Application of water-soluble pore-forming agent in ultra-thin resin cutting grinding wheel

-

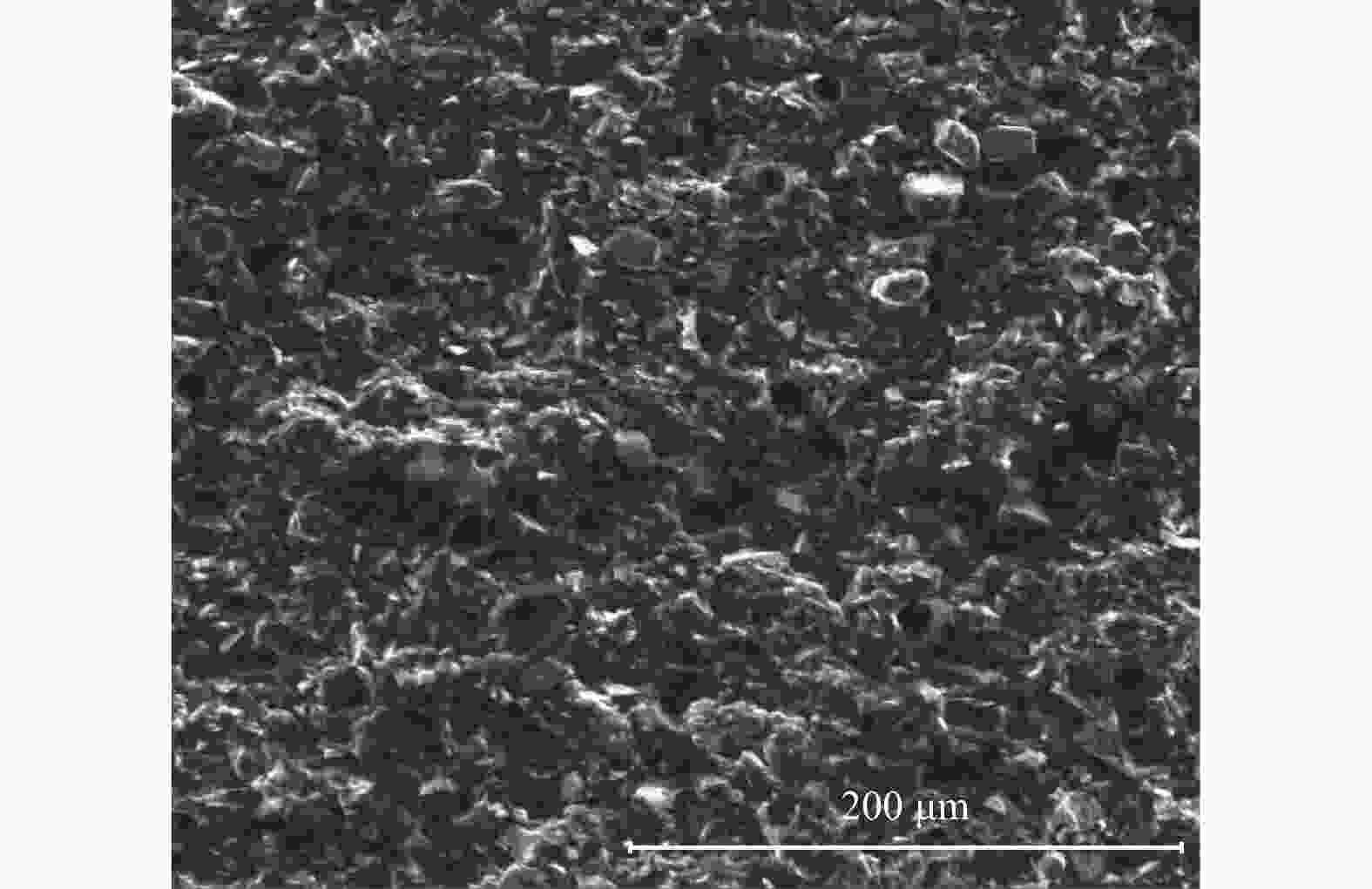

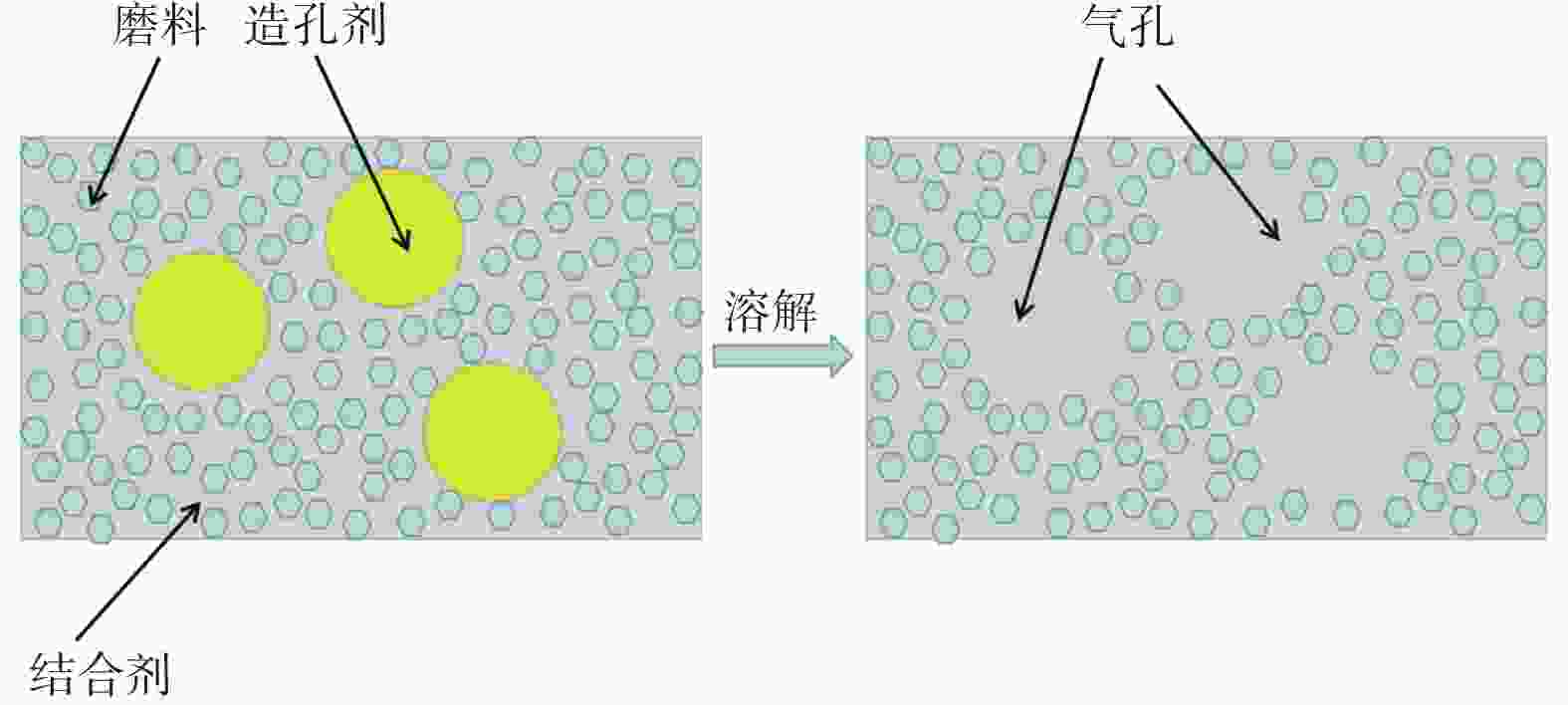

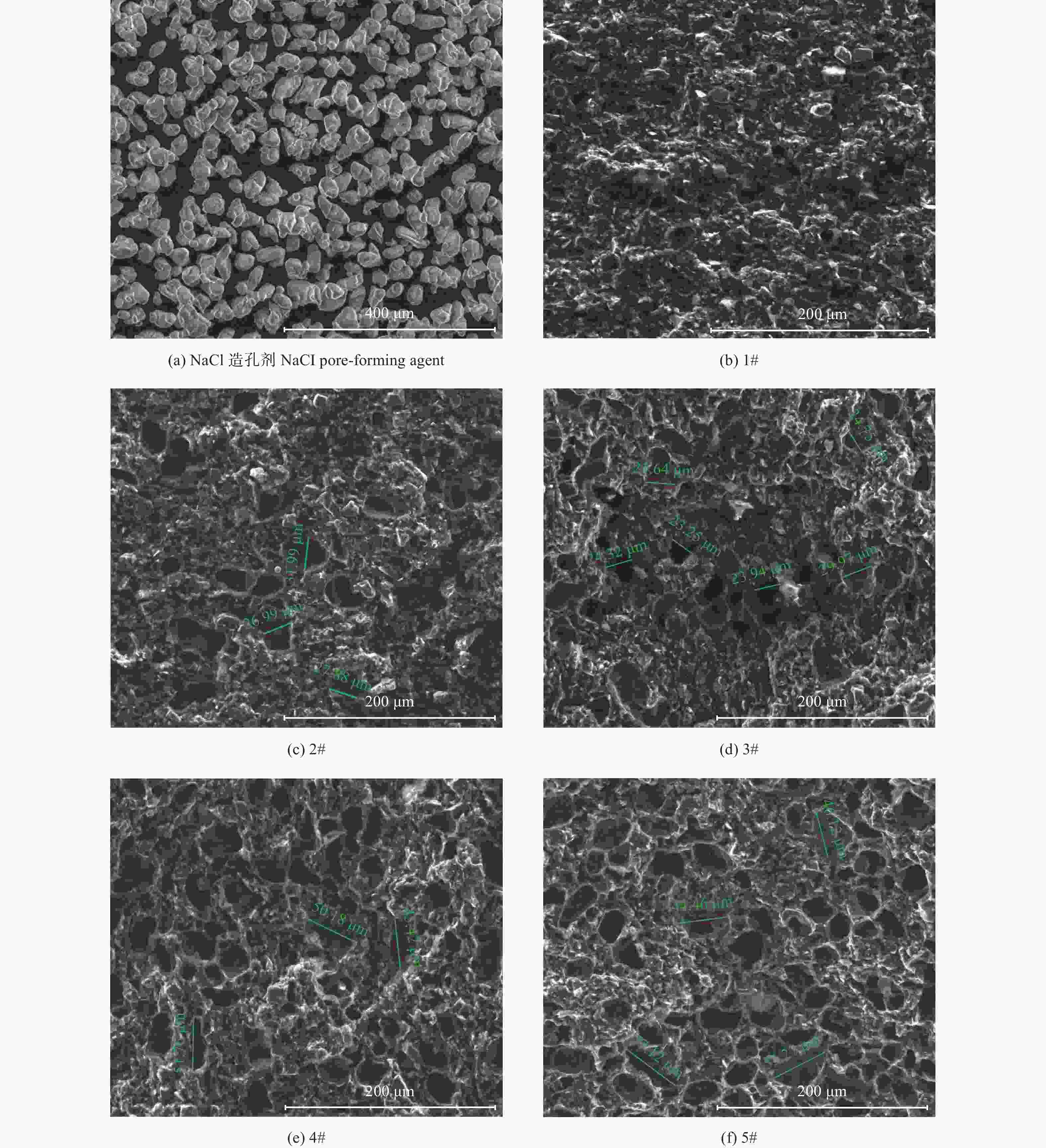

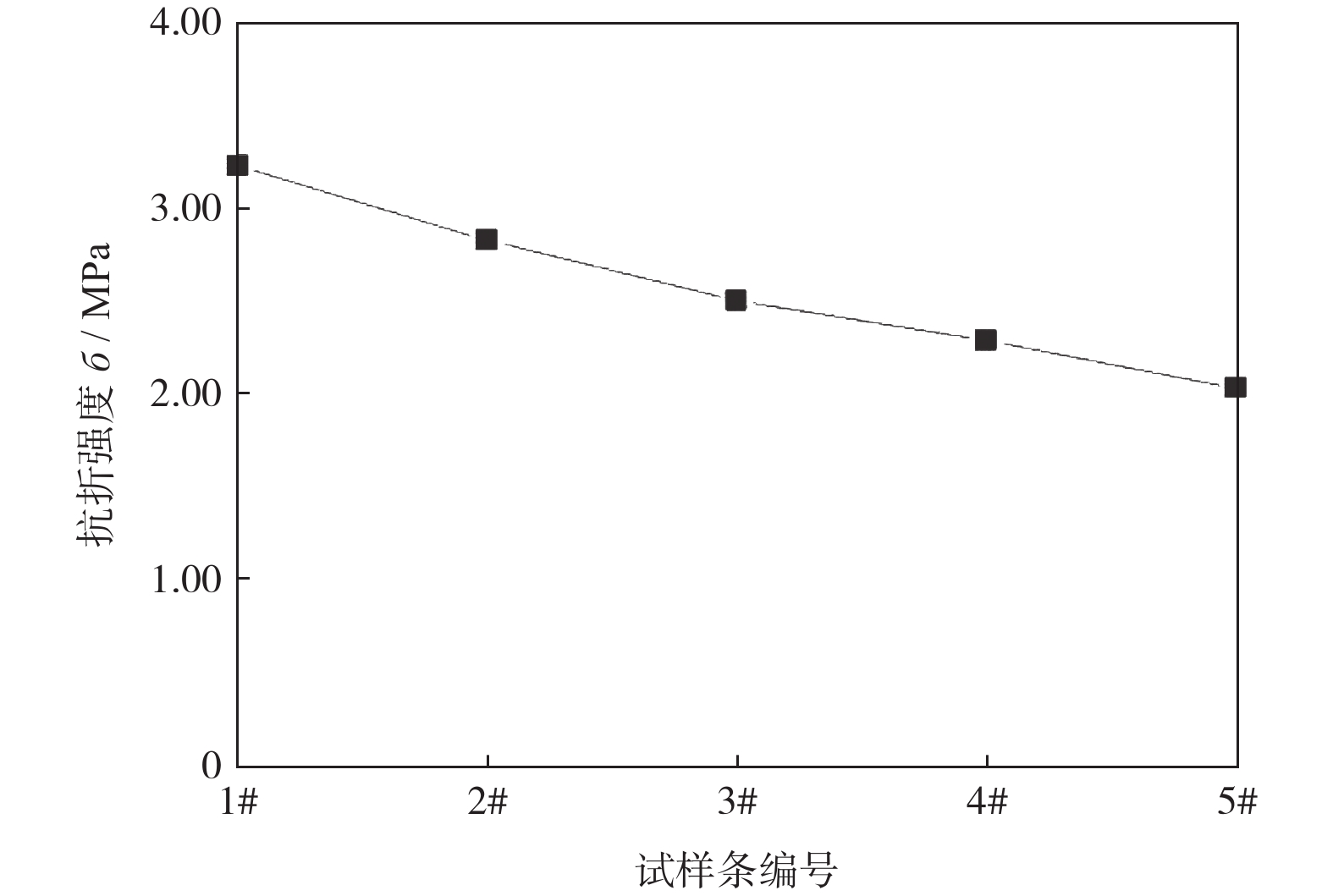

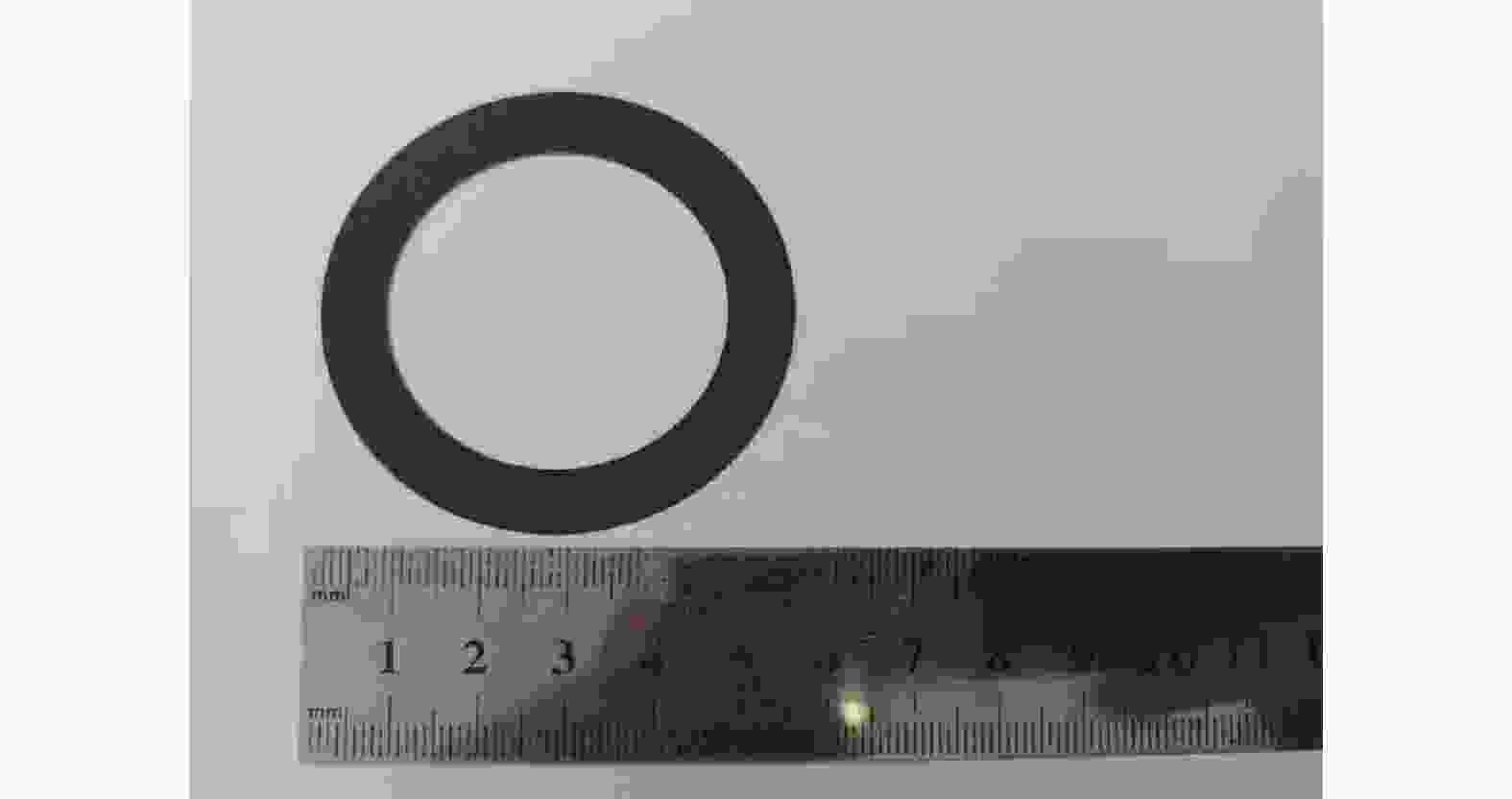

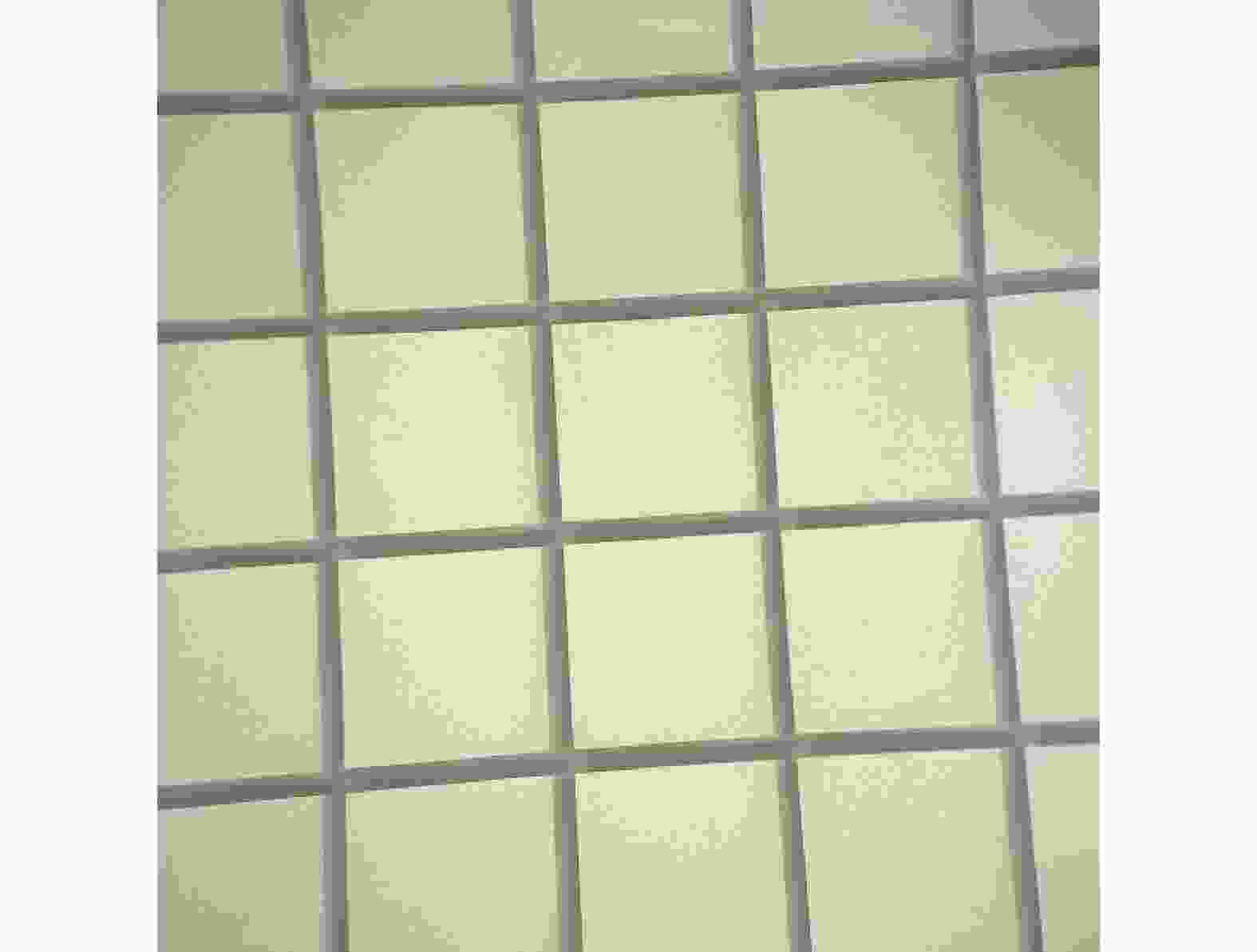

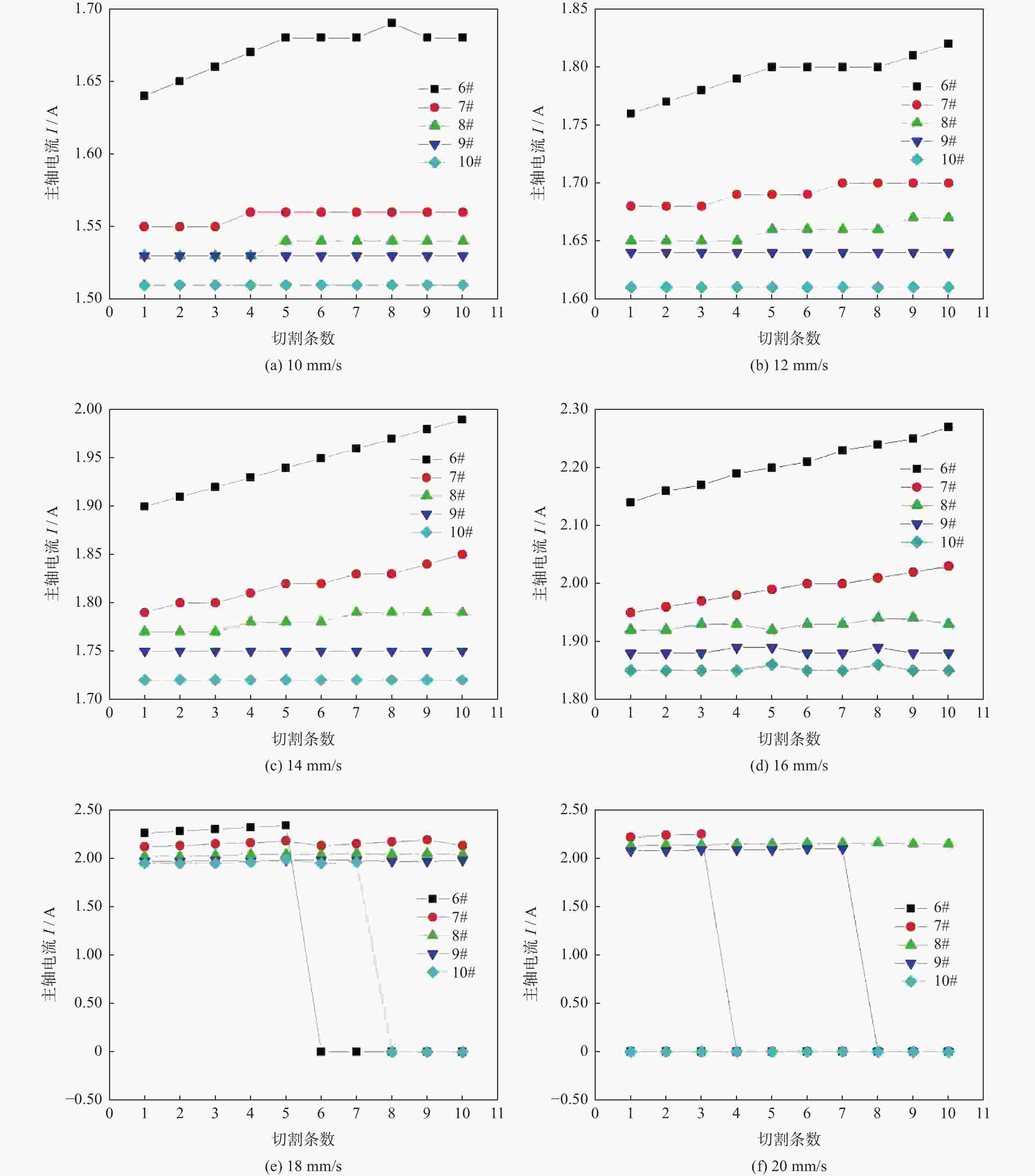

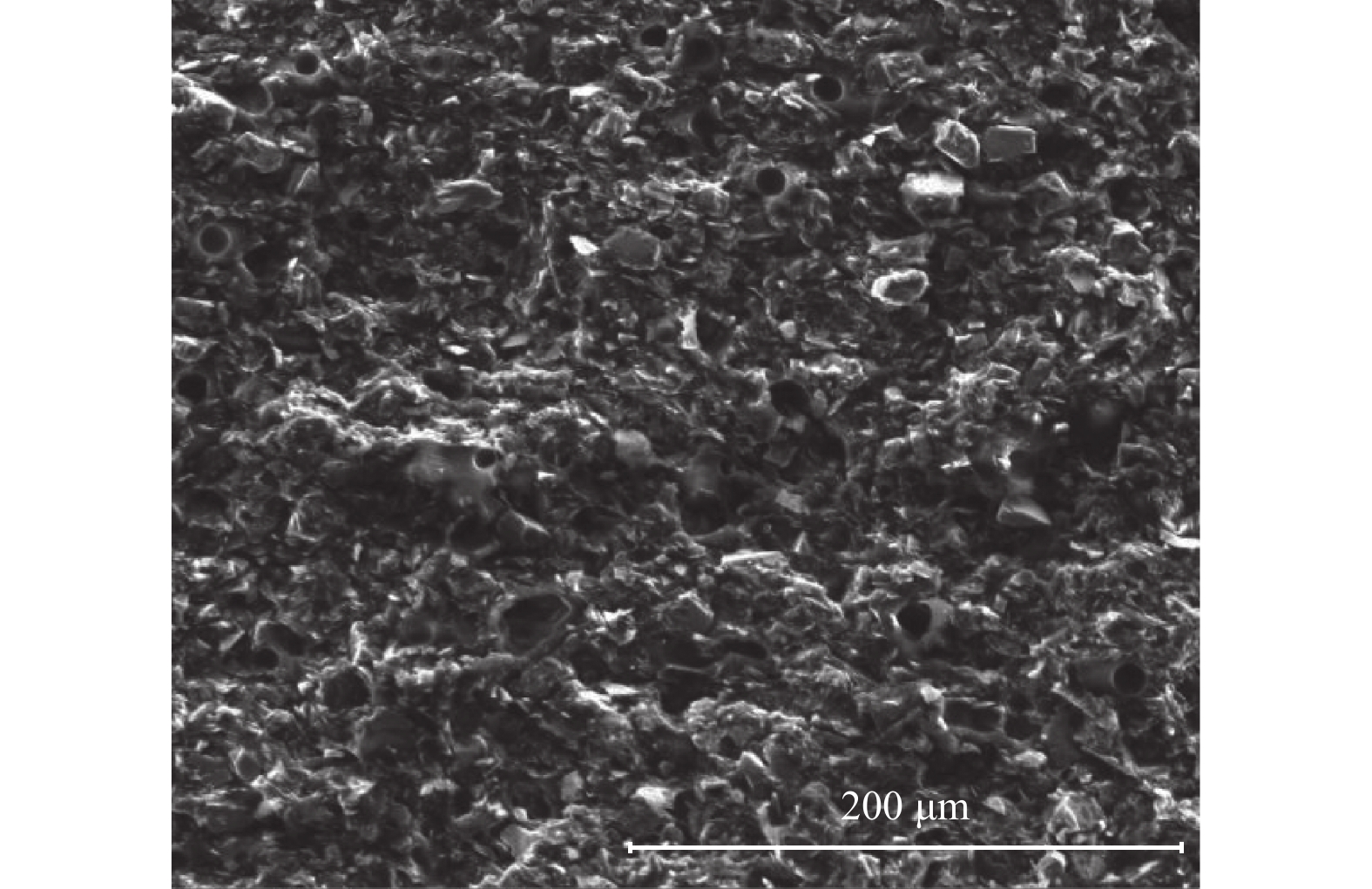

摘要: 为进一步提升超薄树脂切割砂轮的自锐性能和排屑容屑能力,在切割砂轮中加入水溶性造孔剂NaCl,研究其含量对超薄树脂切割砂轮的微观形貌、力学性能及切割性能的影响。结果表明:当造孔剂添加体积分数为10%时,砂轮中的孔隙均匀适中,其切割效率最高,进给速度最高可达20 mm/s。但加入造孔剂会对砂轮的抗折性能和切割寿命产生一定影响,造孔剂含量越高,抗折性能越低,切割寿命越短。Abstract: In order to further improve the self sharpening performance, the chip removal and the chip holding capacity of the ultra-thin resin cutting grinding wheel, the water-soluble pore-forming agent NaCl was added into the cutting grinding wheel, and the effects of its content on the micro morphology, the mechanical property and the cutting property of the ultra-thin resin cutting grinding wheel were studied. The results show that when the volume fraction of pore-forming agent is 10%, the pores in the grinding wheel are uniform and moderate, the cutting efficiency is the highest and the maximum feed speed can reach 20 mm/s. However, the addition of pore-forming agent will have a certain impact on the flexural performance and the cutting life of the grinding wheel. The higher the content of pore-forming agent, the lower the flexural performance and the shorter the cutting life.

-

Key words:

- pore-forming agent /

- resin bond /

- ultra-thin grinding wheel /

- superhard material

-

表 1 试验样条配方

Table 1. Test spline formula

编号 酚醛树脂

体积分数

Vb / %白刚玉

体积分数

VA / %石墨

体积分数

VC / %金刚石

体积分数

Vd / %造孔剂

体积分数

Vp / %1# 55 5 5 35 0 2# 50 5 5 35 5 3# 45 5 5 35 10 4# 40 5 5 35 15 5# 35 5 5 35 20 表 2 切割砂轮切削齿的高度差

Table 2. Height differences of cutting teeth of cutting wheels

砂轮

编号第1次

Δh1 / mm第2次

Δh2 / mm第3次

Δh3 / mm第4次

Δh4 / mm第5次

Δh5 / mm第6次

Δh6 / mm平均值

Δh / mm6# 0.020 0.018 0.022 0.025 0.021 0.025 0.022 7# 0.024 0.022 0.022 0.024 0.021 0.027 0.023 8# 0.020 0.030 0.026 0.025 0.025 0.032 0.026 9# 0.031 0.033 0.025 0.031 0.027 0.032 0.030 10# 0.036 0.028 0.033 0.034 0.035 0.038 0.034 -

[1] 叶晓川, 史冬丽, 曾黎明, 等. 耐热酚醛树脂金刚石砂轮的磨削性能研究 [J]. 超硬材料工程,2010,22(3):11-15. doi: 10.3969/j.issn.1673-1433.2010.03.003YE Xiaochuan, SHI Dongli, ZENG Liming, et al. Study on grinding performance of heat-resistant phenolic resin bond diamond grinding wheels [J]. Superhard Material Engineering,2010,22(3):11-15. doi: 10.3969/j.issn.1673-1433.2010.03.003 [2] 张虹. 晶圆贴膜金刚刀划片工艺 [J]. 宁夏工程技术,2012,11(1):43-45. doi: 10.3969/j.issn.1671-7244.2012.01.014ZHANG Hong. Dicing technology of wafer-bonded diamond blade [J]. Ningxia Engineering Technology,2012,11(1):43-45. doi: 10.3969/j.issn.1671-7244.2012.01.014 [3] 孟庆辉, 李印江. 磨料磨具技术手册 [M]. 北京: 兵器工业出版社, 1993.MENG Qinghui, LI Yinjiang. Technical manual of abrasive tools [M]. Beijing: Ordnance Industry Press, 1993. [4] 廖翠姣. 多孔金属结合剂金刚石砂轮的开发研究 [D]. 泉州: 华侨大学, 2006.LIAO Cuijiao. The development of porous metal bonded diamond grinding wheels [D]. Quanzhou: Huaqiao University, 2006. [5] 张习敏, 王明智, 王艳辉. 不同造孔剂对陶瓷结合剂性能的影响 [J]. 金刚石与磨料磨具工程,2005,131(5):19-22.ZHANG Ximin, WANG Mingzhi, WANG Yanhui. Effect of different pore-forming agents on properties of ceramic bond [J]. Diamond & Abrasives Engineering,2005,131(5):19-22. [6] 王超超, 张凤林, 李伟雄, 等. 空心玻璃微珠对陶瓷结合剂金刚石砂轮微观结构和力学性能的影响 [J]. 工具技术,2017,51(10):36-39. doi: 10.3969/j.issn.1000-7008.2017.10.009WANG Chaochao, ZHANG Fenglin, LI Weixiong, et al. Effect of glass bubble as pore former on micro-structure and mechanical properties of vitrified bond diamond grinding wheels [J]. Tool Engineering,2017,51(10):36-39. doi: 10.3969/j.issn.1000-7008.2017.10.009 [7] HOU Y G, QIAO G Y, SHANG Y, et al. Effect of porosity on the grinding performance of vitrified bond diamond wheels for grinding PCD blades [J]. Ceramics International,2012,38(8):6215-6220. doi: 10.1016/j.ceramint.2012.04.074 [8] 左宏森, 关春龙. 造孔剂对金属结合剂金刚石磨具力学性能的影响 [J]. 金刚石与磨料磨具工程,2009,173(5):82-85. doi: 10.3969/j.issn.1006-852X.2009.05.018ZUO Hongsen, GUAN Chunlong. Effect of pore-forming agents on mechanical properties of metal-bonded diamond wheels [J]. Diamond & Abrasives Engineering,2009,173(5):82-85. doi: 10.3969/j.issn.1006-852X.2009.05.018 [9] 李敏, 胡玲. CBN多孔砂轮制备方法与修整技术的研究进展 [J]. 金属材料与冶金工程,2016,3(2):8-14.LI Min, HU Ling. Progress of fabrication and dressing methods for CBN porous grinding wheel [J]. Metal Materials and Metallurgy Engineering,2016,3(2):8-14. [10] 梁述举. 多孔金属结合剂研究与超硬磨具制备 [D]. 秦皇岛: 燕山大学, 2020.LIANG Shuju. Study on porous metal bond and preparation of super hard abrasive [D]. Qinghuangdao: Yanshan University, 2020. [11] 陈卫东, 涂俊群. 不同的造孔剂对陶瓷结合剂cBN砂轮性能的影响 [J]. 超硬材料工程,2014,26(3):1-5. doi: 10.3969/j.issn.1673-1433.2014.03.001CHEN Weidong, TU Junqun. Influence of different type of pore former on the mechanical property of vitrified bond cBN grinding wheel [J]. Superhard Material Engineering,2014,26(3):1-5. doi: 10.3969/j.issn.1673-1433.2014.03.001 [12] 张元松, 王绍斌, 张梦婷, 等. 不同添加物对金属结合剂金刚石超薄砂轮胎体性能的影响 [J]. 矿冶工程,2013,33(3):113-116. doi: 10.3969/j.issn.0253-6099.2013.03.031ZHANG Yuansong, WANG Shaobin, ZHANG Mengting, et al. Effects of various additives on mechanical properties of ultra-thin metal-bonded diamond grinding wheel body [J]. Mining and Metallurgical Engineering,2013,33(3):113-116. doi: 10.3969/j.issn.0253-6099.2013.03.031 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS