−1/(m·s−1) 10, 15, 20, 25 进给速比u (μm·min)−1/(μm·min−1)×100% 25, 50, 75, 100 表 3 金刚石线锯参数

Table 3. Parameters of diamond wire

平均外径

rm / μm母线外径

rl / μm磨粒尺寸

dg / μm磨粒密度

ρg / (个·mm−1)220 160 30~40 82 表 4 实验工艺参数

Table 4. Process parameters of experiment

参数 单位 取值 走丝速度 vs

m/s

12

比进给速度 kv (μm·min−1/(m·s−1) 15 进给速比 u (μm·min−1)/(μm·min−1)×100% 50 -

[1] CHEN P H, SU V C, WU S H, et al. Defect reduction in GaN on dome-shaped patterned-sapphire substrates [J]. Optical Materials,2018,76:368-374. doi: 10.1016/j.optmat.2018.01.010 [2] 王志强, 方伟, 豁国燕, 等. LED蓝宝石衬底研磨工艺研究 [J]. 金刚石与磨料磨具工程,2015,35(2):59-62. doi: 10.13394/j.cnki.jgszz.2015.2.0012WANG Zhiqiang, FANG Wei, HUO Guoyan, et al. Research on lapping technology of LED sapphire substrate [J]. Diamond & Abrasives Engineering,2015,35(2):59-62. doi: 10.13394/j.cnki.jgszz.2015.2.0012 [3] 葛培琪, 陈自彬, 王沛志. 单晶硅切片加工技术研究进展 [J]. 金刚石与磨料磨具工程,2020,40(4):12-18. doi: 10.13394/j.cnki.jgszz.2020.4.0002GE Peiqi, CHEN Zibin, WANG Peizhi. Review of monocrystalline silicon slicing technology [J]. Diamond & Abrasives Engineering,2020,40(4):12-18. doi: 10.13394/j.cnki.jgszz.2020.4.0002 [4] ZHENG J, GE P, BI W, et al. Action mechanism of liquid bridge between electroplated diamond wires for ultrathin wafer slicing [J]. Solar Energy,2022,231:343-354. doi: 10.1016/j.solener.2021.11.069 [5] DOBROVINSKAYA E R, LYTVYNOV L A, PISHCHIK V. Sapphire: Material, manufacturing, applications [M]. Berlin: Springer Publishing Company Incorporated, 2009. [6] 徐晓明, 周海, 卓志国, 等. 蓝宝石衬底基片工艺质量检测指标及方法的研究进展 [J]. 现代制造工程,2013(3):87-90. doi: 10.3969/j.issn.1671-3133.2013.03.021XIU Xiaoming, ZHOU Hai, ZHUO Zhiguo, et al. Research progress of detection technology for sapphire substrate [J]. Modern Manufacturing Engineering,2013(3):87-90. doi: 10.3969/j.issn.1671-3133.2013.03.021 [7] VODENITCHAROVA T, ZHANG L C, ZARUDI I, et al. The effect of anisotropy on the deformation and fracture of sapphire wafers subjected to thermal shocks [J]. Journal of Materials Processing Technology,2007,194(1):52-62. doi: 10.1016/j.jmatprotec.2007.03.125 [8] GRACA S, TRABADELO V, NEELS A, et al. Influence of mosaicity on the fracture behavior of sapphire [J]. Acta Materialia,2014,67:67-80. doi: 10.1016/j.actamat.2013.12.004 [9] BHATTACHARYA M, DEY A, MUKHOPADHYAY A K. Influence of loading rate on nanohardness of sapphire [J]. Ceramics International,2016,42(12):13378-13386. doi: 10.1016/j.ceramint.2016.05.091 [10] 李茜茜. 线锯切割光电材料的锯切力及锯切质量的试验研究 [D]. 厦门: 华侨大学, 2017.LI Qianqian. Experimental study on force and surface quality of photoelectric material with fixed abrasive diamond wire [D]. Xiamen: Huaqiao University, 2017. [11] WANG N, JIANG F, XU X, et al. Research on the machinability of A-plane sapphire under diamond wire sawing in different sawing directions [J]. Ceramics International,2019,45(8):10310-10320. doi: 10.1016/j.ceramint.2019.02.086 [12] HUANG H, LI X X, XU X P. An experimental research on the force and energy during the sapphire sawing using reciprocating electroplated diamond wire saw [J]. Journal of Manufacturing Science and Engineering,2017,139(12):121011-121016. doi: 10.1115/1.4038109 [13] BHAGAVAT S, KAO I. Theoretical analysis on the effects of crystal anisotropy on wire sawing process and application to wafer slicing [J]. International Journal of Machine Tools and Manufacture,2006,46(5):531-541. doi: 10.1016/j.ijmachtools.2005.07.003 [14] 陈洪荪. 金属弹性的各向异性 [M]. 北京: 冶金工业出版社, 1996.CHEN Hongsun. Elastic anisotropy of metals [M]. Beijing: Metallurgical Industry Press, 1996. [15] LI Z Q, GE P Q, BI W B. Influence of anisotropy of KDP crystal on the surface shape deviation of slice by diamond wire saw [J]. The International Journal of Advanced Manufacturing Technology,2021,113:1771-1785. doi: 10.1007/s00170-021-06764-6 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS