Analysis of thermal deformation of substrate of local induction brazed saw blade

-

摘要:

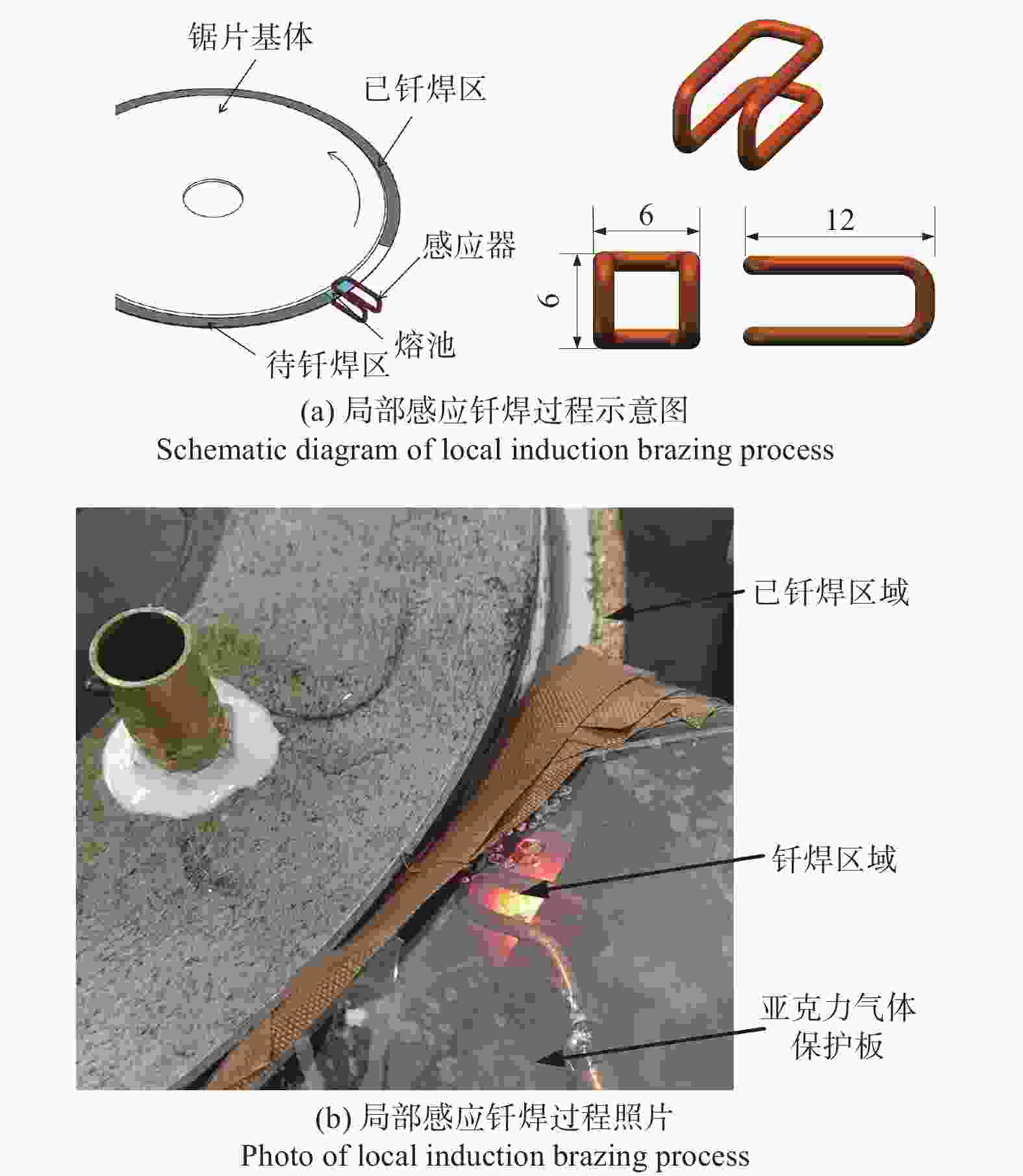

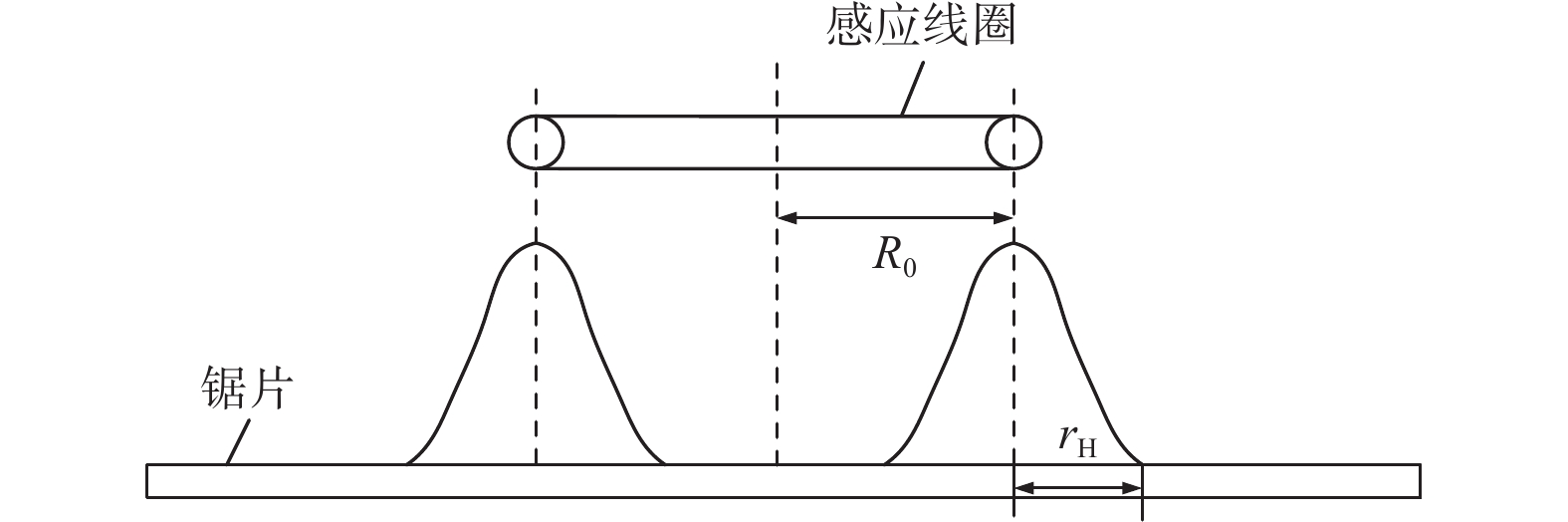

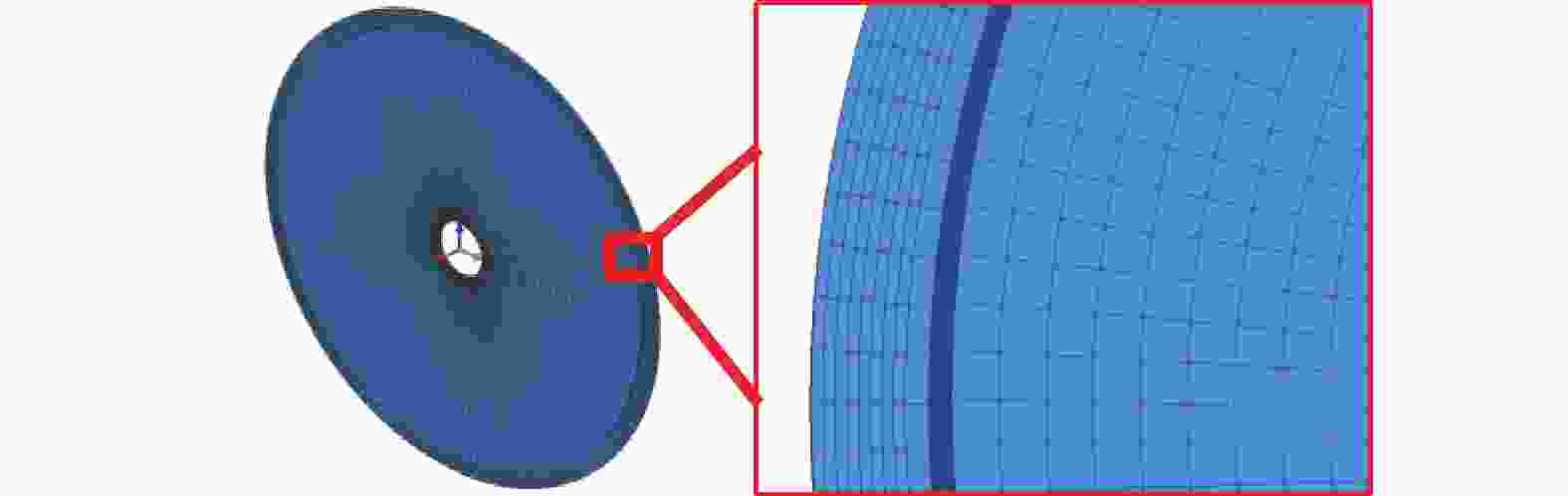

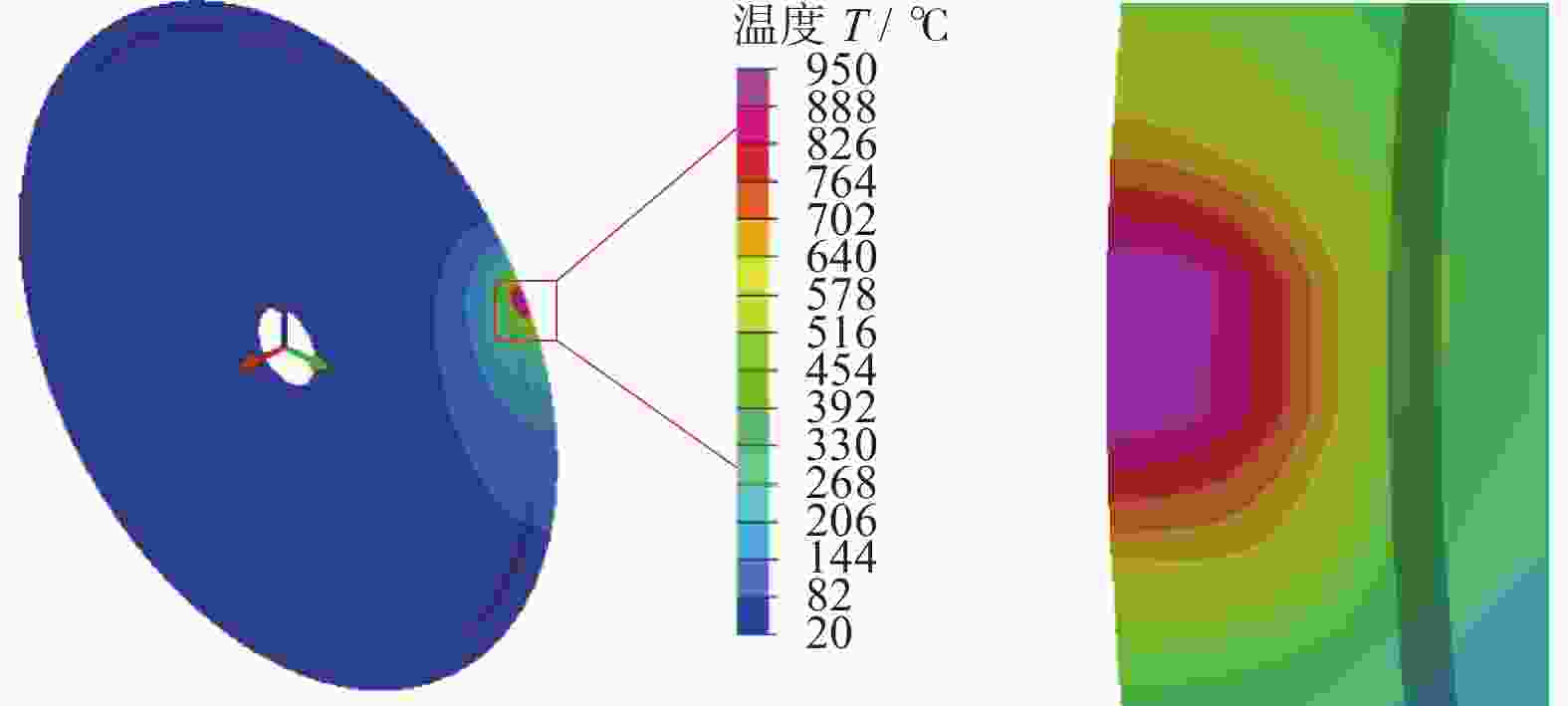

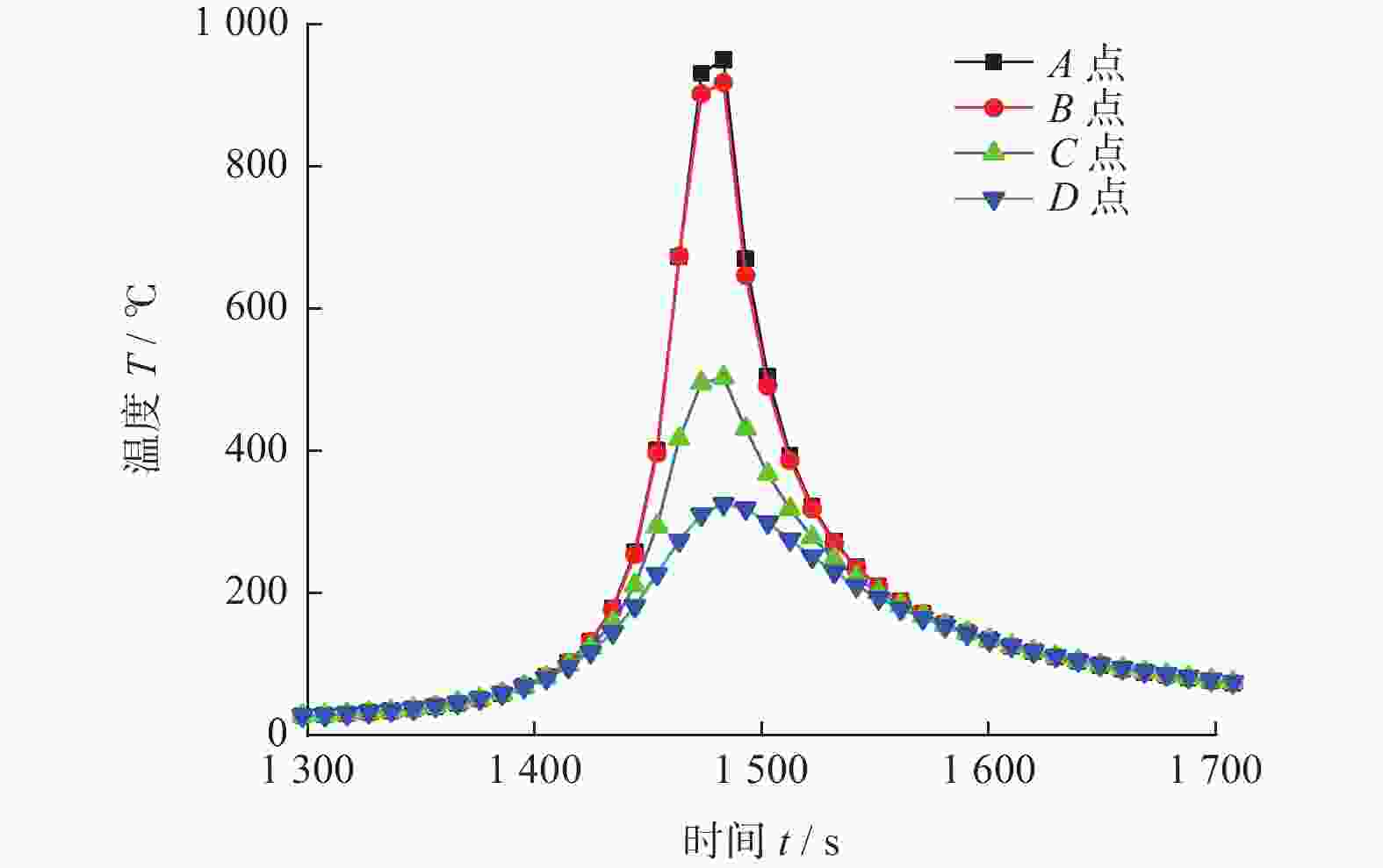

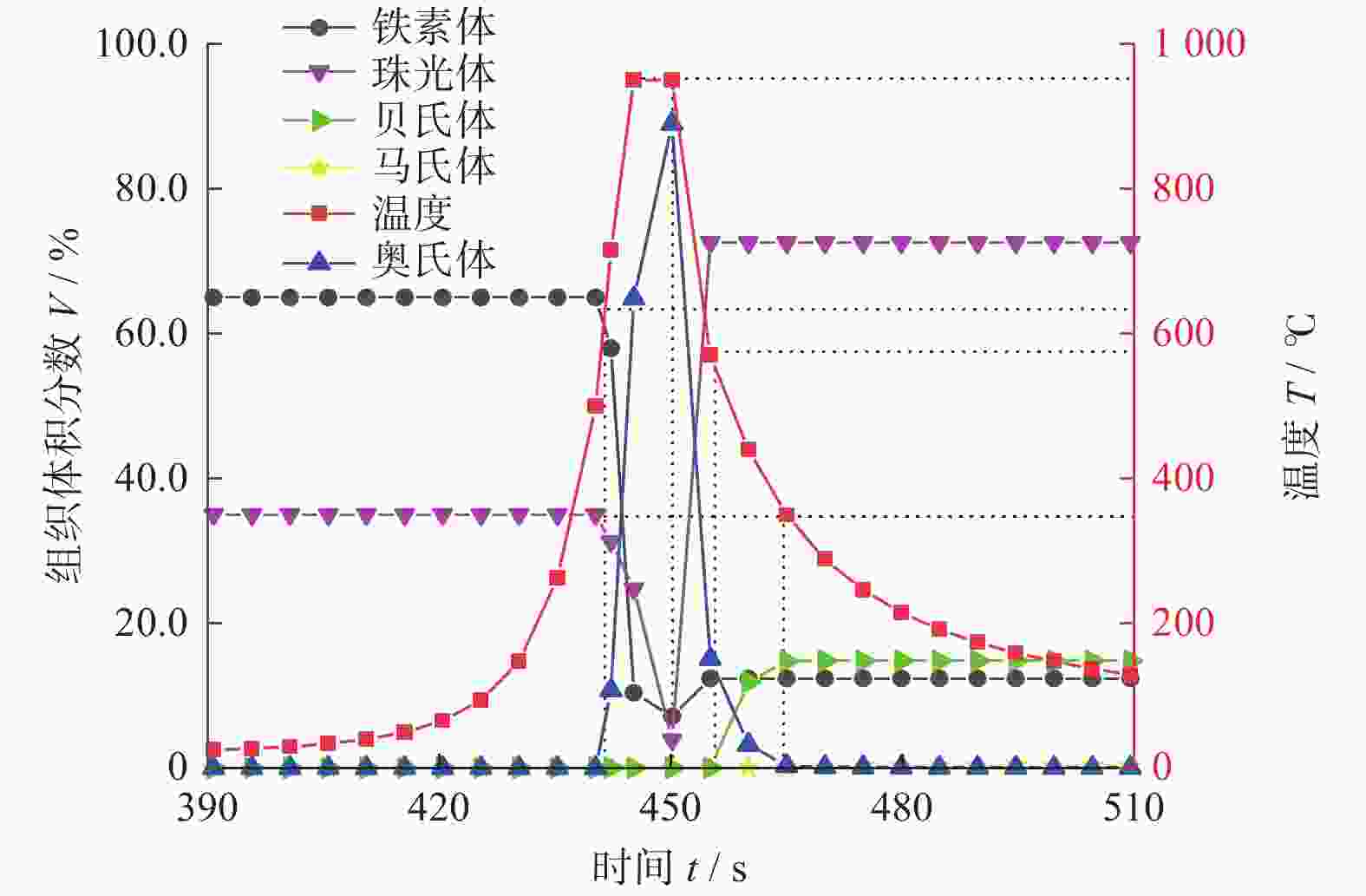

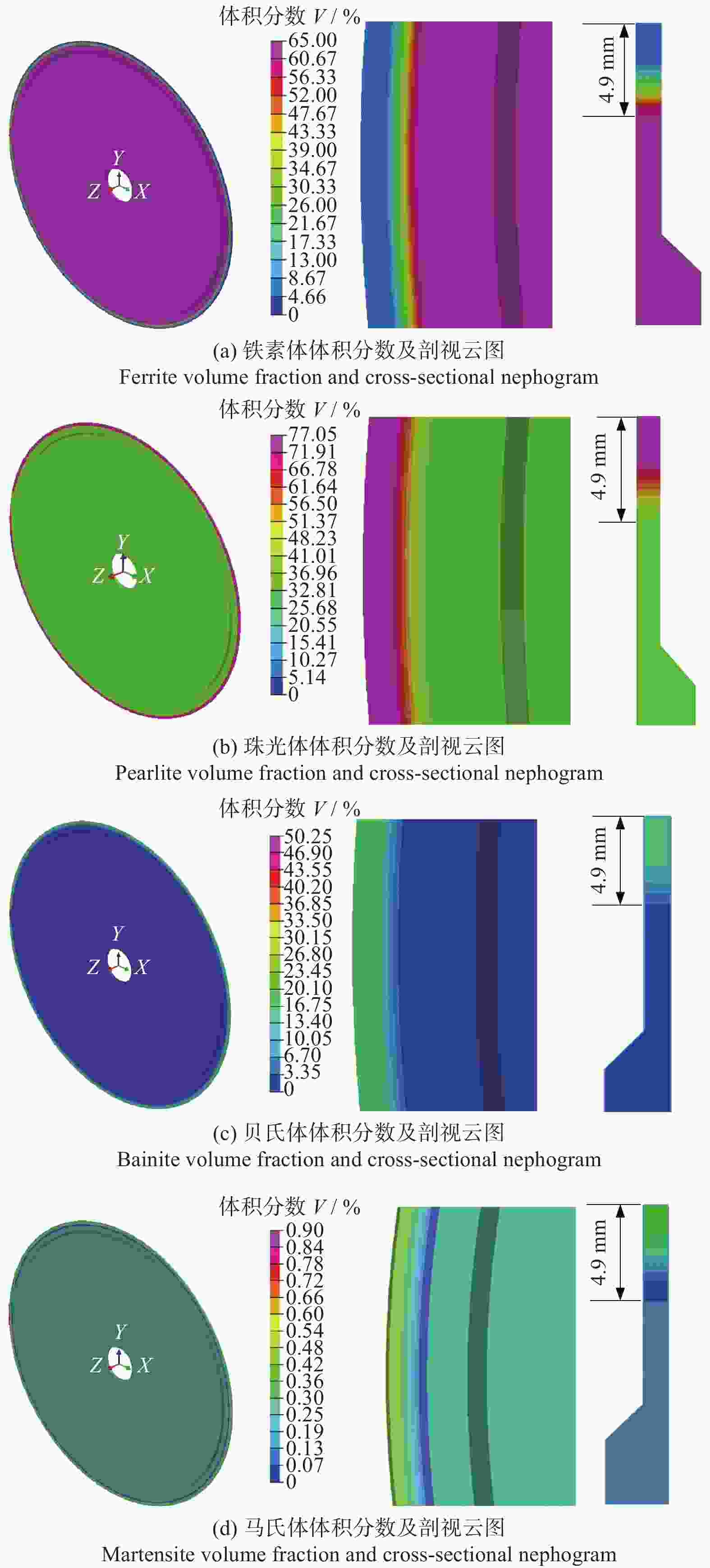

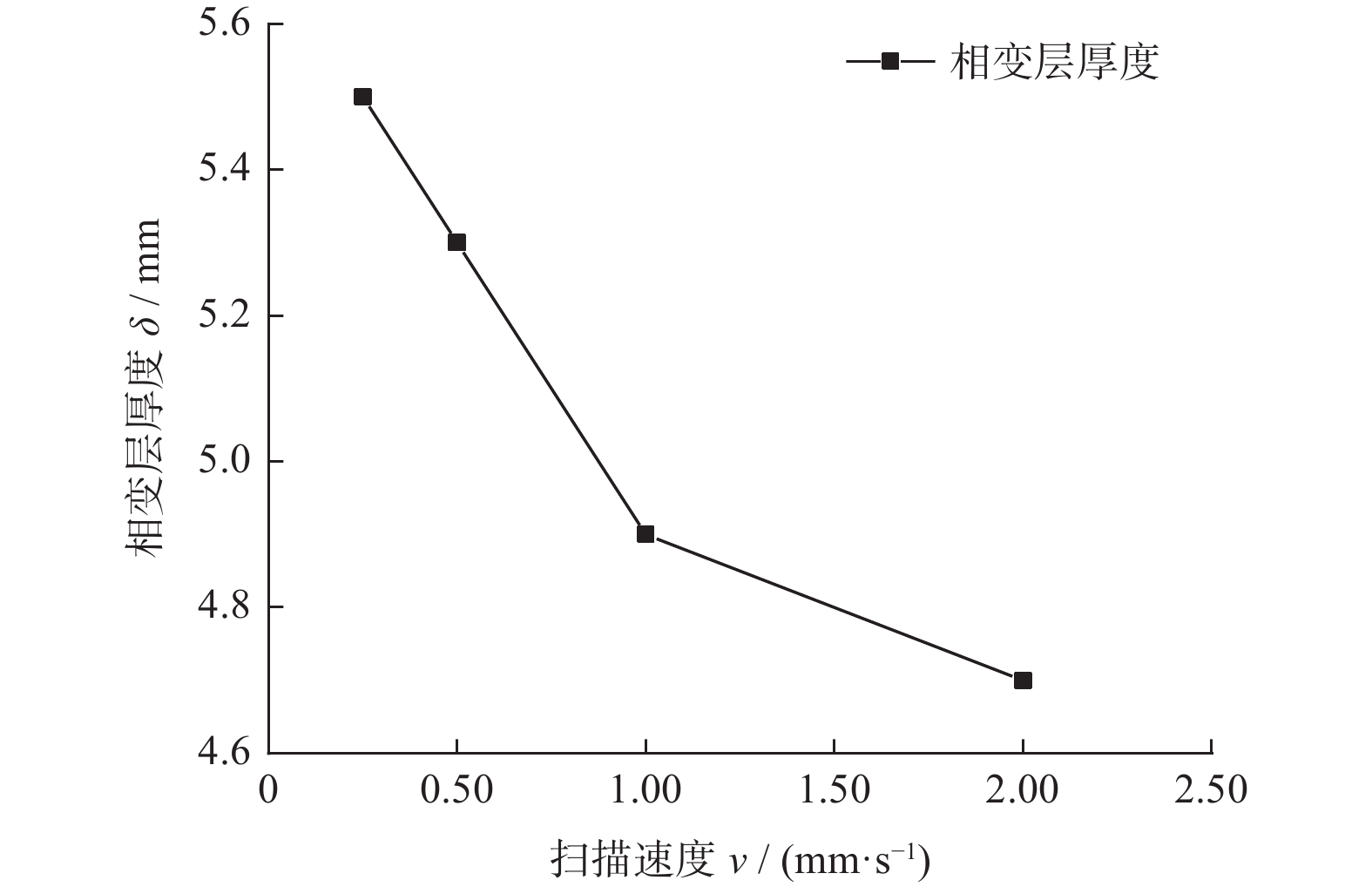

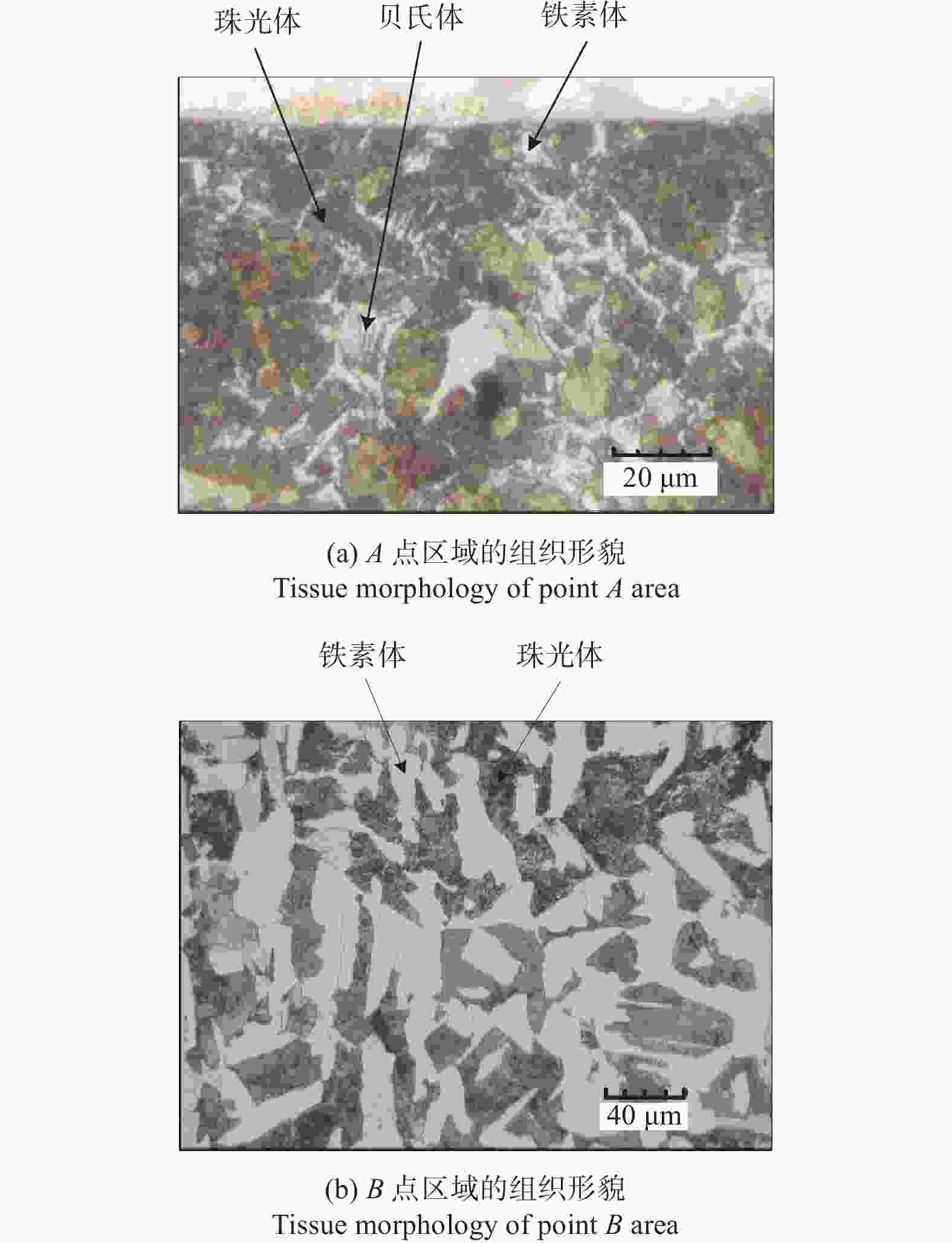

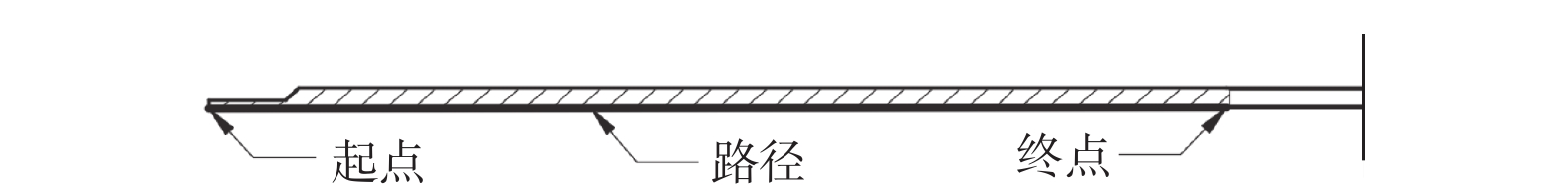

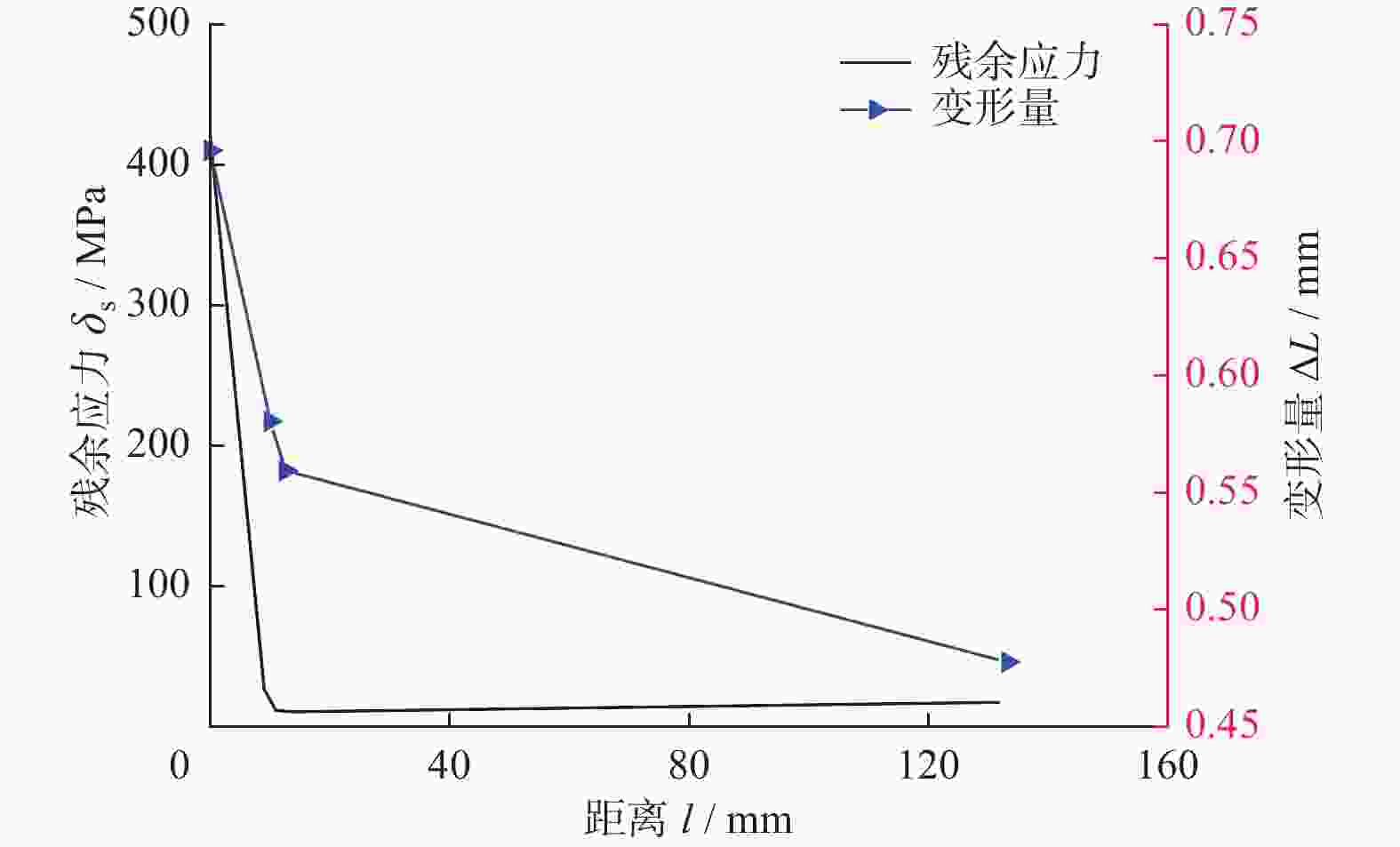

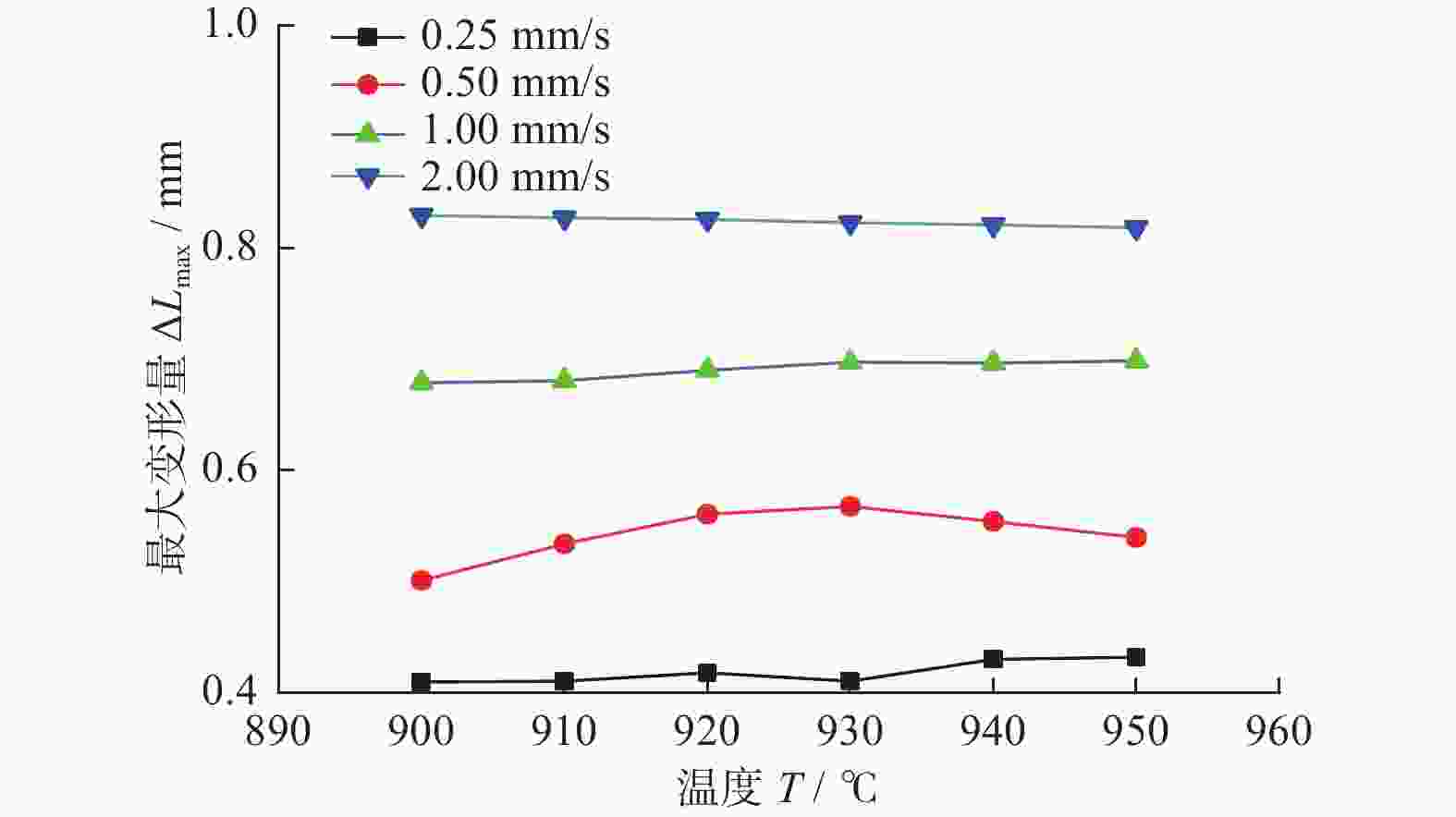

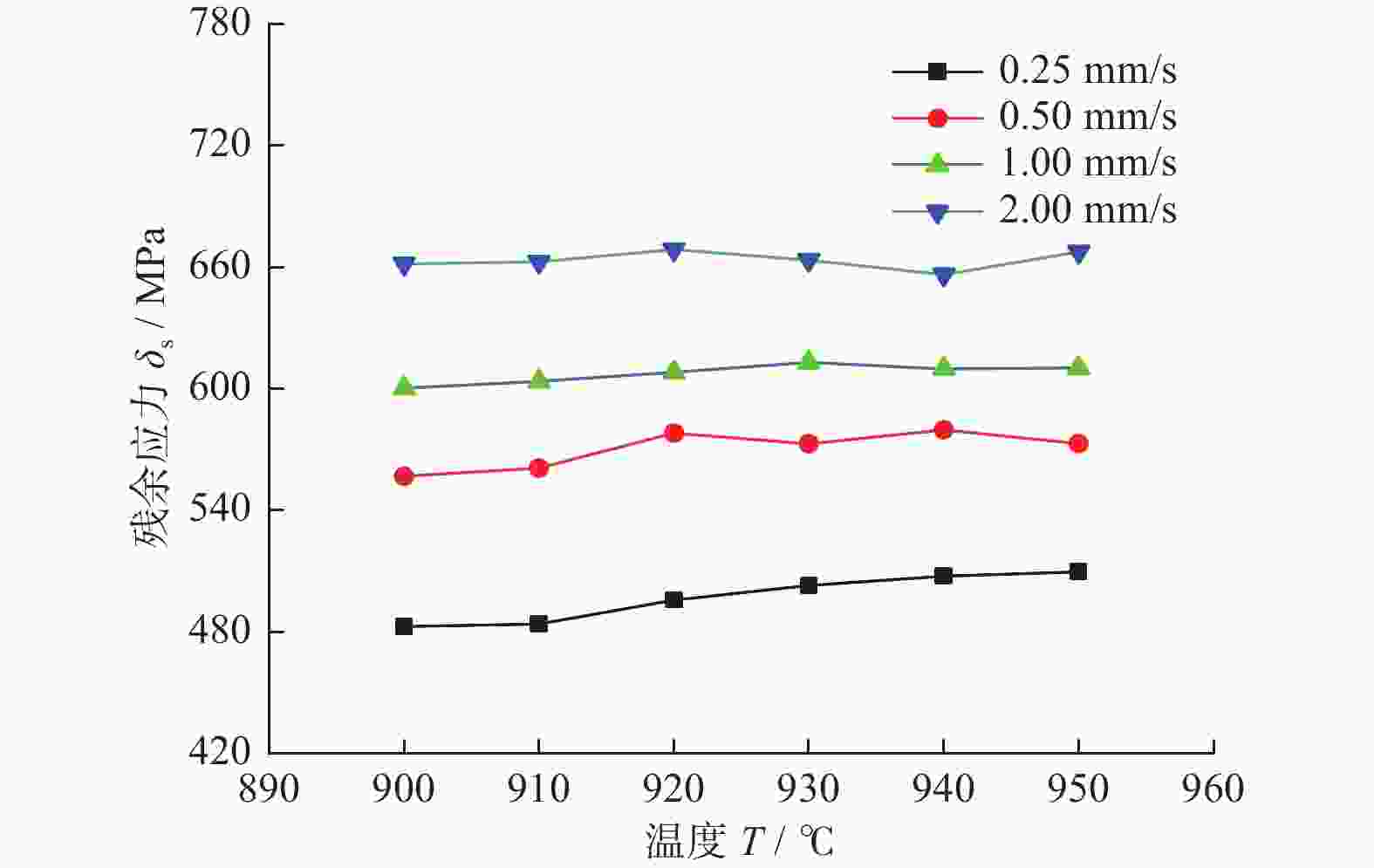

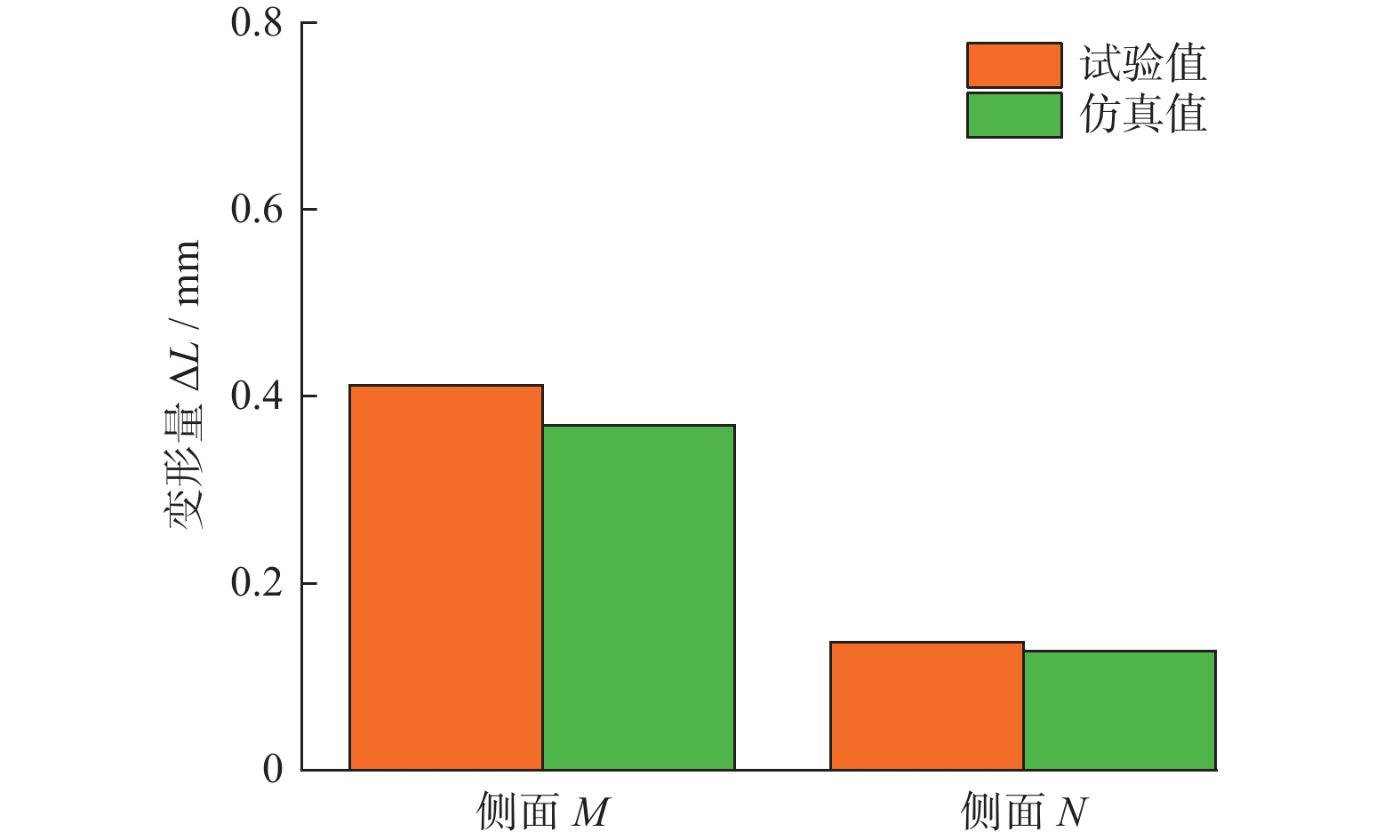

针对钎焊锯片基体在高温条件下的热变形问题,在有限元软件中对局部感应钎焊锯片基体的温度、组织以及应力应变场进行分析,研究影响锯片基体变形的因素。结果显示:锯片基体发生的相变主要分布在钎焊工作面上,冷却至室温后主要得到铁素体、珠光体、贝氏体3种组织。当热源的扫描速度增大,基体的变形量以及残余应力都随之增大。当扫描速度从0.25 mm/s增至2.00 mm/s时,相变层厚度从5.8 mm降至4.7 mm,最大变形量从0.41 mm增至0.82 mm,且残余应力从482 MPa增至667 MPa。试验与仿真结果基本一致。

Abstract:In order to solve the problem of thermal deformation of brazed saw blade substrate under high temperature, the temperature, the microstructure and the stress-strain field of local induction brazed saw blade substrate were analyzed with the finite element software, and the factors affecting the deformation of saw blade substrate were studied. The results show that the phase transformation of the saw blade substrate is mainly distributed on the brazing working surface. After cooling to room temperature, three microstructures including ferrite, pearlite, bainite and trace martensite are obtained. When the scanning speed of the heat source increases, the deformation and the residual stress of the substrate increase. When the scanning speed increases from 0.25 mm/s to 2.00 mm/s, the thickness of the phase change layer decreases from 5.8 mm to 4.7 mm, the maximum deformation increases from 0.41 mm to 0.82 mm, and the residual stress increases from 482 MPa to 667 MPa. The test results are basically consistent with the simulation results.

-

Key words:

- local induction brazing /

- phase transformation /

- thermal deformation /

- brazing temperature /

- saw blade

-

表 1 局部感应钎焊工艺参数

Table 1. Local induction brazing process parameters

工艺参数 取值 热源扫描速度 v / (mm·s−1) 0.25,0.50,1.00,2.00 热源功率 Q / W 67.4~370.0 -

[1] 黄霞, 邹新光, 刘伟, 等. 高铁基金刚石工具胎体烧结工艺及切割性能 [J]. 金刚石与磨料磨具工程,2019,39(2):51-54. doi: 10.13394/j.cnki.jgszz.2019.2.0010HUANG Xia, ZOU Xinguang, LIU Wei, et al. Process and cutting performance of diamond tool with high Fe-content bond [J]. Diamond & Abrasives Engineering,2019,39(2):51-54. doi: 10.13394/j.cnki.jgszz.2019.2.0010 [2] 高冰媛, 于爱兵, 李照. 金刚石工具的回收与再利用 [J]. 工具技术,2010,44(1):11-14. doi: 10.3969/j.issn.1000-7008.2010.01.002GAO Bingyuan, YU Aibing, LI Zhao. Recycling and reusing of diamond tools [J]. Tool Engineering,2010,44(1):11-14. doi: 10.3969/j.issn.1000-7008.2010.01.002 [3] 马伯江, 张绍昆, 朱华东, 等. 局部感应钎焊金刚石锯片的研究 [J]. 焊接,2015(12):35-38. doi: 10.3969/j.issn.1001-1382.2015.12.008MA Bojiang, ZHANG Shaokun, ZHU Huadong, et al. Study on high-performance diamond saw brazed by local induction [J]. Welding,2015(12):35-38. doi: 10.3969/j.issn.1001-1382.2015.12.008 [4] 蒋城杰, 毛人杰, 徐佳宁, 等. Ni-Cr合金真空钎焊金刚石工具基体热损伤分析 [J]. 工具技术,2019,53(6):55-58. doi: 10.3969/j.issn.1000-7008.2019.06.012JIANG Chengjie, MAO Renjie, XU Jianing, et al. Analysis on thermal damage of substrate for brazing diamond tool with Ni-Cr alloy in vacuum furnace [J]. Tool Engineering,2019,53(6):55-58. doi: 10.3969/j.issn.1000-7008.2019.06.012 [5] DENKENA B, GROVE T, BREMER I, et al. Design of bronze-bonded grinding wheel properties [J]. CIRP Annals-Manufacturing Technology,2016,65(1):333-336. doi: 10.1016/j.cirp.2016.04.096 [6] 马伯江, 徐鸿钧. 导引高频磁通感应钎焊制作金刚石砂轮 [J]. 中国机械工程,2009,20(3):358-360. doi: 10.3321/j.issn:1004-132X.2009.03.025MA Bojiang, XU Hongjun. Diamond grinding wheel made by hich-frequency induction brazing with magnetic fluxled [J]. China Mechanical Engineering,2009,20(3):358-360. doi: 10.3321/j.issn:1004-132X.2009.03.025 [7] LI Q L, XU J H, SU H H, et al. Fabrication and performance of monolayer brazed CBN wheel for high speed grinding of superalloy [J]. International Journal of Advanced Manufacturing Technology,2015,80(1):1173-1180. [8] 王薇, 金成, 史春元, 等. Q345E钢焊接热影响区相变的计算机模拟 [J]. 兵器材料科学与工程,2015,38(4):80-84. doi: 10.14024/j.cnki.1004-244x.2015.04.005WANG Wei, JIN Cheng, SHI Chunyuan, et al. Computer simulation of phase transformation in Q345E steel welding heat affected zone [J]. Ordnance Material Science and Engineering,2015,38(4):80-84. doi: 10.14024/j.cnki.1004-244x.2015.04.005 [9] 姜大鑫, 武文华, 胡平, 等. 高强度钢板热成形热、力、相变数值模拟分析 [J]. 机械工程学报,2012,48(12):18-23. doi: 10.3901/JME.2012.12.018JIANG Daxin, WU Wenhua, HU Ping, et al. Thermo-mechanical-martensitic transformation numerical simulation of high strength steel in hot forming [J]. Journal of Mechanical Engineering,2012,48(12):18-23. doi: 10.3901/JME.2012.12.018 [10] 韩阳, 梁国星, 马红帅, 等. 6061铝合金薄板激光成形的仿真与实验研究 [J]. 太原理工大学学报,2018,49(4):566-572. doi: 10.16355/j.cnki.issn1007-9432tyut.2018.04.008HAN Yang, LIANG Guoxing, MA Hongshuai, et al. Simulation and experimental study on the laser forming of 6061 aluminum alloy sheet [J]. Journal of Taiyuan University of Technology,2018,49(4):566-572. doi: 10.16355/j.cnki.issn1007-9432tyut.2018.04.008 [11] 孙玉杰, 崔青春, 韩璇璇, 等. 装甲钢温度-组织-应力耦合本构模型的建立及在焊接模拟中的应用 [J]. 兵工学报,2017,38(3):540-548.SUN Yujie, CUI Qingchun, HAN Xuanxuan, et al. Establishment of thermo-metallurgical-mechanical coupling constitutive model for armour steel and its application in welding numerical simulation [J]. Acta Armamentarii,2017,38(3):540-548. [12] DONG H B, ZHAO Y, YUAN H, et al. A simplified calculation method of heat source model for induction heating [J]. Materials,2019,12(18):326-333. [13] 曹阳, 丛日立, 赵明宇, 等. 热参数扰动下一维相变传热定解问题的稳定性研究 [J]. 内蒙古大学学报(自然科学版),2018,49(6):589-596. doi: 10.13484/j.nmgdxxbzk.20180605CAO Yang, CONG Rili, ZHAO Mingyu, et al. Study on the stability of one-dimension heat conduction definite solution problem with phase transformation under the thermal parameter perturbation [J]. Journal of Inner Mongolia University (Natural Science Edition),2018,49(6):589-596. doi: 10.13484/j.nmgdxxbzk.20180605 [14] 刘广桥, 寇生中, 李望南, 等. Al/45钢高频感应钎焊焊料的研制 [J]. 热加工工艺,2009,38(23):9-12. doi: 10.3969/j.issn.1001-3814.2009.23.003LIU Guangqiao, KOU Shengzhong, LI Wangnan, et al. Development on high-frequency induction brazing solder of Al/45 steel [J]. Hot Working Technology,2009,38(23):9-12. doi: 10.3969/j.issn.1001-3814.2009.23.003 [15] 罗扬, 孙力, 熊自柳, 等. Mo对双相钢过冷奥氏体连续冷却转变的影响 [J]. 河北冶金,2009,38(23):9-12. doi: 10.13630/j.cnki.13-1172.2021.0502LUO Yang, SUN Li, XIONG Ziliu, et al. Effect of Mo on continuous transformation of overcooled austenite for dual phase (DP) steel [J]. Hebei Metallurgy,2009,38(23):9-12. doi: 10.13630/j.cnki.13-1172.2021.0502 [16] 霍建生, 阎冬. 700 MPa级高强度耐候钢过冷奥氏体连续冷却相变行为 [J]. 金属热处理,2021,46(7):94-98.HUO Jiansheng, YAN Dong. Continuous cooling transformation behavior of undercooled austenite of 700 MPa high strength weathering resistance steel [J]. Heat Treatment of Metals,2021,46(7):94-98. [17] 赵步青, 徐利建, 朱敏, 等. 低碳钢的强烈淬火 [J]. 热处理,2021,36(4):31-33. doi: 10.3969/j.issn.1008-1690.2021.04.009ZHANG Buqing, XU Lijian, ZHU Min, et al. Intense quenching for lowcarbon steel [J]. Heat Treatment,2021,36(4):31-33. doi: 10.3969/j.issn.1008-1690.2021.04.009 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS