Experimental study on grinding force in axial feed grinding of cemented carbide with diamond grinding wheel

-

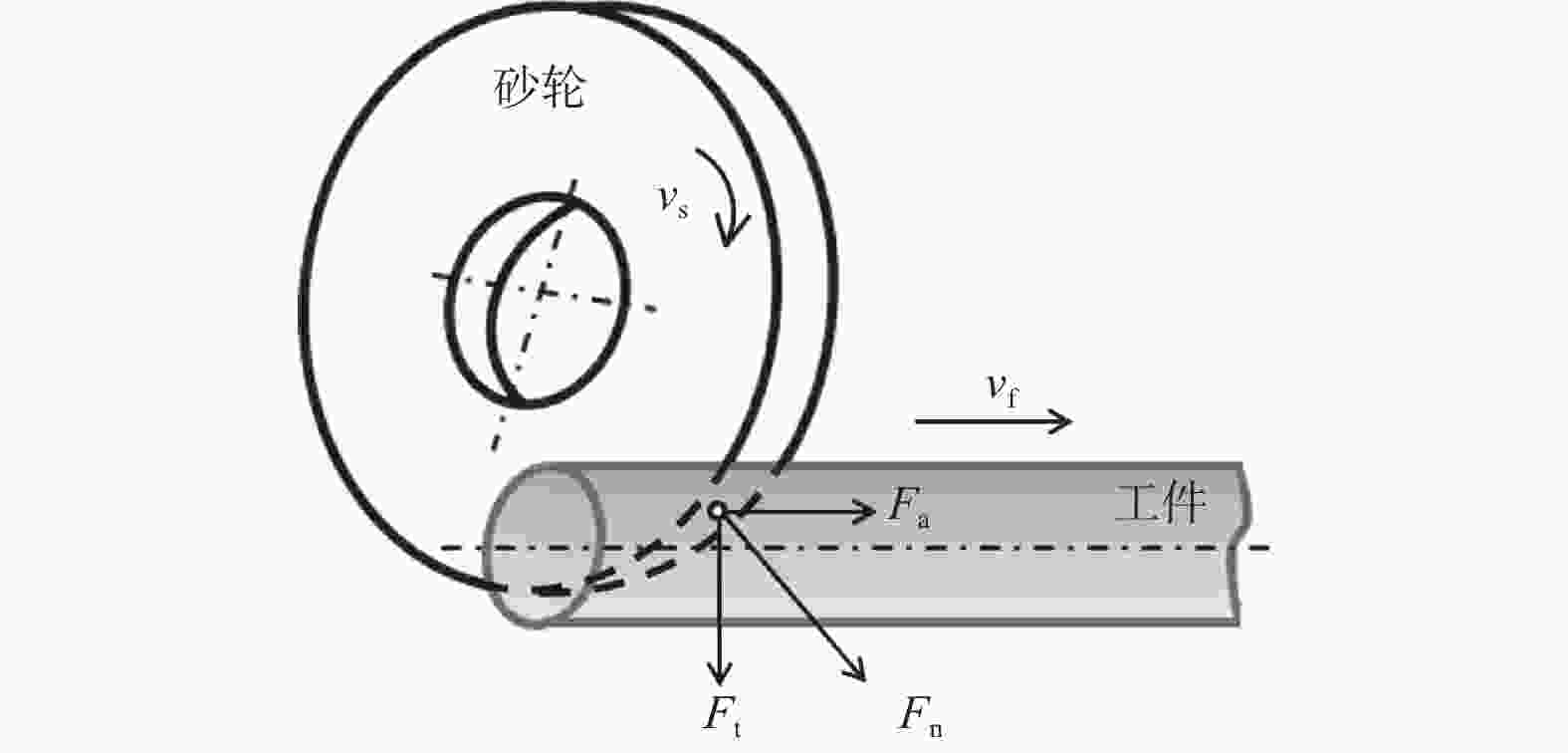

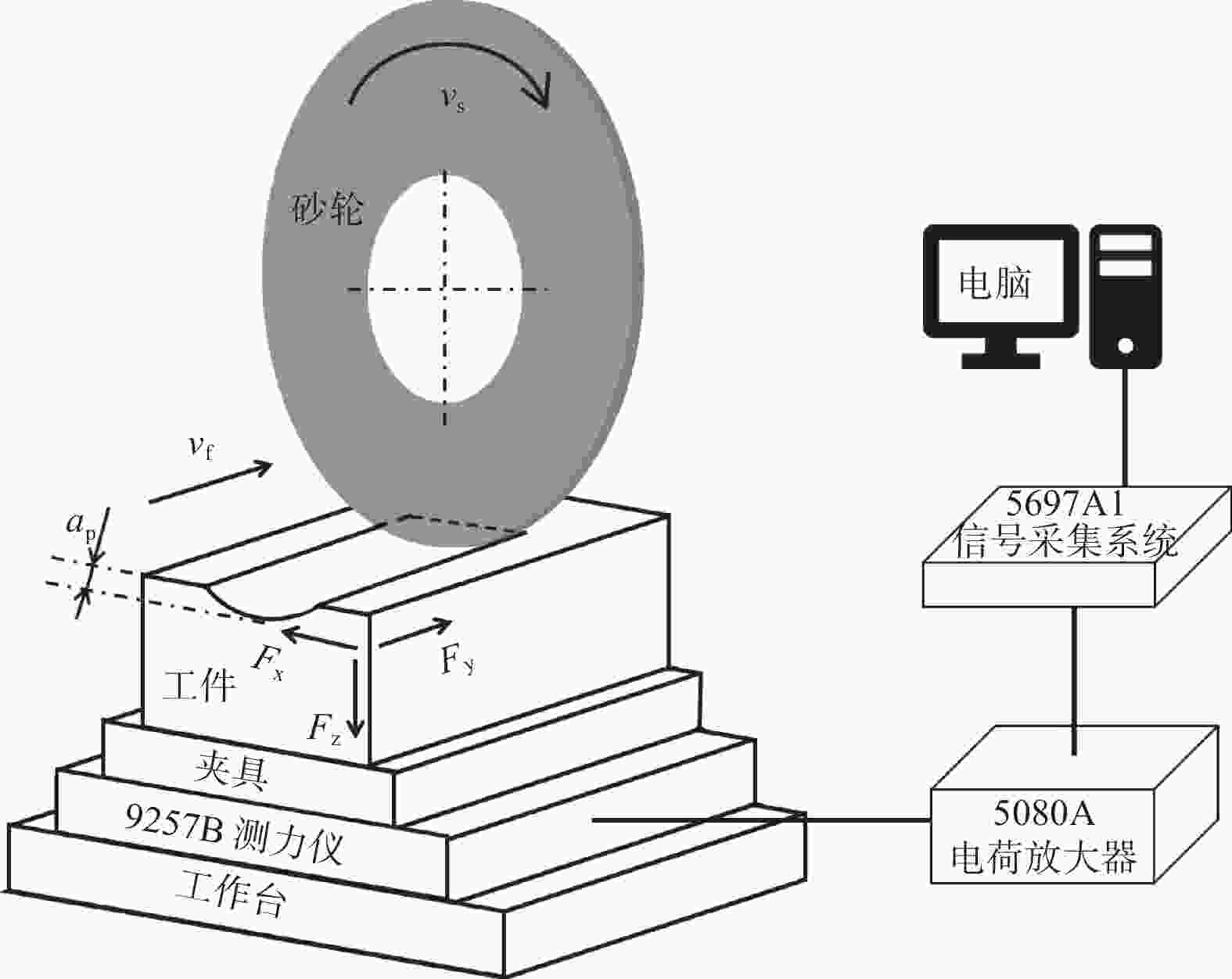

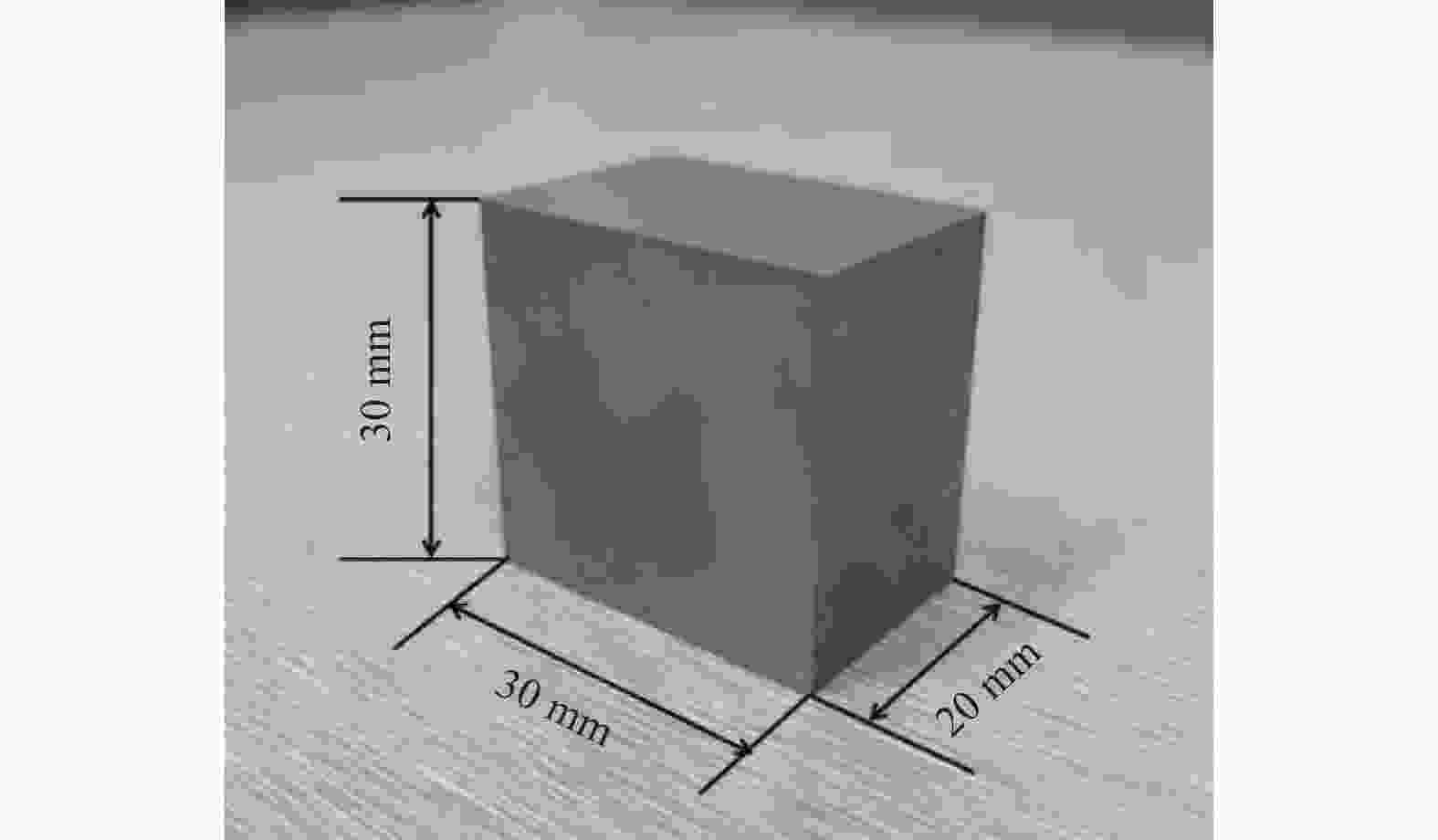

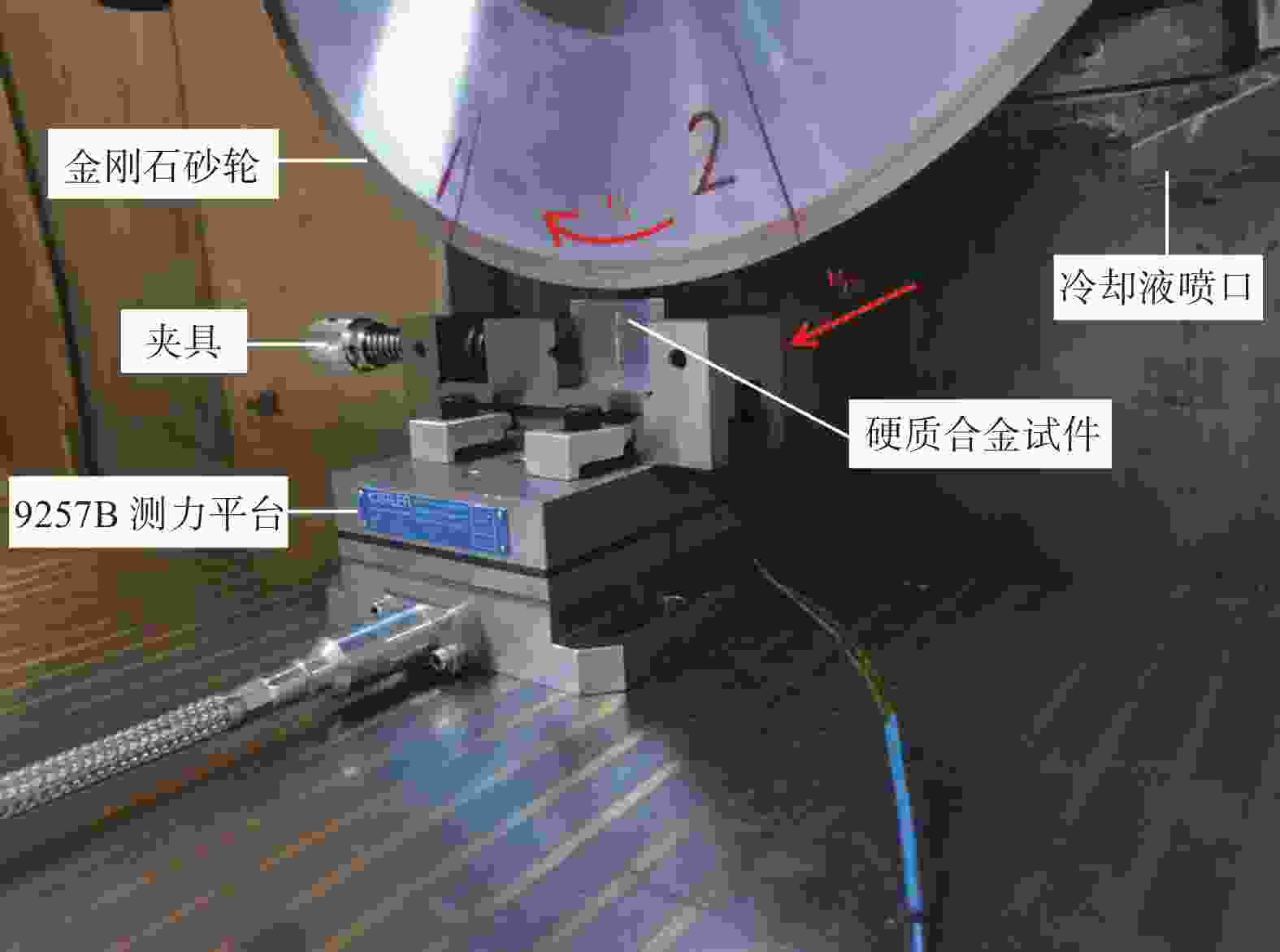

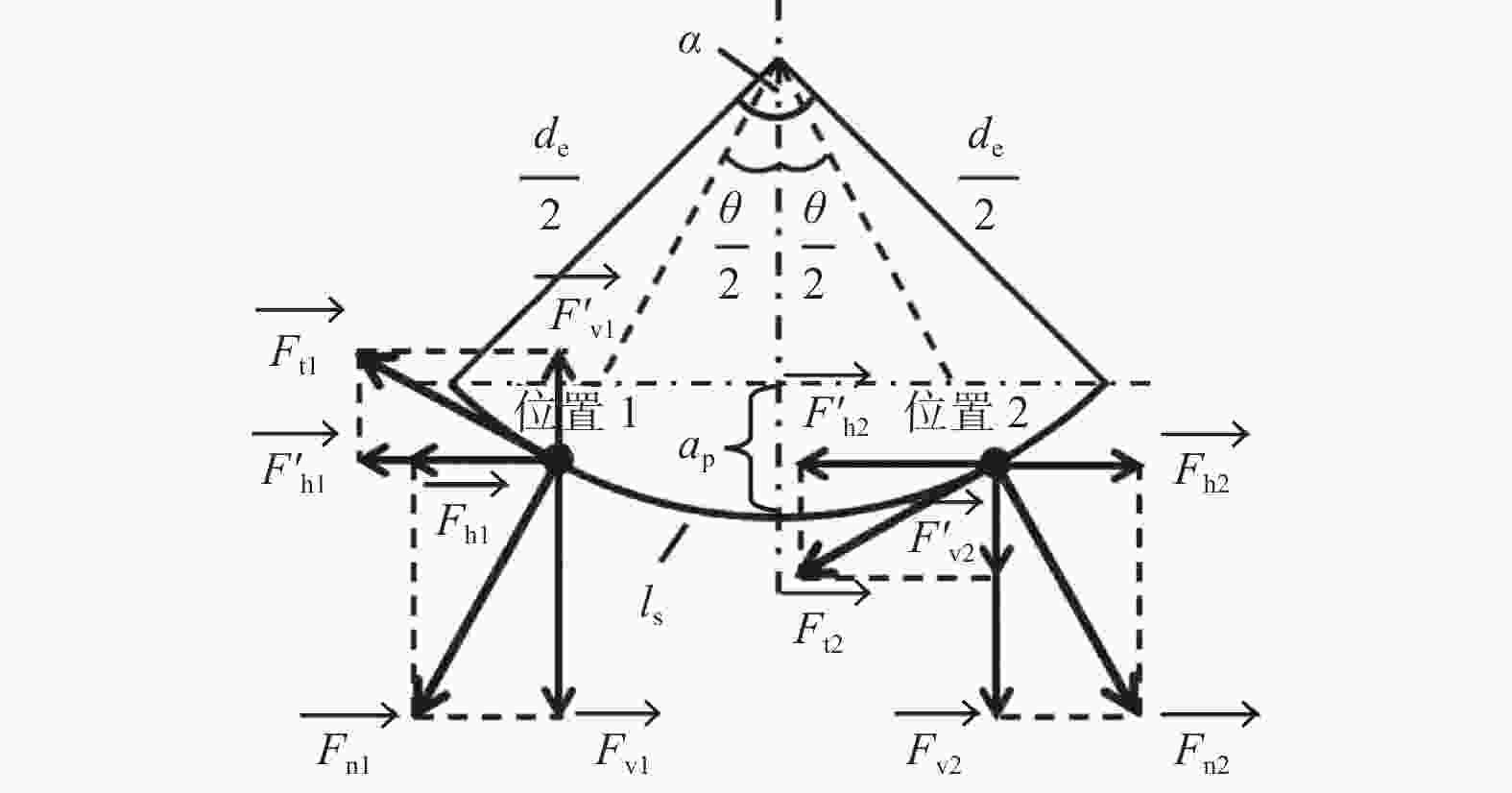

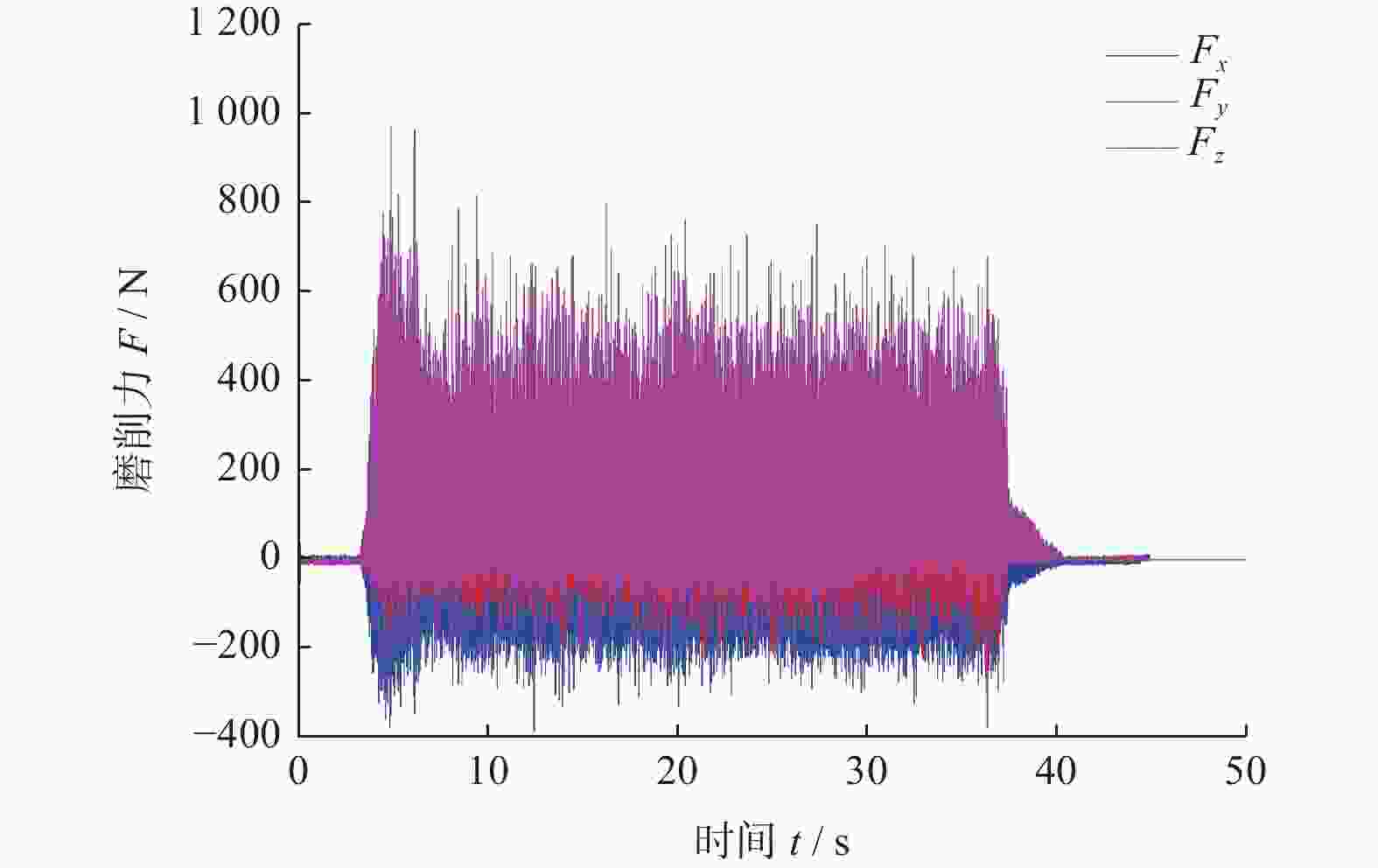

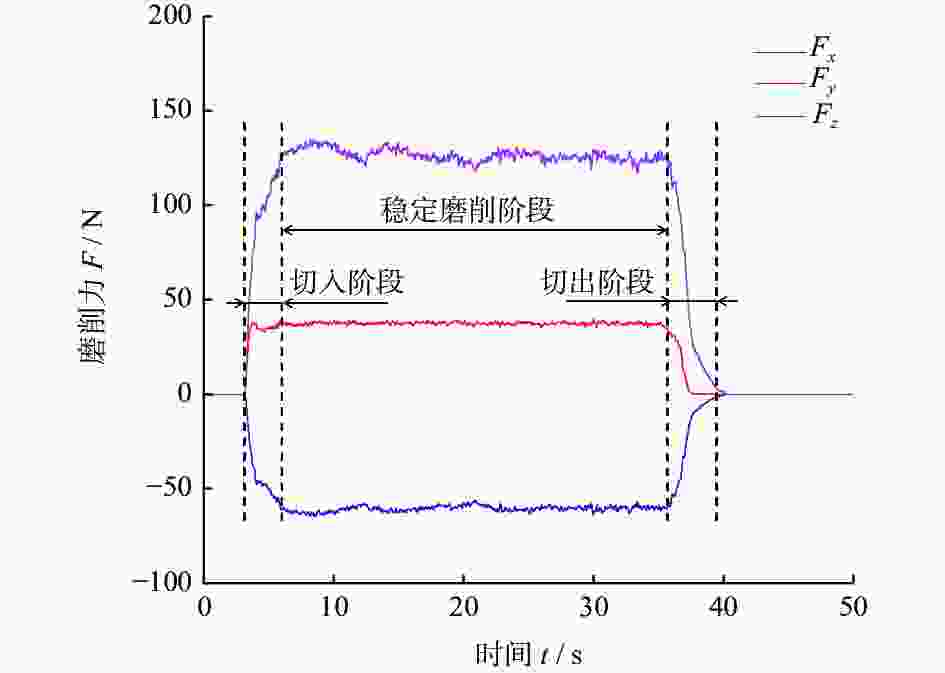

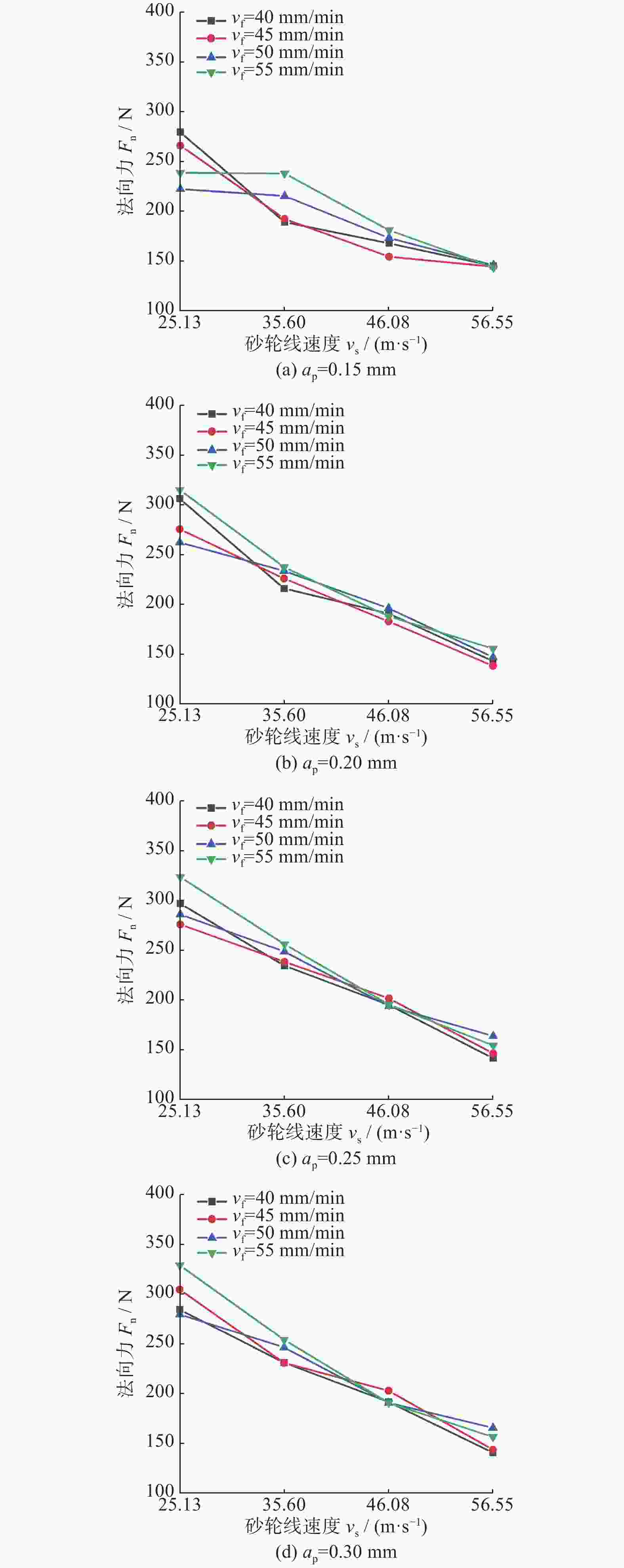

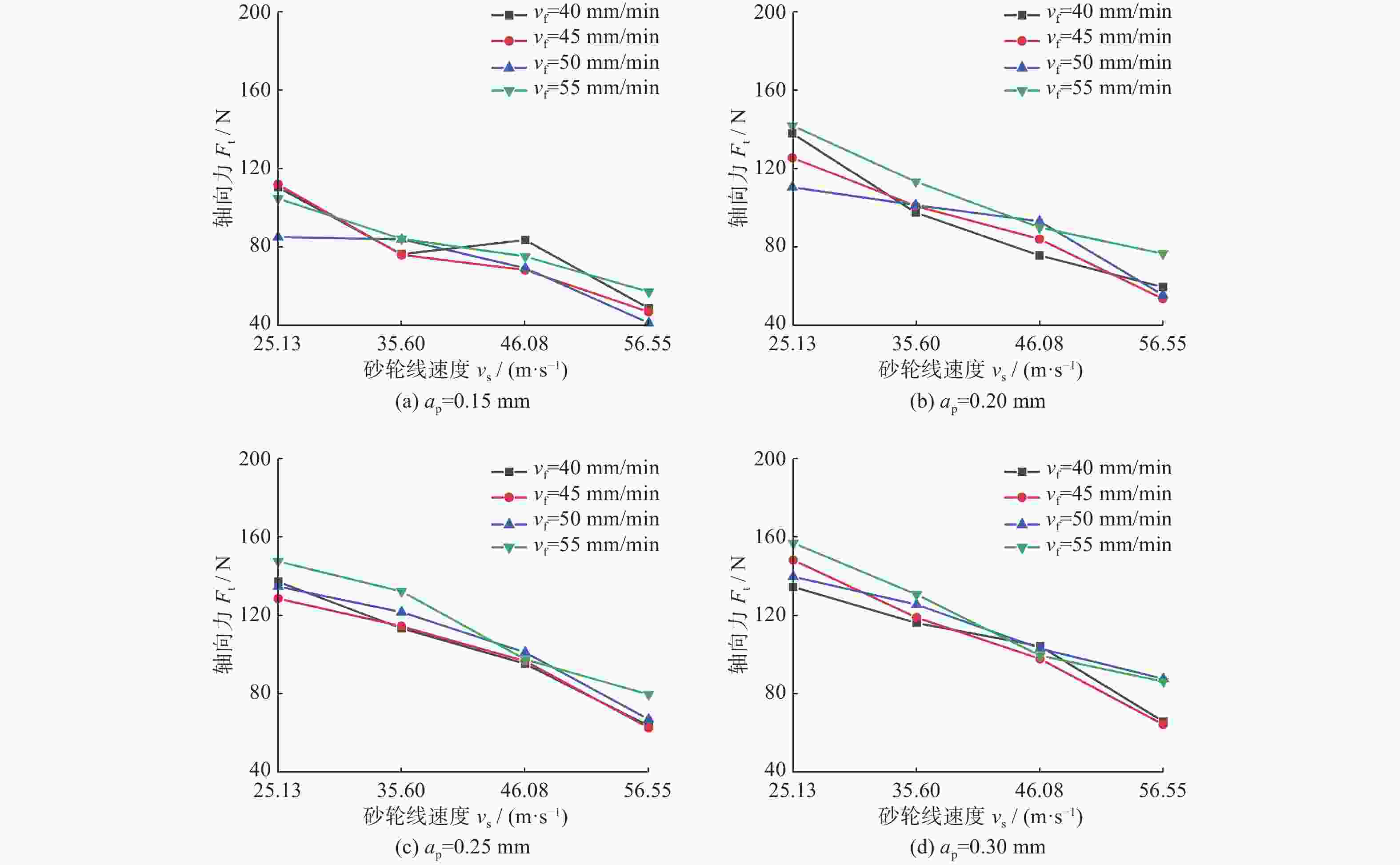

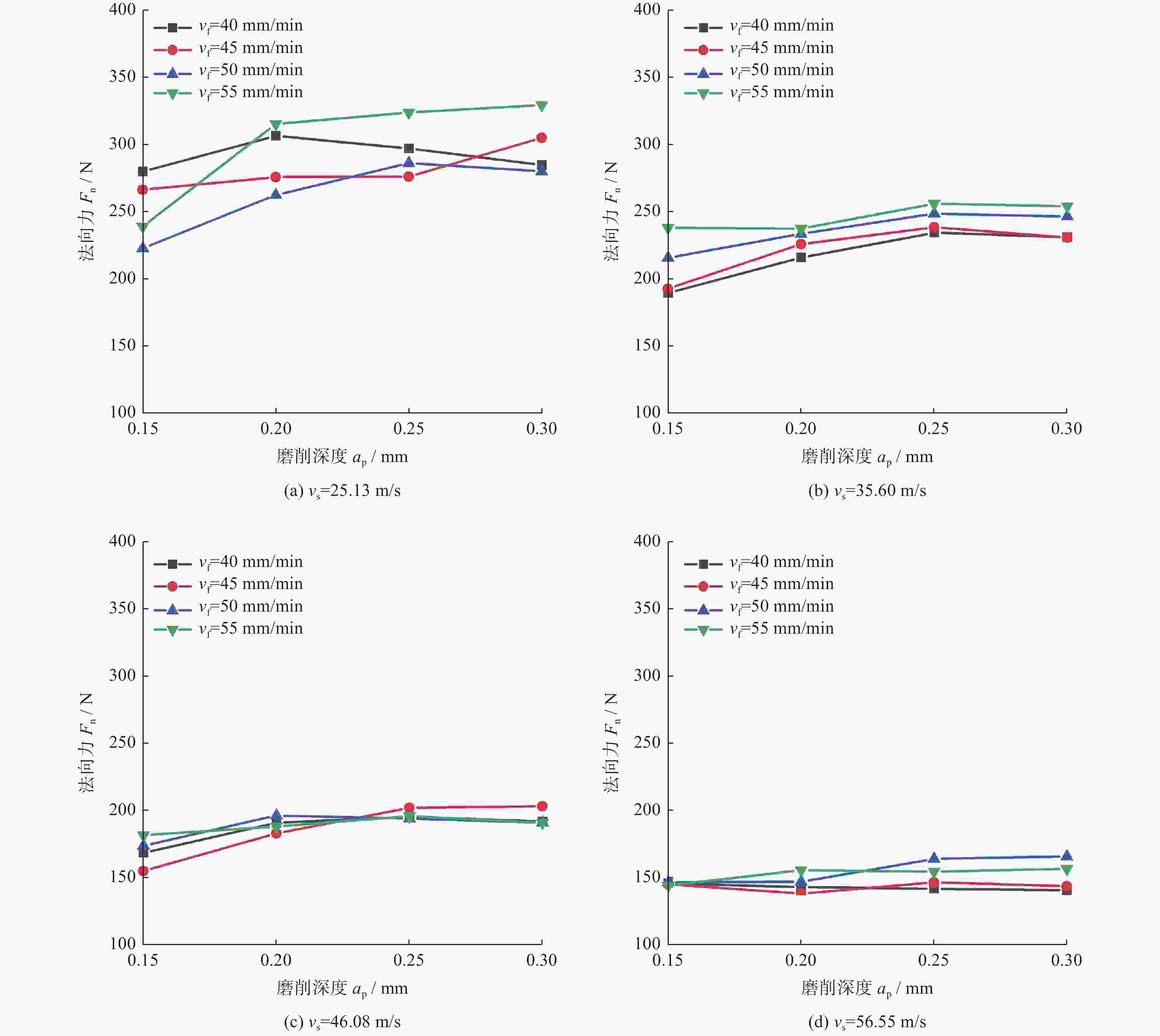

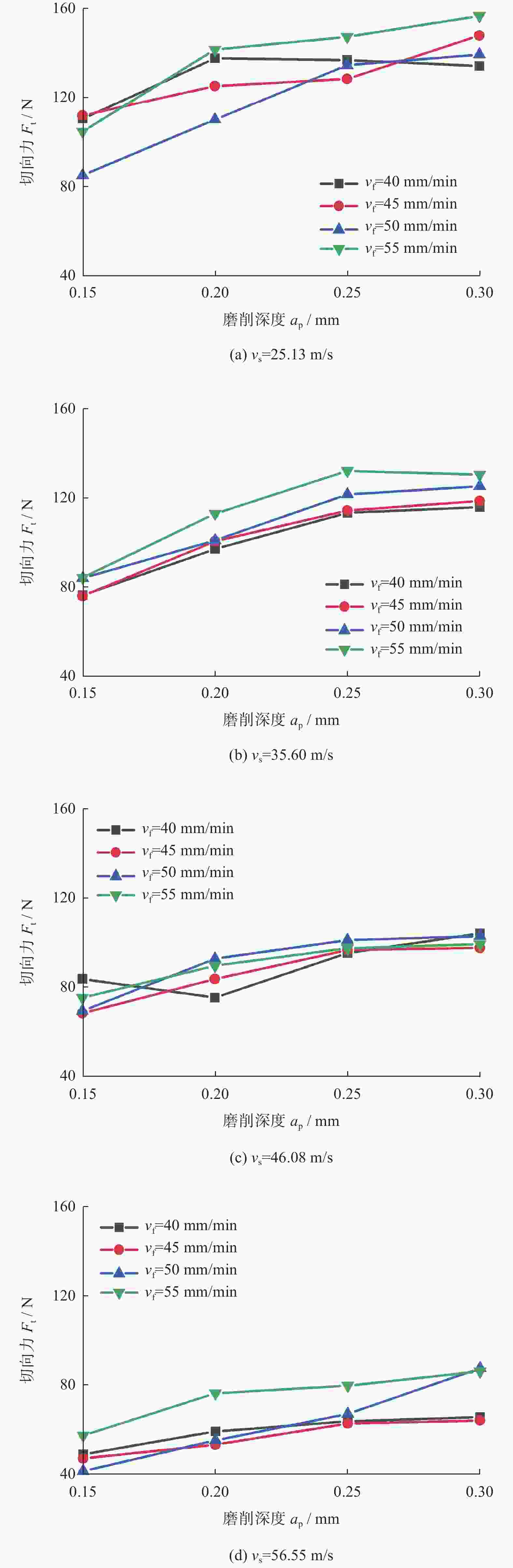

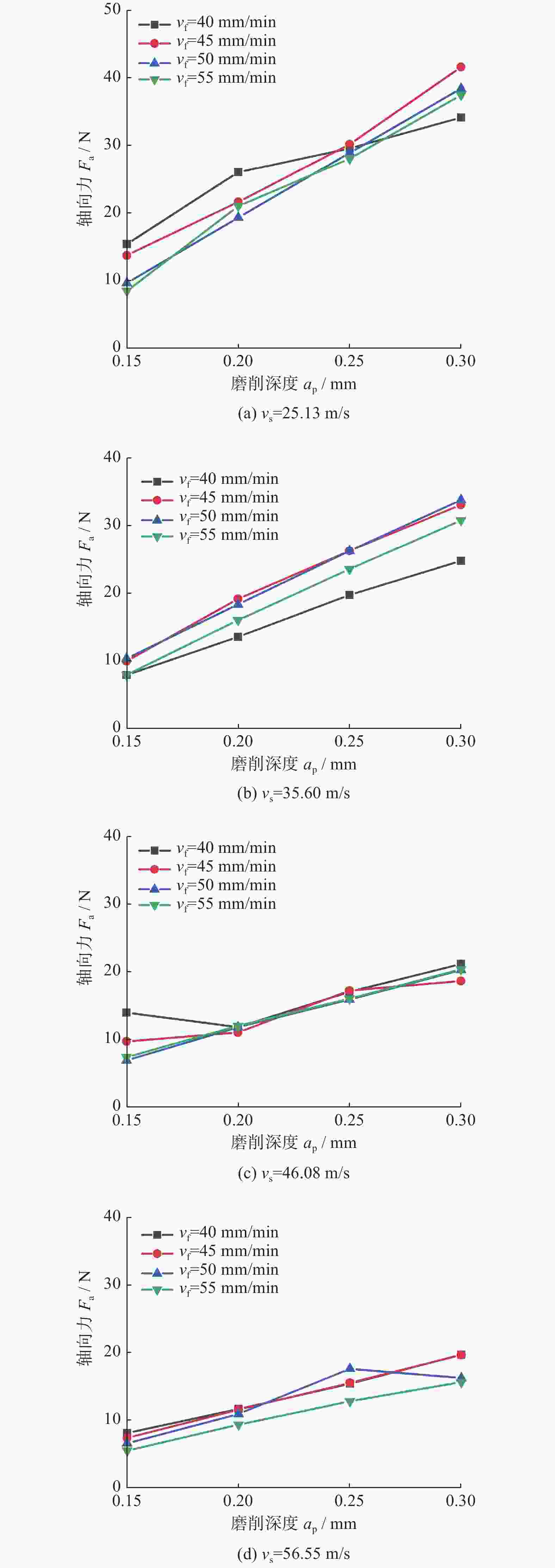

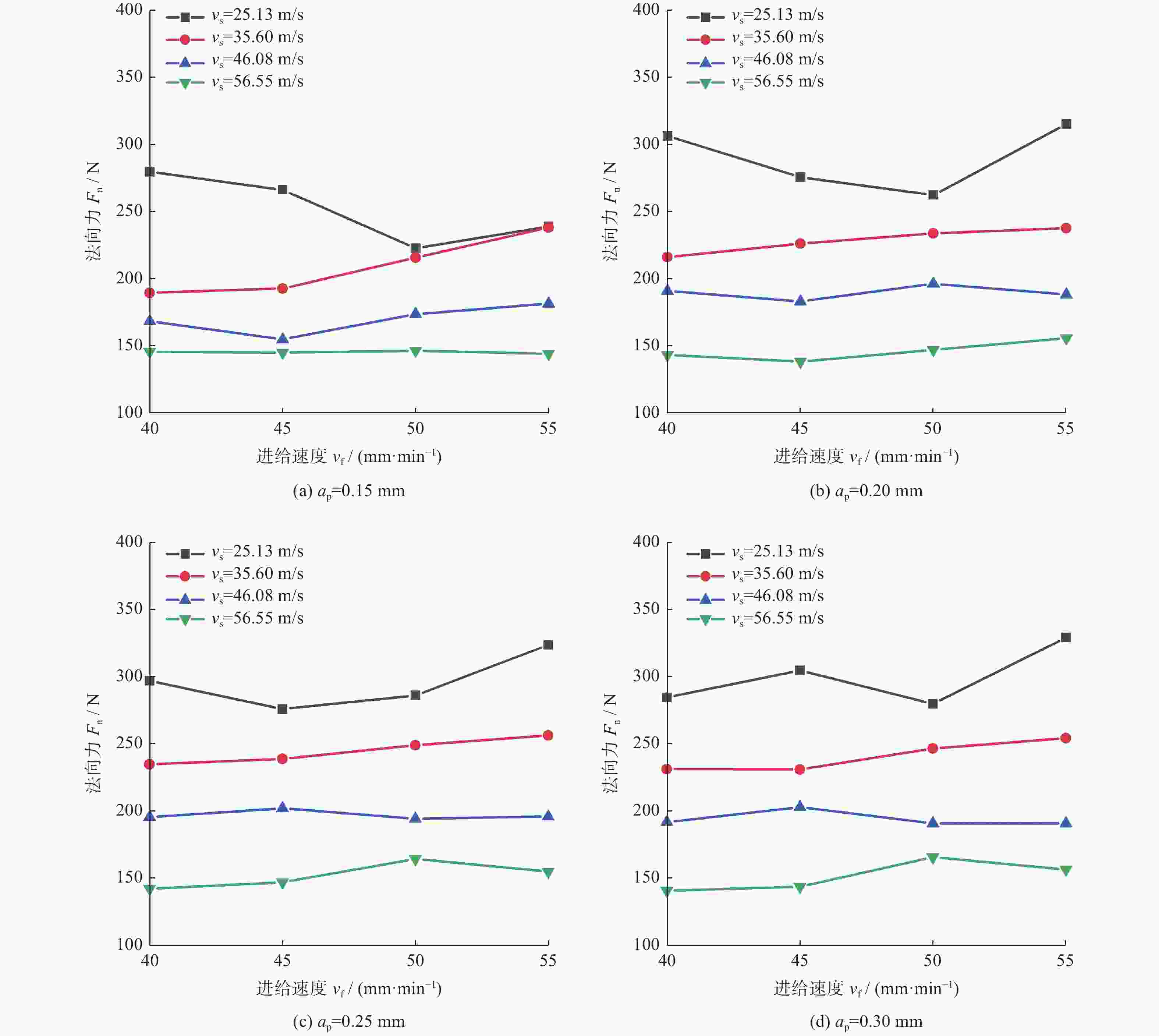

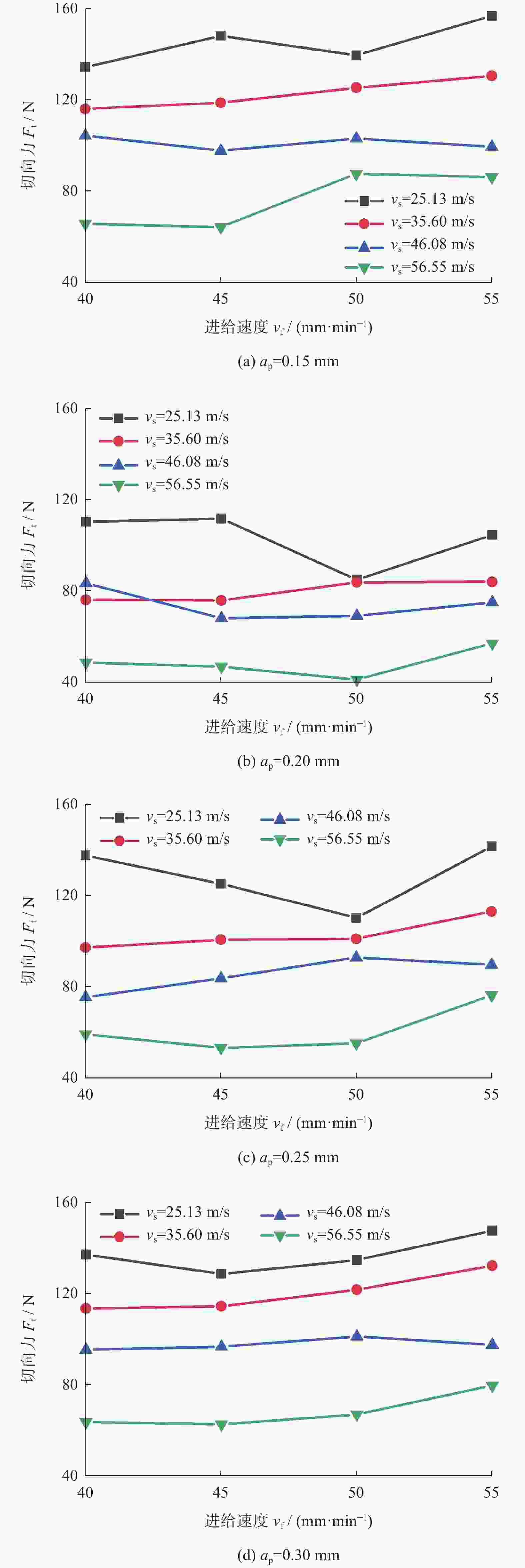

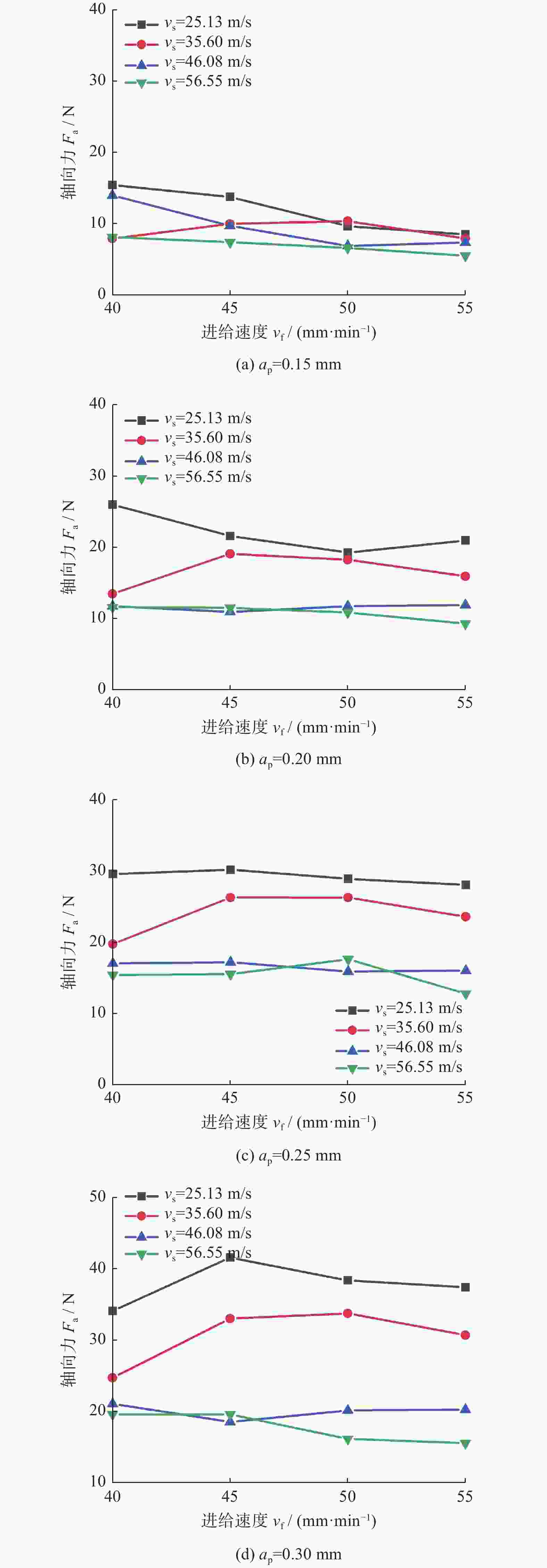

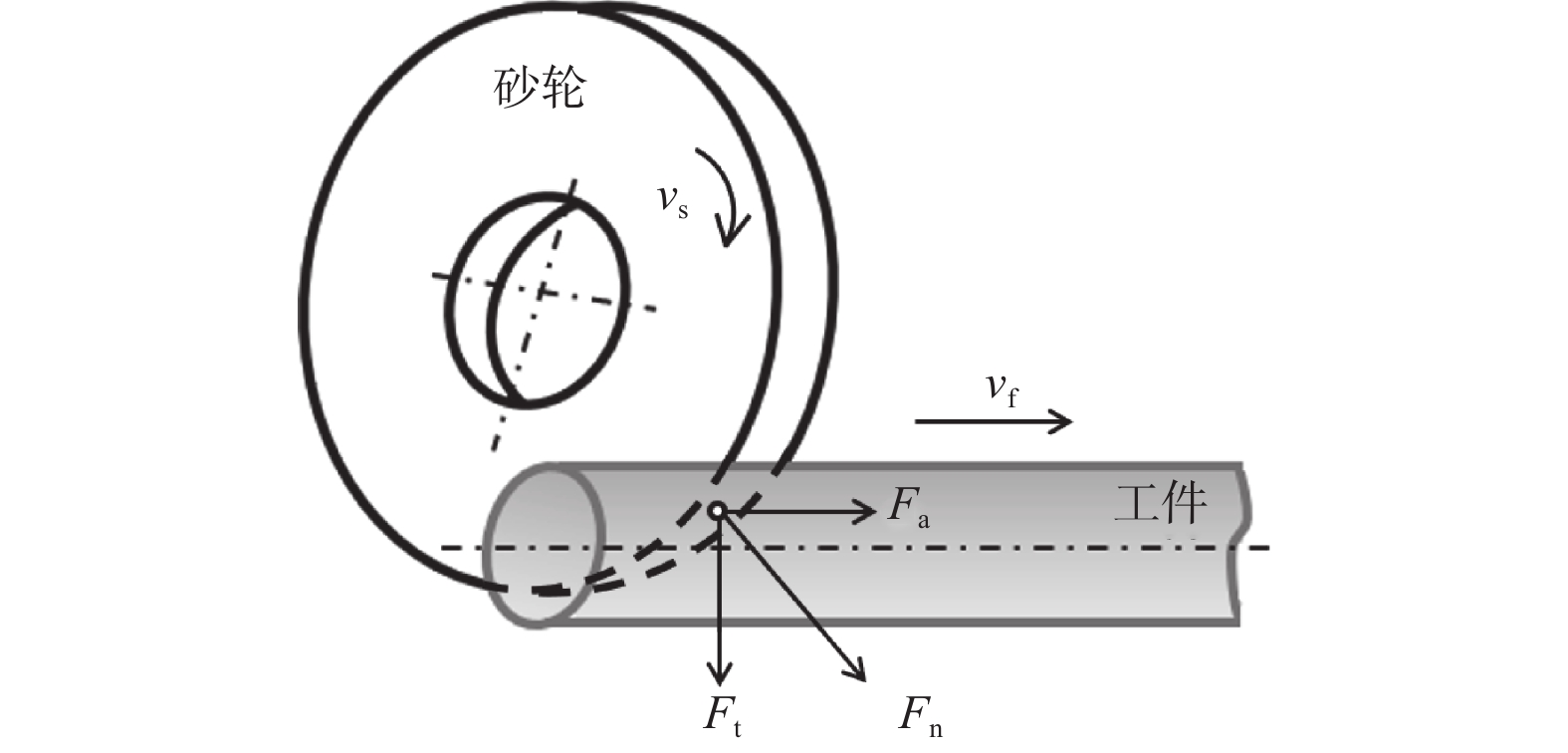

摘要: 为研究金刚石砂轮轴向进给磨削硬质合金时的磨削力,建立轴向力与法向力、切向力的转化模型;测量不同工艺参数下的磨削力变化;分析工艺参数对法向力、切向力、轴向力的影响规律并建立磨削力的经验公式。结果表明:在轴向进给磨削过程中,最大的磨削力是法向力,而轴向力略小于切向力。砂轮线速度对3个方向的磨削力的影响大致相同。磨削深度对法向、切向及轴向3个方向的磨削力的影响明显不同。进给速度对3个方向磨削力的影响不显著。Abstract: In order to study the grinding force of diamond wheel in axial feed grinding of cemented carbide, the transformation models of horizontal grinding force, vertical grinding force, normal force and tangential force are established, the variation of grinding force under different process parameters was measured, the effects of process parameters on normal force, tangential force and axial force are analyzed, the empirical formula of grinding force is established. The results show that in the process of axial feed grinding, the maximum grinding force is the normal force, and the axial force is slightly less than the tangential force. The influence of grinding wheel linear speed on grinding force in three directions is roughly the same. The influence of grinding depth on grinding force in three directions is obviously different. The effect of feed rate on grinding force is not significant.

-

Key words:

- axial feed grinding /

- cemented carbide /

- grinding force /

- empirical formula

-

表 1 GU20机械物理性能

Table 1. Mechanical and physical properties of GU20

主要参数 取值 WC晶粒度 d50 / μm 0.7 密度 ρ / (g·mm−3) 14.5 弹性模量 E / GPa 525 硬度 91.9 HRA 抗弯强度 σ / MPa 3800 比热 c / (J·kg−1·K−1) 950 导热率 K / (W·m−1·K−1) 110 热膨胀系数 λ / (K−1) 5×10−6 表 2 硬质合金磨削工艺参数表

Table 2. Cemented carbide grinding process parameters

工艺参数 取值 砂轮线速度 $ {v}_{{\rm{s}}} $ / (m·s−1) 25.13,35.60,46.08,56.55 磨削深度 $ {a}_{{\rm{p}}} $ / mm 0.15,0.20,0.25,0.30 轴向进给速度 $ {v}_{{\rm{f}}} $ / (mm·min−1) 40,45,50,55 表 3 磨削深度对磨削力变化幅度的影响

Table 3. Effect of grinding depth on variation of grinding forces

磨削深度

$ {a}_{\mathrm{p}} $ / mm法向力降幅

ΔFn / N切向力降幅

ΔFt / N轴向力降幅

ΔFa / N0.15 106.30 54.32 4.89 0.20 143.67 67.61 11.11 0.25 143.67 68.43 13.84 0.30 147.76 68.66 20.09 -

[1] WANG Kaifei, ZHANG Guohua. Synthesis of high-purity ultrafine tungsten and tungsten carbide powders [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(6): 1697-1706. [2] 王倩玉, 秦明礼, 吴昊阳, 等. 新型纳米晶硬质合金的研究现状及发展趋势 [J]. 粉末冶金技术,2022,40(4):1-17. doi: 10.19591/j.cnki.cn11-1974/tf.2021040010WANG Qianyu, QIN Mingli, WU Haoyang, et al. Research status and development trend of new nanocrystalline cemented carbide [J]. Powder Metallurgy Technology,2022,40(4):1-17. doi: 10.19591/j.cnki.cn11-1974/tf.2021040010 [3] 柯明峰, 吕冰海, 邵蓝樱, 等. 硬质合金刀片前刀面的剪切增稠抛光实验研究 [J]. 表面技术,2022,51(1):220-228.KE Mingfeng, LYU Binghai, SHAO Lanying, et al. Experimental study on shearing thickening polishing of rake surface of cemented carbide inserts [J]. Surface Technology,2022,51(1):220-228. [4] FANG S. Wear assessment of cemented carbide tools (WC-Co) with defined cutting edges under grinding-like service conditions [J]. Wear,2021,476:203744. doi: 10.1016/j.wear.2021.203744 [5] VENTURA C, CRUZ D C, SORDI V L, et al. Effect of the grinding process on the wear of a cemented tungsten carbide cutting insert during turning [J]. Procedia CIRP,2021,101:174-177. doi: 10.1016/j.procir.2021.02.020 [6] YANG J, ODEN M, JOHANSSON-JOESAAR M P, et al. Grinding effects on surface integrity and mechanical strength of WC-Co cemented carbides [J]. Procedia CIRP,2014,13(1):257-263. [7] LIU X, WANG H, FENG H, et al. On the enhanced wear resistance of ultra-coarse WC-Co cemented carbides by WCoB addition [J]. Journal of Alloys and Compounds,2022,894:162449. doi: 10.1016/j.jallcom.2021.162449 [8] 刘鹏程, 谢鹏, 李想, 等. 整体硬质合金刀具磨削工艺实验分析 [J]. 工具技术,2021,55(10):41-44. doi: 10.3969/j.issn.1000-7008.2021.10.008LIU Pengcheng, XIE Peng, LI Xiang, et al. Experimental analysis on grinding technology of solid carbide tools [J]. Tool Engineering,2021,55(10):41-44. doi: 10.3969/j.issn.1000-7008.2021.10.008 [9] 许鹏飞, 刘志林, 易为, 等. 磨削工艺对硬质合金切槽刀片刃口质量的影响 [J]. 硬质合金,2018,35(1):50-56.XU Pengfei, LIU Zhilin, YI Wei, et al. The effect of grinding process on cutting edge quality of carbide groove inserts [J]. Cemented Carbides,2018,35(1):50-56. [10] 郑清, 姚斌, 蔡思捷, 等. 硬质合金可转位刀片周边刃磨磨削力模型研究 [J]. 组合机床与自动化加工技术,2020(8):16-20.ZHENG Qing, YAO Bin, CAI Sijie, et al. Research on grinding force model for peripheral grinding of cemented carbide indexable inserts [J]. Modular Machine Tool & Automatic Manufacturing Technique,2020(8):16-20. [11] 宋铁军, 周志雄, 李伟, 等. 硬质合金立铣刀螺旋槽磨削表面粗糙度模型研究 [J]. 机械工程学报,2017,53(17):185-192. doi: 10.3901/JME.2017.17.185SONG Tiejun, ZHOU Zhixiong, LI Wei, et al. Roughness model for helical flute of cemented carbide end mill under grinding [J]. Journal of Mechanical Engineering,2017,53(17):185-192. doi: 10.3901/JME.2017.17.185 [12] WIRTZ C, DEHMER A, TRAUTH D, et al. Analysis of the grinding wheel wear in dependency of the cemented carbide specification [J]. International Journal of Advanced Manufacturing Technology,2018,1-4(99):747-754. [13] KLOCKE F, WIRTZ C, MUELLER S, et al. Analysis of the material behavior of cemented carbides (WC-Co) in grinding by single grain cutting tests [J]. Procedia CIRP,2016,46:209-213. doi: 10.1016/j.procir.2016.03.209 [14] 熊建超, 邹芹, 李艳国, 等. WC 基硬质合金刀具材料研究进展 [J]. 金刚石与磨料磨具工程, 2019, 39(02): 95-102Xiong J C, Zhou Q, Li Y G, et al. Research progress of WC-based cemented carbide tool materials [J]. Diamond & Abrasives Engineering, 2019, 39(02): 95-102 [15] 杨军, 黄向明, 蒋福星, 等. 纳米硬质合金高速深磨工艺试验研究 [J]. 现代制造工程,2015(10):12-17,21. doi: 10.3969/j.issn.1671-3133.2015.10.004YANG Jun, HUANG Xiangming, JIANG Fuxing, et al. Experimental investigation on high speed grinding characteristics of the nano-cemented carbides [J]. Modern Manufacturing Engineering,2015(10):12-17,21. doi: 10.3969/j.issn.1671-3133.2015.10.004 [16] 陈哲, 陈春晖, 刘一波, 等. 树脂结合剂金刚石堆积磨料砂轮磨削YG8硬质合金 [J]. 金刚石与磨料磨具工程,2020,40(6):25-30.CHEN Zhe, CHEN Chunhui, LIU Yibo, et al. Grinding YG8 cemented carbide with resin bond grinding wheels made of diamond agglomerate abrasive [J]. Diamond & Abrasives Engineering,2020,40(6):25-30. [17] 张大将, 王颖达, 陈世隐, 等. 钎焊金刚石砂轮磨削YG8硬质合金的试验研究 [J]. 超硬材料工程,2017,29(3):19-23. doi: 10.3969/j.issn.1673-1433.2017.03.003ZHANG Dajiang, WANG Yingda, CHEN Shiyin, et al. Experimental study of the grinding of YG8 cemented carbide by brazed diamond wheel [J]. Superhard Material Engineering,2017,29(3):19-23. doi: 10.3969/j.issn.1673-1433.2017.03.003 [18] 刘伟, 刘一波, 黄霞, 等. 陶瓷金刚石砂轮在YG10X顶锤磨削加工中的应用 [J]. 金刚石与磨料磨具工程,2018,38(5):73-77.LIU Wei, LIU Yibo, HUANG Xia, et al. Application of vitrified bonded diamond wheel in YG10X cemented carbide anvil grinding [J]. Diamond & Abrasives Engineering,2018,38(5):73-77. [19] 陶洪亮, 宋鹏涛, 刘泓, 等. 陶瓷结合金刚石砂轮磨削硬质合金表面粗糙度的研究 [J]. 金刚石与磨料磨具工程,2011,31(3):54-56. doi: 10.3969/j.issn.1006-852X.2011.03.014TAO Hongliang, SONG Pengtao, LIU Hong, et al. Experimental research on surface roughness of cemented carbide ground with vitrified bond diamond wheel [J]. Diamond & Abrasives Engineering,2011,31(3):54-56. doi: 10.3969/j.issn.1006-852X.2011.03.014 [20] ONISHI T, TAKASHIMA T, SAKAKURA M, et al. Improvement of the form accuracy of a slender workpiece in cylindrical traverse grinding [J]. International Journal of Automation Technology,2019,13(6):728-735. doi: 10.20965/ijat.2019.p0728 [21] 高成. 基于硬脆材料端面轴向进给的磨削力建模与实验分析研究 [D]. 温州: 温州大学, 2020.GAO Cheng. Grinding force modeling and experimental analysis based on axial feed grinding of hard and brittle materials [D]. Wenzhou: Wenzhou University, 2020. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS