Analysis on the lapping uniformity of MPCVD polycrystalline diamond wafer

-

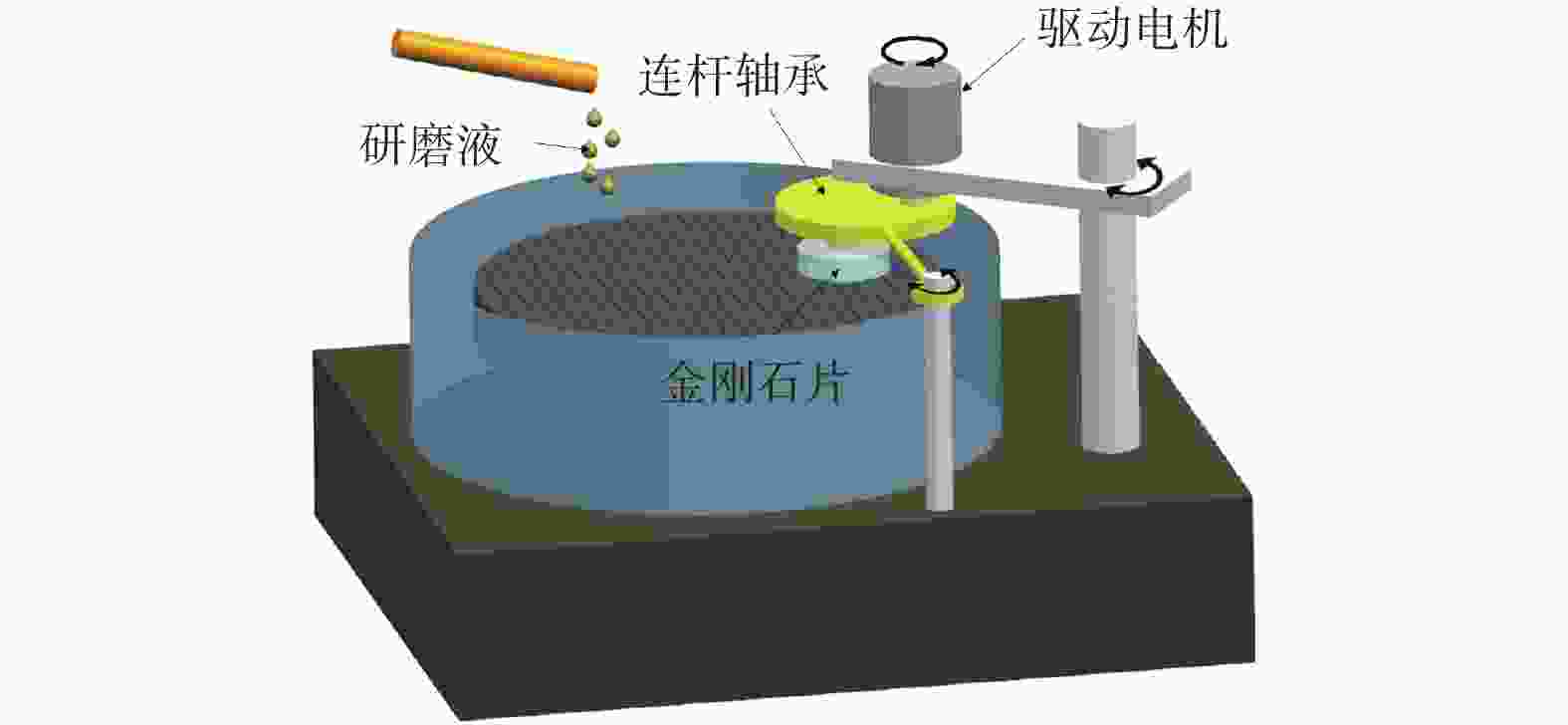

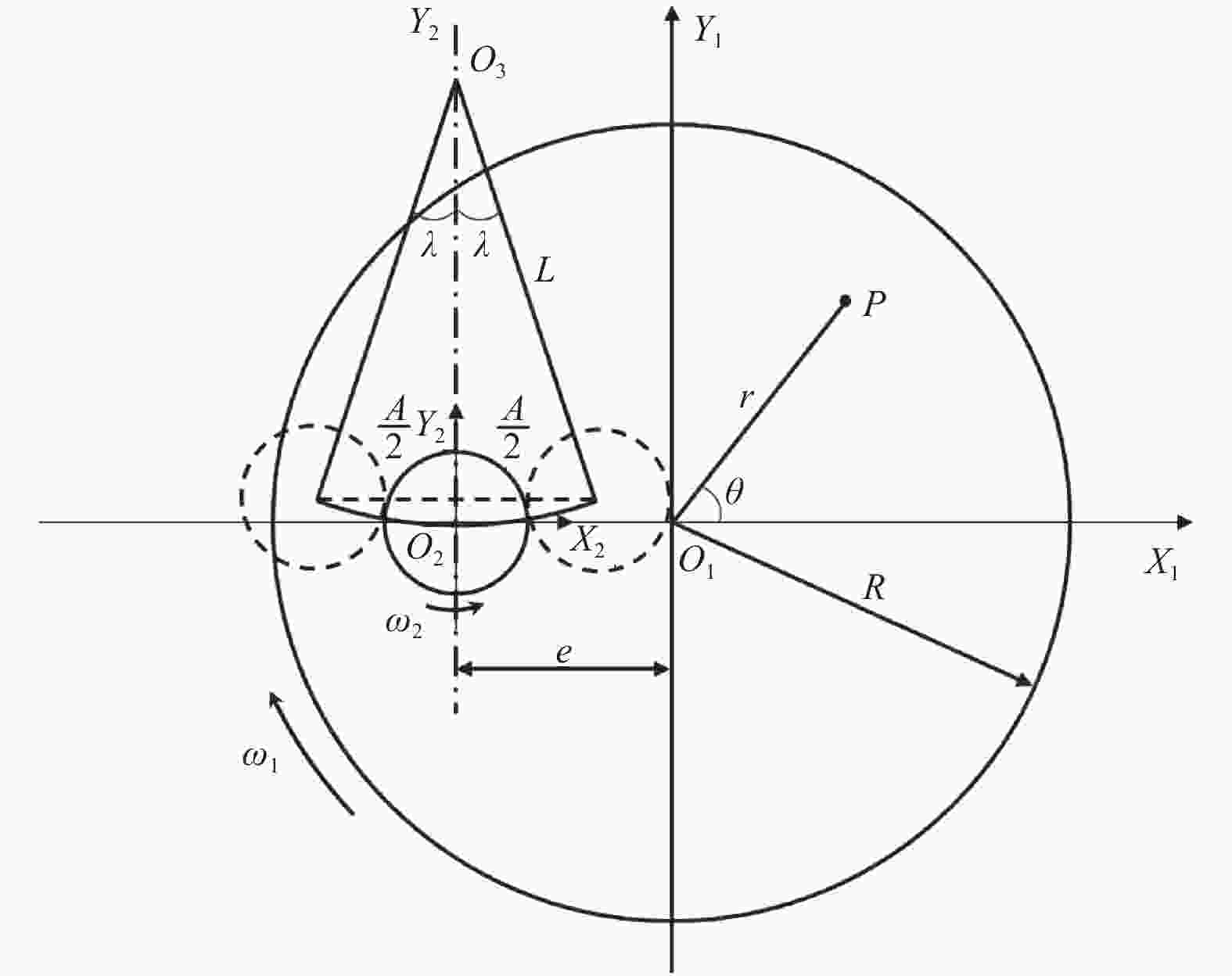

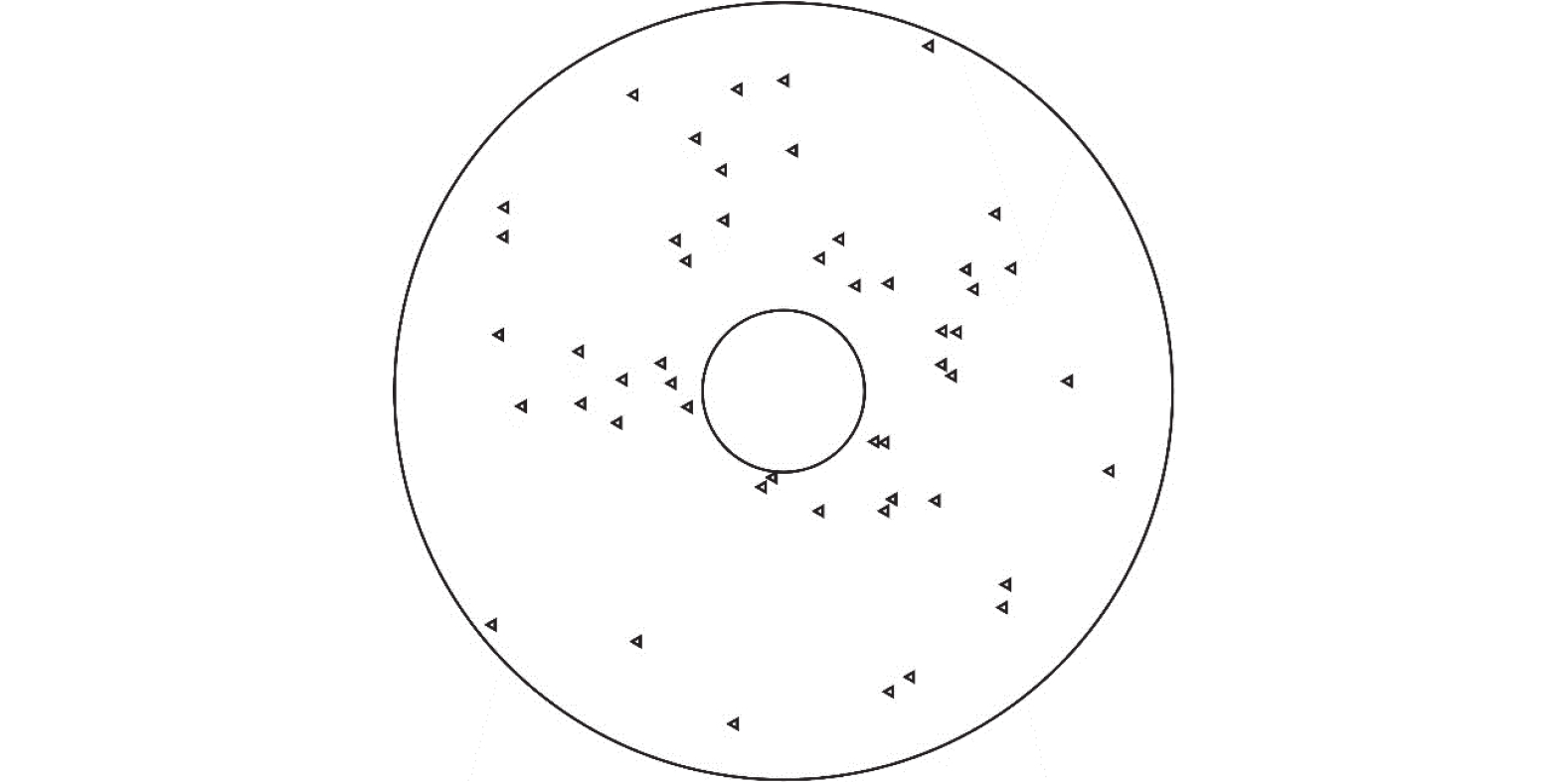

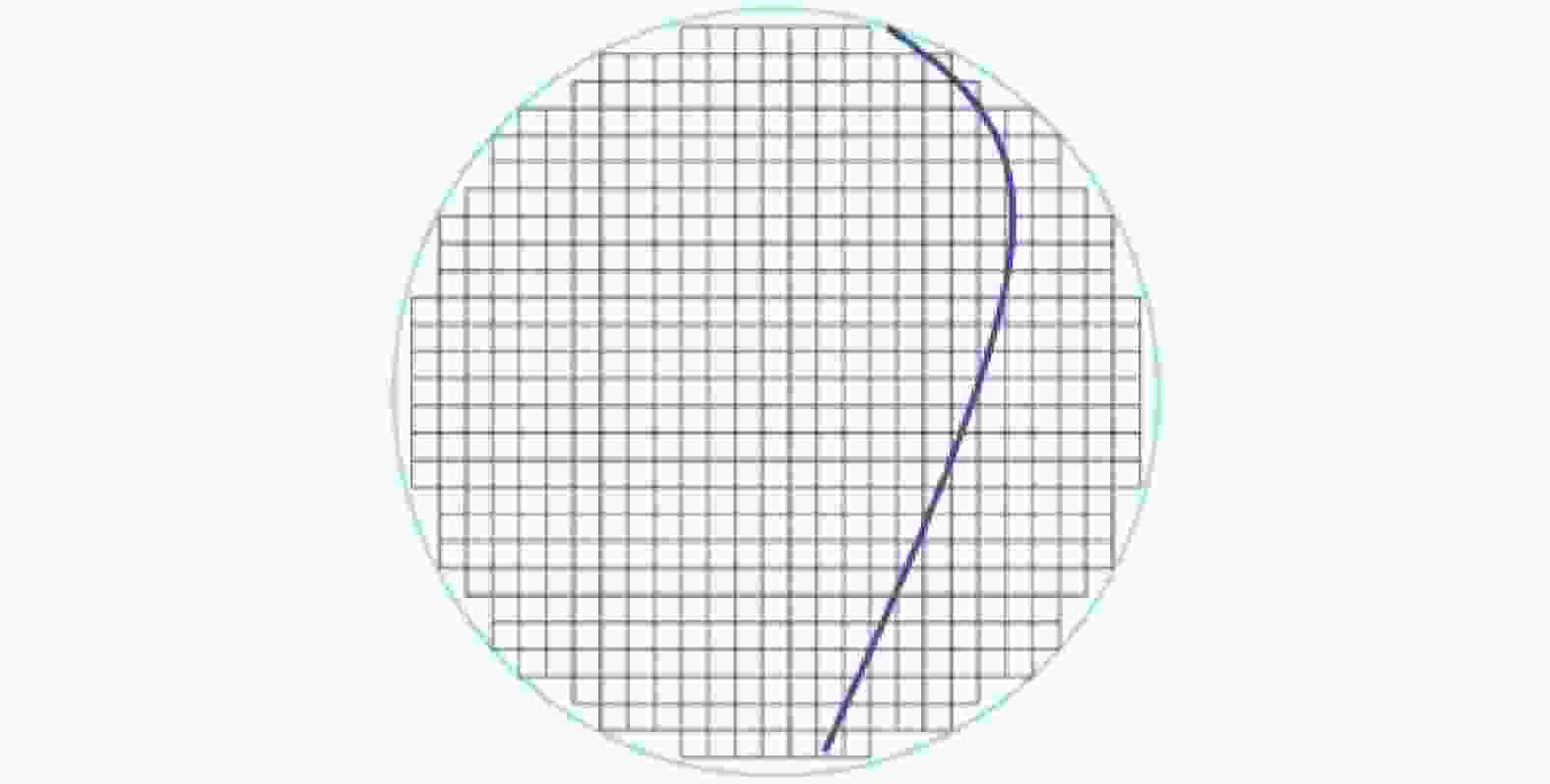

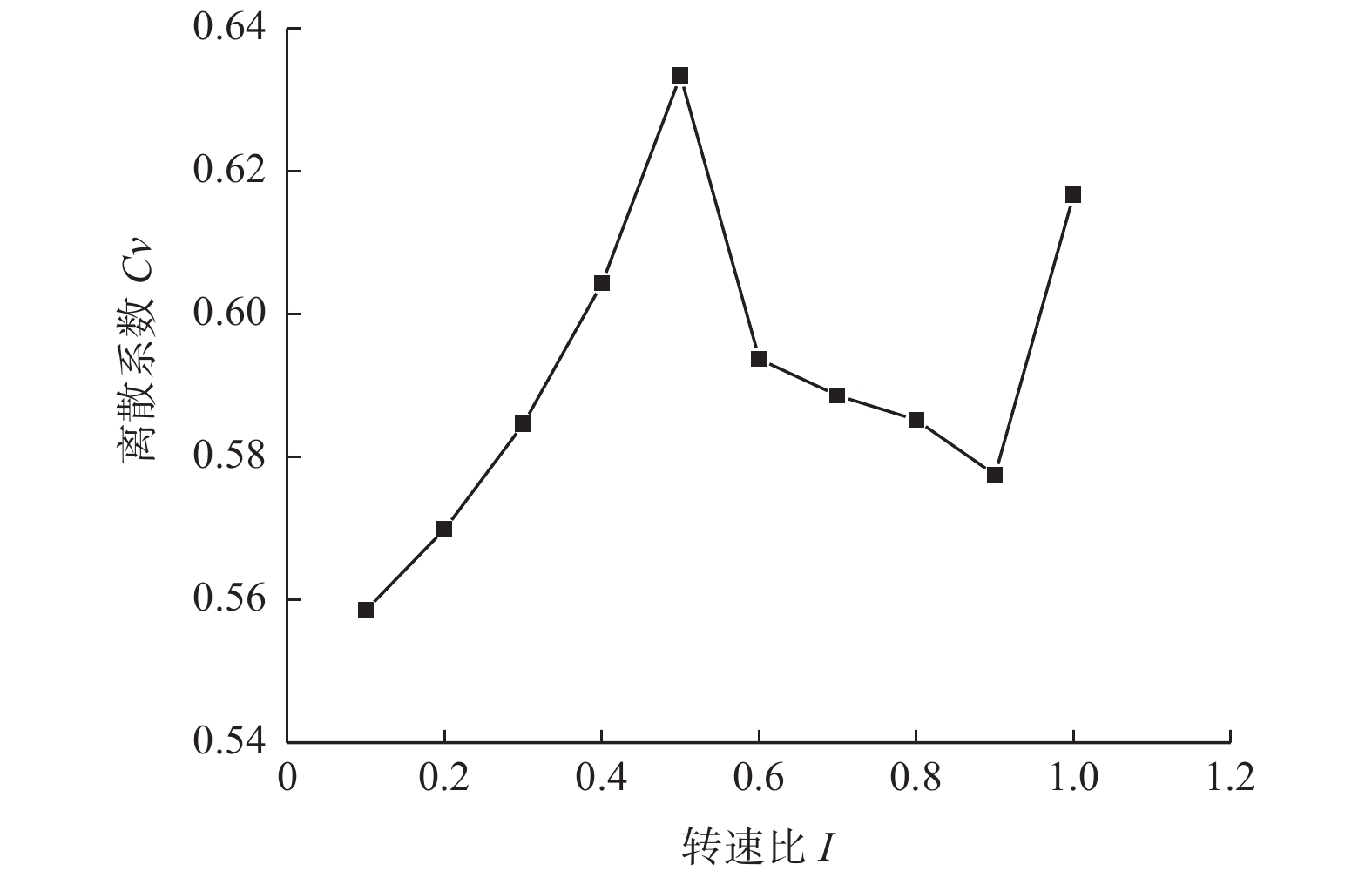

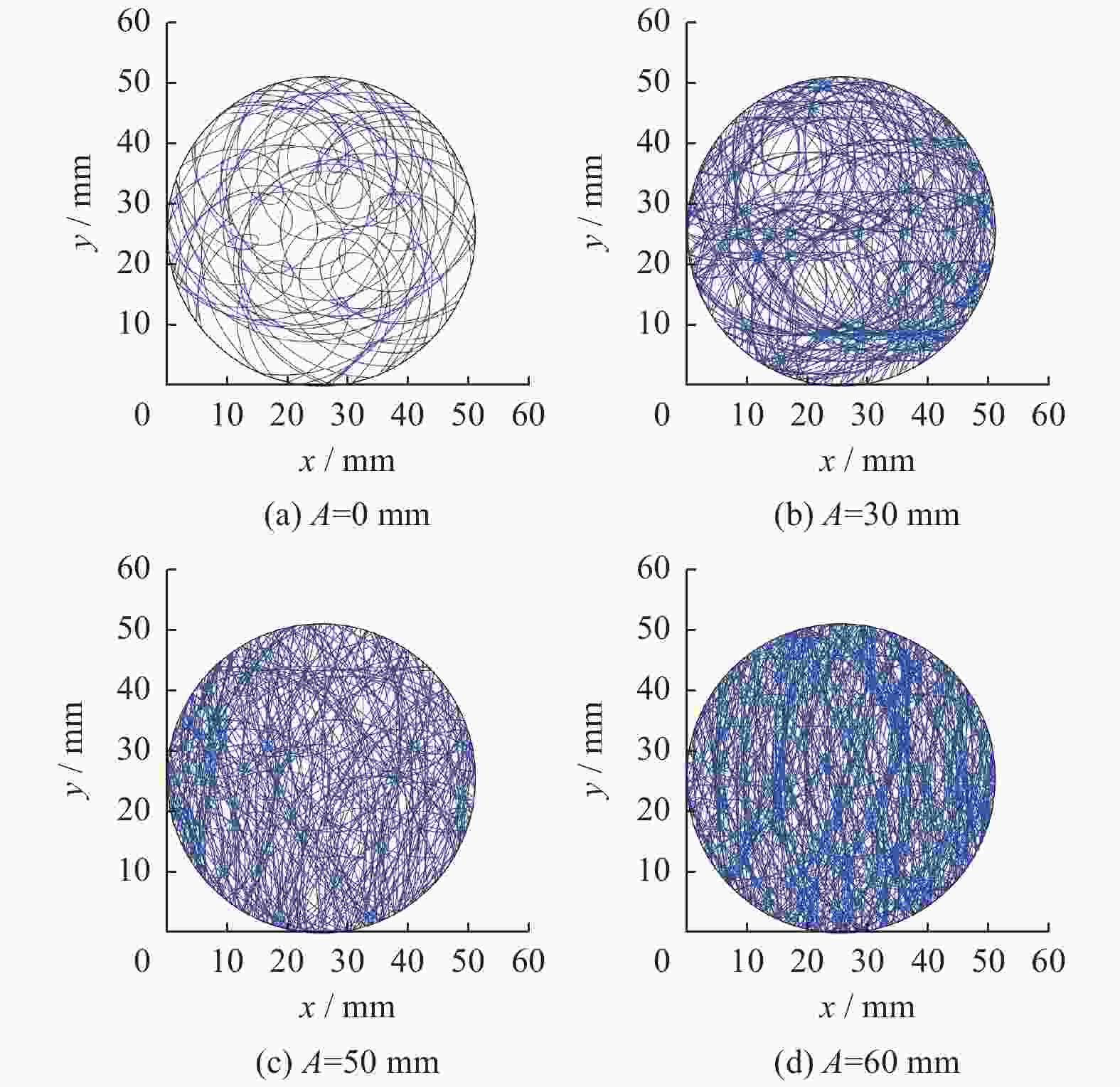

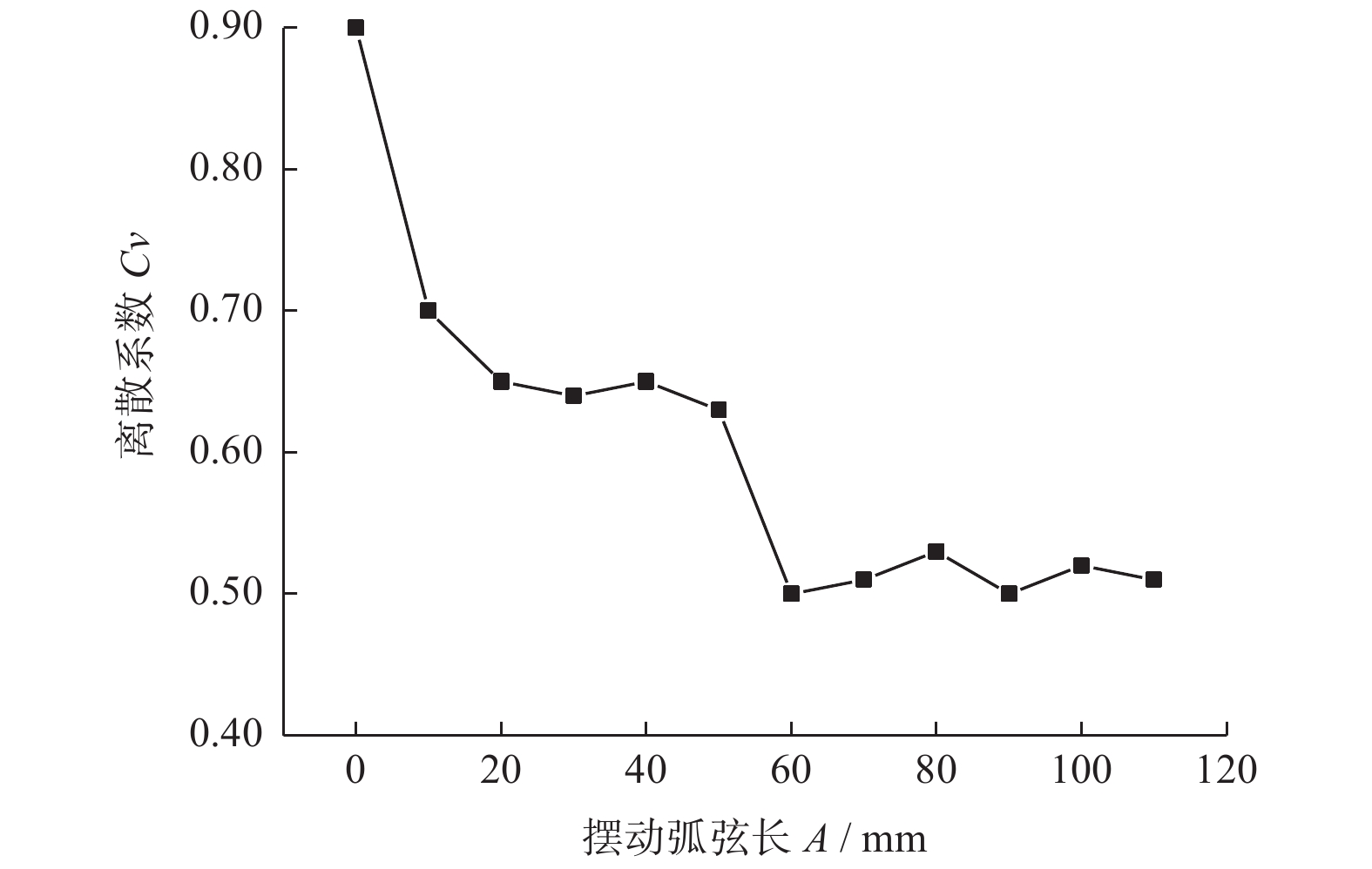

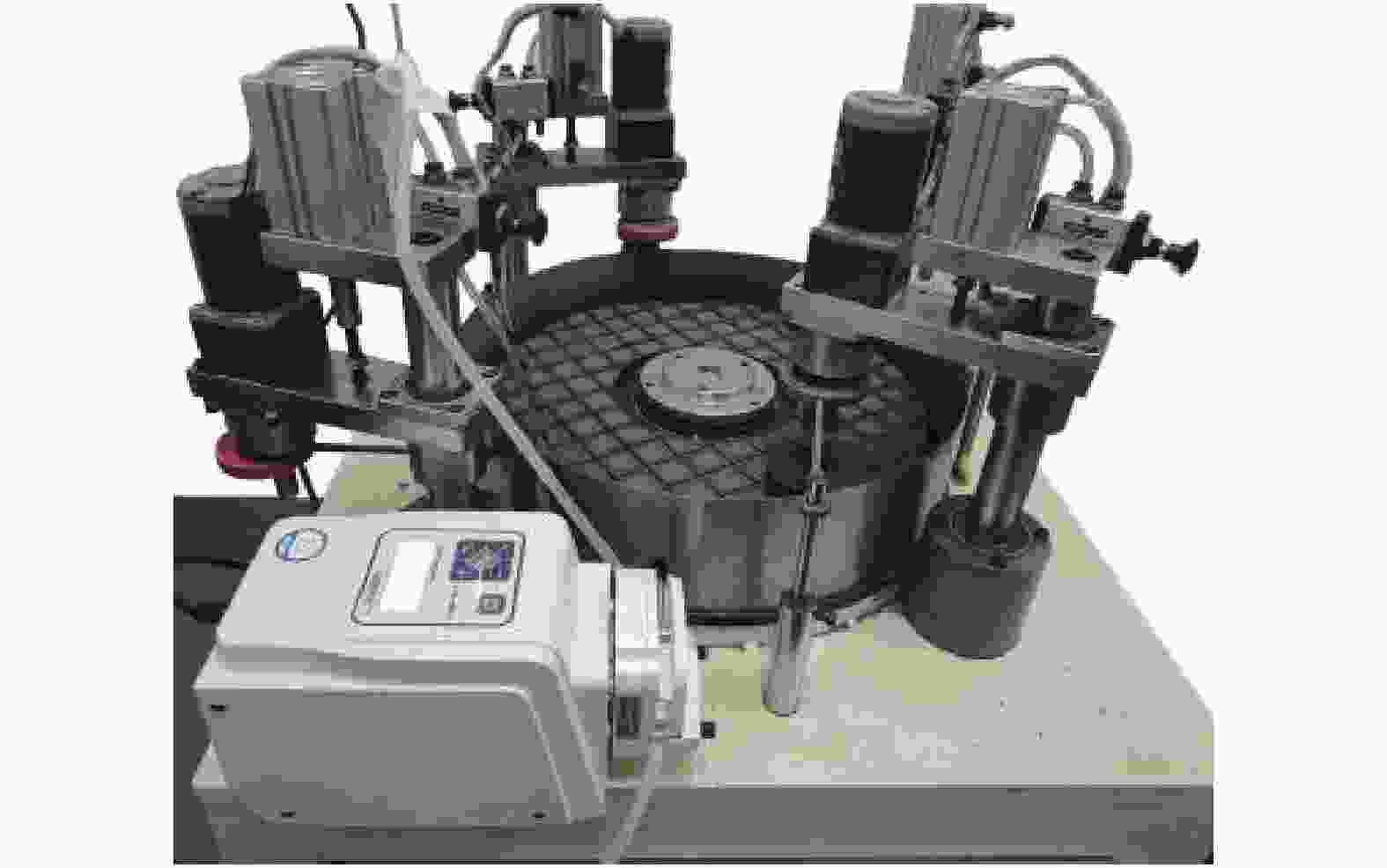

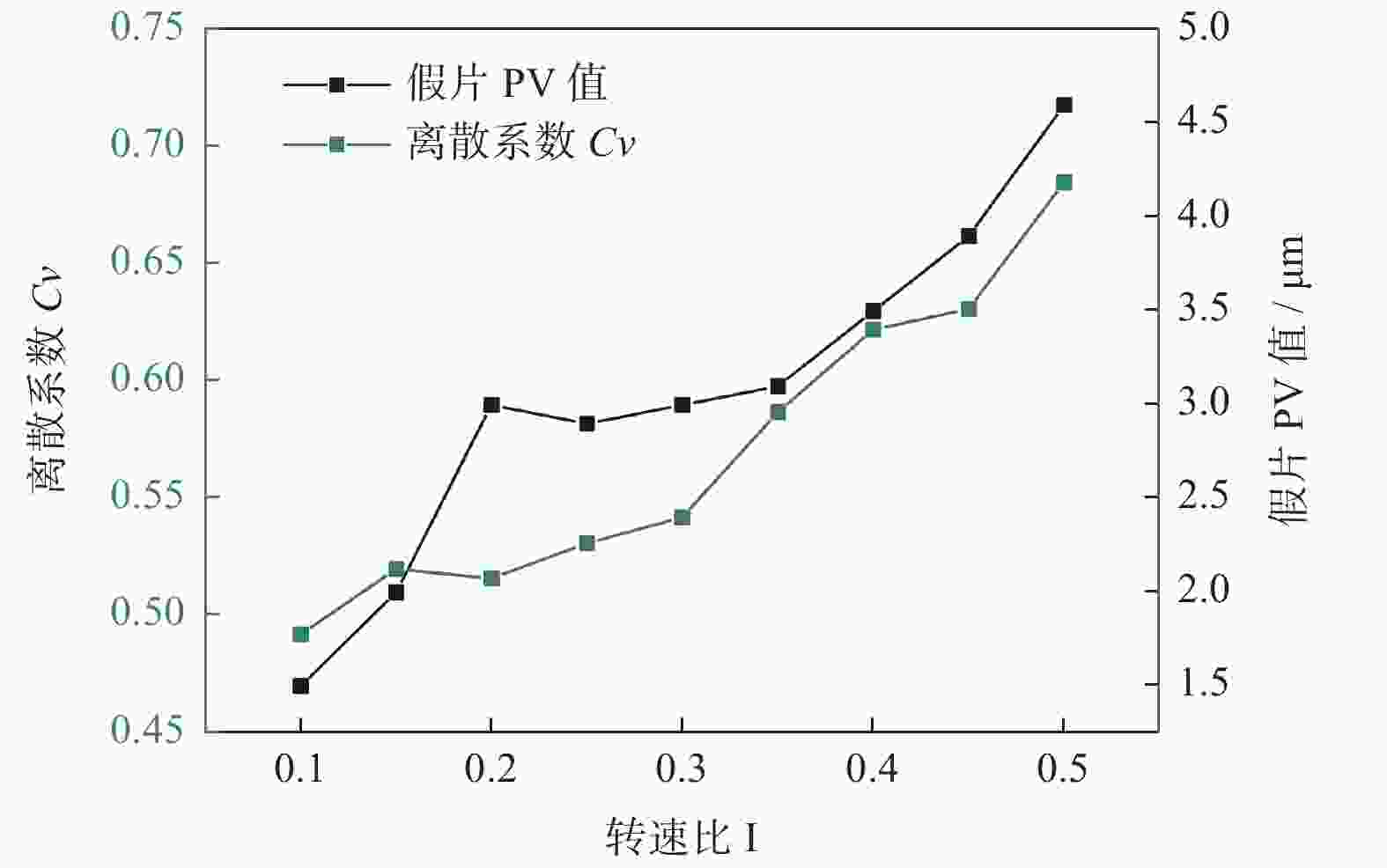

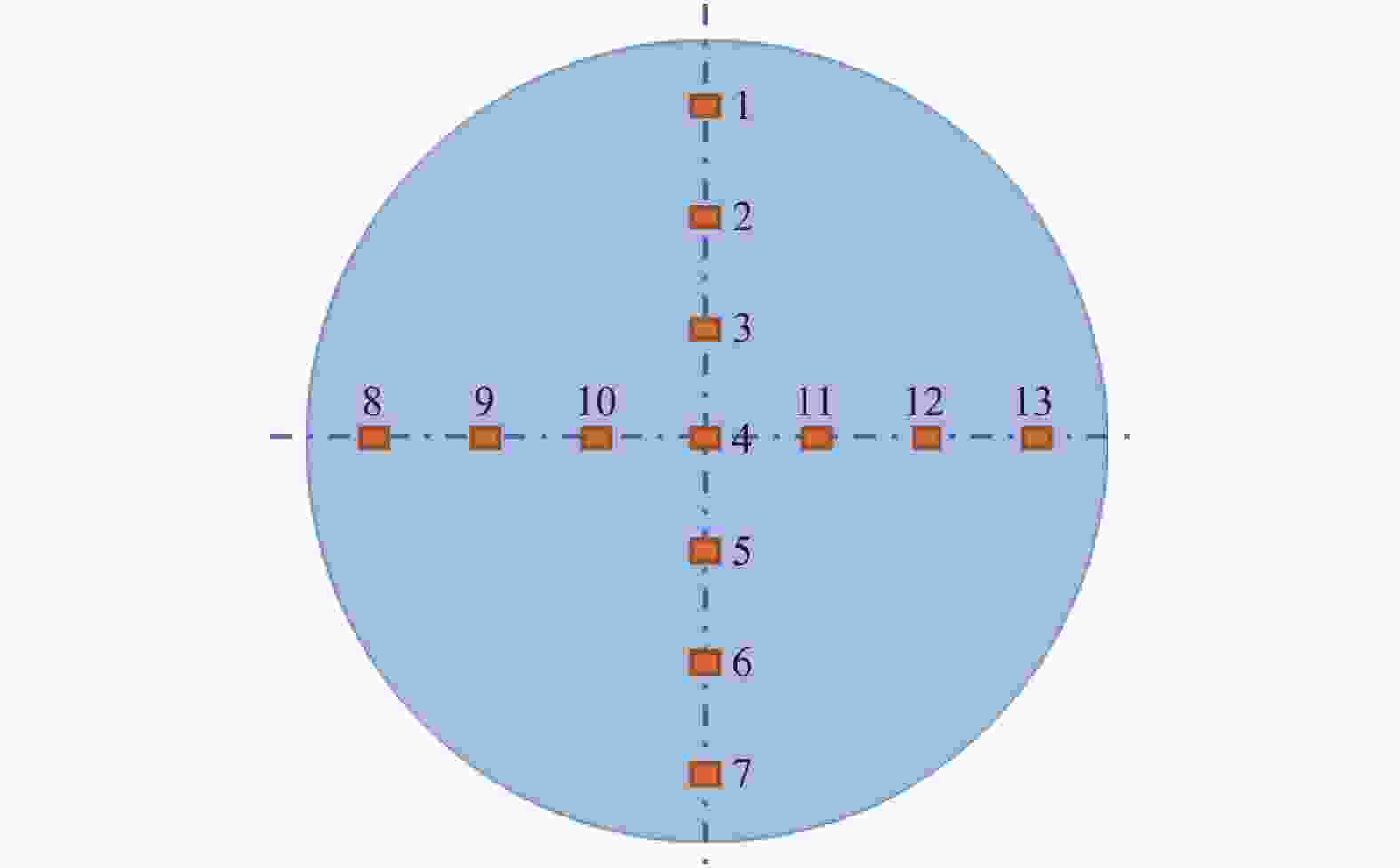

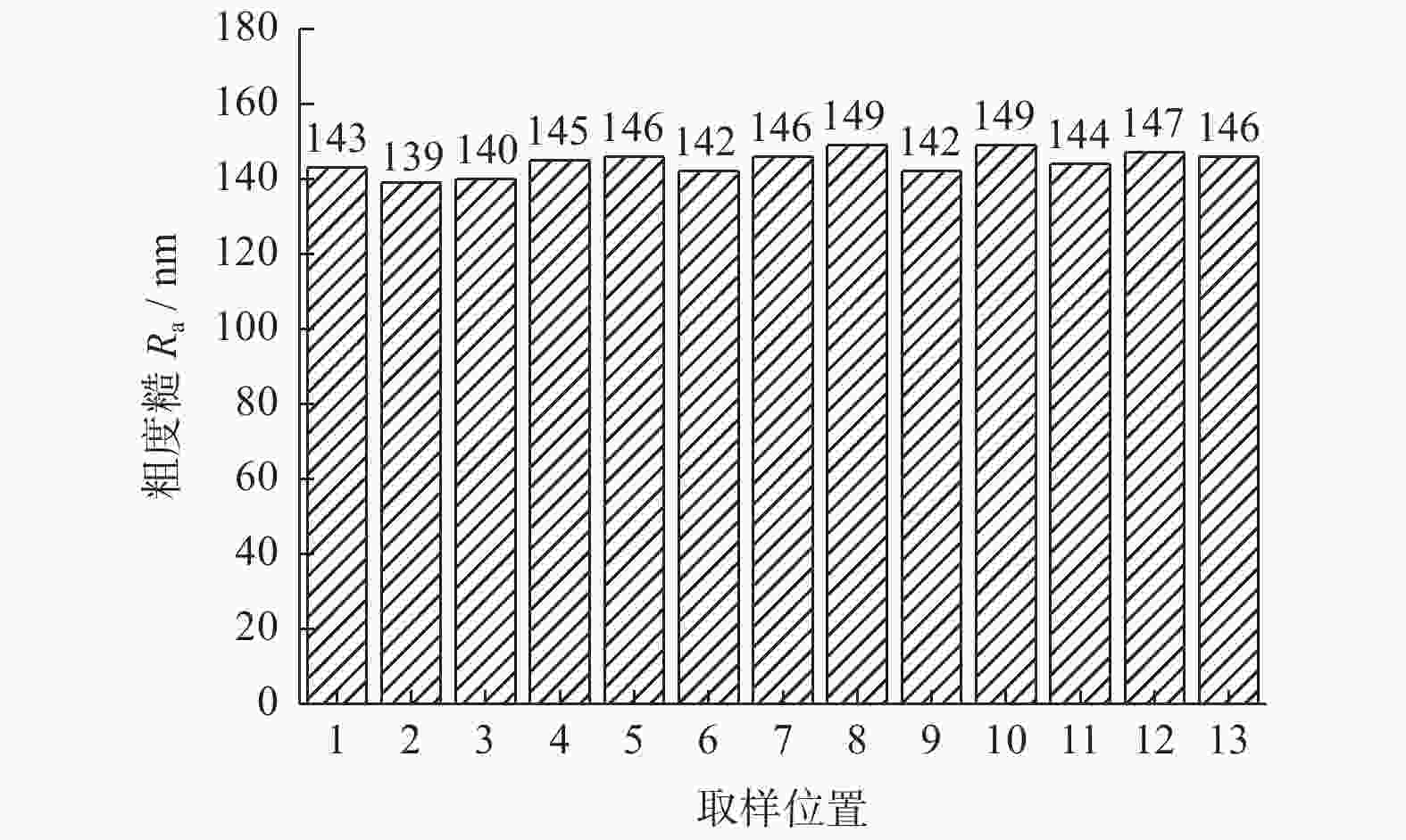

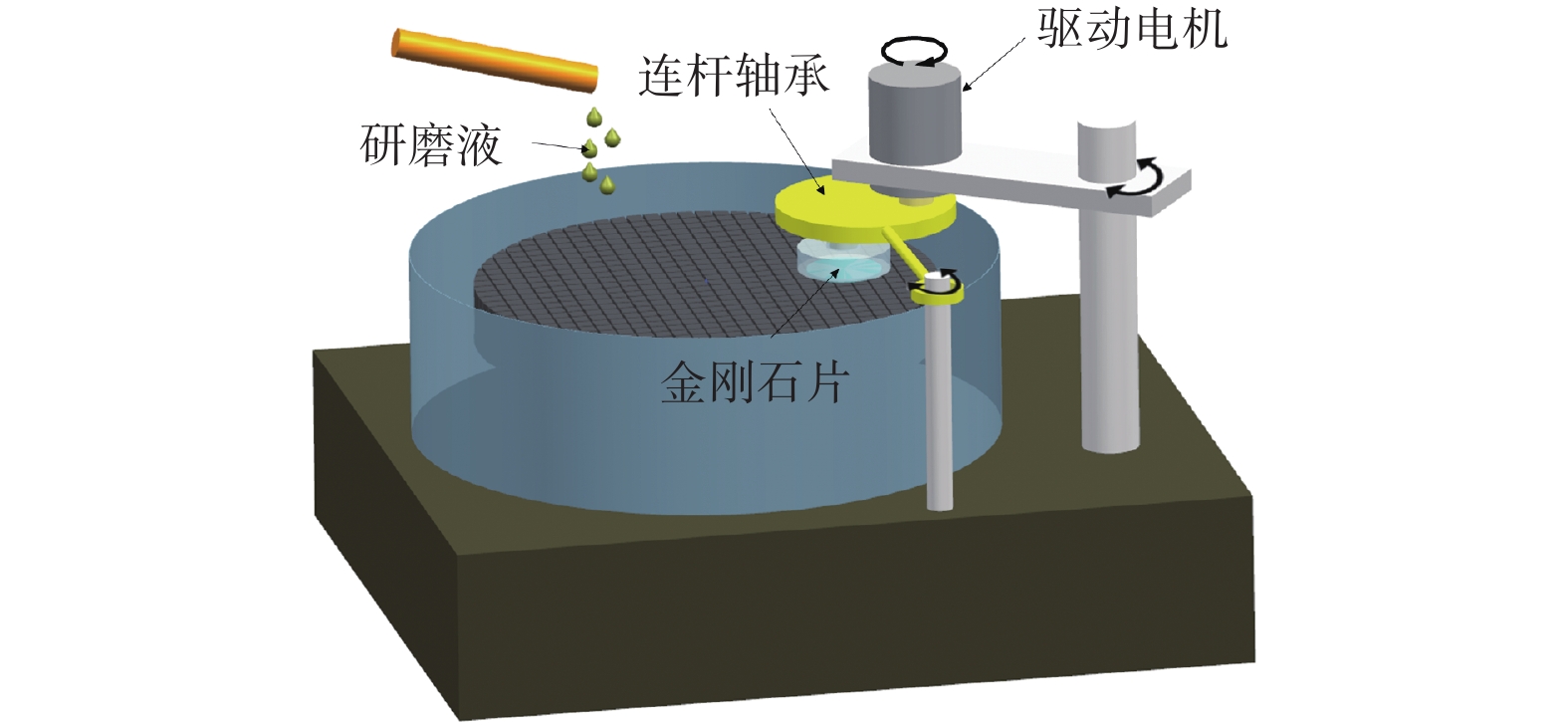

摘要: 在游离磨料研磨过程中,研磨的驱动方式及工艺参数等直接影响加工后工件的平面度和表面粗糙度。为了探究基于旋摆式驱动的游离磨料研磨工艺参数对MPCVD多晶金刚石片平整化的影响,建立旋摆式驱动平面研磨过程中的单磨粒运动学模型,根据实际研磨过程采用多磨粒随机分布模型进行计算机仿真计算,引入多磨粒轨迹的均匀性离散系数对磨粒轨迹均匀性进行分析。结果表明:当转速比取值等于0.5时,磨粒轨迹离散系数最大;当转速比小于等于0.5时,离散系数与转速比为正相关;研磨盘摆动弧线的弦长大于金刚石片直径时,磨粒相对于整个金刚石片表面的运动轨迹分布较为均匀;计算机仿真计算得到了研磨最优参数,并通过2英寸MPCVD多晶金刚石片研磨试验验证了仿真结果的有效性。研磨后金刚石片表面PV值为2.4 μm,表面粗糙度Ra达到139 nm,材料去除率dMRR为10.1 μm/h。Abstract: In the process of free abrasive lapping, the driving mode and process parameters directly affect the flatness and surface roughness of the workpiece. To explore the effect of free abrasive lapping process parameters based on rotary swing drive on the planarization of MPCVD polycrystalline diamond film, a kinematic model of single abrasive grain in rotary swing drive plane lapping process was established in this study. According to the actual lapping process, this paper adopts the multi-abrasive random distribution model for computer simulation and introduces the uniformity dispersion coefficient of multi-abrasive trajectory to analyze the diamond surface abrasive trajectory. The results suggest that when the speed ratio equals 0.5, the dispersion coefficient of abrasive trajectory is the largest; when the speed ratio is less than or equals 0.5, the dispersion coefficient of abrasive trajectory is positively correlated with the speed ratio; and when the length of the swing arc chord of the lapping workpiece disc is larger than the diameter of the diamond film, the motion trajectory of the abrasive particles relative to the whole diamond film surface is evenly distributed. The optimal lapping parameters are obtained by computer simulation. Through the 2 inch polycrystalline diamond lapping test, the final surface PV value of diamond is 2.4 μm, the surface roughness Ra is 139 nm and the material removal rate

dMRR is 10.1 μm/h. -

表 1 计算机仿真参数

Table 1. Parameters of computer simulation

参数 类型或数值 微单元类型 正方形 微单元边长 l /mm 1 虚拟工件直径 D/ mm 51 研磨盘直径 R/ mm 500 随机磨粒数 n1 100 研磨盘转速 ω1/(r·min−1) 63 转速比 I 0~1 摆动周期 T/ s 1/ω2 摆动弧弦长A/ mm 60 仿真时间t /s 80 摆动中心偏心距 e/ mm 160 -

[1] AN K, CHEN L, YAN X, et al. Fracture strength and toughness of chemical-vapor-deposited polycrystalline diamond films [J]. Ceramics International,2018,44(15):17845-17851. doi: 10.1016/j.ceramint.2018.06.253 [2] JIA X, WEI J, HUANG Y, et al. Fabrication of low stress GaN-on-diamond structure via dual-sided diamond film deposition [J]. Journal of Materials Science,2021,56(11):6903-6911. doi: 10.1007/s10853-020-05743-8 [3] COUTO M, ENEKEVORT W, WICHMAN B, et al. Scanning tunneling microscopy of polished diamond surfaces [J]. Applied Surface Science,1992,62(4):263-268. doi: 10.1016/0169-4332(92)90367-7 [4] 文星凯, 魏俊俊, 刘金龙, 等. 大面积自支撑金刚石膜的机械研磨研究 [J]. 金刚石与磨料磨具工程,2013,33(5):22-26. doi: 10.13394/j.cnki.jgszz.2013.05.004WEN Xingkai, WEI Junjun, LIU Jinlong, et al. Study on mechanical grinding for large area free-standing diamond film [J]. Diamond & Abrasives Engineering,2013,33(5):22-26. doi: 10.13394/j.cnki.jgszz.2013.05.004 [5] LIU H, ZONG W J, XIAO C. Behaviors of carbon atoms induced by friction in mechanical polishing of diamond [J]. Computational Materials Science,2020,186:110069. [6] 鲁聪达, 王笑, 文东辉, 等. 超精密研磨技术及其发展的研究(上) [J]. 现代制造工程, 2008(3): 126-128.LU Congda, WANG Xiao, WEN Donghui, et al. Research on the development of ultra-precision lapping and detection technology [J]. Modern Manufacturing Engineering, 2008(3): 126-128. [7] 袁慧, 陈春林, 王成勇. 机械法抛光加工金刚石膜研究 [J]. 超硬材料工程,2007(1):5-9. doi: 10.3969/j.issn.1673-1433.2007.01.002YUAN Hui, CHEN Chunlin, WANG Chengyong. Mechanical polishing of CVD diamond films [J]. Superhard Material Engineering,2007(1):5-9. doi: 10.3969/j.issn.1673-1433.2007.01.002 [8] ZHOU L, HUANG S T, WANG X L, et al. High-speed mechanical lapping of CVD diamond films using diamond wheel [J]. International Journal of Refractory Metals and Hard Materials,2012,35:185-190. doi: 10.1016/j.ijrmhm.2012.05.007 [9] RYL J, ZIELINSKI A, BURCZYK L, et al. Chemical-assisted mechanical lapping of thin boron-doped diamond films: A fast route toward high electrochemical performance for sensing devices [J]. Electrochimica Acta,2017,242:268-279. doi: 10.1016/j.electacta.2017.05.027 [10] 徐锋, 左敦稳, 王珉, 等. CVD金刚石厚膜的机械抛光及其残余应力的分析 [J]. 人工晶体学报,2004,33(3):436-440. doi: 10.3969/j.issn.1000-985X.2004.03.038XU Feng, ZUO Dunwen, WANG Min, et al. Study on mechanical polishing for cvd diamond thick film and its residual stresses [J]. Journal of Synthetic Crystals,2004,33(3):436-440. doi: 10.3969/j.issn.1000-985X.2004.03.038 [11] 肖燏婷, 吴晓峰, 蔡姚杰, 等. 无理偏摆式平面研磨加工均匀性的数值模拟 [J]. 机械工程学报,2021,57(13):232-241. doi: 10.3901/JME.2021.13.232XIAO Yuting, WU Xiaofeng, CAI Yaojie, et al. Numerical simulation on uniformity of plane lapping with irrational swinging method [J]. Journal of Mechanical Engineering,2021,57(13):232-241. doi: 10.3901/JME.2021.13.232 [12] 张志鹏, 陈燕, 潘明诗, 等. 基于Hilbert曲线磁粒研磨轨迹均匀性实验研究 [J]. 表面技术,2022,51(8):408-417. doi: 10.16490/j.cnki.issn.1001-3660.2022.08.037ZHANG Zhipeng, CHEN Yan, PAN Mingshi, et al. Experimental study on magnetic particle grinding uniformity based on hilbert curve [J]. Surface Technology,2022,51(8):408-417. doi: 10.16490/j.cnki.issn.1001-3660.2022.08.037 [13] 严振, 方从富, 刘冲. 偏摆式平面研磨抛光轨迹的理论研究 [J]. 金刚石与磨料磨具工程,2018,38(4):77-82. doi: 10.13394/j.cnki.jgszz.2018.4.0015YAN Zhen, FANG Congfu, LIU Chong. Theoretical study on trajectory of swinging plane lapping and polishing [J]. Diamond & Abrasives Engineering,2018,38(4):77-82. doi: 10.13394/j.cnki.jgszz.2018.4.0015 [14] BINDU K H, RAGHAVA M, DEY N, et al. Coefficient of variation and machine learning applications [M]. Boca Raton: CRC Press, 2019. [15] 田业冰, 金洙吉, 康仁科, 等. 硅片自旋转磨削的运动几何学分析 [J]. 中国机械工程,2005,16(20):4. doi: 10.3321/j.issn:1004-132X.2005.20.004TIAN Yebing, JIN Zhuji, KANG Renke, et al. Analysis of kinematic geometry on wafer rotation grinding processes [J]. China Mechanical Engineering,2005,16(20):4. doi: 10.3321/j.issn:1004-132X.2005.20.004 [16] 李姚, 郑子轩, 蒲红斌. 金刚石衬底上GaN HEMT沟道温度建模: 各向异性且非均匀热导率的影响 [J]. 人工晶体报,2022,51(2):222-228.LI Yao, ZHENG Zixuan, PU Hongbin. Analysis of channel temperature in GaN on diamond HEMT: Effect of anisotropic and inhomogeneous thermal conductivity [J]. Journal of Synthetic Crystals,2022,51(2):222-228. [17] SCHOLZ T, SCHNEIDER G A, MUNOZ-SALDANA J, et al. Fracture toughness from submicron derived indentation cracks [J]. Applied Physics Letters,2004,84(16):3055-3057. doi: 10.1063/1.1711164 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS