Undeformed chip thickness characteristics in grain-workpiece contact zone in ultrasonic vibration assisted grinding

-

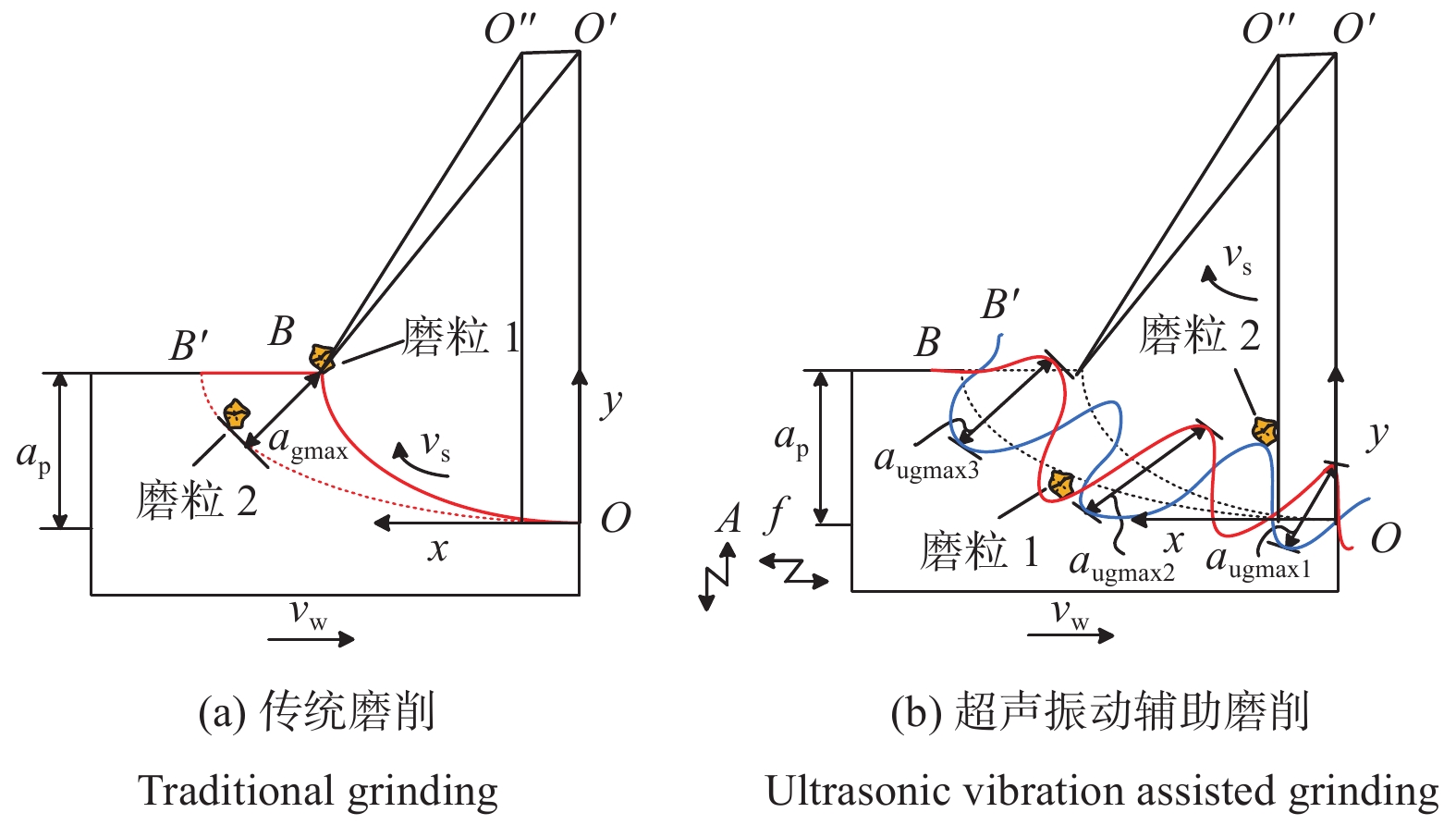

摘要: 为准确描述超声振动下的单颗磨粒切厚特征,实测多层金属结合剂金刚石砂轮表面的相邻2颗磨粒的周向间距以及磨粒出刃高度;依据超声振动辅助磨削的磨粒运动轨迹方程及相邻磨粒运动轨迹干涉理论,采用等分线法,利用MATLAB软件求解磨粒在完整接触弧区的单颗磨粒切厚值,并分析各主要参数对单颗磨粒切厚特征的影响。结果表明:相邻磨粒间距、相邻磨粒高度差对单颗磨粒切厚的影响均呈线性变化;单颗磨粒切厚随超声振幅的增大而线性增大,且随超声振动频率的增大而阶段性变化;超声振动辅助磨削的单颗磨粒切厚特征受砂轮转速、磨削深度的影响较大,受工件进给速度的影响相对较小。Abstract: To accurately describe the undeformed chip thickness characteristics in ultrasonic vibration assisted grinding, the grain space and grain protrusion height of a metal bond multi-layer diamond wheel were measured. According to the particle trajectory equation of ultrasonic vibration assisted grinding and the trajectory interference theory of two nearby grains, the undeformed chip thickness in a complete grain-workpiece contact zone was solved by using the bisector method and MATLAB software. Then the influence of the main parameters on the undeformed chip thickness characteristics was analyzed. The results show that the undeformed chip thickness varies linearly against the distance between adjacent grains and the height difference of adjacent grains, increases linearly with the increase of ultrasonic amplitude and changes periodically with the increase of ultrasonic vibration frequency. In ultrasonic vibration assisted grinding, the undeformed chip thickness characteristics are greatly affected by the grinding wheel speed and grinding depth, and relatively less affected by the workpiece feed speed.

-

表 1 加工参数

Table 1. Processing parameters

参数 数值 砂轮基体直径 db / mm 20 工件长度 Lw / mm 2 磨粒间距 Lg / mm 0.145~0.908 磨粒出刃高度 h / µm 27~93 超声振动方向 x, y 超声振幅 A / µm 2, 4, 6, 8, 10, 12 超声振动频率 f / kHz 18, 20, 25, 28, 33, 35, 40 初始相位 φ π/6 砂轮转速 n / (r∙min−1) 6 000,9 000,10 700,12 000,

15 000,16 800,18 000,21 000工件进给速度 vw / (mm∙min−1) 50, 100, 150, 200, 250, 300 磨削深度 ap / µm 5, 12, 15, 20, 25, 29, 35 -

[1] SUN G, SHI F, MA Z. Effects of axial ultrasonic vibration on grinding quality in peripheral grinding and end grinding of ULE [J]. The International Journal of Advanced Manufacturing Technology,2020,109(7/8):2285-2298. doi: 10.1007/s00170-020-05761-5 [2] DAI J, DING W, ZHANG L, et al. Understanding the effects of grinding speed and undeformed chip thickness on the chip formation in high-speed grinding [J]. The International Journal of Advanced Manufacturing Technology,2015,81(5/6/7/8):995-1005. doi: 10.1007/s00170-015-7265-1 [3] 郎献军, 何玉辉, 唐进元, 等. 基于磨粒突出高度为瑞利分布的磨削力模型 [J]. 中南大学学报(自然科学版),2014,45(10):3386-3391.LANG Xianjun, HE Yuhui, TANG Jinyuan, et al. Grinding force model based on rayleigh distribution of abrasive protrusion height [J]. Journal of Central South University (Science and Technology),2014,45(10):3386-3391. [4] 程军, 巩亚东, 武治政, 等. 硬脆材料微磨削表面形成机理试验研究 [J]. 机械工程学报,2012,48(21):190-198. doi: 10.3901/JME.2012.21.190CHENG Jun, GONG Yadong, WU Zhizheng, et al. Experimental study on surface formation mechanism of micro grinding of hard and brittle materials [J]. Journal of Mechanical Engineering,2012,48(21):190-198. doi: 10.3901/JME.2012.21.190 [5] ZHANG Y, FANG C, HUANG G, et al. Modeling and simulation of the distribution of undeformed chip thicknesses in surface grinding [J]. International Journal of Machine Tools and Manufacture,2018,127:14-27. doi: 10.1016/j.ijmachtools.2018.01.002 [6] DING W, DAI C, YU T, et al. Grinding performance of textured monolayer CBN wheels: Undeformed chip thickness nonuniformity modeling and ground surface topography prediction [J]. International Journal of Machine Tools and Manufacture,2017,122:66-80. doi: 10.1016/j.ijmachtools.2017.05.006 [7] 丁晨, 丁文锋, 戴晨伟, 等. 单层钎焊CBN砂轮表面形貌重构与磨粒切厚分布特征研究 [J]. 金刚石与磨料磨具工程,2016,36(4):24-28.DING Chen, DING Wenfeng, DAI Chenwei, et al. Study on surface morphology reconstruction and abrasive thickness distribution characteristics of single layer brazed CBN grinding wheel [J]. Diamond & Abrasives Engineering,2016,36(4):24-28. [8] 田霖, 傅玉灿, 杨路, 等. 基于速度效应的高温合金高速超高速磨削成屑过程及磨削力研究 [J]. 机械工程学报,2013,49(9):169-177. doi: 10.3901/JME.2013.09.169TIAN Lin, FU Yucan, YANY Lu, et al. Research on chip forming process and grinding force of superalloy based on velocity effect in high and ultra high speed grinding [J]. Journal of Mechanical Engineering,2013,49(9):169-177. doi: 10.3901/JME.2013.09.169 [9] 刘立飞, 张飞虎, 刘民慧. 碳化硅陶瓷的超声振动辅助磨削 [J]. 光学精密工程,2015,23(8):2229-2235. doi: 10.3788/OPE.20152308.2229LIU Lifei, ZHANG Feihu, LIU Minhui. Ultrasonic assisted grinding for silicon carbide [J]. Optics and Precision Engineering,2015,23(8):2229-2235. doi: 10.3788/OPE.20152308.2229 [10] CAO Y, YIN J, DING W, et al. Alumina abrasive wheel wear in ultrasonic vibration-assisted creep-feed grinding of Inconel 718 nickel-based superalloy [J]. Journal of Materials Processing Technology,2021,297:117241. doi: 10.1016/j.jmatprotec.2021.117241 [11] ZHAO B, CHEN F, JIA X, et al. Surface quality prediction model of nano-composite ceramics in ultrasonic vibration-assisted ELID mirror grinding [J]. Journal of Mechanical Science and Technology,2017,31:1877-1884. doi: 10.1007/s12206-017-0335-6 [12] CHEN J, AN Q, MING W, et al. Investigation on machined surface quality in ultrasonic-assisted grinding of Cf/SiC composites based on fracture mechanism of carbon fibers [J]. The International Journal of Advanced Manufacturing Technology,2020,109(5-6):1583-1599. doi: 10.1007/s00170-020-05739-3 [13] JAIN A K, PANDEY P M. Modeling of un-deformed chip thickness in RUM process and study of size effects in μ-RUM [J]. Ultrasonics,2017,77:1-16. doi: 10.1016/j.ultras.2017.01.015 [14] ZHOU W, SU H, DAI J, et al. Numerical investigation on the influence of cutting-edge radius and grinding wheel speed on chip formation in SiC grinding [J]. Ceramics International,2018,44(17):21451-21460. doi: 10.1016/j.ceramint.2018.08.206 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS