| [1] |

黄烁. 金刚石增强聚合物基导热复合材料的制备及性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2020.HUANG Shuo. Preparation and properties of diamond-reinforced polymer based thermal conductivity composites [D]. Harbin: Harbin Institute of Technology, 2020.

|

| [2] |

李扬林. LED封装用水玻璃基导热胶研究 [D]. 哈尔滨: 哈尔滨工业大学, 2011.LI Yanglin. Research on water-glass based thermal conductive adhesive for LED packaging [D]. Harbin: Harbin Institute of Technology, 2011.

|

| [3] |

张晓辉, 徐传骧. 新型电力电子器件封装用导热胶粘剂的研究 [J]. 电力电子技术,1999(5):61-62.ZHANG Xiaohui, XU Chuanxiang. Research on new thermal adhesive for power electronic device packaging [J]. Power Electronics Technology,1999(5):61-62.

|

| [4] |

熊雯雯. 高导热环氧树脂复合绝缘胶黏剂的制备与性能研究 [D]. 北京: 北京交通大学, 2020.XIONG Wenwen. Study on preparation and properties of epoxy resin composite insulation adhesive with high thermal conductivity [D]. Beijing: Beijing Jiaotong University, 2020.

|

| [5] |

关云来. 含多粒径h-BN粉导热胶的制备与性能研究 [D]. 南京: 南京工业大学, 2017.GUAN Yunlai. Preparation and properties of h-BN powder thermal conductive adhesive containing multi-particle size [D]. Nanjing: Nanjing University of Technology, 2017.

|

| [6] |

GOJNY F H, WICHMANN M, FIEDLER B, et al. Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites [J]. Polymer: The International Journal for the Science and Technology of Polymers,2006,47(6):2036-2045.

|

| [7] |

NITHIKARNJANATHARN J, UEDA H, TANOUE S, et al. The rheological behavior and thermal conductivity of melt-compounded polycarbonate/vapor-grown carbon fiber composites [J]. Polymer Journal,2012,44(5):427-432. doi: 10.1038/pj.2011.149

|

| [8] |

KIM J, KIM Y D, NAM D G, et al. Thermal properties of epoxy composites with silicon carbide and/or graphite [J]. Journal of the Korean Physical Society,2016,68(4):551-556. doi: 10.3938/jkps.68.551

|

| [9] |

林雪春, 徐志娟, 罗大为. LED封装用环氧树脂/金刚石导热胶的研制 [J]. 塑料科技,2015,43(3):59-62. doi: 10.15925/j.cnki.issn1005-3360.2015.03.008LIN Xuechun, XU Zhijuan, LUO Dawei. Preparation of epoxy resin/diamond thermal conductive adhesive for LED packaging [J]. Plastics Science and Technology,2015,43(3):59-62. doi: 10.15925/j.cnki.issn1005-3360.2015.03.008

|

| [10] |

GUO H, SHENG H, PENG X, et al. Preparation and mechanical properties of epoxy/diamond nanocomposites [J]. Polymer Composites,2014,35(11):2144-2149. doi: 10.1002/pc.22877

|

| [11] |

GHIM D, KIM J H. Fabrication of acrylic copolymer with aluminum nitride fillers and its physical and thermal properties [J]. The Korean Journal of Chemical Engineering,2017,34(1):245-248. doi: 10.1007/s11814-016-0235-y

|

| [12] |

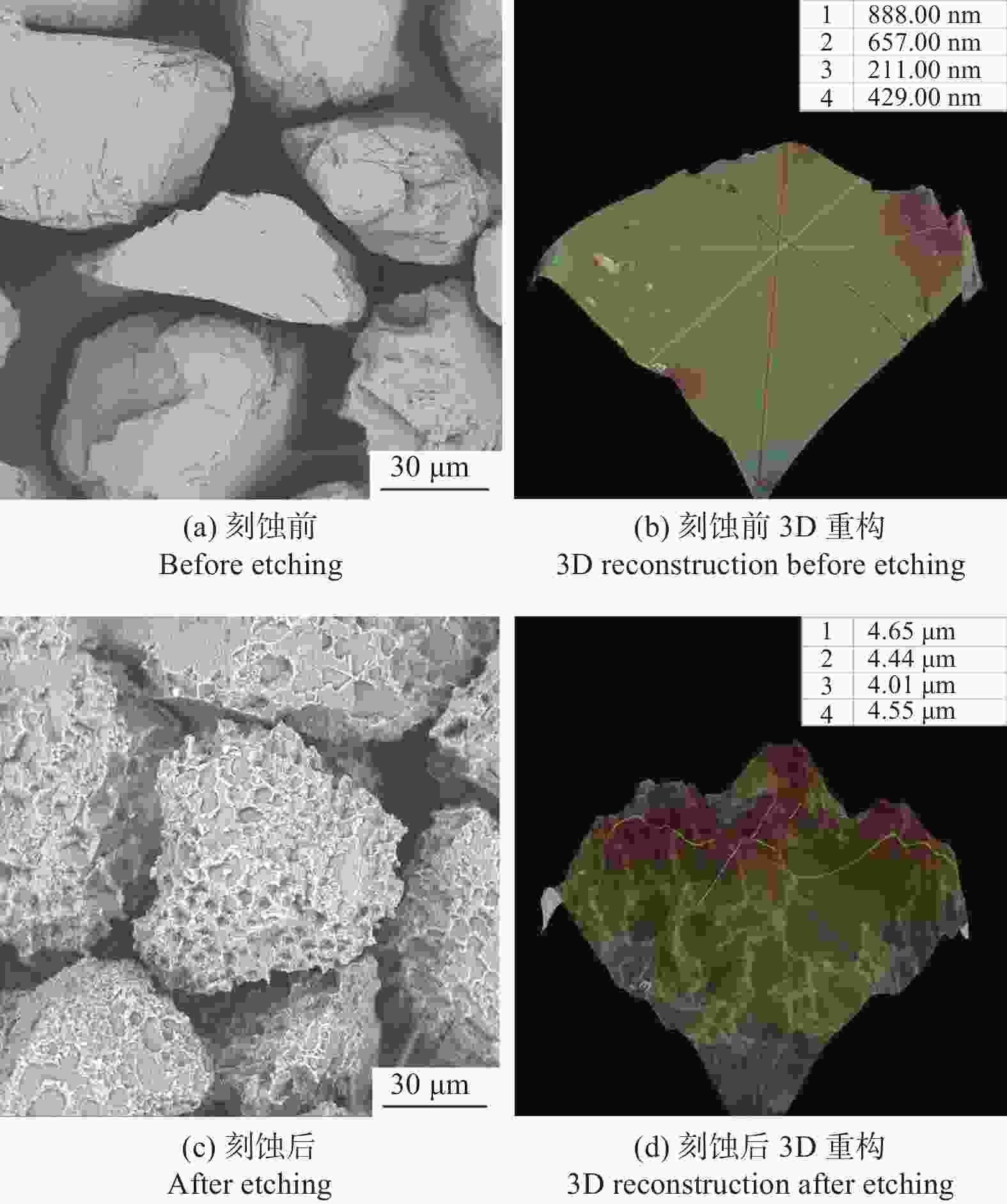

陈冰威, 杨雪峰, 朱振东, 等. 氧化铈刻蚀金刚石表面形貌表征 [J]. 粉末冶金技术,2022,40(4):318-324, 333. doi: 10.19591/j.cnki.cn11-1974/tf.2021090018CHEN Bingwei, YANG Xuefeng, ZHU Zhendong, et al. Surface morphology characterization of cerium oxide etched diamond [J]. Powder Metallurgy Technology,2022,40(4):318-324, 333. doi: 10.19591/j.cnki.cn11-1974/tf.2021090018

|

| [13] |

湖南大学. 一种多孔泡沫金刚石的制备方法: CN201610040477.1 [P]. 2016-07-06.Hunan University. Preparation method of porous foam diamond : CN201610040477.1 [P]. 2016-07-06.

|

| [14] |

高波. 金刚石微粉增强聚碳酸酯复合树脂的制备及力学性能研究 [D]. 北京: 北京理工大学, 2015.GAO Bo. Preparation and mechanical properties of polycarbonate composite resin reinforced with diamond micropowder [D]. Beijing: Beijing Institute of Technology, 2015.

|

| [15] |

赵雨薇. 磷酸盐基无机导热胶的制备及性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2021.ZHAO Yuwei. Preparation and properties of phosphate-based inorganic thermal conductive adhesive [D]. Harbin: Harbin Institute of Technology, 2021.

|

| [16] |

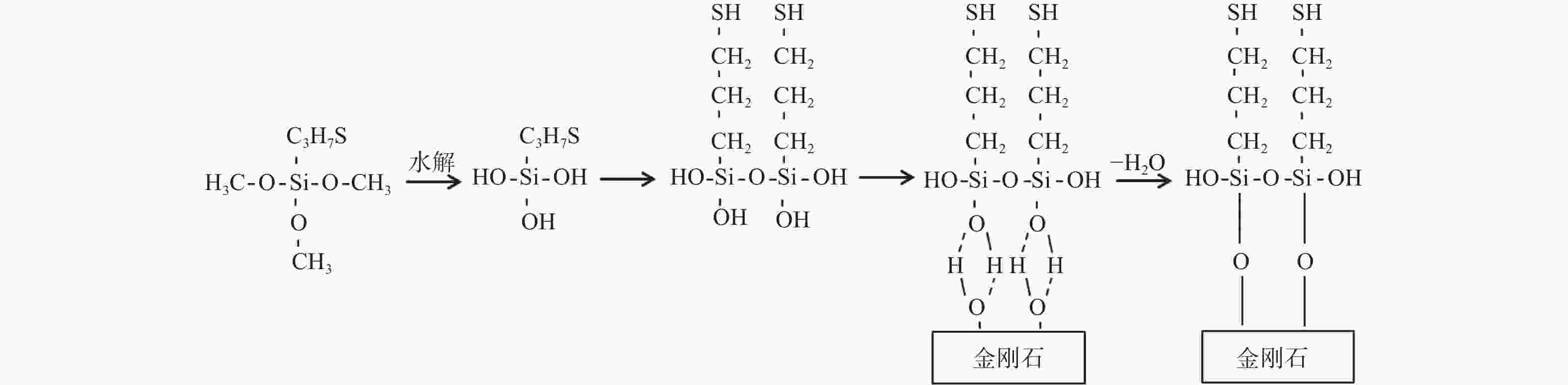

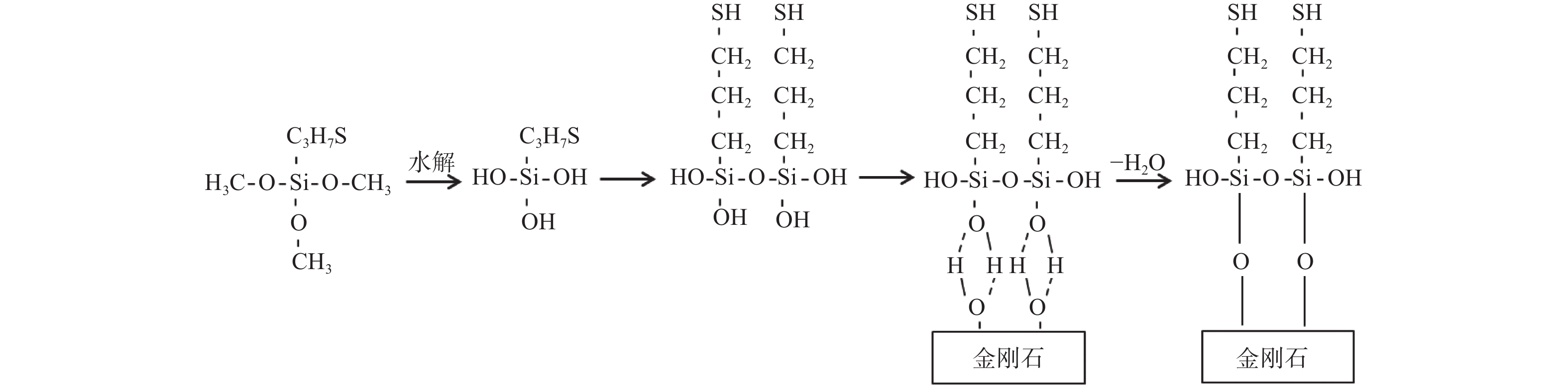

万隆, 时丹, 王俊沙, 等. 硅烷偶联剂对金刚石表面改性研究 [J]. 湖南大学学报(自然科学版),2013,40(4):71-74.WAN Long, SHI Dan, WANG Junsha, et al. Study on the surface modification of diamond by silane coupling agent [J]. Journal of Hunan University (Natural Science Edition),2013,40(4):71-74.

|

| [17] |

吉晓莉, 郑彩华, 魏磊, 等. 氨基硅烷偶联剂表面改性SiC微粉的研究 [J]. 化学与生物工程,2008(1):21-23. doi: 10.3969/j.issn.1672-5425.2008.01.007JI Xiaoli, ZHENG Caihua, WEI Lei, et al. Study on surface modification of SiC micropowder by aminosilane coupling agent [J]. Chemical and Biological Engineering,2008(1):21-23. doi: 10.3969/j.issn.1672-5425.2008.01.007

|

| [18] |

胡晓刚, 顾晓宇, 仝毅, 等. 改性纳米金刚石增强增韧医用口腔复合树脂的研究 [J]. 化工新型材料,2006,34(2):60-62,67. doi: 10.3969/j.issn.1006-3536.2006.02.019HU Xiaogang, GU Xiaoyu, TONG Yi, et al. Study on modified nano-diamond reinforced and toughened medical oral composite resin [J]. New Chemical Materials,2006,34(2):60-62,67. doi: 10.3969/j.issn.1006-3536.2006.02.019

|

| [19] |

常明, 郧海丽, 李中秋, 等. 二甲基硅油 C-Si 伸缩振动模式红外光谱研究 [J]. 材料导报,2016,30(4):81-84, 89.CHANG Ming, YUN Haili, LI Zhongqiu, et al. Infrared spectroscopy study of silicone oil C-Si stretching vibration [J]. Materials Review,2016,30(4):81-84, 89.

|

| [20] |

张萌. 改性环氧树脂基填充型导热胶的制备及性能研究 [D]. 石家庄: 河北科技大学, 2018ZHANG Meng. Preparation and Properties of modified epoxy resin filled thermal conductive adhesive [D]. Shijiazhuang: Hebei University of Science and Technology, 2018

|

| [21] |

石金亨, 刘莉, 邱钦标. 聚氨酯胶黏剂与镀锌板粘接强度的影响因素探讨 [J]. 广州化工, 2022, 50(4): 67-69.SHI Jinheng, LIU Li, QIU Qinbiao. Discussion on the influencing factors of the bond strengthbetween polyurethane adhesive and galvanized sheet [J]. Guangzhou Chemical Industry, 2022, 50(4): 67-69.

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS