Study on removal mechanism of steel bonded cemented carbide material GT35 in cutting process

-

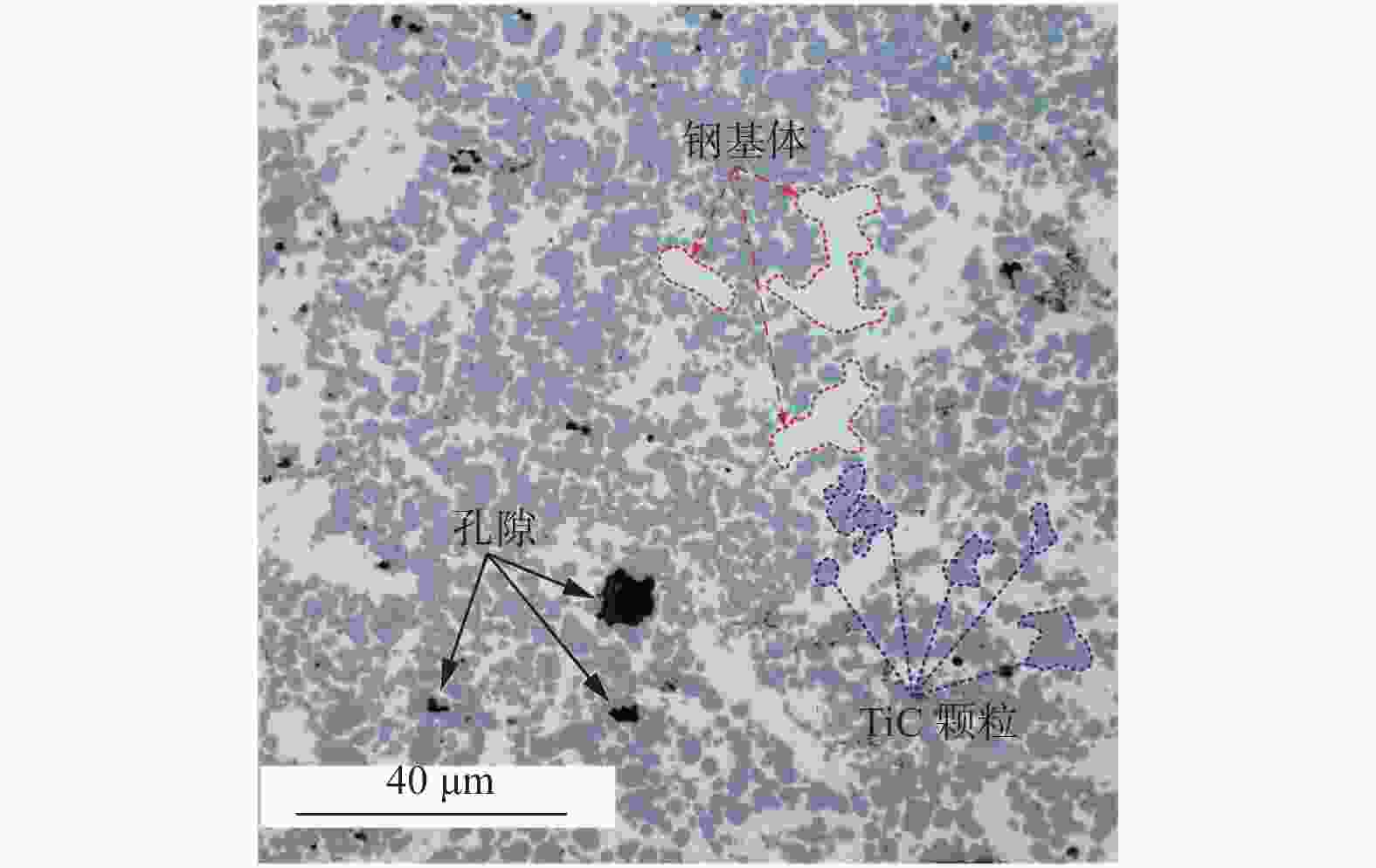

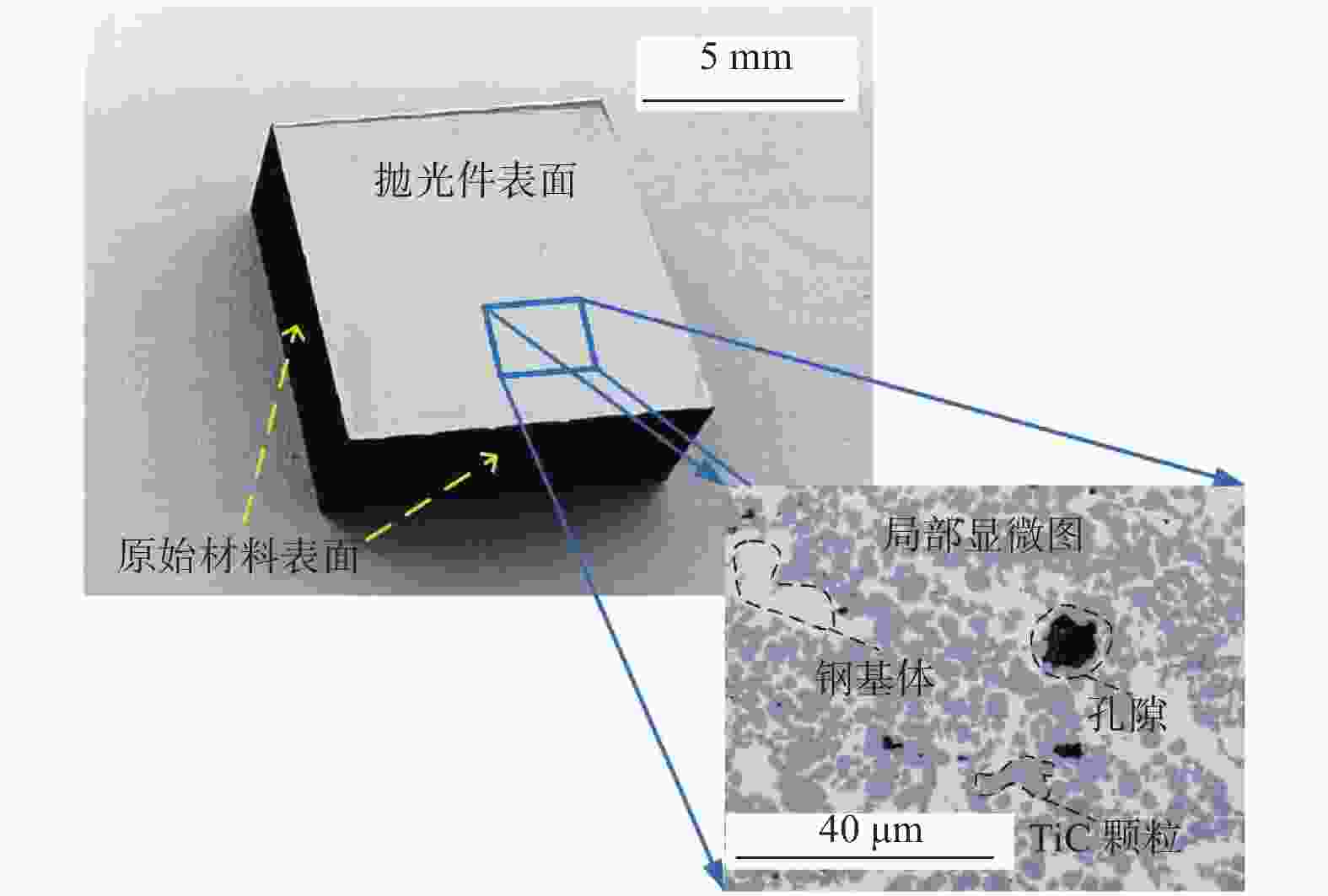

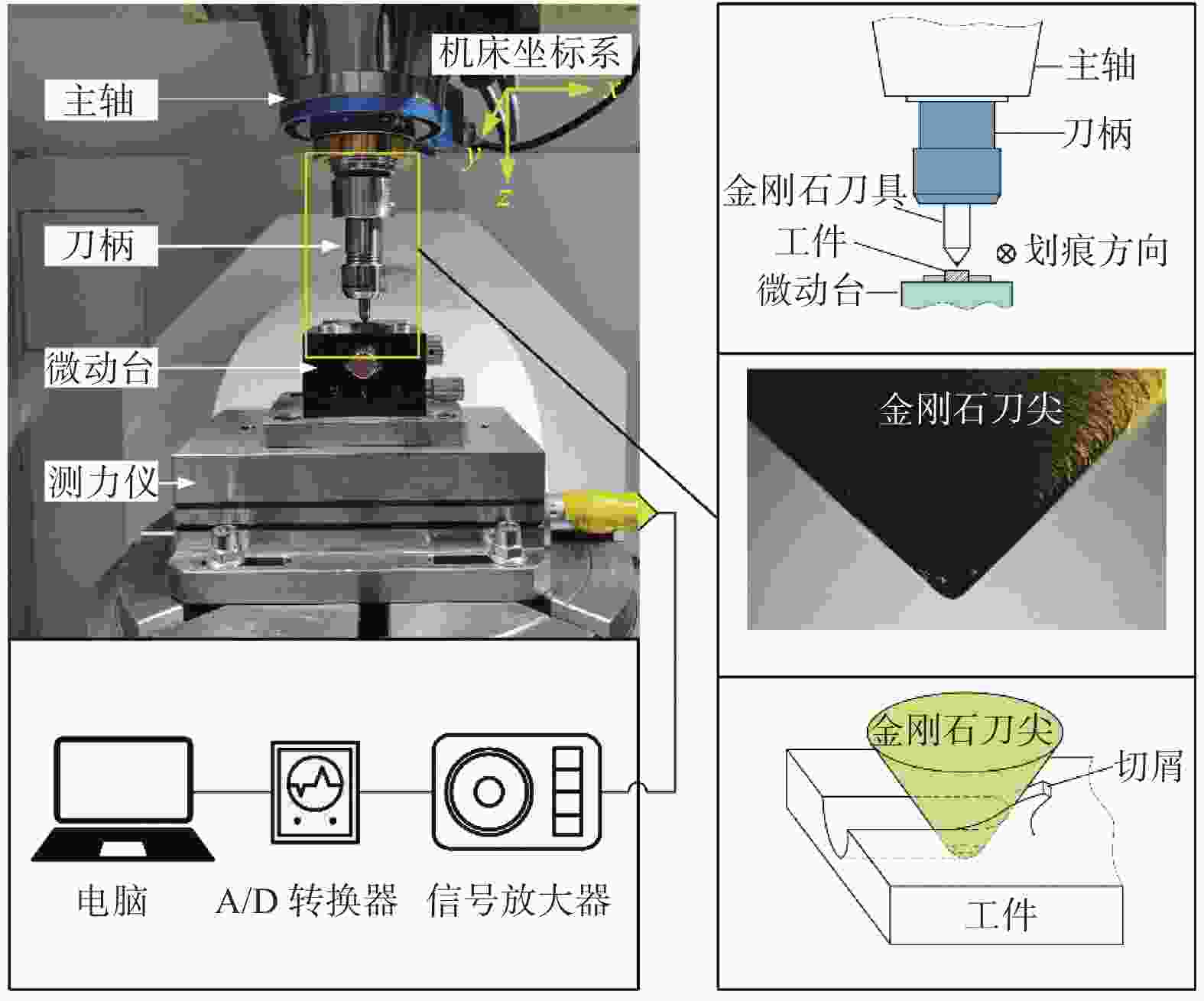

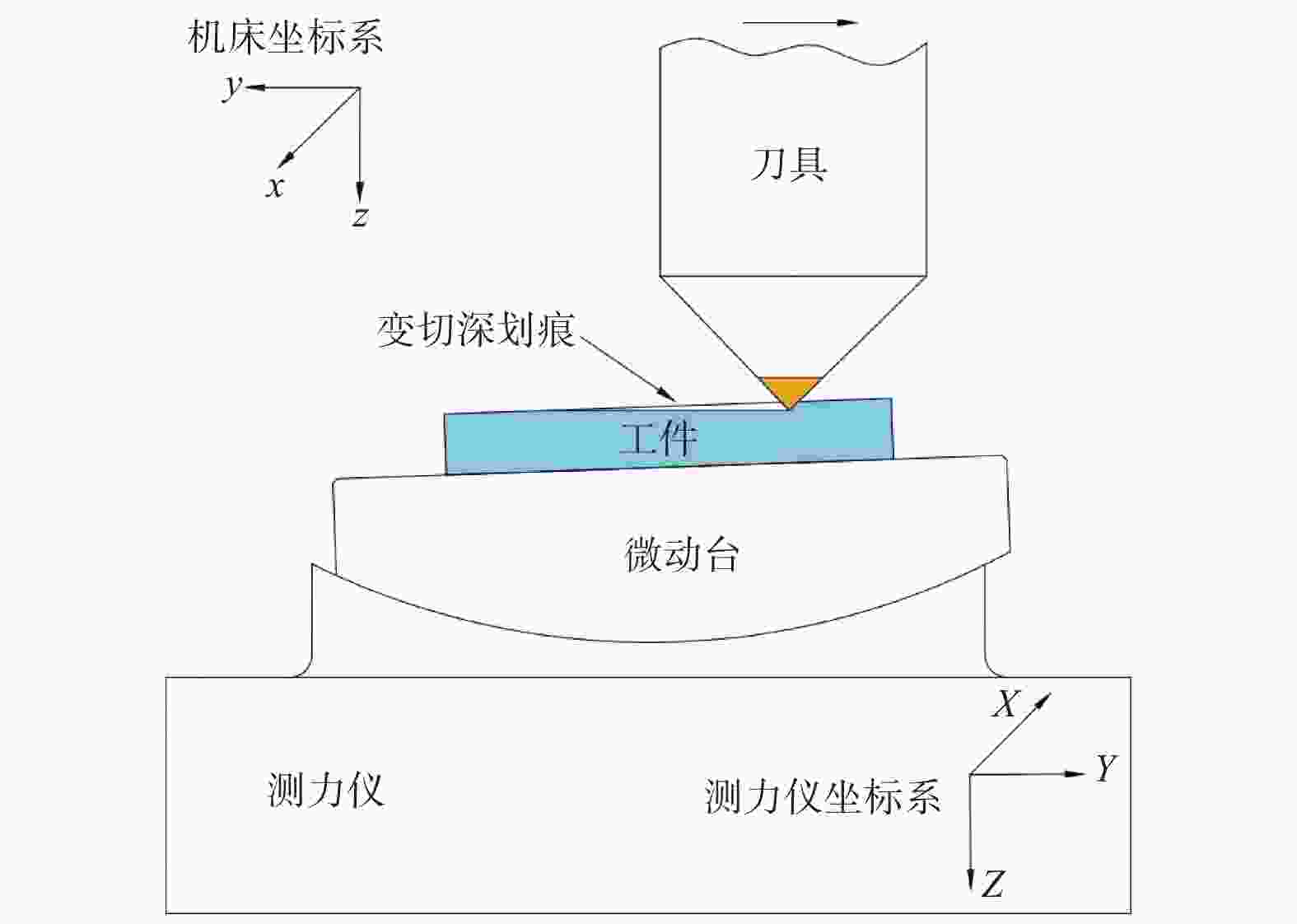

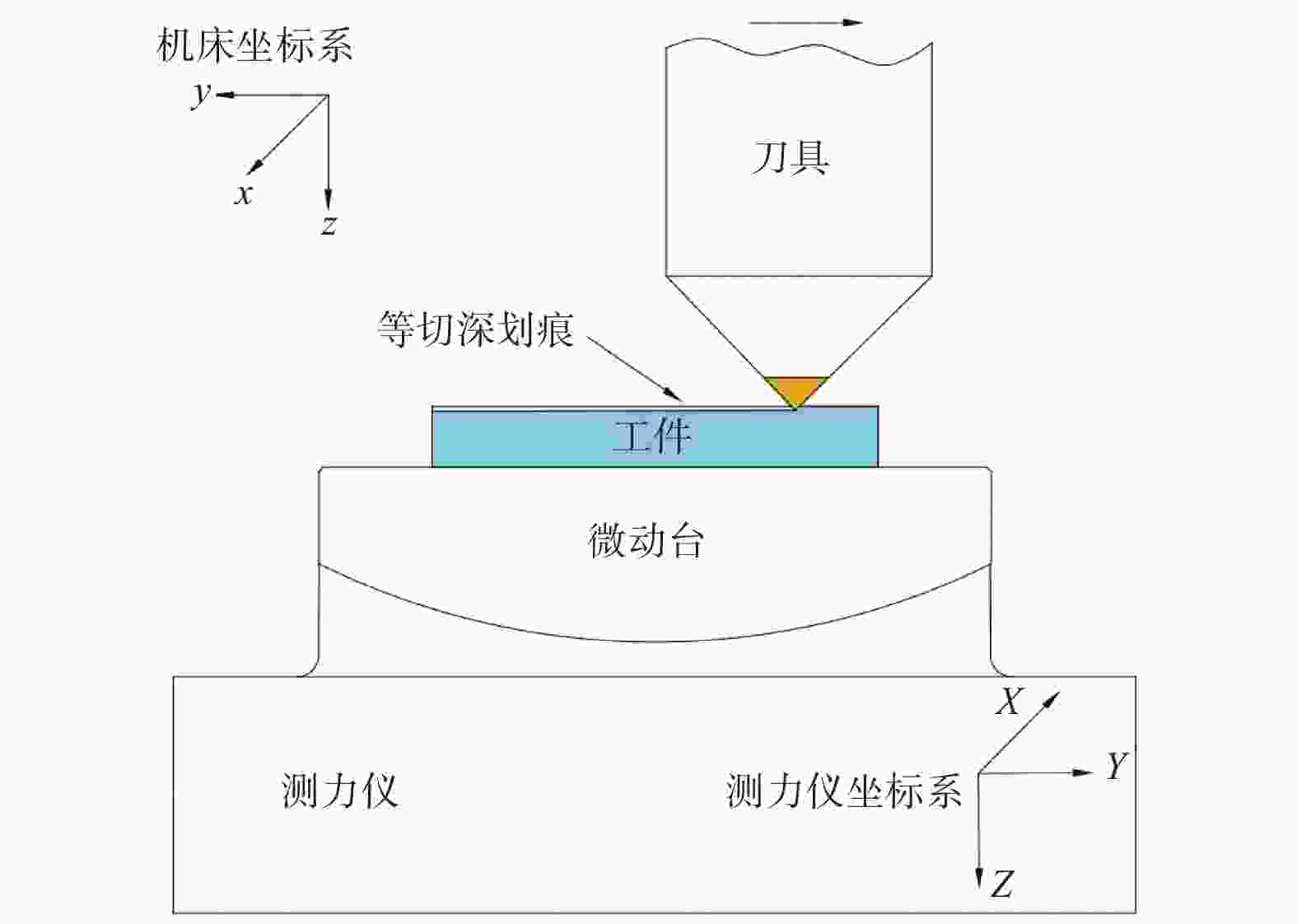

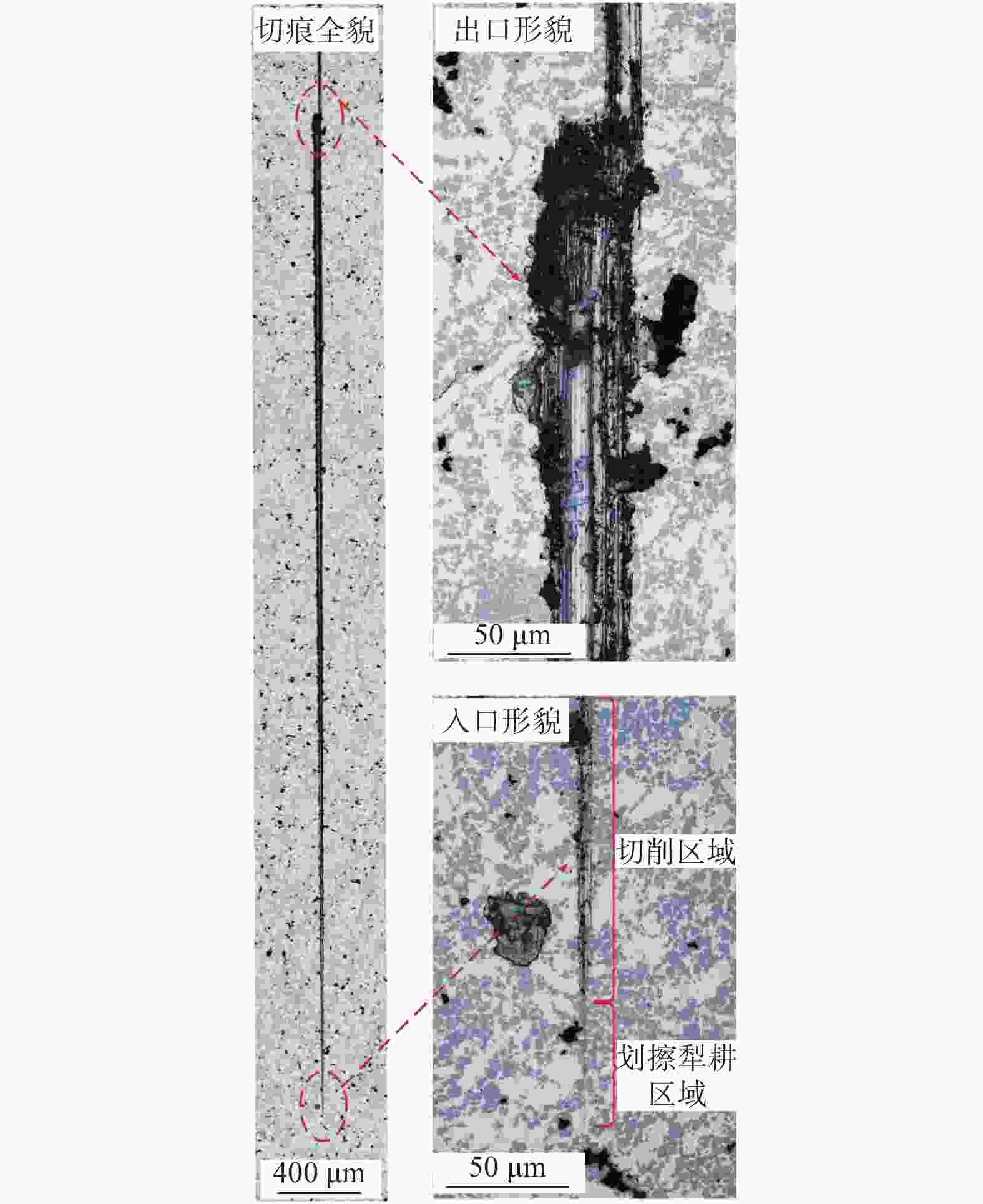

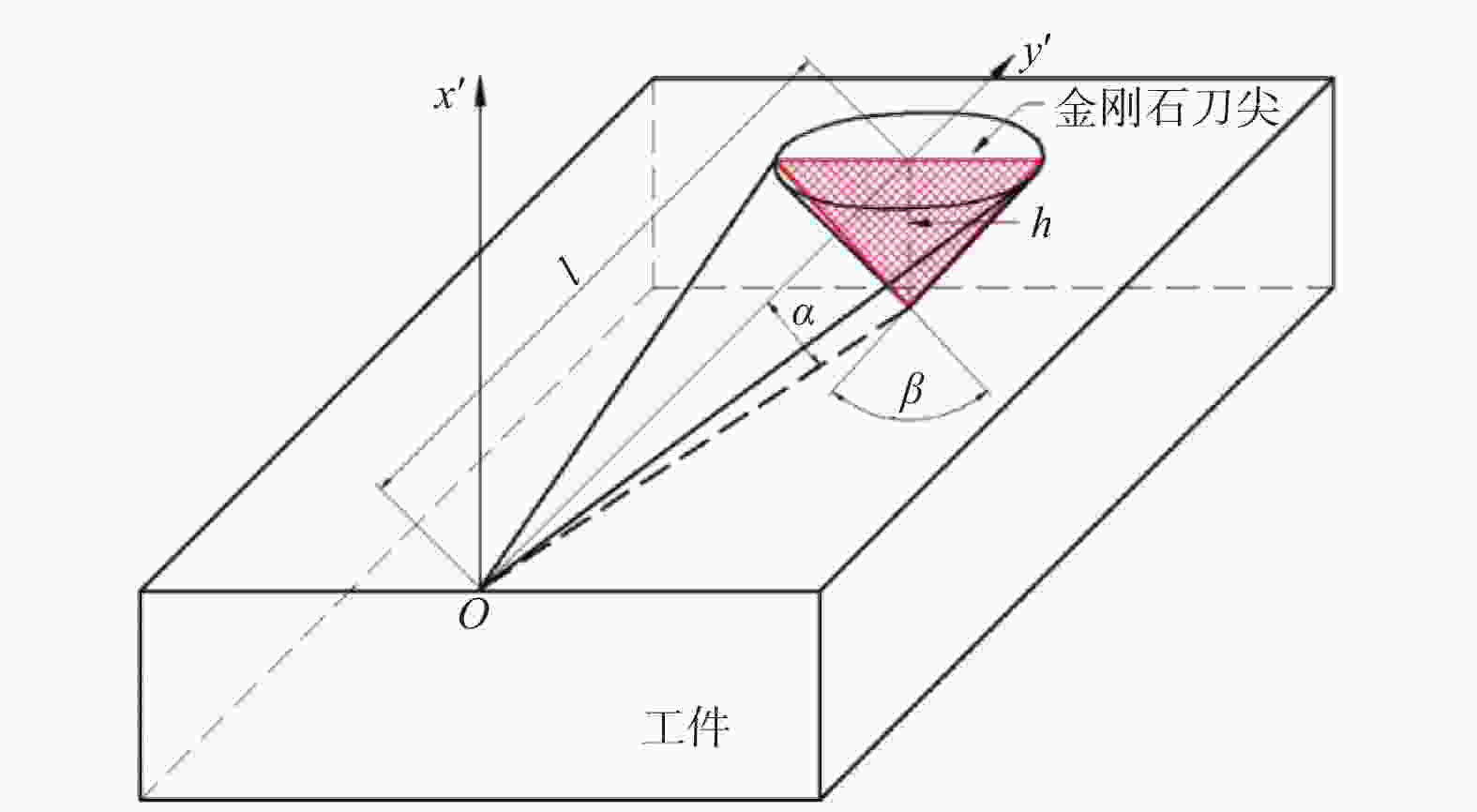

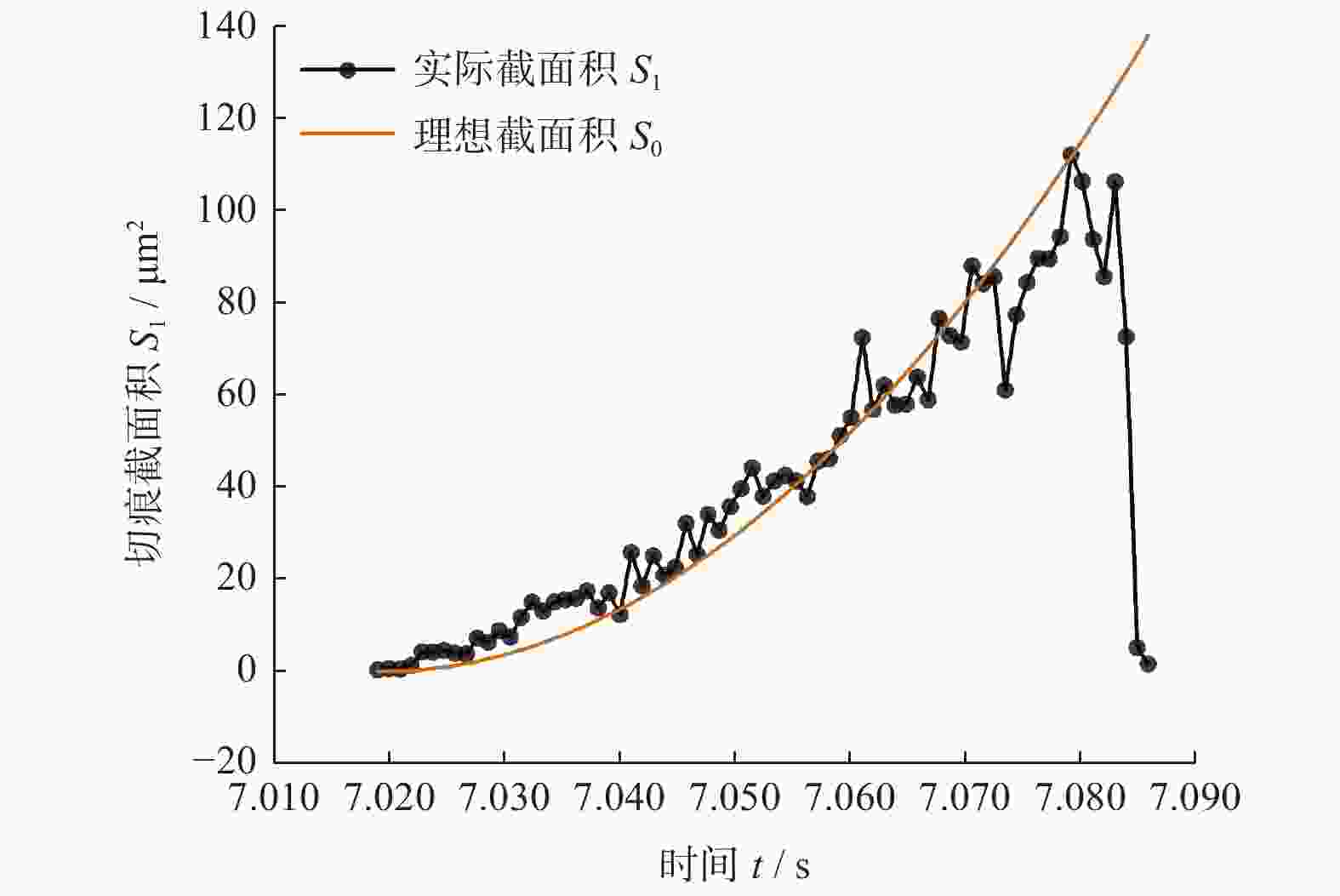

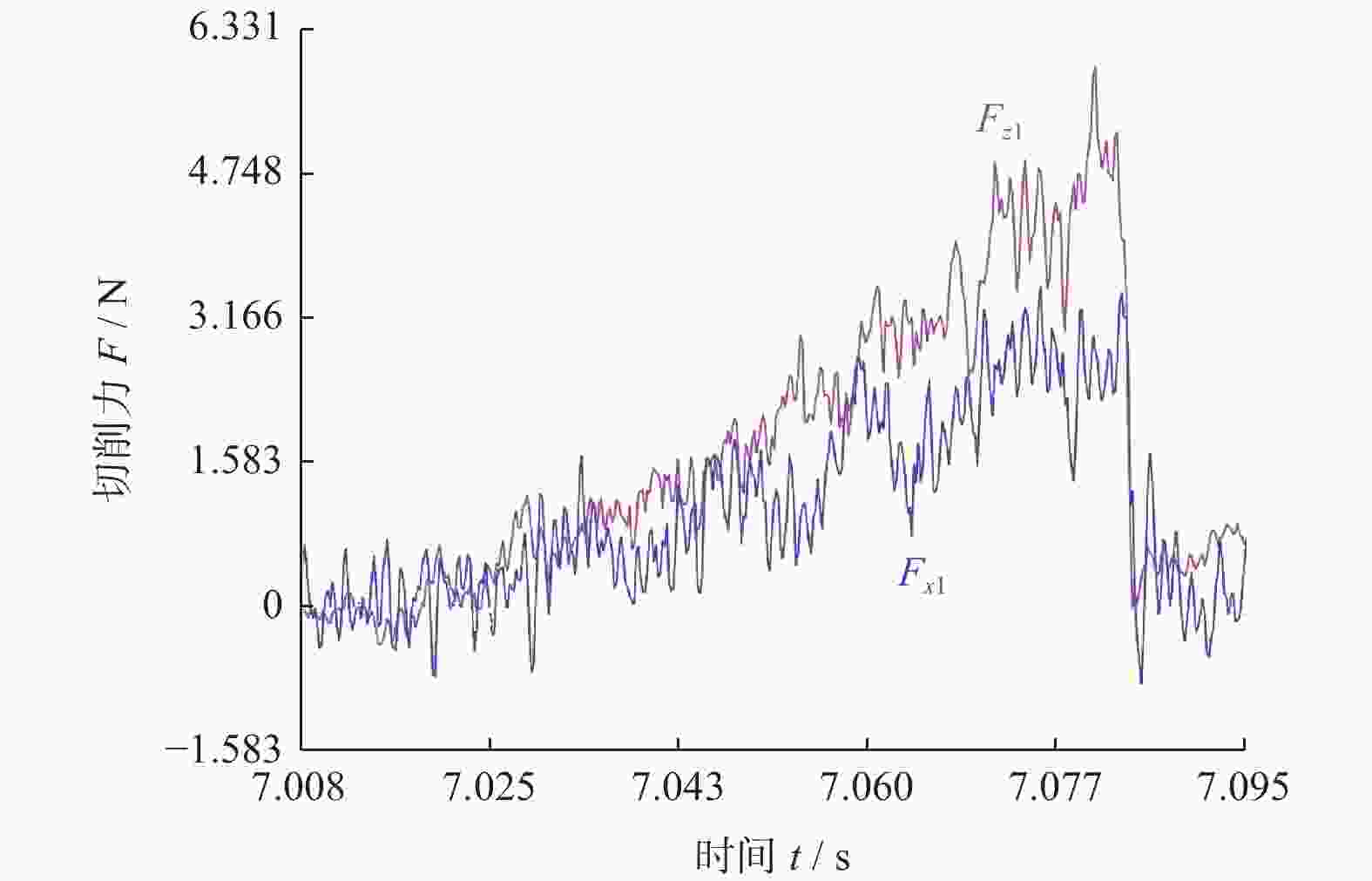

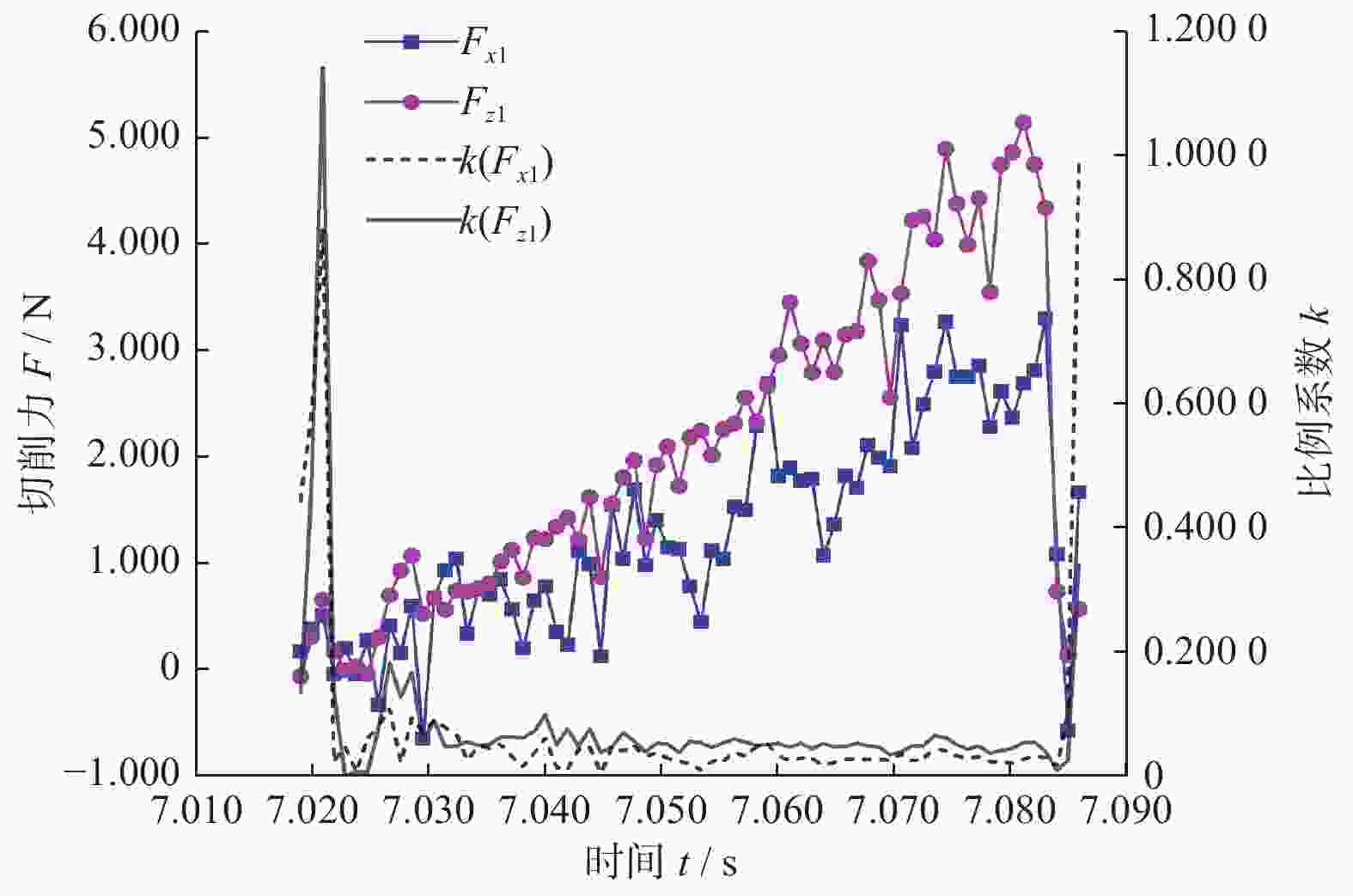

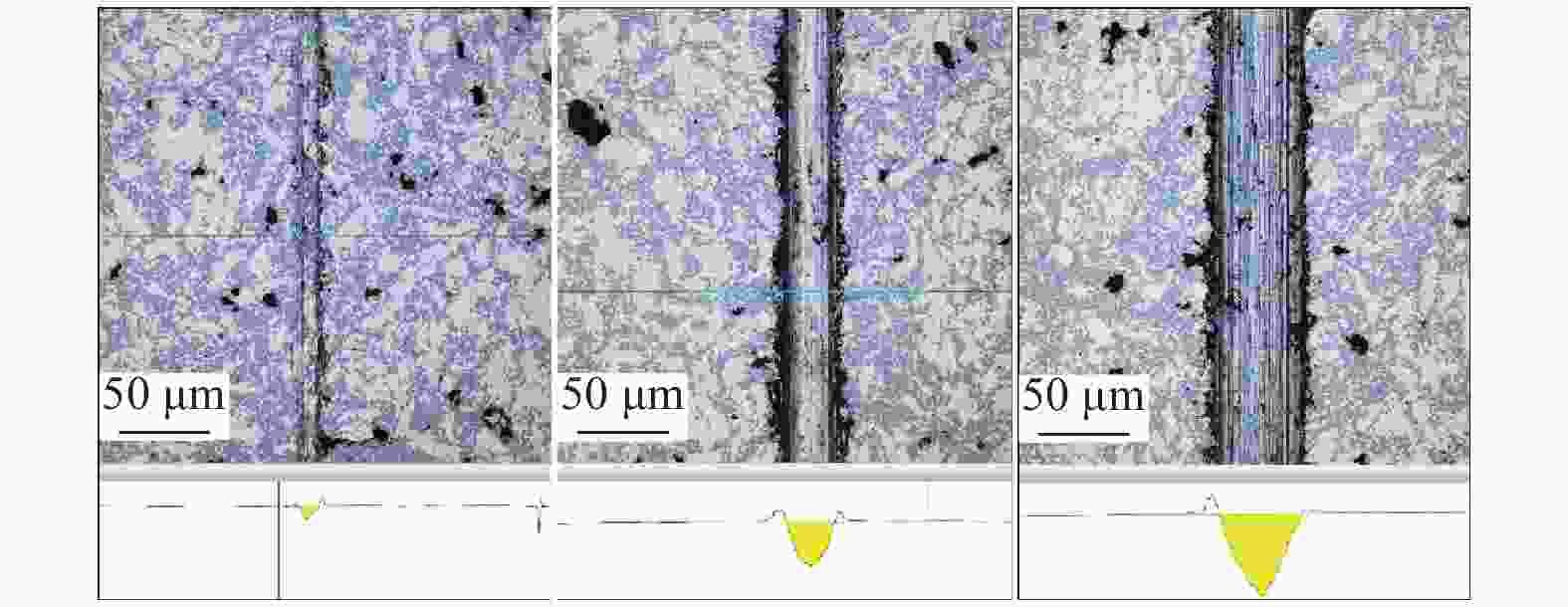

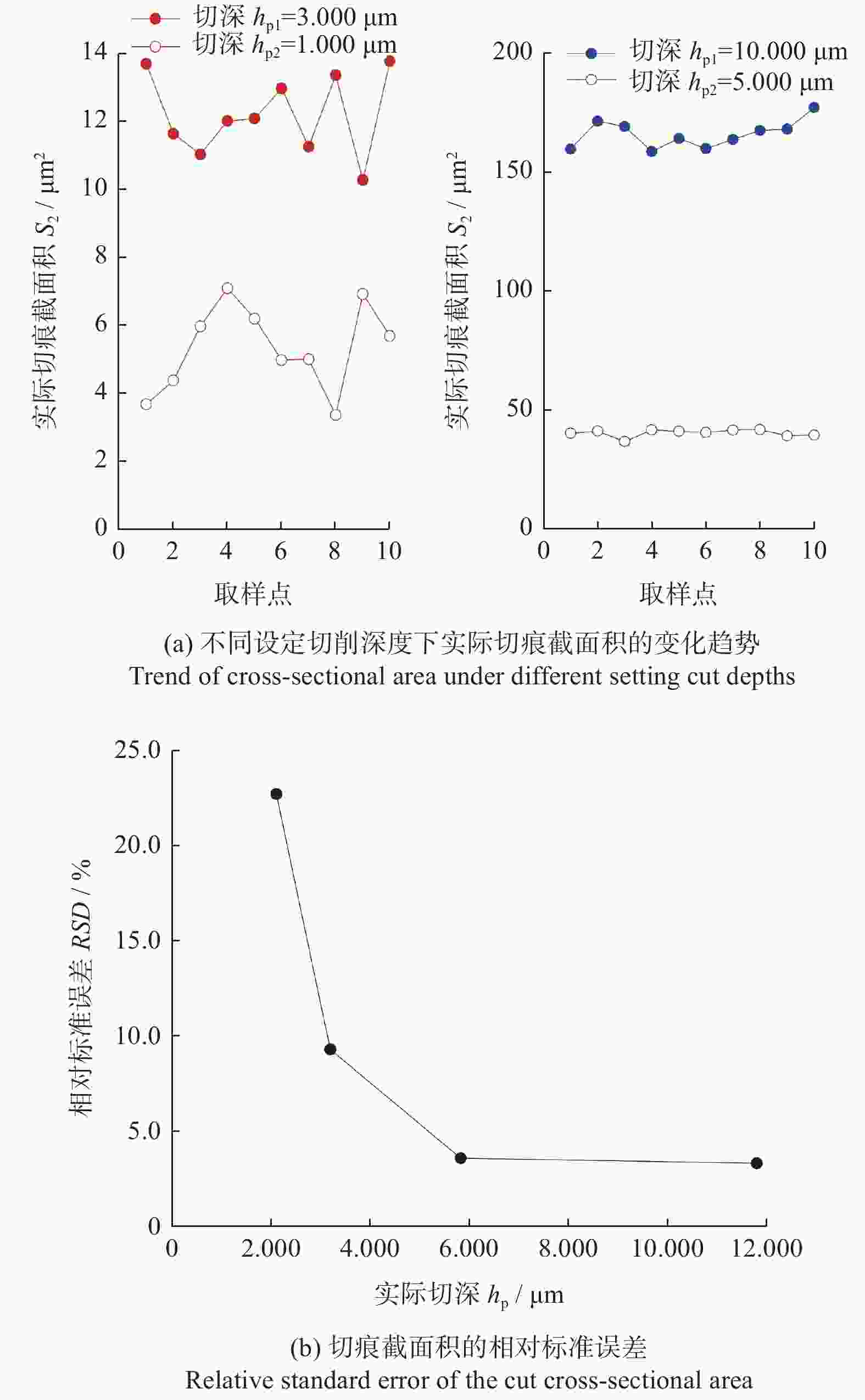

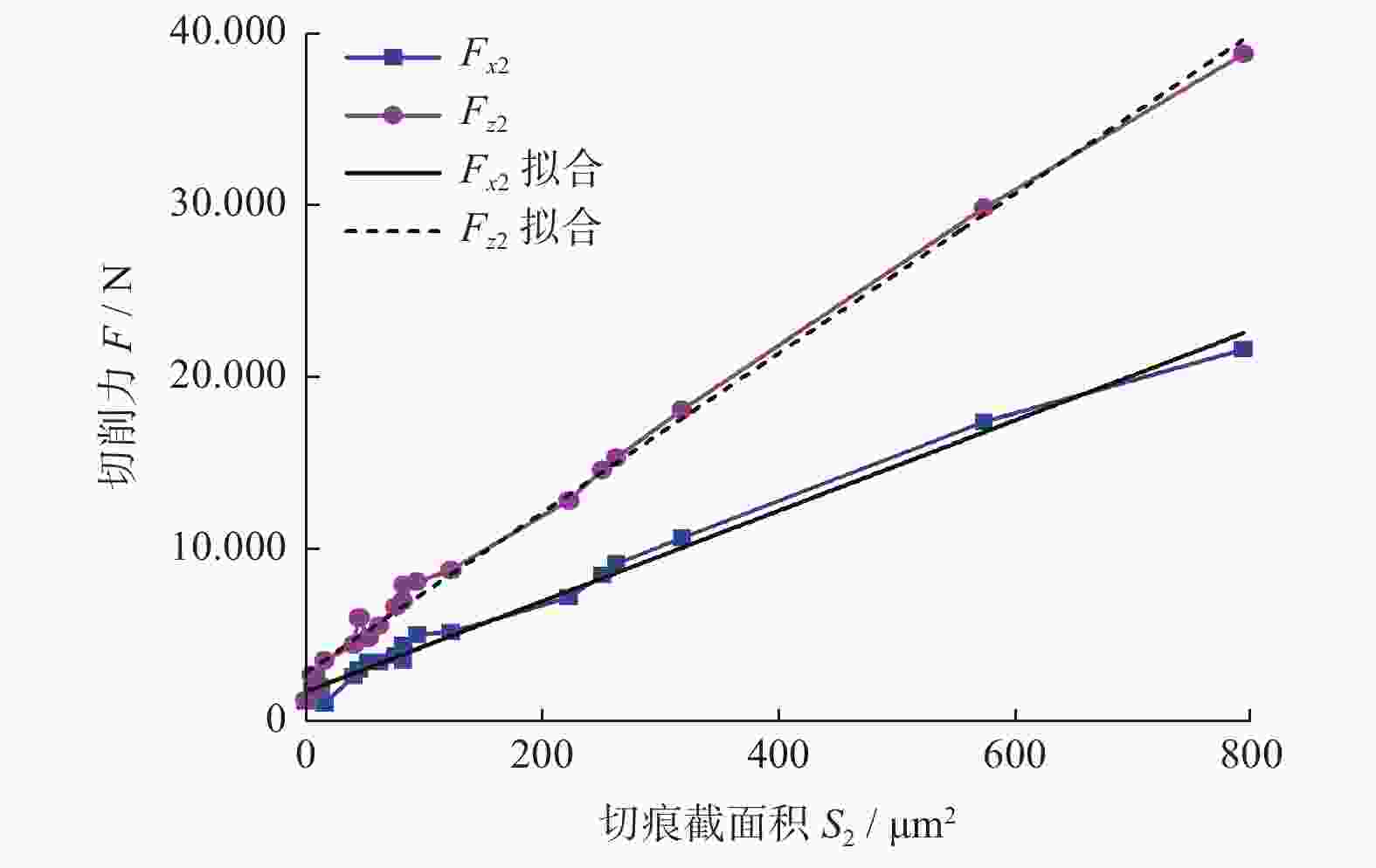

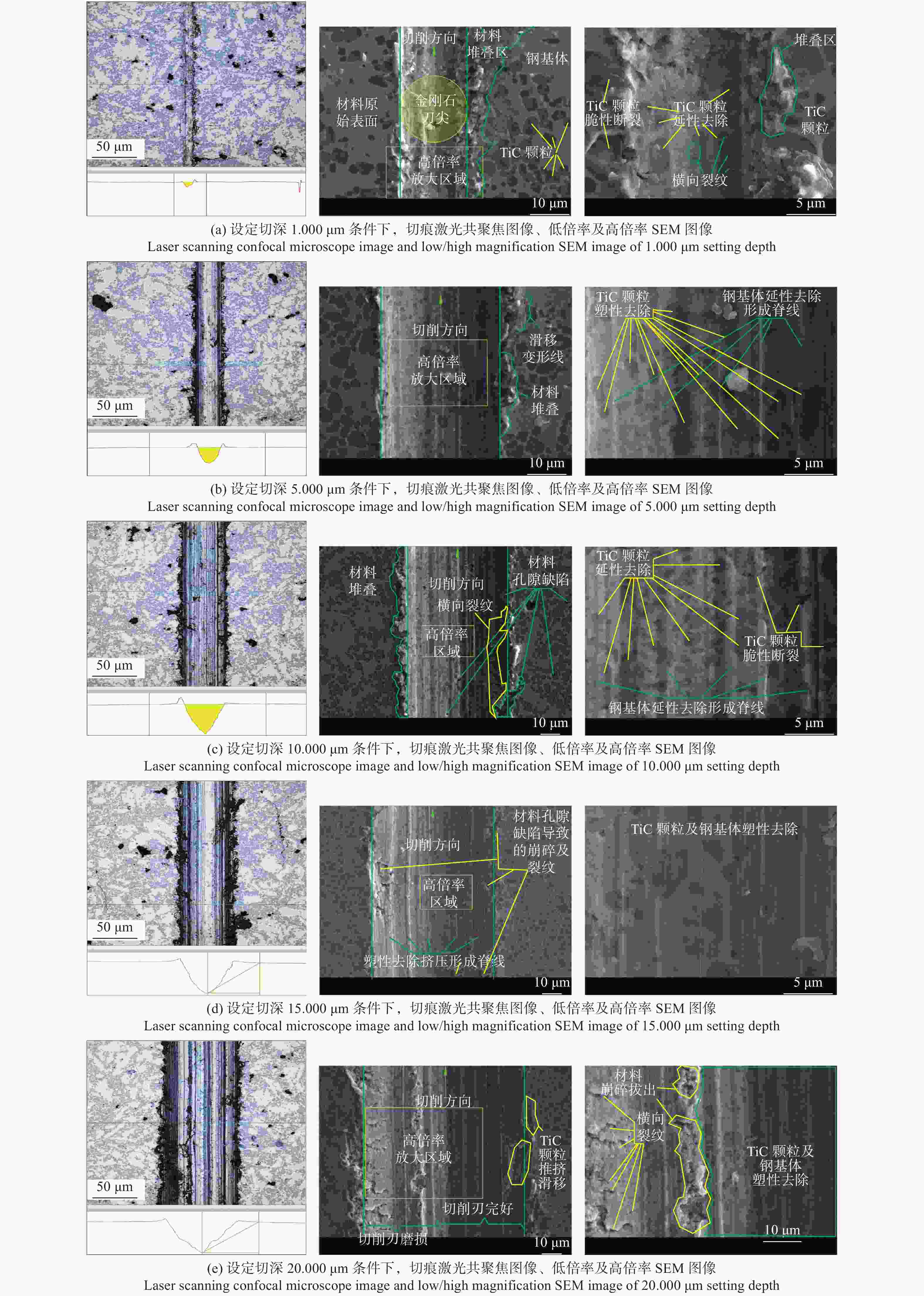

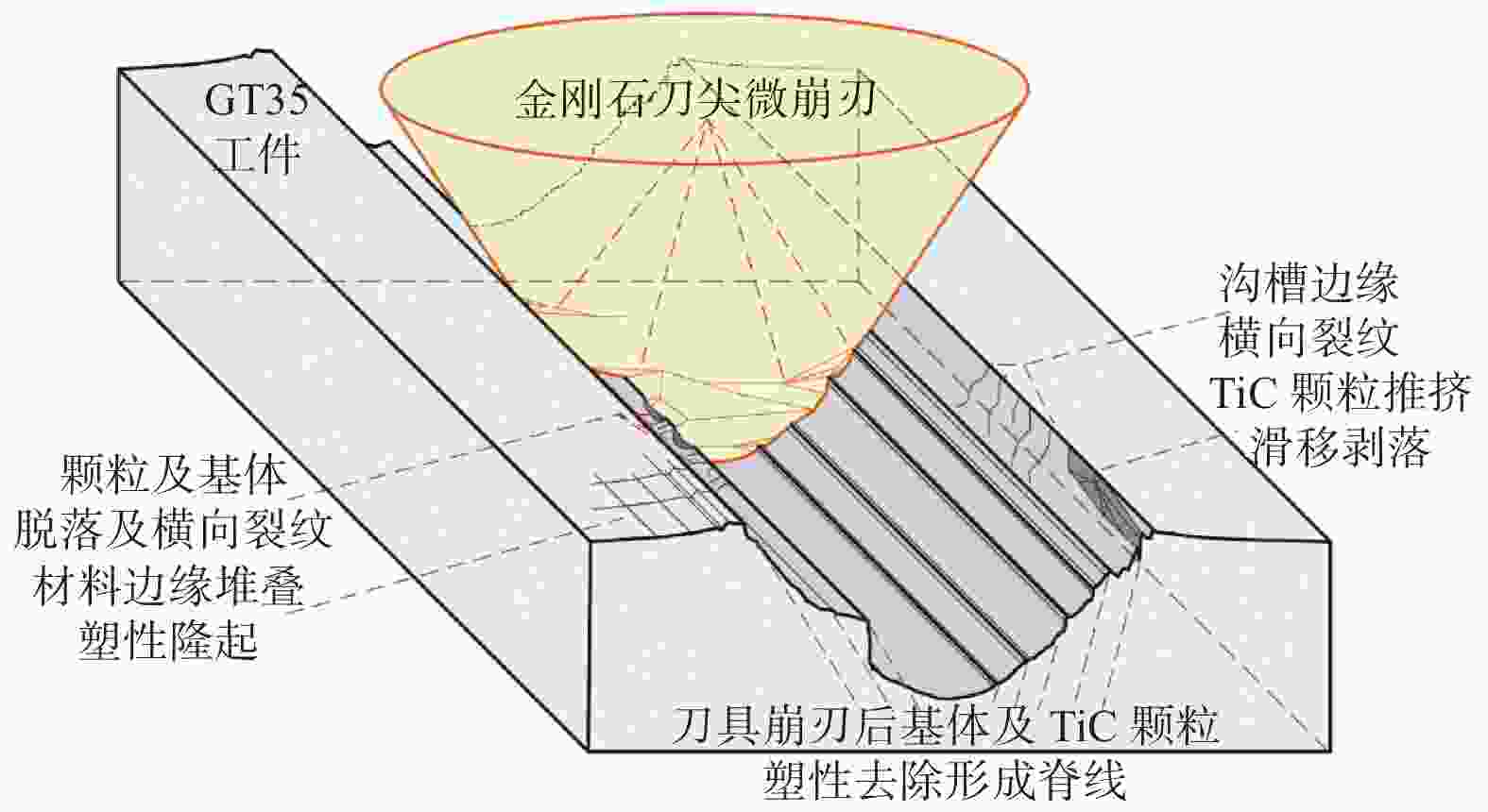

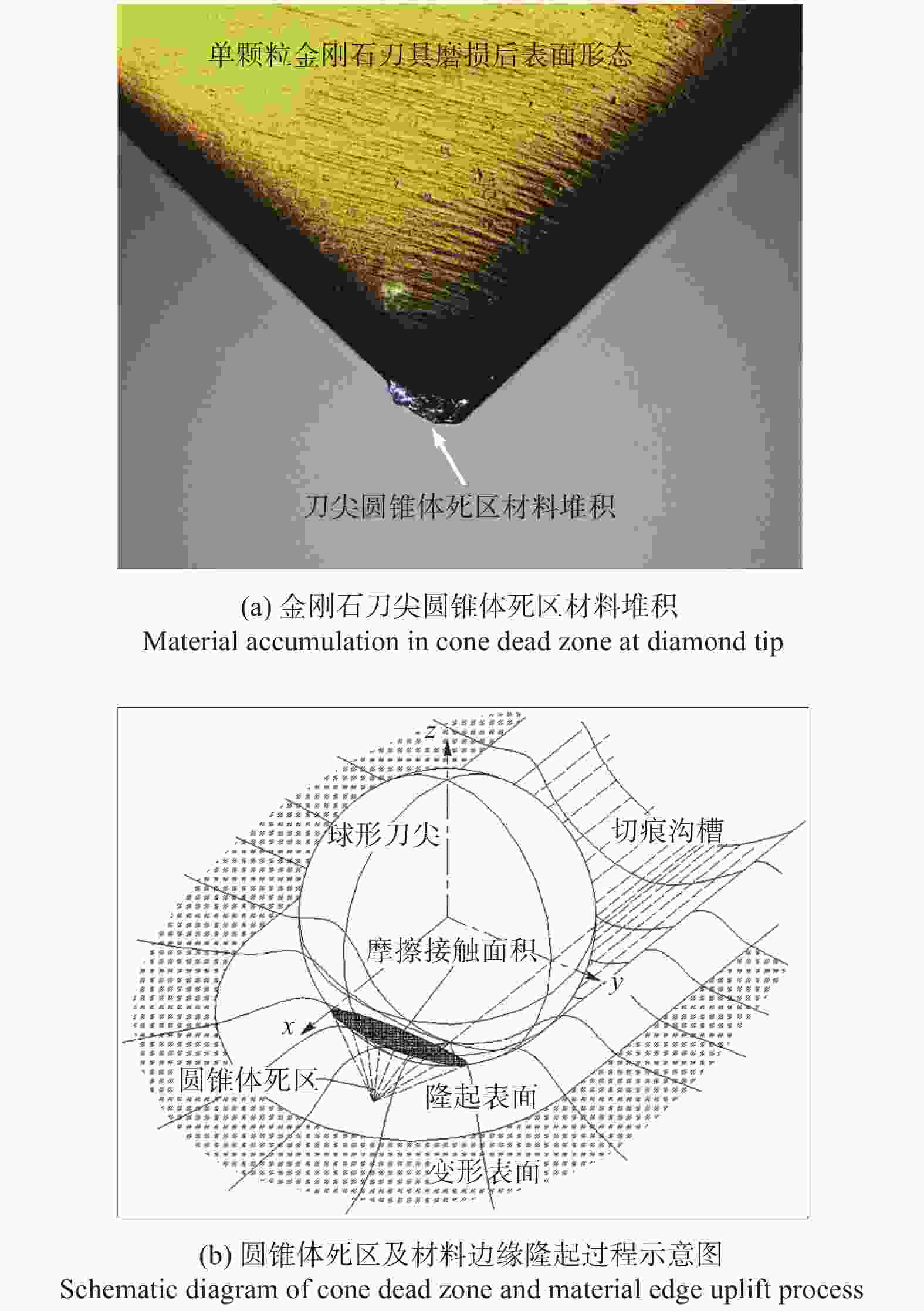

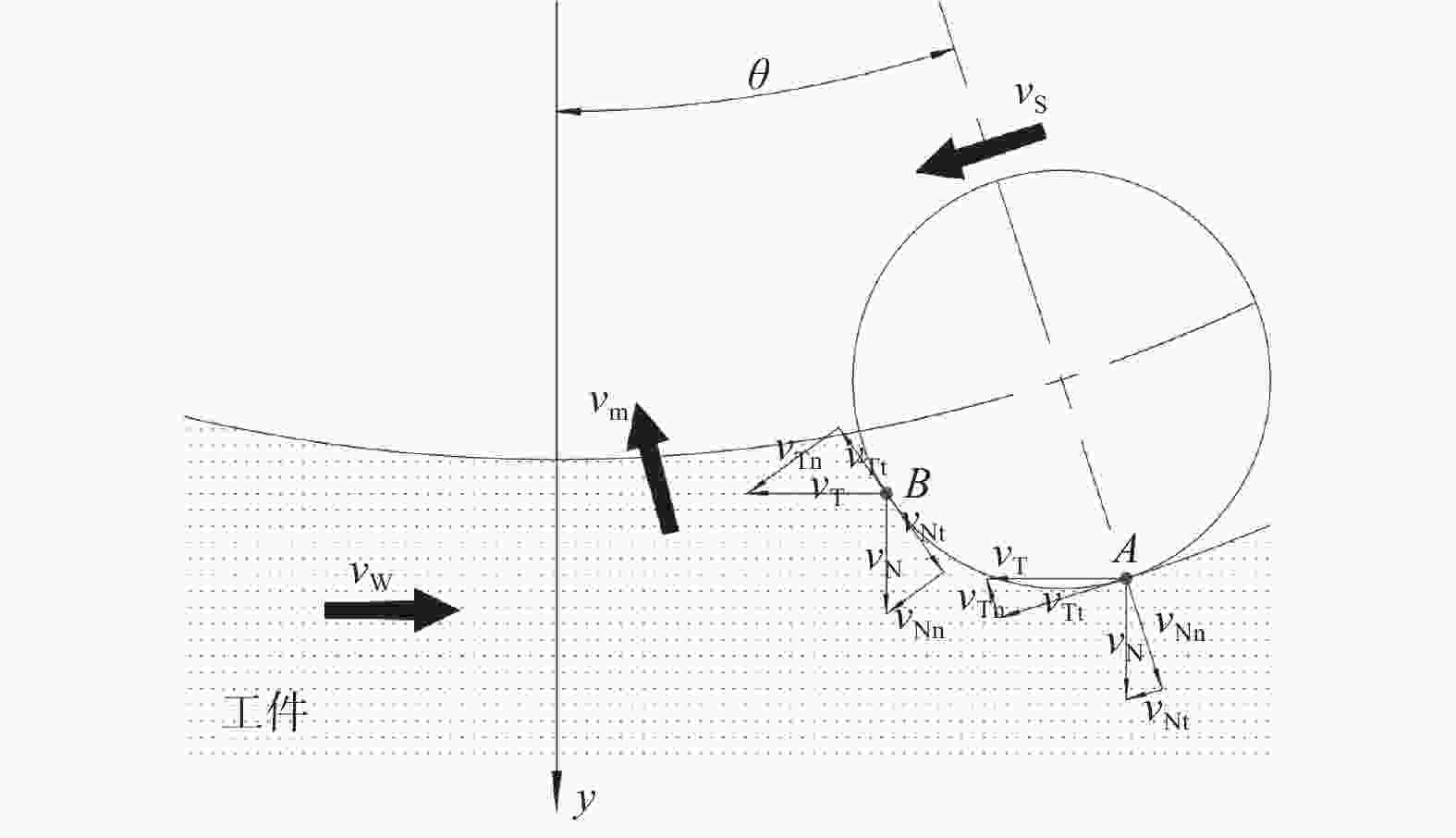

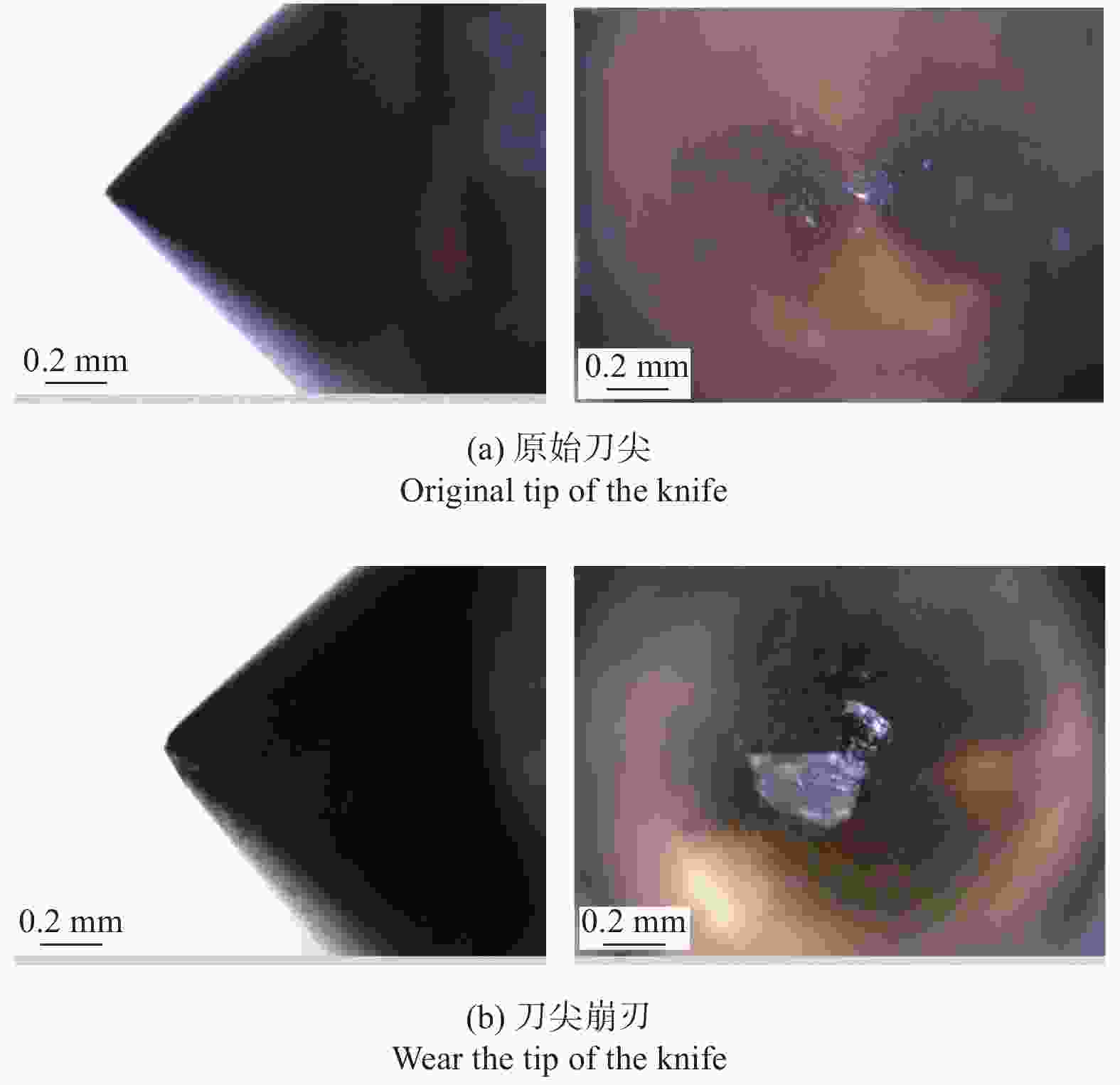

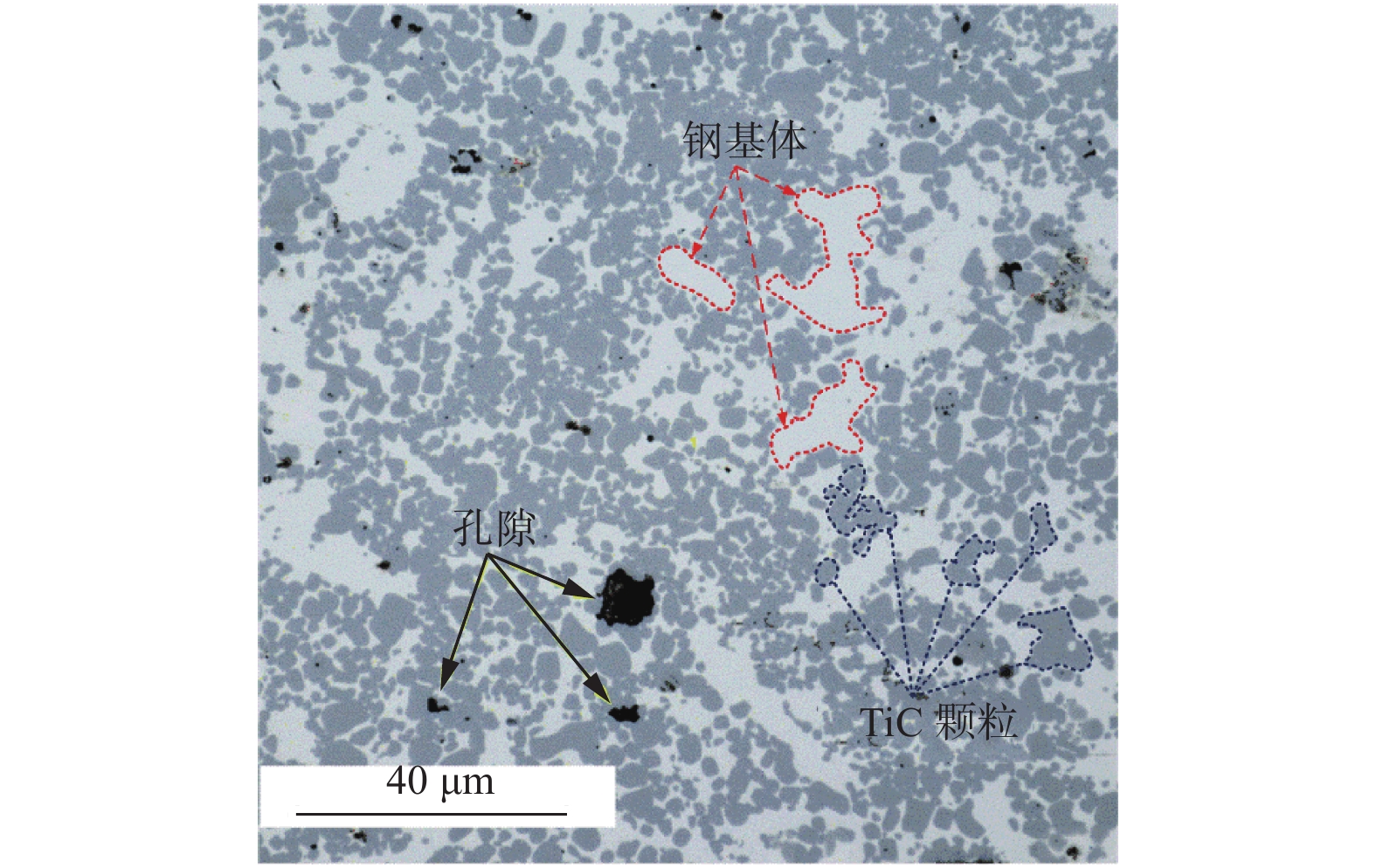

摘要: 为研究金刚石磨粒刀具切削钢结硬质合金GT35的微观刻划过程与材料去除机理,以单颗粒金刚石刻划实验为研究手段,分析其微观切削力的影响因素及材料的微观去除过程。通过单颗粒金刚石变切深实验发现,切削力与切痕截面积之间呈线性关系,获得的线性比例系数k的估计值可通过单颗粒金刚石等切深实验修正。随后,通过扫描电镜对GT35材料表面切痕形貌进行观测,并用激光共聚焦显微镜对其形貌进行三维建模,研究不同刻划深度下的材料去除模式。结果表明:修正后k(Fx)为0.026 29 N/μm2(R1=0.990 46),k(Fz)为0.046 42 N/μm2(R2=0.994 08); 调质GT35材料在多种切深下均以塑性去除为主,其中切痕底面呈现明显塑性剪切去除状态,切痕边缘位置呈现一定的脆性断裂状态。刀具在切削过程中会在刀尖处形成材料堆叠死区,引起刀具崩刃及磨损,且切痕表面形貌的形成与刀具磨损密切相关。

-

关键词:

- 单颗粒金刚石切削 /

- GT35钢结硬质合金 /

- 切削力模型 /

- 材料去除模式 /

- 磨削

Abstract: Single particle diamond cutting experiments are designed to research the micro scratching process and material removal mechanism of GT35 steel bonded cemented carbide. The value of linear scale coefficient k is estimated as well. The exact value of k is further confirmed by equal depth cutting experiment. Furthermore, the material removal approaches at different cutting depths are discussed by microscopic observation and three-dimensional morphology modeling by SEM and laser confocal microscope. It is observed that there is a linear functional relationship between cutting force and groove cross-sectional area. k (Fx) is 0.026 29 N/μm2(R2=0.990 46) and k (Fz) is 0.046 42 N/μm2(R2=0.994 08) after fitting. The quenched and tempered GT35 material is mainly plastic removal under various cutting depths, in which the bottom surface of the groove shows an obvious plastic shear removal state, and the edge shows a certain brittle removal state. During the cutting process, there will form a material stacking dead zone at the tool tip, causing tool edge collapse and wear. The formation of the surface morphology is closely related to tool wear. -

参数 数值 TiC 质量分数 ω1 / % 35.0 Cr 质量分数 ω2 / % 2.0 Mo 质量分数 ω3 / % 2.0 C 质量分数 ω4 / % 0.5 Fe 质量分数 ω5 / % 余量 表 2 切削参数设置

Table 2. Cutting parameter setting

参数 数值 切削速度 v / (mm·s−1) 75 等切深 ap1 / μm 1.000,5.000,10.000,15.000,20.000 变切深 ap2 / μm 0~5.000 -

[1] 瞿峻. Ti(C, N)基金属陶瓷增强技术及其组织和性能研究 [D]. 武汉: 华中科技大学, 2010.QU Jun. The research on the reinforcement technology and microstructure, mechanical properties of Ti(C, N)-based ceramics [D]. Wuhan: Huazhong University of Science & Technology, 2010. [2] 杨展. 钢结硬质合金胎体冲击回转钻进金刚石钻头研究 [D]. 北京: 中国地质大学, 2010.YANG Zhan. Study on diamond bit with steel bonded carbide type of matrix for percussive rotary drilling [D]. Beijing: China University of Geosciences, 2010. [3] 赵勋, 章伟, 李屏, 等. 钢结硬质合金抗振镗杆设计及应用研究 [J]. 硬质合金,2018,35(1):44-49.ZHAO Xun, ZHANG Wei, LI Ping, et al. Research on design and application of steel bonded cemented carbide vibration resistance boring bar [J]. Cemented Carbide,2018,35(1):44-49. [4] 张英, 贾玲玲. 钢结硬质合金材料实际应用的技术分析 [J]. 山东工程学院学报,2000(3):72-74.ZHANG Ying, JIA Lingling. Application of steel work kentanium to moudles of ceramic tiles [J]. Journal of Shandong Institute of Technology,2000(3):72-74. [5] 邓世谦. 钢结硬质合金GT35在内灯座拉伸模中的应用 [J]. 模具制造,2003(12):40-41. doi: 10.3969/j.issn.1671-3508.2003.12.015DENG Shiqian. Application of steel bonded cemented carbide GT35 in drawing die of inner lamp holder [J]. Die & Mould Manufacture,2003(12):40-41. doi: 10.3969/j.issn.1671-3508.2003.12.015 [6] 张春河, 徐燕申, 林彬, 等. GT35钢结硬质合金材料镜面加工的试验研究 [J]. 天津大学学报,1999(2):89-92.ZHANG Chunhe, XU Yanshen, LIN Bin, et al. An experimental study of mirror machining techniques for GT35 steel based cemented carbide composites [J]. Journal of Tianjin University,1999(2):89-92. [7] 王荣滨. 钢结硬质合金模具冷热加工工艺研究 [J]. 有色金属加工,2009,38(3):15-17, 51. doi: 10.3969/j.issn.1671-6795.2009.03.006WANG Rongbin. The research for cold & heat processing of steel bond hard alloy mould [J]. Non Ferrous Metal Processing,2009,38(3):15-17, 51. doi: 10.3969/j.issn.1671-6795.2009.03.006 [8] PARASHIVAMURTHY K I, KUMAR R K, SEETHARAMU S, et al. Review on TiC reinforced steel composites [J]. Journal of Materials Science,2001,36(18):4519-4530. doi: 10.1023/A:1017947206490 [9] 熊拥军, 李溪滨, 赵福安. 钢结硬质合金材料的研究进展 [J]. 硬质合金,2005,22(2):121-124. doi: 10.3969/j.issn.1003-7292.2005.02.015XIONG Yongjun, LI Xibin, ZHAO Fu′an. Process in steel-bonded cemented carbide [J]. Cemented Carbide,2005,22(2):121-124. doi: 10.3969/j.issn.1003-7292.2005.02.015 [10] 赵悦, 李素莲. 钢结硬质合金的加工性能 [J]. 机械工人: 冷加工,1988(8):34-35.ZHAO Yue, LI Sulian. Machinability of steel bonded cemented carbide [J]. Machinist: Cold-working,1988(8):34-35. [11] 范安平, 肖平安, 李晨坤, 等. TiC基钢结硬质合金的研究现状 [J]. 粉末冶金技术,2013,31(4):298-303. doi: 10.3969/j.issn.1001-3784.2013.04.011FAN Anping, XIAO Ping′an, LI Chenkun, et al. Research situation of TiC-based steel bonded carbide [J]. Powder Metallurgy Technology,2013,31(4):298-303. doi: 10.3969/j.issn.1001-3784.2013.04.011 [12] 关佳亮, 仇忠臣, 赵增强, 等. 钢结硬质合金的ELID高效磨削实验研究 [J]. 机械设计与制造,2008(11):107-108. doi: 10.3969/j.issn.1001-3997.2008.11.042GUAN Jialiang, QIU Zhongchen, ZHAO Zengqiang, et al. Experimental study on high efficiency grinding of steel bonded cemented carbide by ELID [J]. Machinery Design & Manufacture,2008(11):107-108. doi: 10.3969/j.issn.1001-3997.2008.11.042 [13] 杨雄, 冉小丰, 帅玉妹, 等. GT35钢结硬质合金电火花加工工艺试验 [J]. 硬质合金,2009,26(4):236-239. doi: 10.3969/j.issn.1003-7292.2009.04.008YANG Xiong, RAN Xiaofeng, SHUAI Yumei, et al. Electrical discharge machining (EDM) technological test of GT35 steel-bonded carbide [J]. Cemented Carbide,2009,26(4):236-239. doi: 10.3969/j.issn.1003-7292.2009.04.008 [14] 郑涌. TiC增强Fe基复合材料的制备与性能研究 [D]. 北京: 北京交通大学, 2018.ZHENG Yong. Preparation and properties of TiC reinforced Fe matrix composites [D]. Beijing: Beijing Jiaotong University, 2018. [15] 张祥雷, 姚斌, 冯伟, 等. 基于多颗磨粒随机分布的虚拟砂轮建模及磨削力预测 [J]. 航空学报,2014,35(12):3489-3498. doi: 10.7527/S1000-6893.2014.0065ZHANG Xianglei, YAO Bin, FENG Wei, et al. Modeling of virtual grinding wheel based random distribution of multi abrasive grains and prediction of grinding force [J]. Acta Aeronautica et Astronautica Sinica,2014,35(12):3489-3498. doi: 10.7527/S1000-6893.2014.0065 [16] ANDERSON D, WARKENTIN A, BAUER R. Experimental and numerical investigations of single abrasive-grain cutting [J]. International Journal of Machine Tools and Manufacture,2011,51(12):898-910. doi: 10.1016/j.ijmachtools.2011.08.006 [17] 周雯雯, 王建青, 赵晶, 等. 单颗磨粒划擦SiCf/SiC陶瓷基复合材料的试验研究 [J]. 金刚石与磨料磨具工程,2021,41(1):51-57.ZHOU Wenwen, WANG Jianqing, ZHAO Jing, et al. Experimental research on single abrasive grain scratch SiCf/SiC ceramic matrix composite [J]. Diamond & Abrasives Engineering,2021,41(1):51-57. [18] ZHOU H, DING W, LIU C. Material removal mechanism of PTMCs in high-speed grinding when considering consecutive action of two abrasive grains [J]. The International Journal of Advanced Manufacturing Technology,2019,100(1):153-165. [19] LI Z, DING W, LIU C, et al. Grinding performance of TiCp/Ti-6Al-4V composites with CBN wheels, part II: Material removal behavior based on FEM [J]. Procedia CIRP,2018,77:525-528. doi: 10.1016/j.procir.2018.08.243 [20] ZHANG Z, YAO P, WANG J, et al. Analytical modeling of surface roughness in precision grinding of particle reinforced metal matrix composites considering nanomechanical response of material [J]. International Journal of Mechanical Sciences,2019,157:243-253. [21] FARID A, GUO S. On the processing, microstructure, mechanical and wear properties of cermet/stainless steel layer composites [J]. Acta Materialia,2007,55(4):1467-1477. doi: 10.1016/j.actamat.2006.10.009 [22] 康泰胜. 钢结硬质合金的磨削 [J]. 模具技术,1986(6):75-76.KANG Taisheng. Grinding of steel bonded cemented carbide [J]. Die and Mould Technology,1986(6):75-76. [23] 尤显卿. 钢结硬质合金的加工 [J]. 机械科学与技术,1989(2):28-32.YOU Xianqing. Processing of steel bonded cemented carbide [J]. Mechanical Science and Technology for Aerospace Engineering,1989(2):28-32. [24] 孟昊. 钢结硬质合金轴的精密点磨削工艺及砂轮在位修整方法研究 [D]. 济南: 山东大学, 2016.MENG Hao. Precision point grinding technology for steel bonded carbide axles and on-machine conditioning of grinding wheel [D]. Jinan: Shandong University, 2016. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS