Laser dressing technology for micro-grooves on the surface of metal-bonded diamond wheels

-

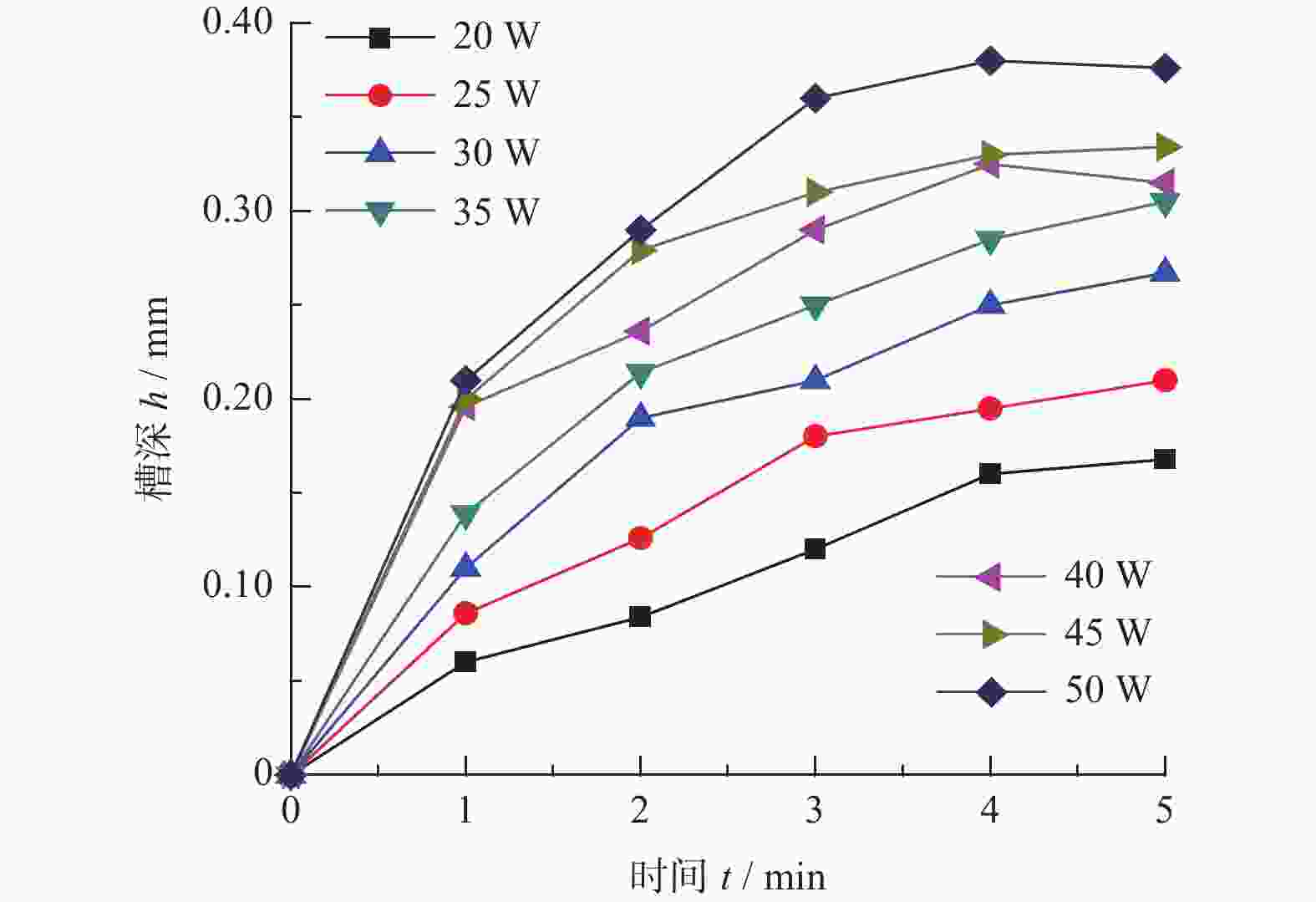

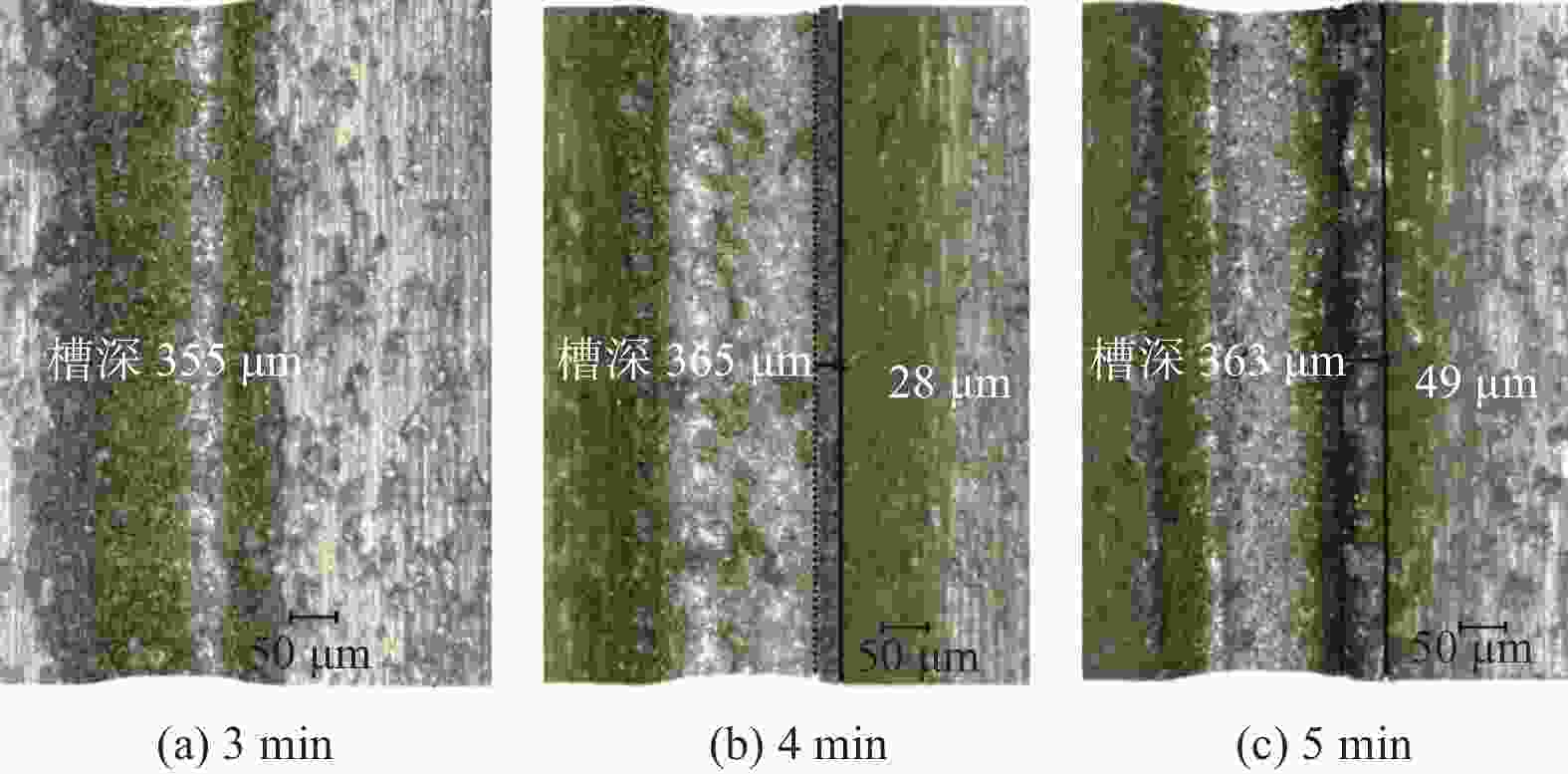

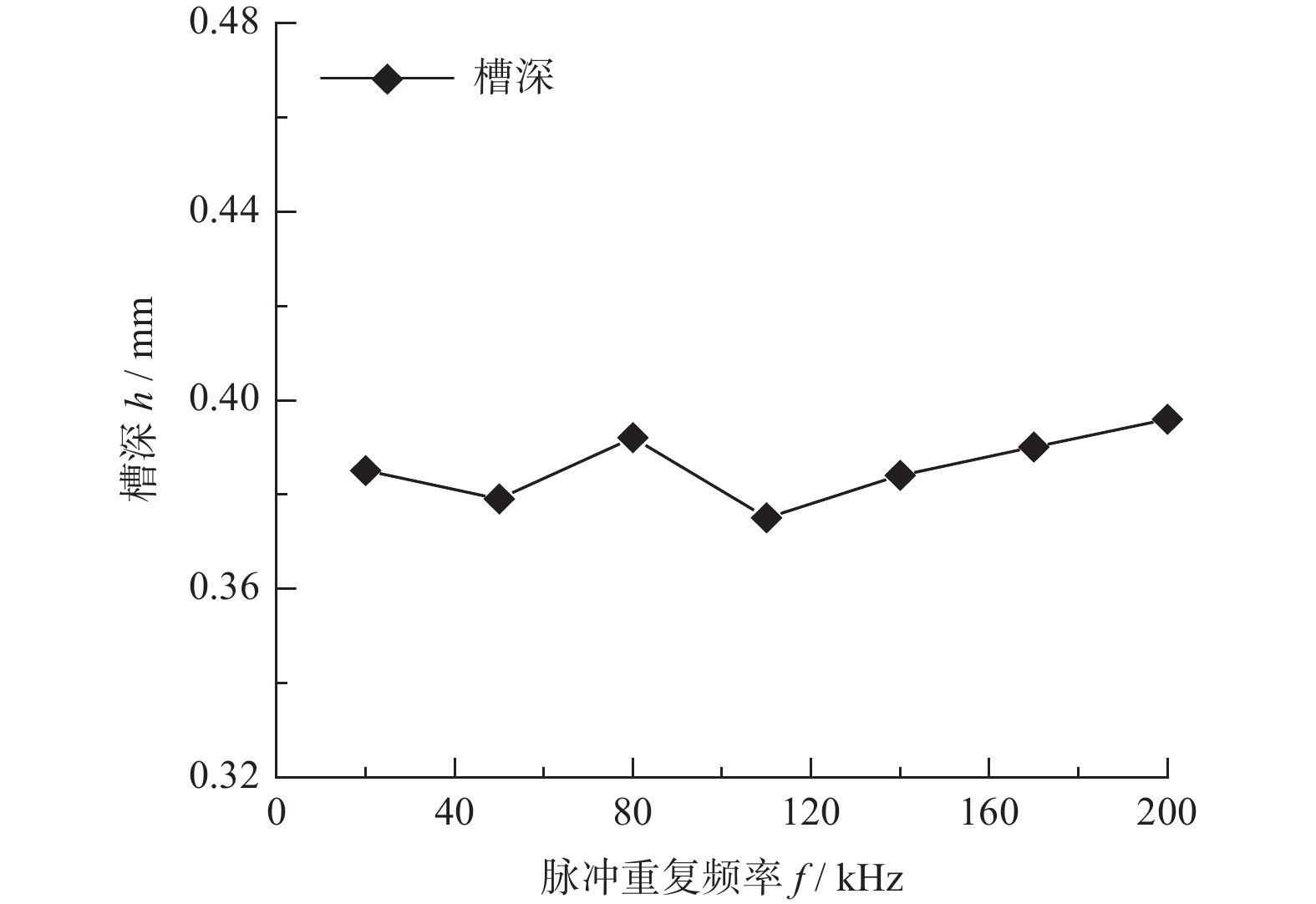

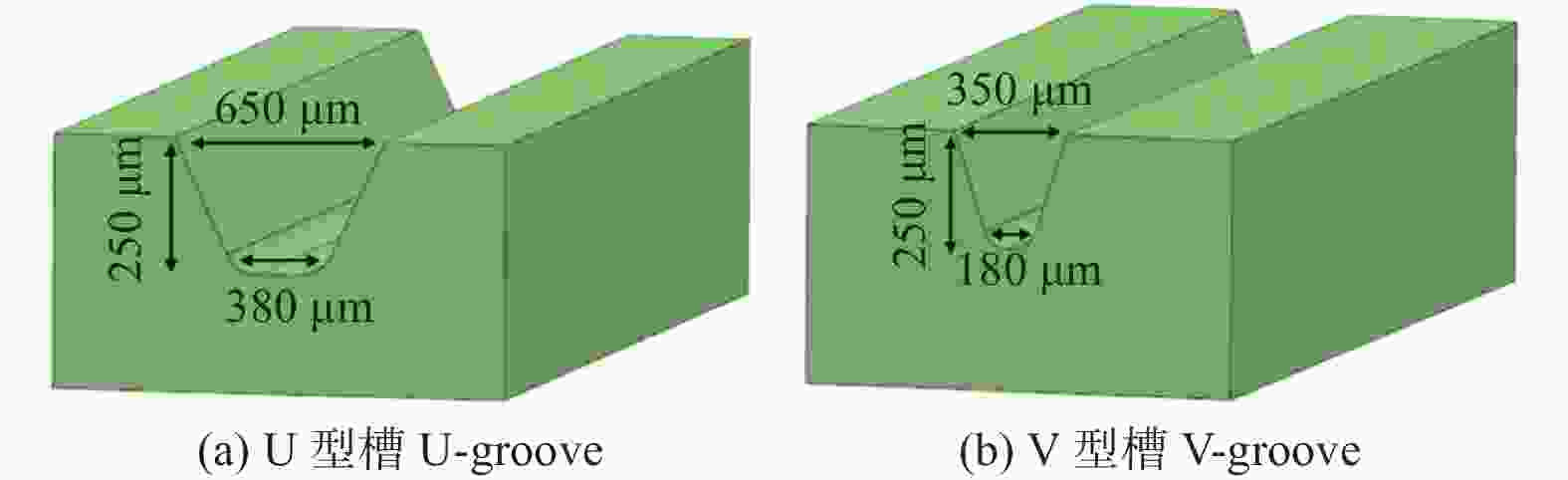

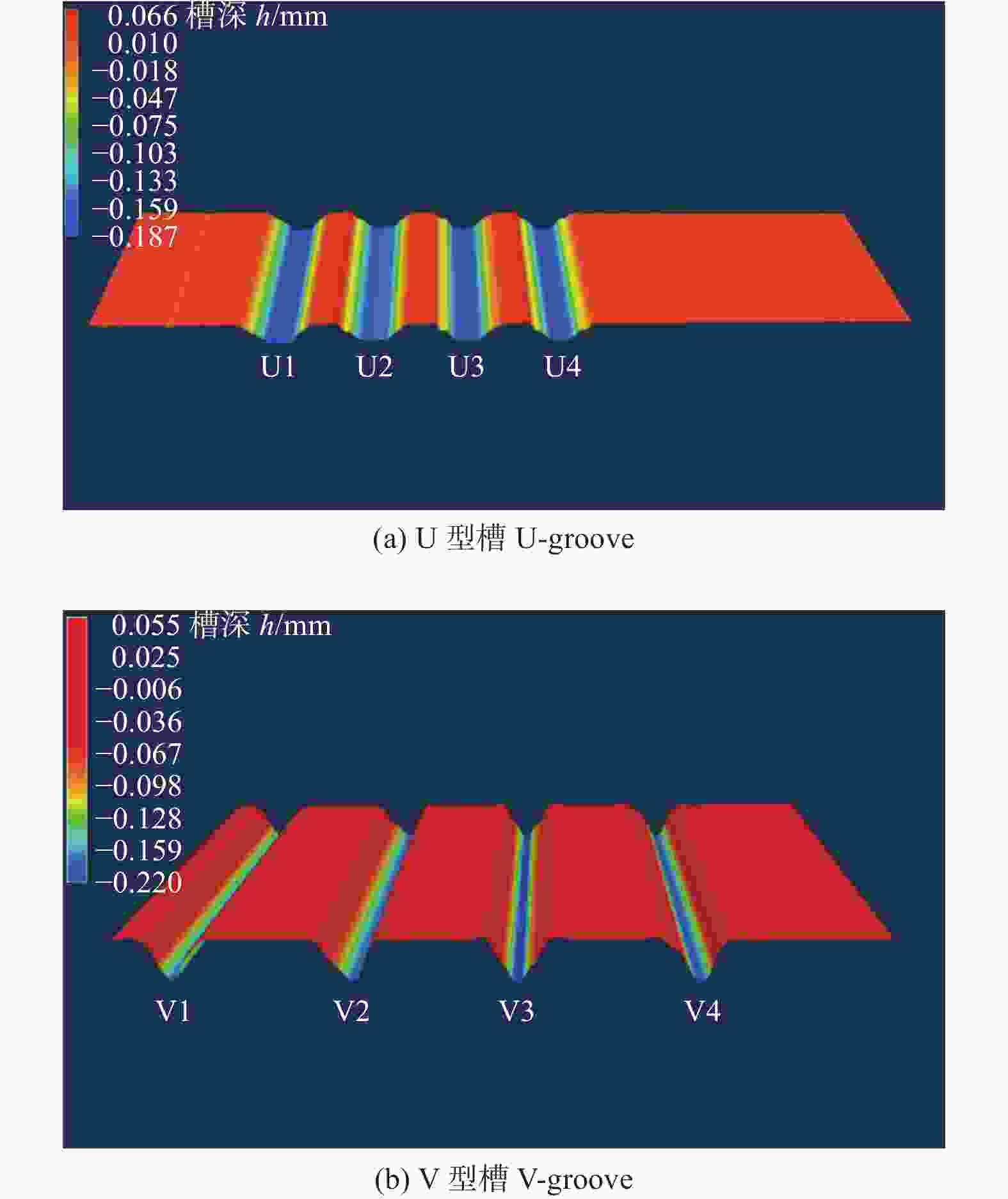

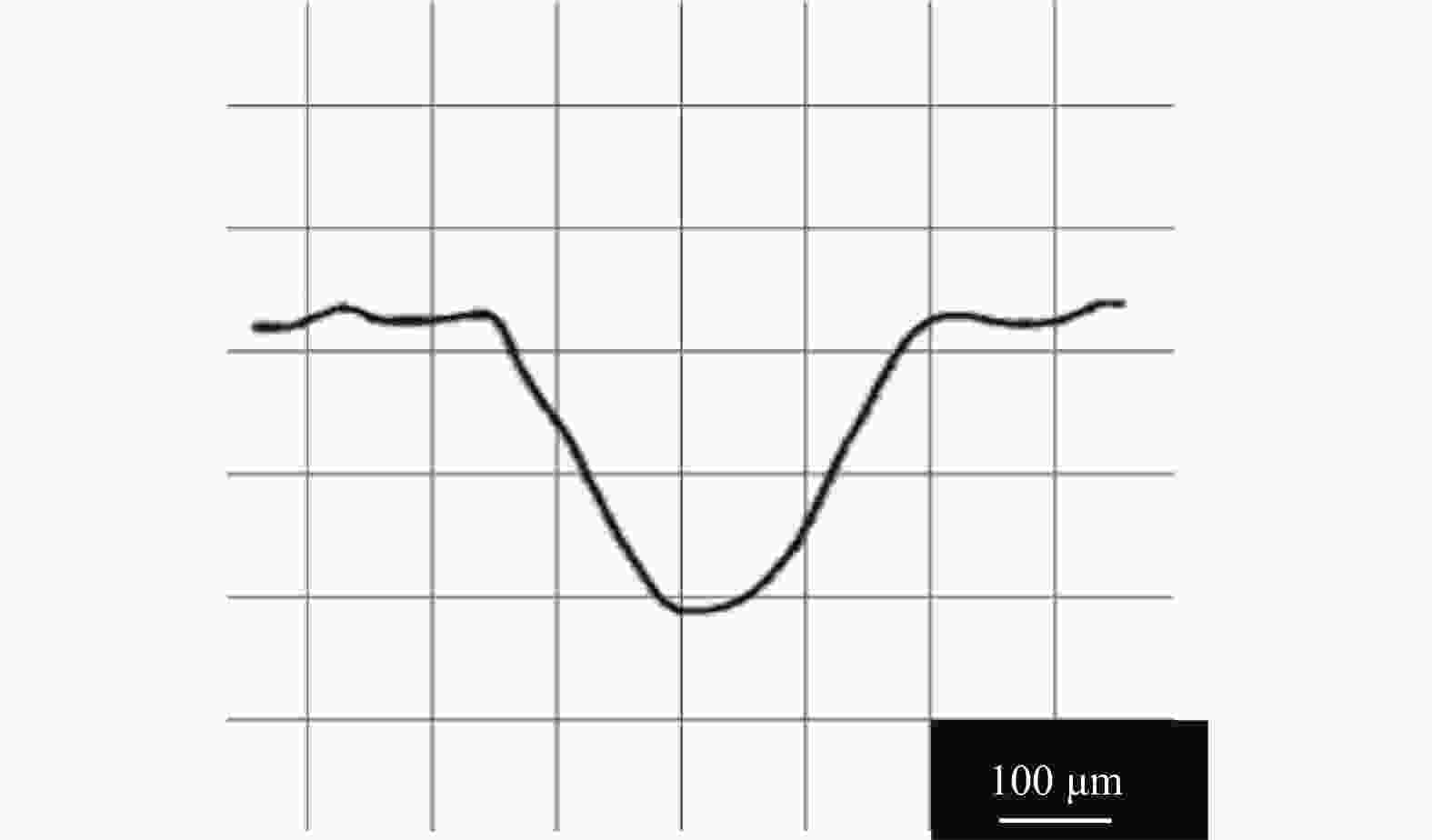

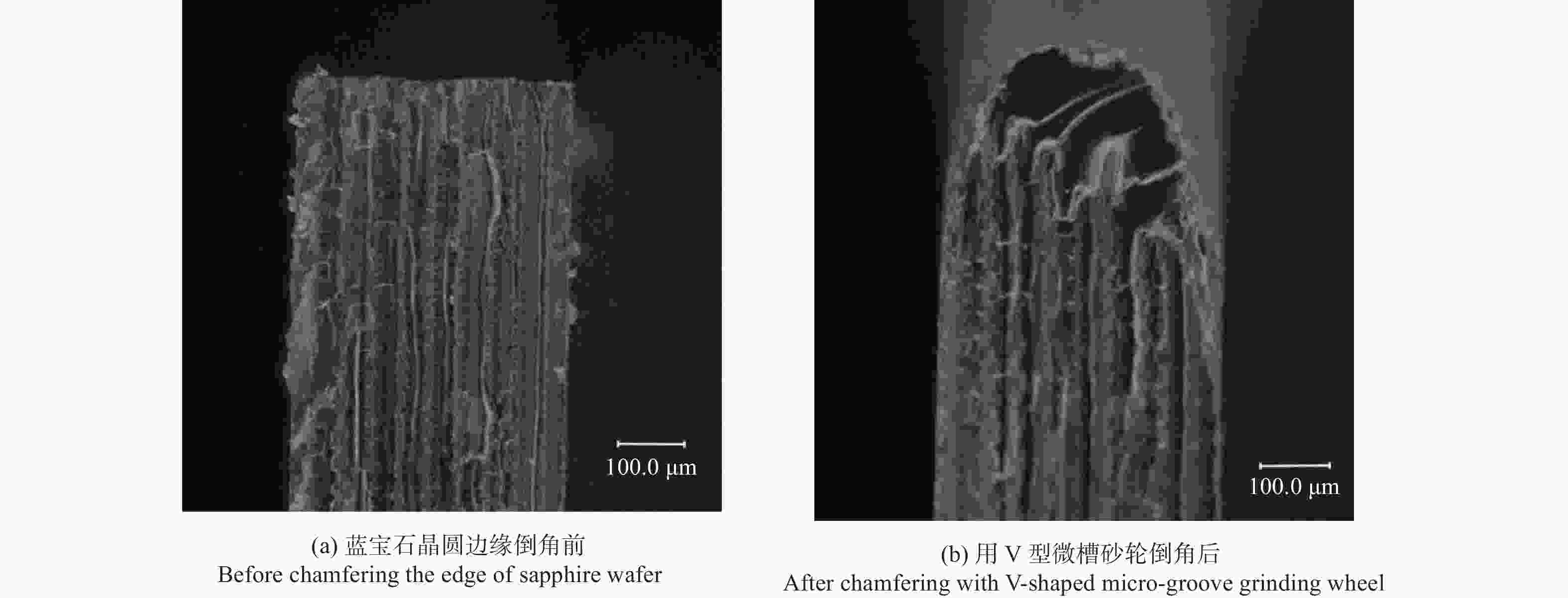

摘要: 针对金属结合剂金刚石砂轮表面微槽修整困难的问题,采用红外纳秒激光器开展修整试验,探究激光功率、脉冲重复频率、激光烧蚀时间等因素对其材料去除的影响规律,并对U型和V型2种砂轮微槽提出梯度步进激光修整工艺。结果表明:修整后的砂轮微槽实际轮廓与设计轮廓对比,其顶部和底部实际宽度相对误差的绝对值最大为4.4%,实际深度相对误差的绝对值最大为9.6%。用修整后的砂轮V型微槽对直径为4英寸(10.16 cm)的蓝宝石晶圆边缘进行倒角,晶圆锐利的边缘被修整成规则形状,边缘轮廓对称度良好,且与激光修整后砂轮表面的微槽轮廓一致,验证了金属结合剂金刚石砂轮表面微槽激光成型修整的可行性。

-

关键词:

- 激光加工 /

- 金属结合剂金刚石砂轮 /

- 微槽修整 /

- 晶圆边缘磨削

Abstract: In order to solve the difficult problem of dressing micro-grooves on the surface of metal-bonded diamond wheel, an infrared nanosecond laser was used to carry out the dressing test. The influences of laser average power, pulse repetition frequency, laser ablation time and other factors on the material removal of metal-bonded diamond grinding wheel was investigated. A gradient step laser dressing process was proposed for U-shaped and V-shaped grinding wheel micro-grooves. The results show that the actual contour of the grinding wheel micro-groove after dressing is compared with the designed contour, the maximum absolute value of the relative error of the actual width at the top and bottom is 4.4%, and the maximum absolute value of the relative error of the actual depth is 9.6%. The edge of the sapphire wafer with a diameter of 4 inches (10.16 cm) is chamfered with the V-shaped micro-groove of the trimmed grinding wheel. The sharp edge of the wafer is trimmed into a regular shape, and the symmetry of the edge contour is good, which is consistent with the micro-groove contour of the surface of the laser trimmed grinding wheel. The feasibility of laser shaping and dressing of the micro-groove on the surface of metal-bonded diamond grinding wheel is verified. -

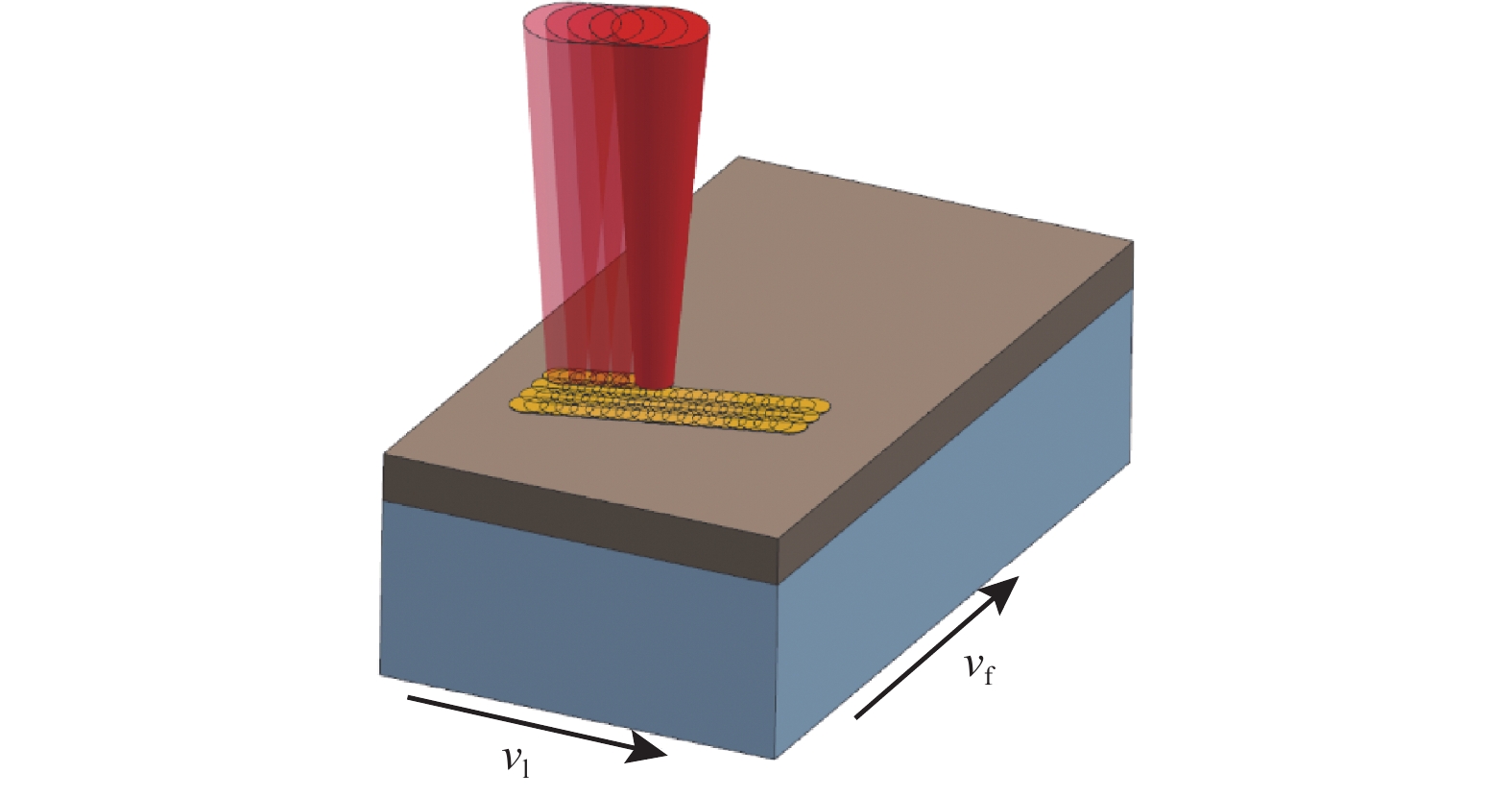

表 1 激光修整试验参数

Table 1. Parameters of laser dressing test

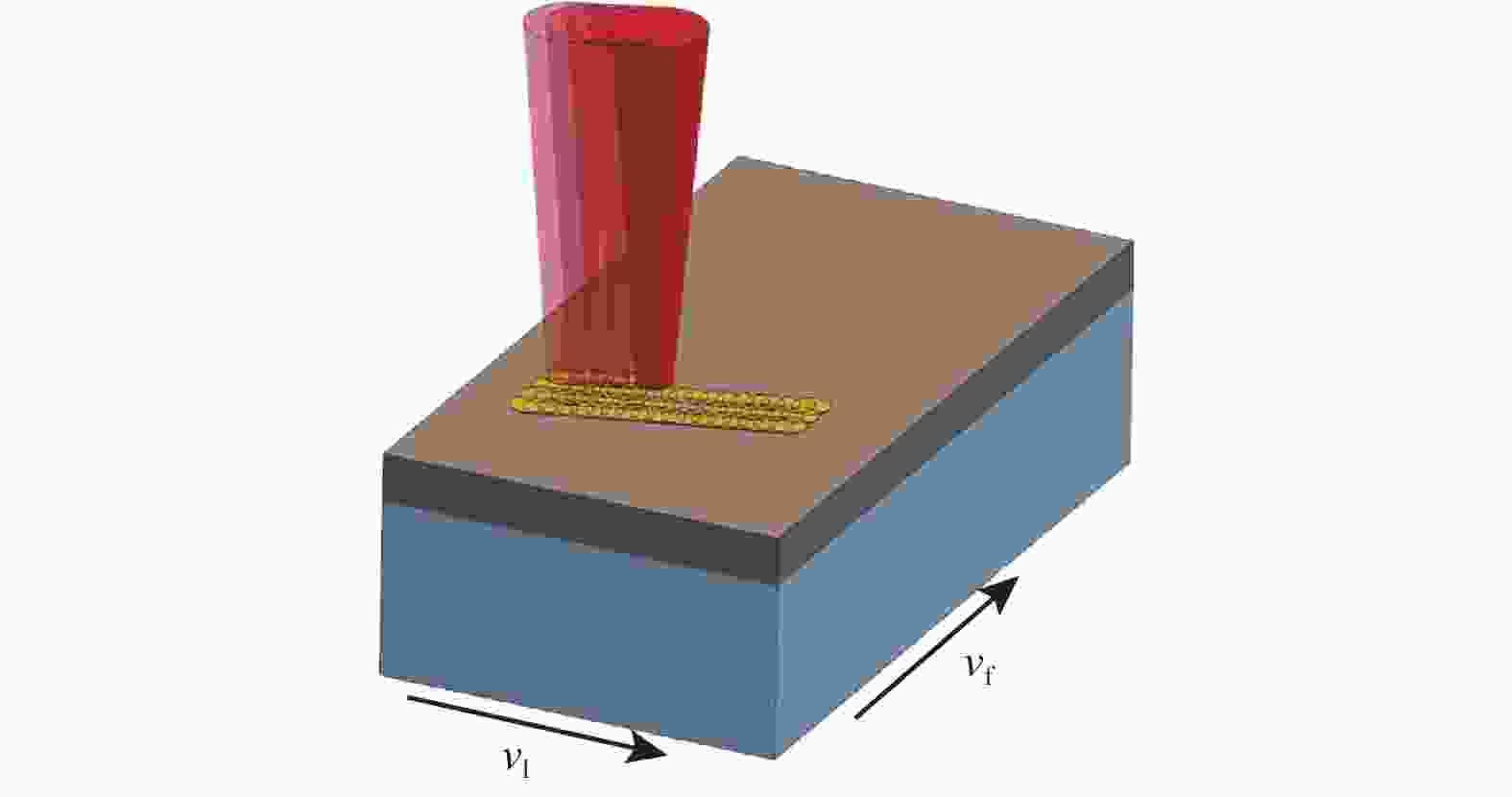

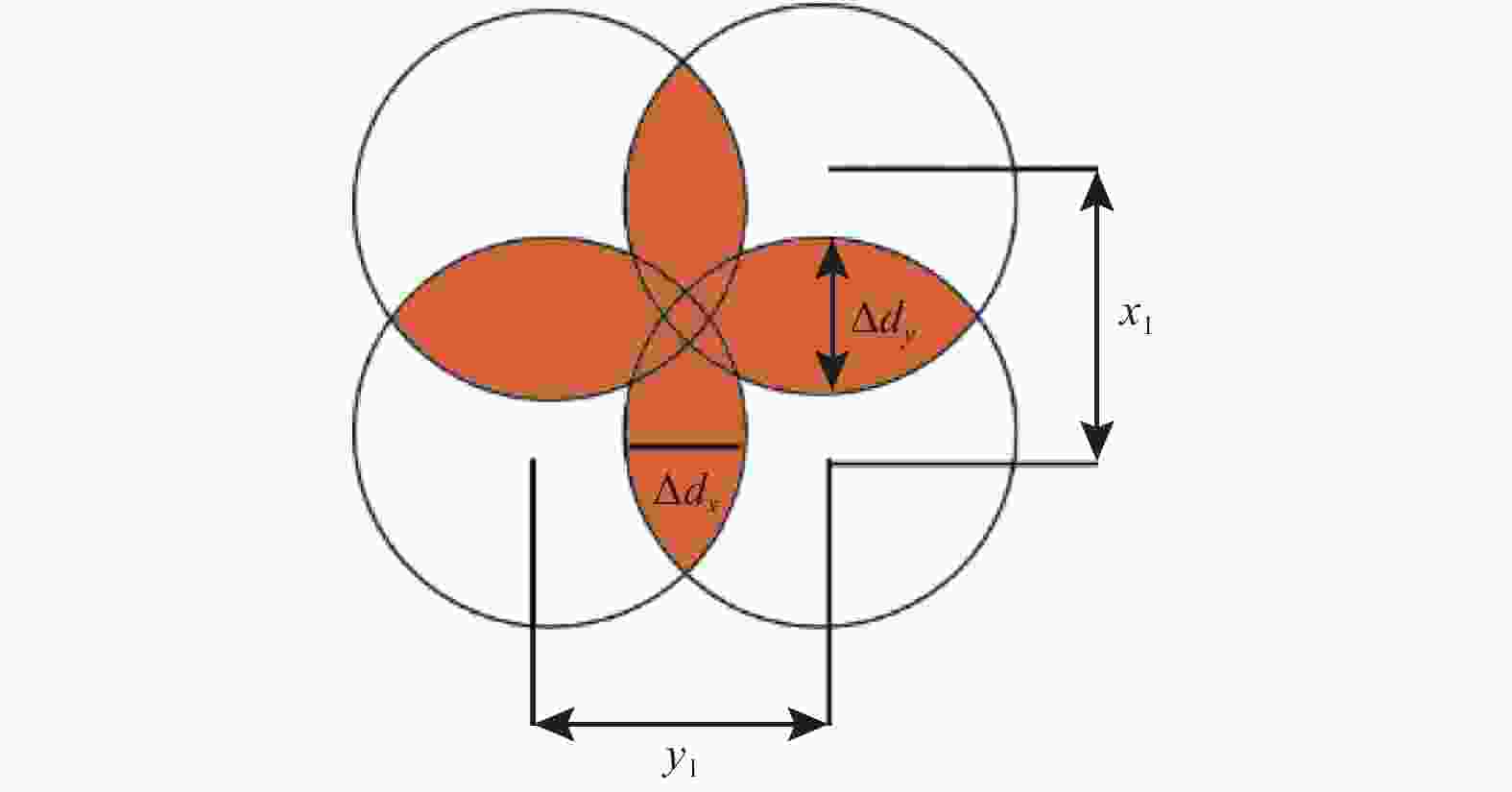

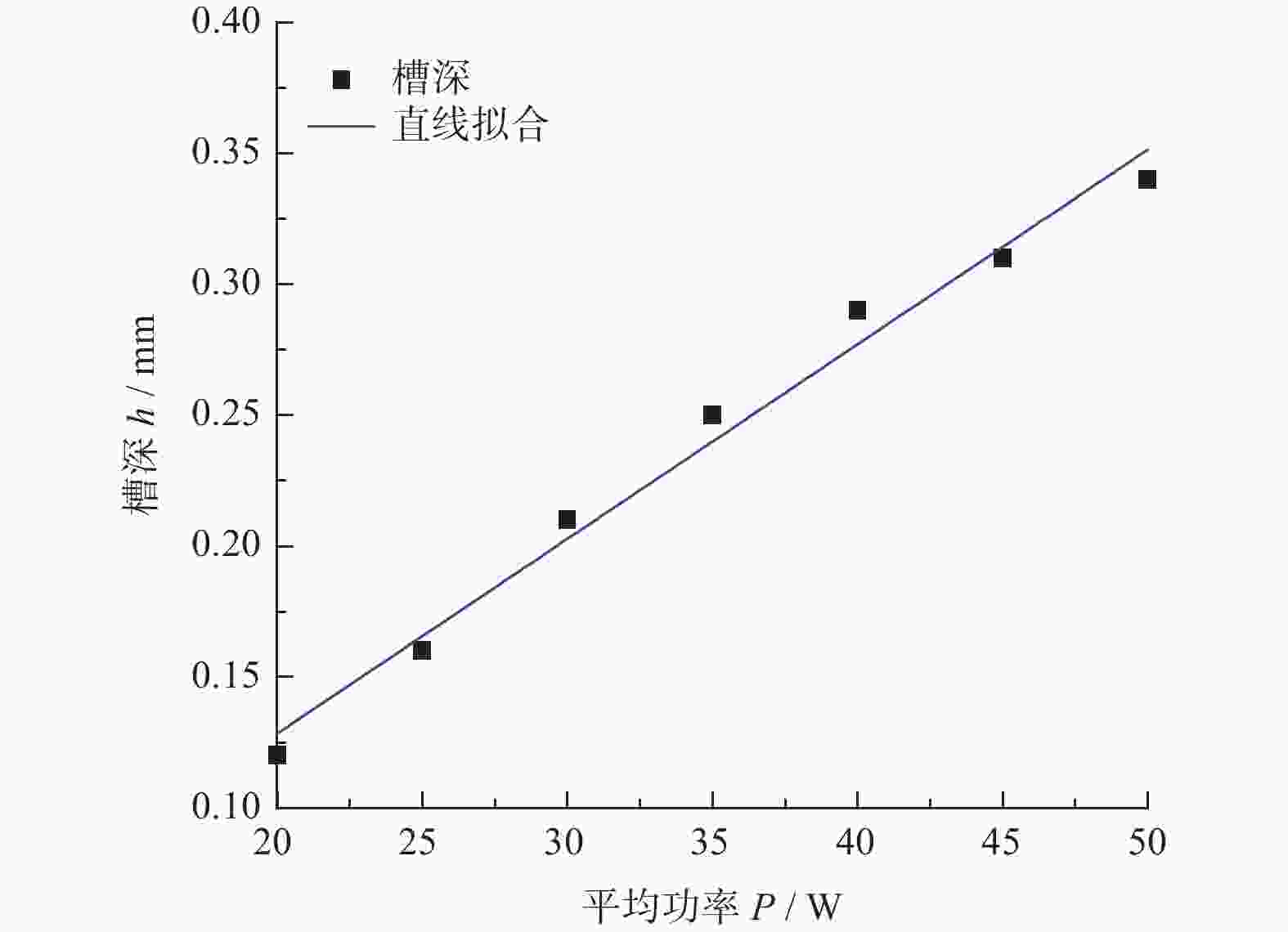

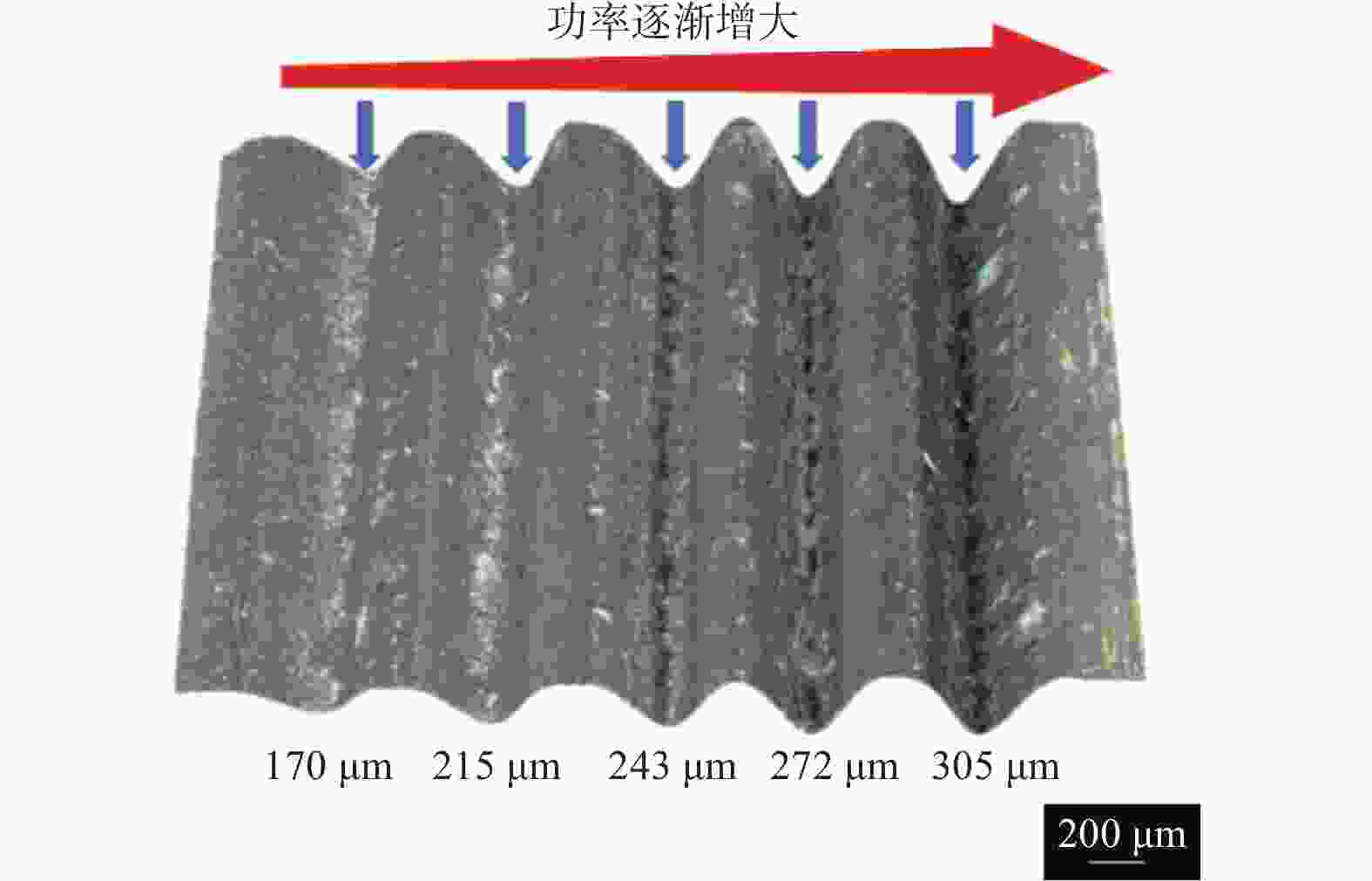

脉冲重复频率 f / kHz 20~200 激光平均功率 P / W 20~50 激光扫描速度 vl / (mm·s−1) 750 砂轮线速度 vf / (mm·s−1) 11 烧蚀时间 t / min 1~5 烧蚀线宽 l / μm 300 表 2 2种砂轮槽型修整方案

Table 2. Dressing schemes of two grinding wheel grooves

烧蚀步数 U型槽 V型槽 烧蚀线宽

l / μm烧蚀时间

t / min烧蚀线宽

l / μm烧蚀时间

t / min1 600 1 300 1 2 450 1 200 1 3 300 1 100 1 表 3 实际修整槽尺寸及相对误差

Table 3. Dimension and relative error of actual dressing groove

槽型 槽编号 顶部设计槽宽

L1 / μm顶部实际槽宽

L2 / μm相对误差

δ1 / %底部设计槽宽

L3 / μm底部实际槽宽

L4 / μm相对误差

δ2 / %设计槽深

h1 / μm实际槽深

h2 / μm相对误差

δ3 / %U型槽 U1 650 635 −2.3 380 373 −1.8 250 234 −6.4 U2 640 −1.5 369 −2.9 230 −8.0 U3 640 −1.5 375 −1.3 235 −6.0 U4 655 0.8 377 −0.8 230 −8.0 V型槽 V1 350 335 −4.3 180 182 1.1 261 4.4 V2 335 −4.3 176 −2.2 274 9.6 V3 345 −1.5 185 2.8 239 −4.4 V4 345 −1.5 172 −4.4 249 −0.4 表 4 蓝宝石及设备工艺参数

Table 4. Sapphire and equipment process parameters

参数 类型或取值 4英寸晶圆直径 D / cm 10.16 晶圆厚度 H / μm 300 晶圆晶向 C(0001)面 倒角设备 东京精密晶圆倒角机床W−GM 主轴转速 n / ( r·min−1) 2 000 吸盘转速 v / (mm·s−1) 6 一次切入量 d1 / μm 50 -

[1] 安瑞阳, 蔡丽艳, 苏冰, 等. 改善200 mm晶圆边缘加工产能的工艺研究 [J]. 材料科学,2020,10(9):794-798. doi: 10.12677/MS.2020.109094AN Ruiyang, CAI Liyan, SU Bing, et al. Process research to improve the edge processing capacity of 200 mm wafers [J]. Material Sciences,2020,10(9):794-798. doi: 10.12677/MS.2020.109094 [2] 庄司克雄. 磨削加工技术 [M]. 郭隐彪, 王振忠, 译. 北京: 机械工业出版社, 2007.SYOJI Katsuo. Grinding technology [M]. Translated by GUO Yinbiao, WANG Zhenzhong. Beijing: China Machine Press, 2007. [3] 范红伟, 袁巨龙, 吕冰海, 等. 金属结合剂砂轮的研究与发展 [J]. 航空精密制造技术, 2010, 46(4): 38-41.FAN Hongwei, YUAN Julong, LYU Binghai, et al. Progress and prospect metal bonded grinding wheel [J]. Aviation Precision Manufacturing Technology, 2010, 46(4): 38-41. [4] 陈海深, 张喜平. 金属结合剂金刚石成型砂轮电火花修整方法研究 [J]. 工具技术,2015,49(6):25-29. doi: 10.3969/j.issn.1000-7008.2015.06.006CHEN Haishen, ZHANG Xiping. Study on EDM dressing method of metal bond matrix diamond grinding wheel [J]. Tool Engineering,2015,49(6):25-29. doi: 10.3969/j.issn.1000-7008.2015.06.006 [5] 焦峰, 李成龙, 牛赢, 等. 砂轮修整技术研究现状与展望 [J]. 中国机械工程,2021(3):1-16.JIAO Feng, LI Chenglong, NIU Ying, et al. Review and prospect of grinding wheel dressing technique [J]. China Mechanical Engineering,2021(3):1-16. [6] 何广川. 浅谈激光加工技术的现状及发展 [J]. 现代制造技术与装备,2020,56(10):160-161. doi: 10.3969/j.issn.1673-5587.2020.10.069HE Guangchuan. The present situation and development of laser processing technology [J]. Modern Manufacturing Technology and Equipment,2020,56(10):160-161. doi: 10.3969/j.issn.1673-5587.2020.10.069 [7] 胡晓冬, 李元龙, 白少状, 等. 激光在材料去除加工中应用的研究进展 [J]. 激光与光电子学进展,2020(7):1-16.HU Xiaodong, LI Yuanlong, BAI Shaozhuang, et al. Research progress of laser application in material removal [J]. Laser & Optoelectronics Progress,2020(7):1-16. [8] 杜洋, 赵凯, 朱忠良, 等. 超快激光精密制造技术的研究与应用 [J]. 激光与红外,2020(12):1419-1425. doi: 10.3969/j.issn.1001-5078.2020.12.001DU Yang, ZHAO Kai, ZHU Zhongliang, et al. Research and application of ultrafast laser precision manufacturing technology [J]. Laser & Infrared,2020(12):1419-1425. doi: 10.3969/j.issn.1001-5078.2020.12.001 [9] 江海河. 激光加工技术应用的发展及展望 [J]. 光电子技术与信息,2001(4):1-12.JIANG Haihe. Development and forecast of the laser processing technology application [J]. Optoelectronic Technology & Information,2001(4):1-12. [10] HOSOKAWA A, UEDA T, YUNOKI T. Laser dressing of metal bonded diamond wheel [J]. CIRP Annals Manufacturing Technology,2006,55(1):329-332. doi: 10.1016/S0007-8506(07)60428-4 [11] ADRIAN H A, ALESSANDRO F, FILIPPO Z, et al. Pulsed laser profiling of grinding wheels at normal and quasi-tangential incidence [J]. Lasers in Manufacturing & Materials Processing,2016(3):158-173. [12] 陈根余, 陈冲, 卜纯, 等. 激光在线修整青铜金刚石砂轮数值仿真与试验 [J]. 激光技术,2012,36(4):433-437. doi: 10.3969/j.issn.1001-3806.2012.04.001CHEN Genyu, CHEN Chong, BU Chun, et al. Numerical simulation and experiment for on-line truing and dressing of bronze-bonded diamond grinding wheels with laser [J]. Laser Technology,2012,36(4):433-437. doi: 10.3969/j.issn.1001-3806.2012.04.001 [13] 陈根余, 周兴才, 周聪, 等. 树脂结合剂CBN砂轮光纤激光径向修锐及磨削实验研究 [J]. 中国激光,2015,42(2):124-131.CHEN Genyu, ZHOU Xingcai, ZHOU Cong, et al. Experimental research on fiber laser radial sharpening of resin-bonded CBN grinding wheels and grinding characteristics [J]. Chinese Journal of Lasers,2015,42(2):124-131. [14] SHANKAR U, BABU N R. A model for predicting the geometry of crater on grinding wheel surface ablated with a single pulsed laser [J]. Procedia Manufacturing,2018,26:509-520. doi: 10.1016/j.promfg.2018.07.060 [15] 刘健平, 陈根余, 周聪, 等. V形凹面青铜金刚石砂轮脉冲激光修整试验研究 [J]. 应用激光,2017,37(4):557-562.LIU Jianping, CHEN Genyu, ZHOU Cong, et al. Experimental study on pulsed laser dressing bronze diamond wheel V-shaped concave surfaces [J]. Applied Laser,2017,37(4):557-562. [16] CHANG J J, WARNER B E, DRAGON E P, et al. Precision micromachining with pulsed green lasers [J]. Journal of Laser Applications,1998,10(6):285-291. doi: 10.2351/1.521863 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS