Numerical simulation of multiphysics coupling for magnetic fluid grinding of germanium wafer by rotating magnetic field

-

摘要:

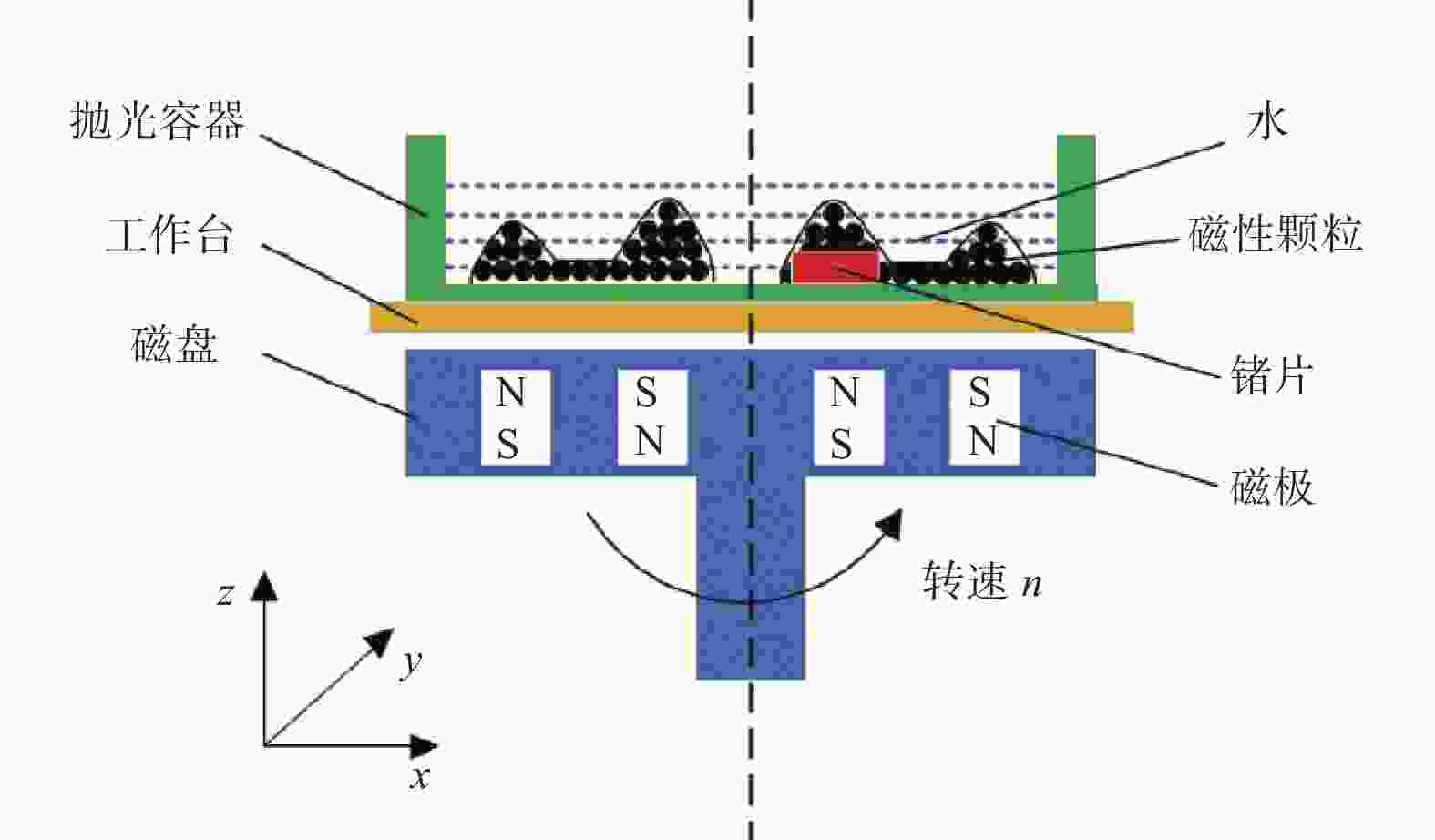

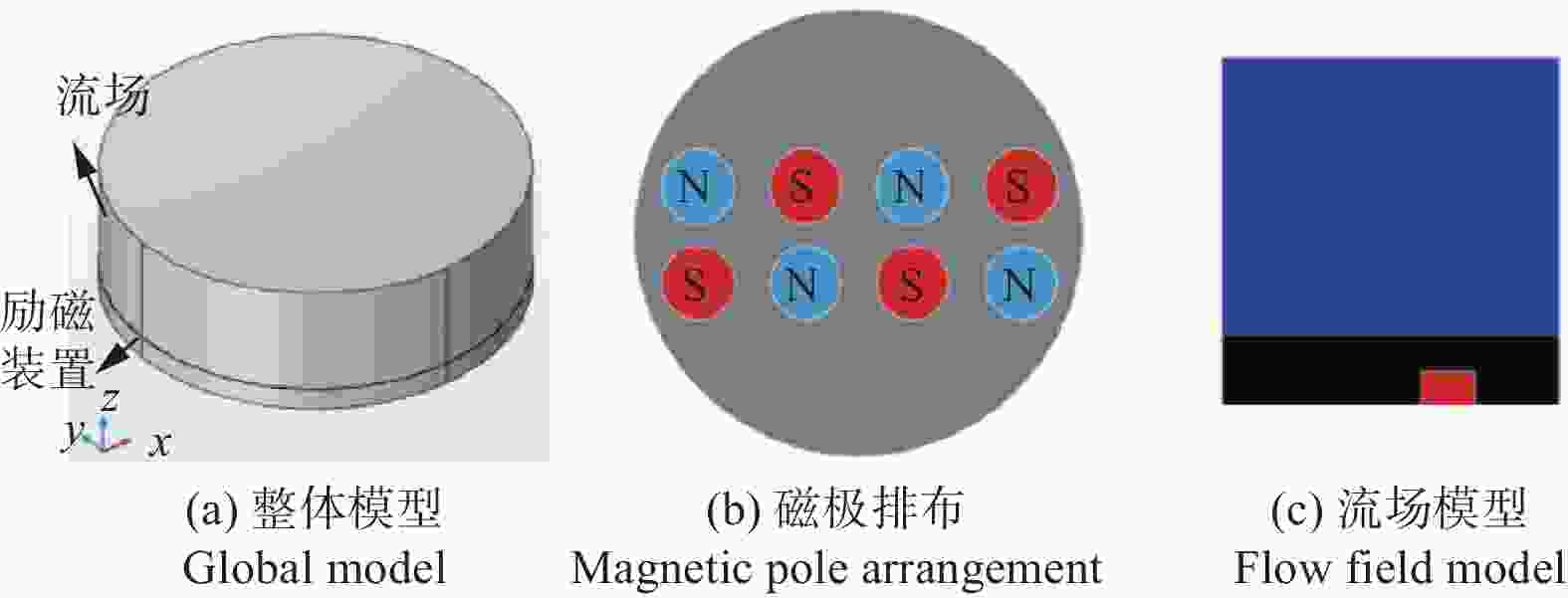

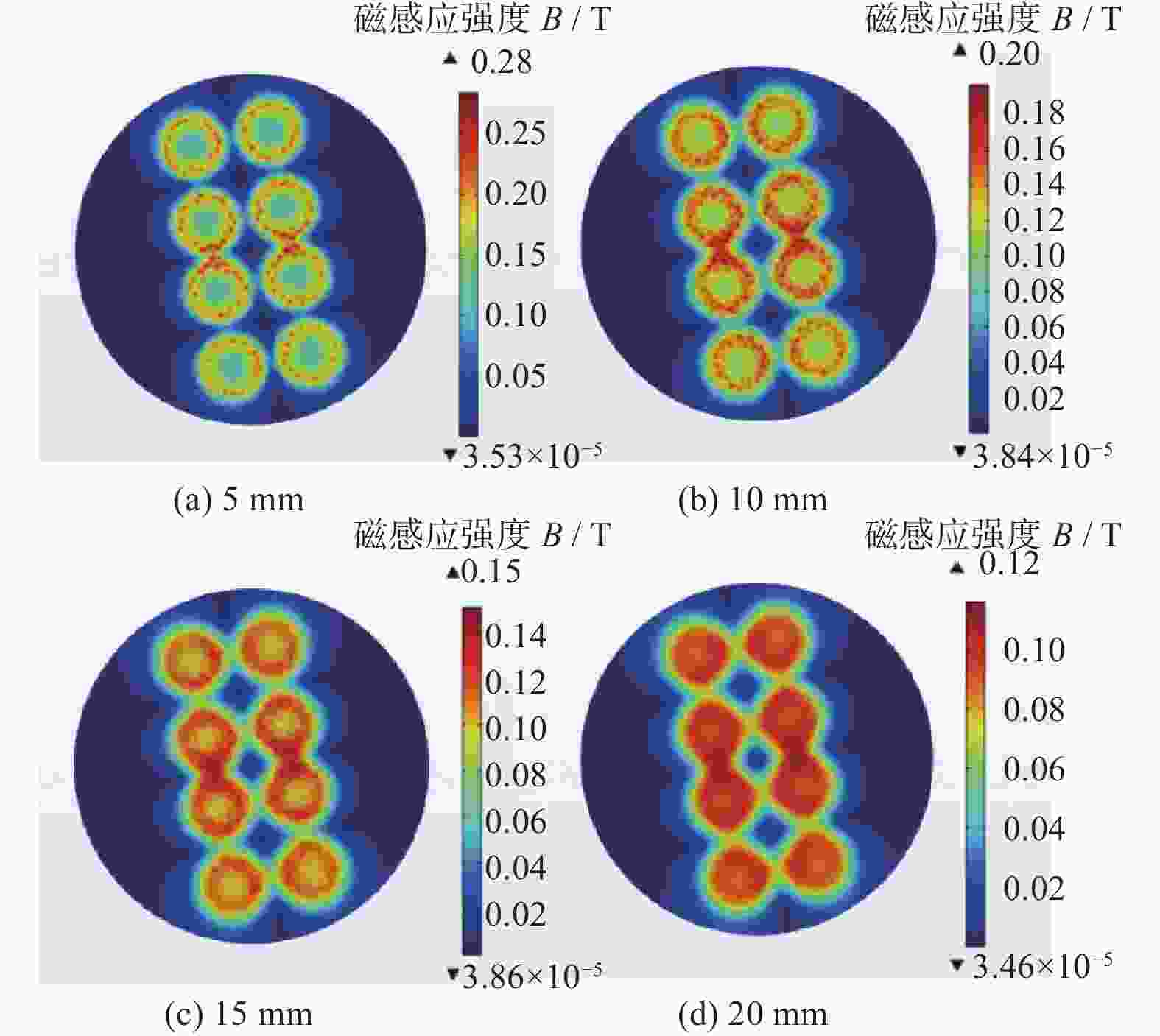

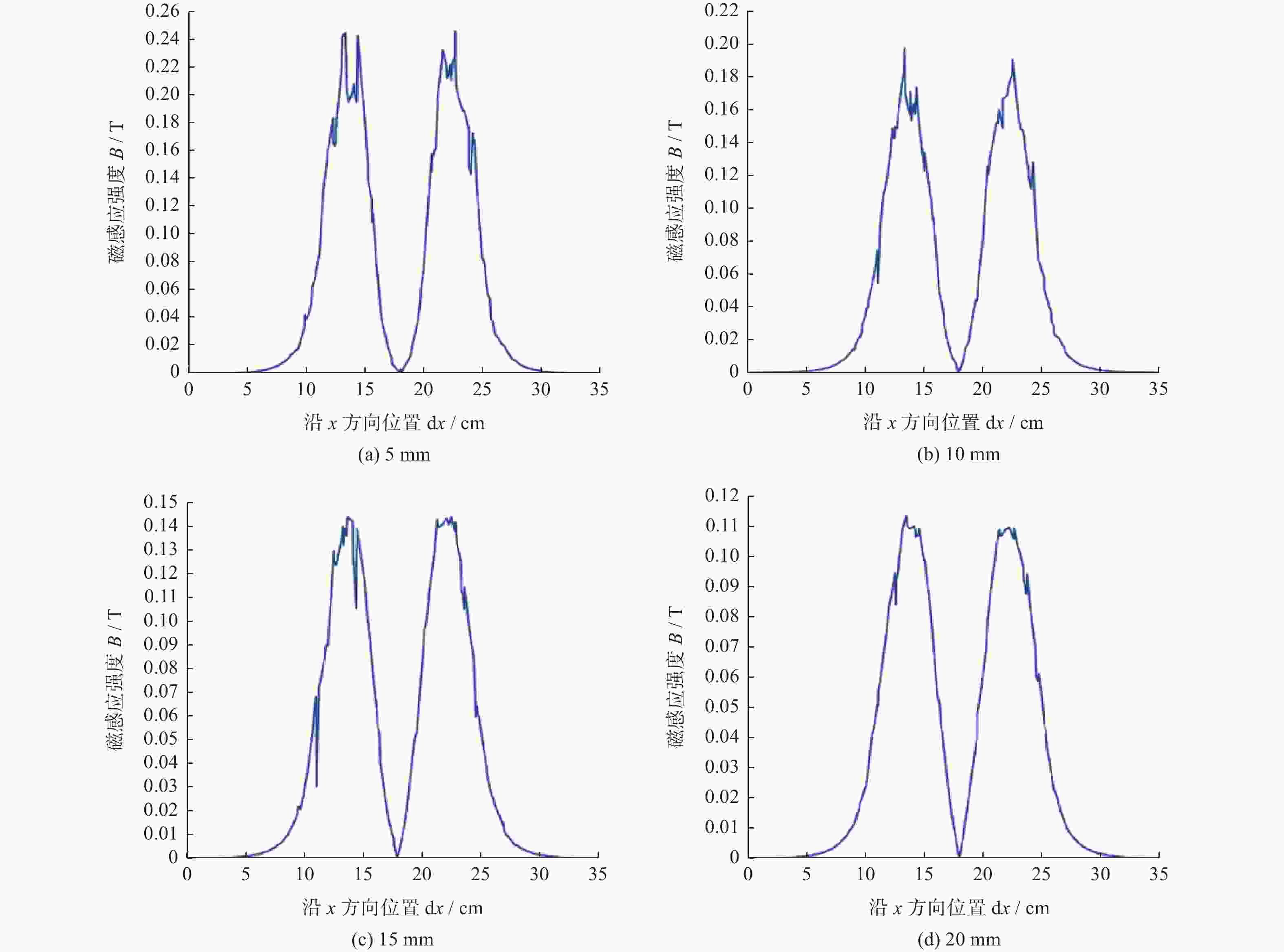

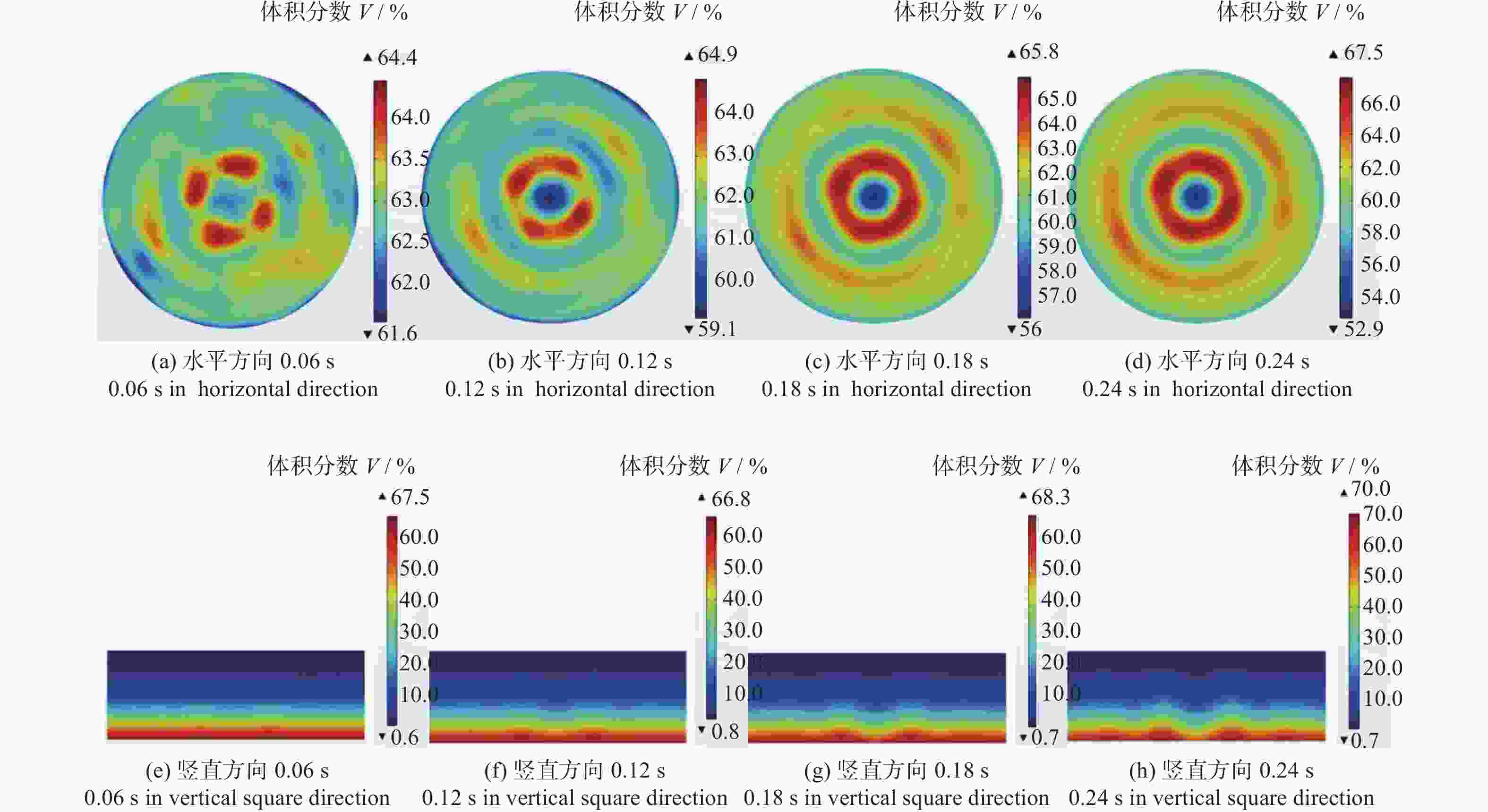

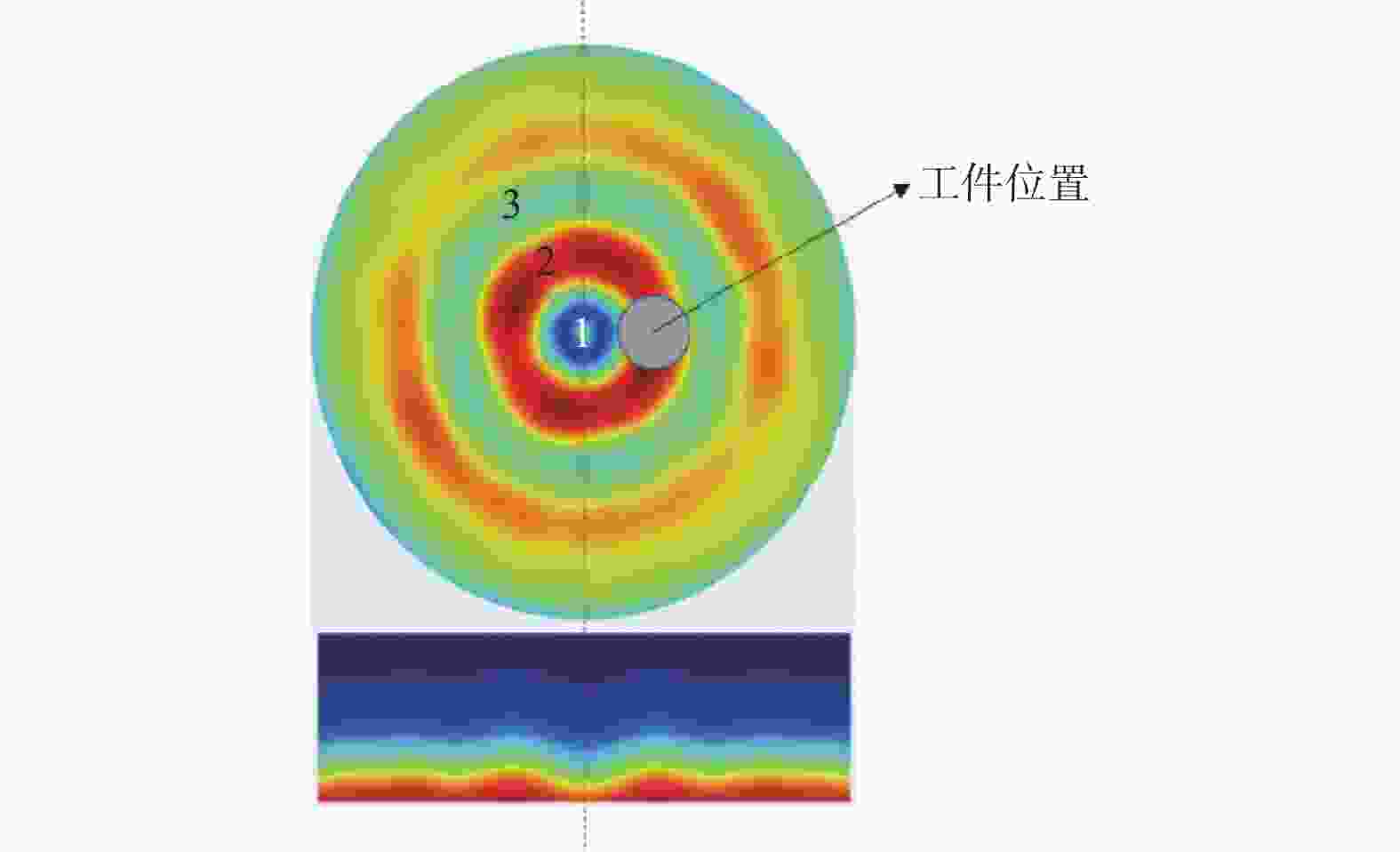

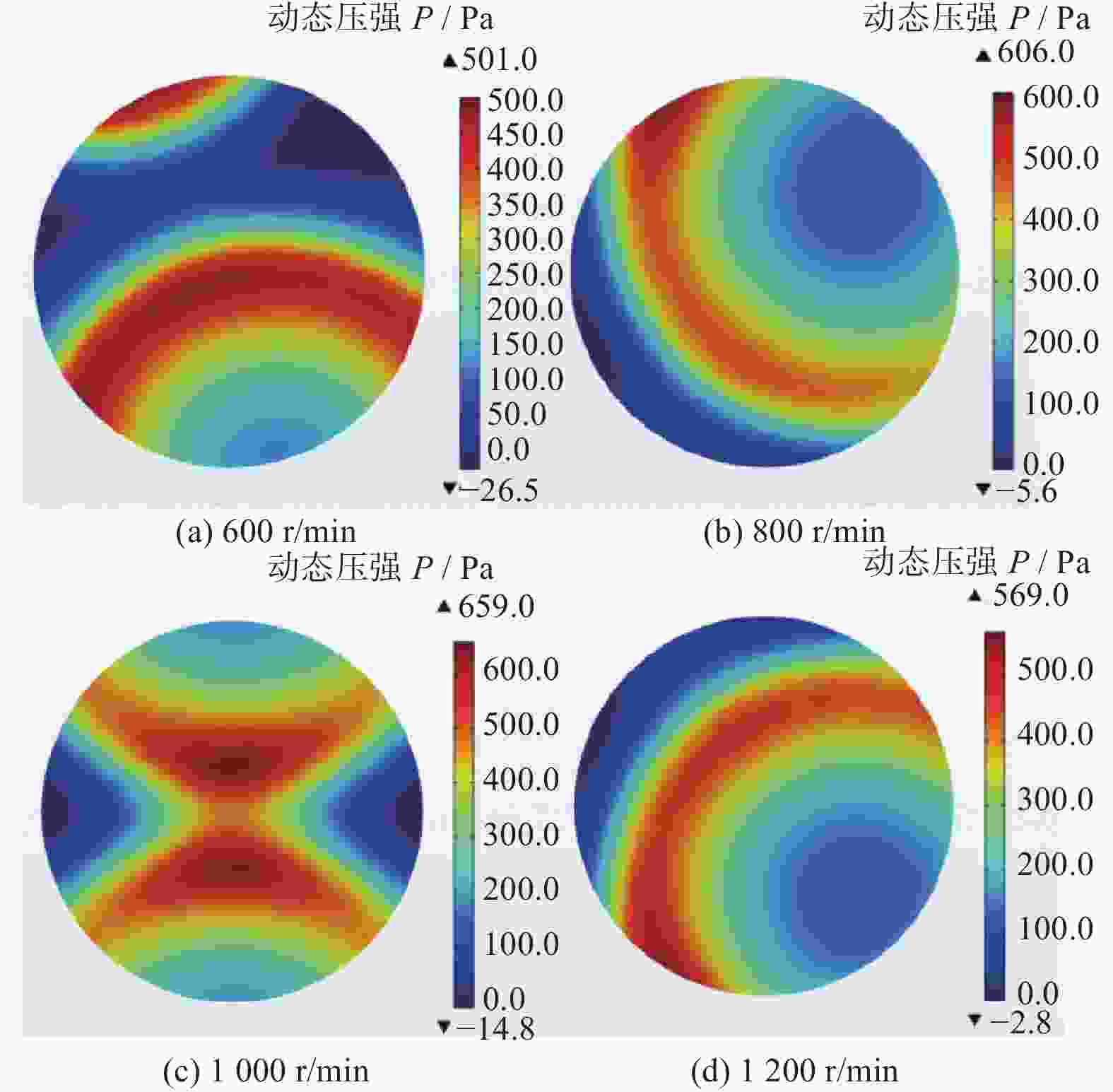

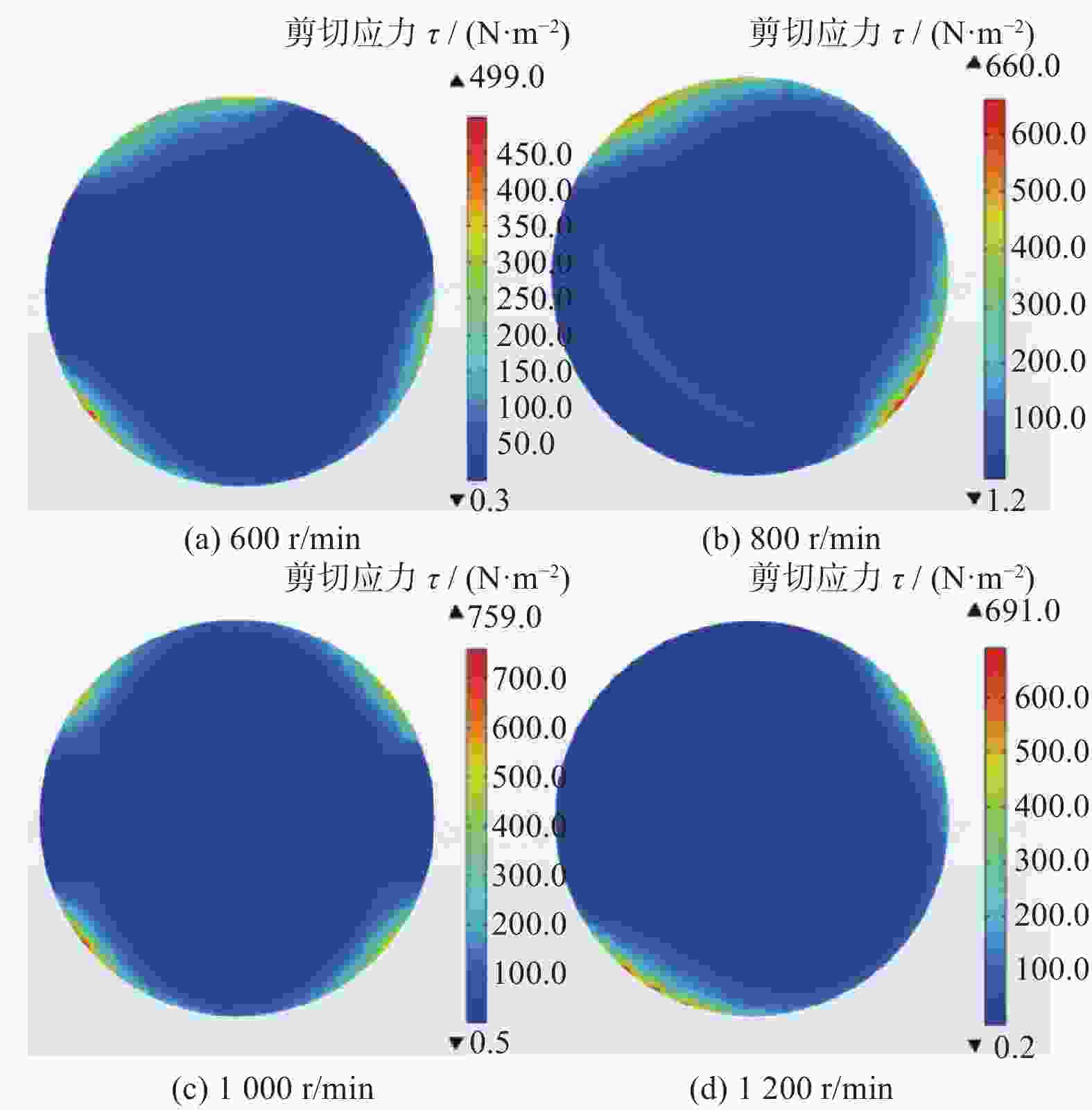

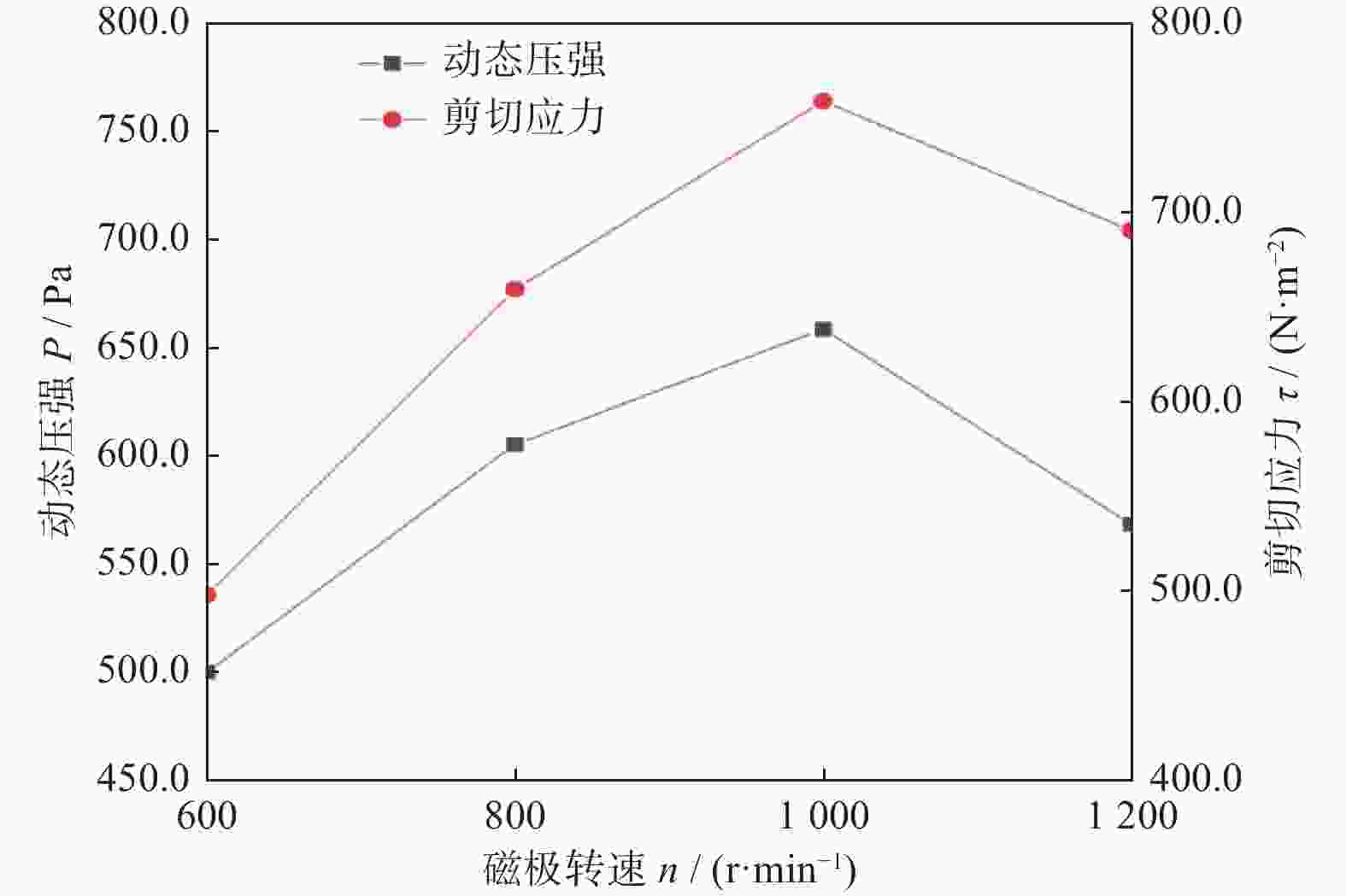

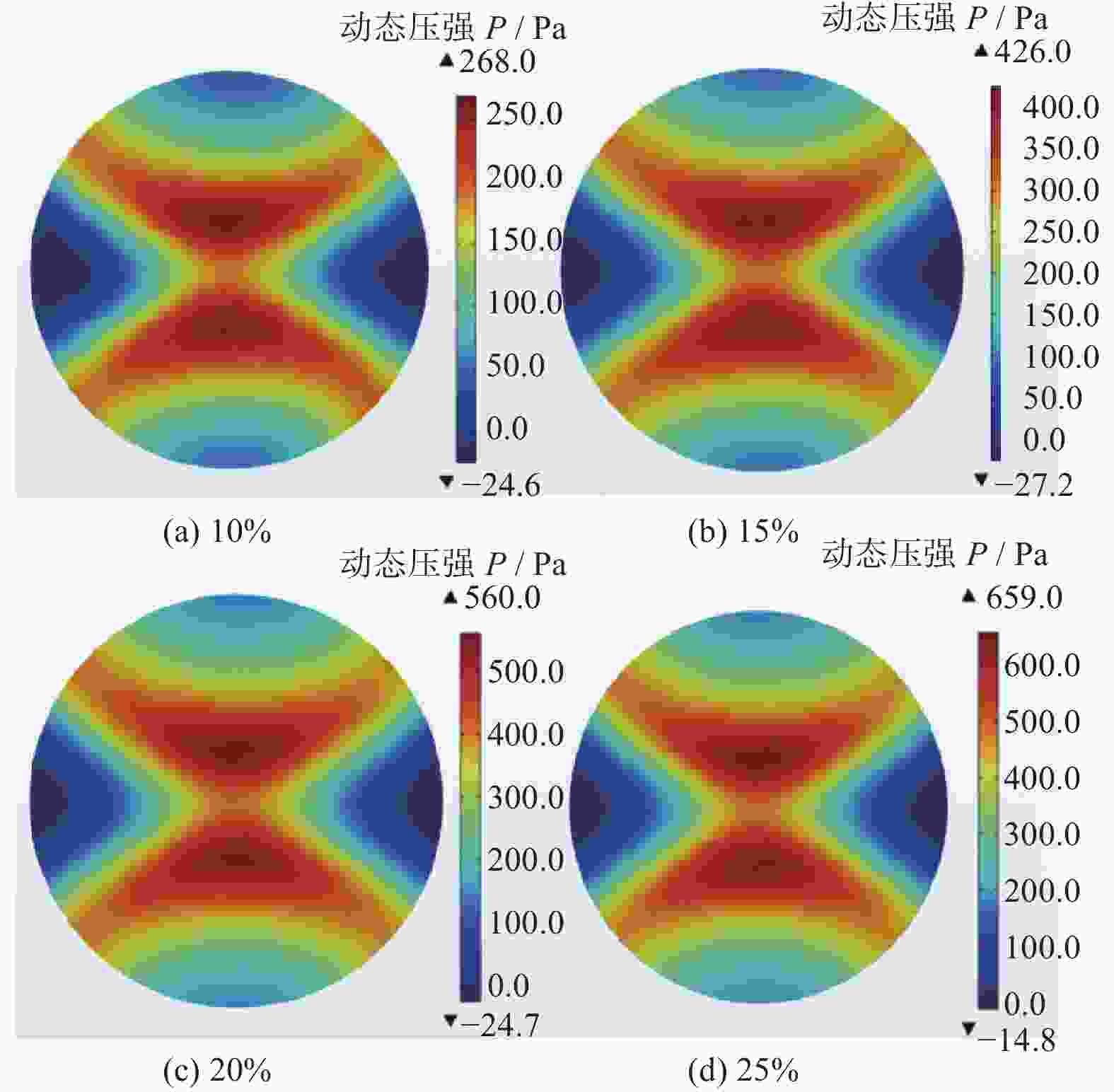

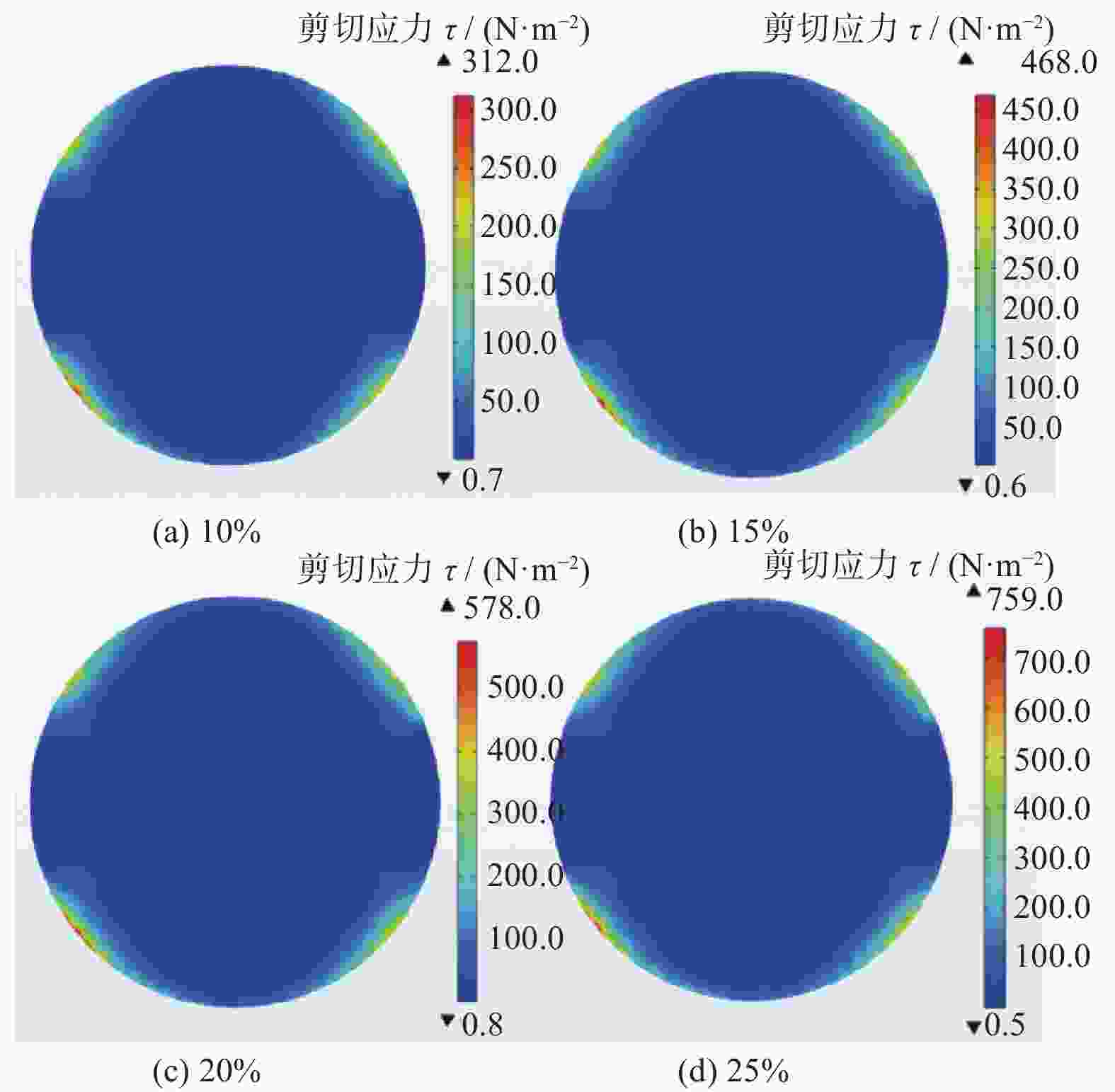

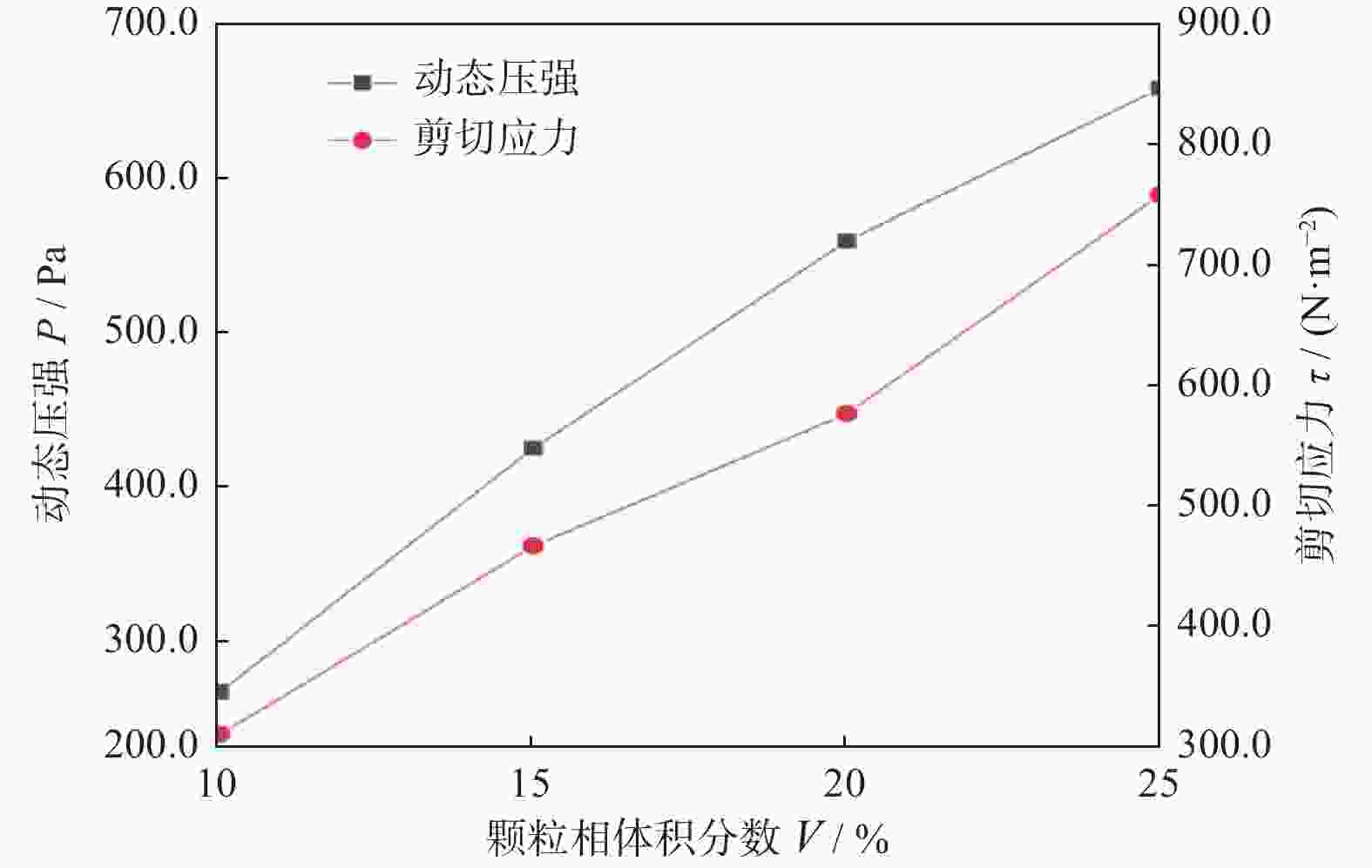

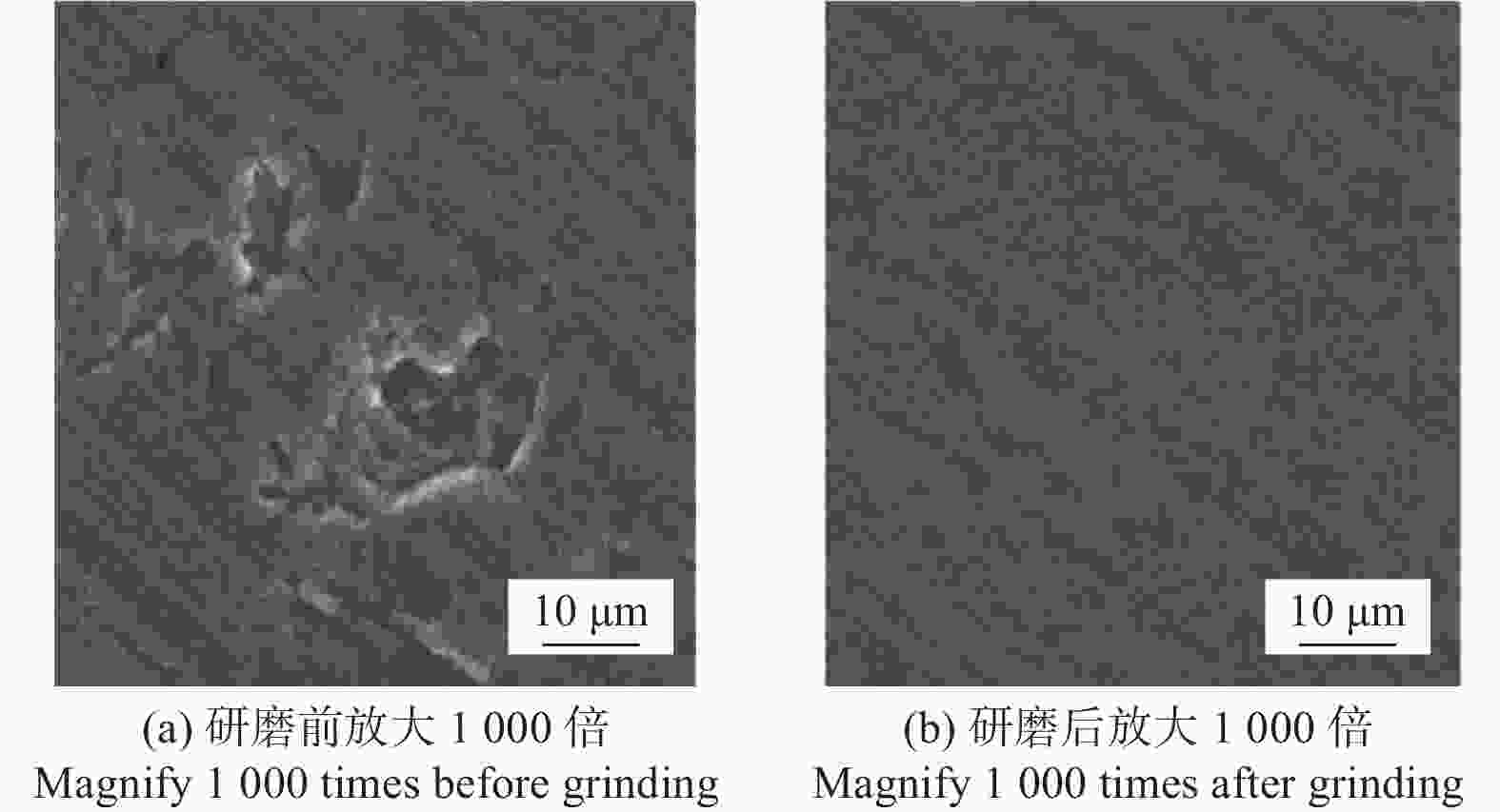

为了提高锗片的表面质量,采用旋转磁场磁流体研磨的方法,以数值模拟为研究手段,研究锗片表面在固液两相流作用下的材料去除行为。依据磁流体的研磨原理建立仿真模型,从磁流体研磨的工艺参数出发,结合有限元分析以表面力学特性为切入点,分析不同励磁间隙、磁极转速、颗粒相体积分数等加工参数对锗片表面质量的影响,确定其最佳加工工艺参数,并进行磁流体研磨试验。结果表明:在励磁间隙为5 mm,磁极转速为1 000 r/min,颗粒相体积分数为25%时,经过60 min研磨,锗片的表面质量得到有效改善,其表面粗糙度Ra由500 nm下降到47 nm,实现了锗片表面微小的塑性材料去除。

Abstract:In order to improve the surface quality of germanium wafer, the material removal behavior of germanium wafer under the action of solid-liquid two-phase flow was studied by means of rotating magnetic field magnetic fluid grinding and numerical simulation. Firstly, the grinding principle of magnetic fluid was introduced. Secondly, a simulation model was established. Starting from the process parameters of magnetic fluid grinding and combined with finite element analysis, the surface mechanical properties are taken as the breakthrough point. The effects of processing parameters such as different excitation gaps, magnetic pole rotation speeds, and particle phase volume fractions on the surface quality of the germanium wafer were analyzed. The optimal processing parameters were determined. Finally, the magnetic fluid grinding test was carried out. The results show that when the excitation gap is 5 mm, the magnetic pole rotation speed is 1000 r/min, and the volume fraction of the particle phase is 25%. After grinding for 60 minutes, the surface quality of germanium wafer was improved effectively, and the surface roughness Ra decreased from 500 nm to 47 nm, which realized the removal of small plastic materials on the surface of germanium wafer.

-

-

[1] CHEN W S, CHANG B C, CHIU K L. Recovery of germanium from waste optical fibers by hydrometallurgical method [J]. Journal of Environmental Chemical Engineering,2017,5:5215-5221. doi: 10.1016/j.jece.2017.09.048 [2] ZHAO Y, ZUO D W, SUN Y L, et al. Experimental study on multi-layer ice fixed abrasive polishing of single crystal germanium wafer [J]. The International Journal of Advanced Manufacturing Technology,2016,85:1045-1051. doi: 10.1007/s00170-015-8020-3 [3] 张亚萍, 席珍强, 张瑞丽, 等. 锗单晶材料的生长与应用 [J]. 材料导报,2009,23(1):14-16, 20.ZHANG Yaping, XI Zhenqiang, ZHANG Ruili, et al. Growth and application of germanium single crystal materials [J]. Material Reports,2009,23(1):14-16, 20. [4] 叶荣昌, 刘书进, 高宏, 等. 磁流体制备技术的研究现状及其存在问题 [J]. 机械工程材料,2003(3):33-34, 50. doi: 10.3969/j.issn.1000-3738.2003.03.011YE Rongchang, LIU Shujin, GAO Hong, et al. Research status and existing problems of magnetic fluid preparation technology [J]. Mechanical Engineering Materials,2003(3):33-34, 50. doi: 10.3969/j.issn.1000-3738.2003.03.011 [5] DONALD G, STEVEN D J, KORDONSKY W. Fabrication of glass aspheres using deterministic microgrinding and magnetorheological finishing [J]. Optical Manufacturing and Testing, 1995, 2536: 208-211. [6] WILLIAM K, DONALD G. Progress update in magnetorheological finishing [J]. International Journal of Modern Physics B,1999,13:2205-2212. doi: 10.1142/S0217979299002320 [7] 李蓓智, 王安伟, 杨建国, 等. 磁流变抛光磁路的结构设计及有限元仿真 [J]. 机械研究与应用,2008,21(2):92-95. doi: 10.3969/j.issn.1007-4414.2008.02.038LI Beizhi, WANG Anwei, YANG Jianguo, et al. Structure design and finite element simulation of magnetic circuit for magnetorheological polishing [J]. Mechanical Research and Application,2008,21(2):92-95. doi: 10.3969/j.issn.1007-4414.2008.02.038 [8] 石峰, 戴帆, 彭小强, 等. 磁流变抛光消除磨削亚表面损伤层新工艺 [J]. 光学精密工程,2010,18(1):162-168.SHI Feng, DAI Fan, PENG Xiaoqiang, et al. A new technique of magnetorheological polishing to eliminate subsurface damaged layer in grinding [J]. Optical precision engineering,2010,18(1):162-168. [9] 褚聪, 戴勇, 沈明, 等. 基于Fluent的强约束磨粒射流抛光特性 [J]. 表面技术,2016,45(6):198-204.CHU Cong, DAI Yong, SHEN Ming, et al. Characteristics of abrasive jet polishing with strong constraint based on Fluent [J]. Surface Technology,2016,45(6):198-204. [10] 陈宏安, 梁威. 基于COMSOL的液滴驱动模型仿真分析及实验研究 [J]. 软件工程,2022,25(8):34-38. doi: 10.19644/j.cnki.issn2096-1472.2022.008.008CHEN Hong′an, LIANG Wei. Droplet drive model simulation and experimental research based on COMSOL [J]. Software Engineering,2022,25(8):34-38. doi: 10.19644/j.cnki.issn2096-1472.2022.008.008 [11] 王强. 基于旋转磁场的磁流变光整加工技术研究 [D]. 武汉: 华中科技大学, 2020.WANG Qiang. Research on Magnetorheological finishing technology based on rotating magnetic field [D]. Wuhan: Huazhong University of Science and Technology, 2020. [12] 冯洋. 磁场作用下磁性粒子的团聚行为模拟及实验研究 [D]. 武汉: 华中科技大学, 2016.FENG Yang. Simulation and experimental study on agglomeration behavior of magnetic particles under magnetic field [D]. Wuhan: Huazhong University of Science and Technology, 2016. [13] ROSENSWEIG R E. Ferrohydrodynamics [M]. Cambridge: Cambridge University Press, 1985. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS