| [1] |

冯克明, 王庆伟. 超薄砂轮高速精密切割磨削影响因素系统分析 [J]. 模具制造,2016,16(12):73-79.FENG Keming, WANG Qingwei. Systematic analysis on the influencing factors for super-speed precision cutting-grinding using the super-thin grinding wheel [J]. Die & Mould Manufacture,2016,16(12):73-79.

|

| [2] |

冯克明, 赵金坠. 先进磨削技术应用现状与展望 [J]. 轴承,2020(4):60-67.FENG Keming, ZHAO Jinzhui. Present situation and prospect of advanced grinding technology application [J]. Bearing,2020(4):60-67.

|

| [3] |

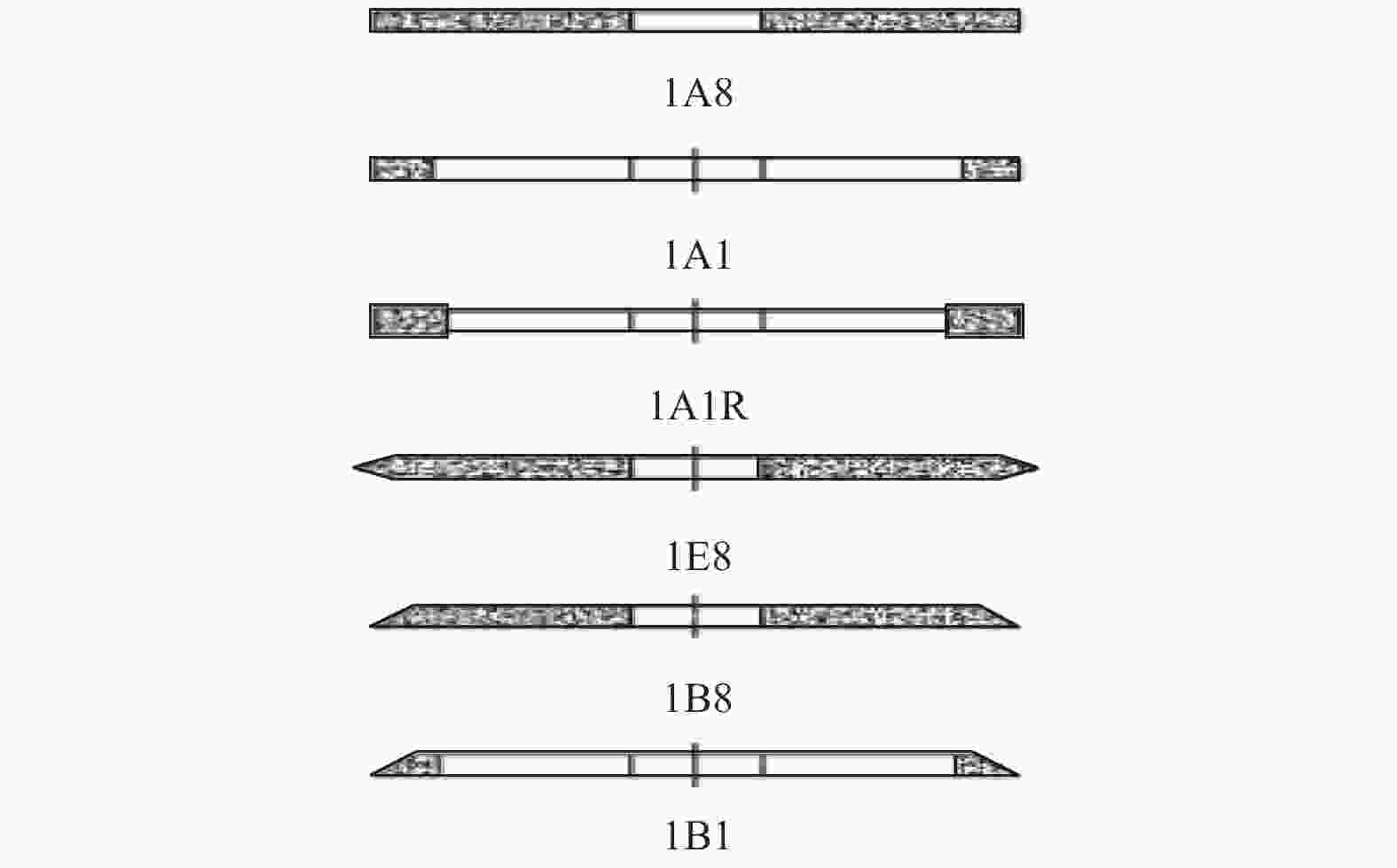

侯长红. 电子信息行业用超硬材料切割工具综述 [J]. 金刚石与磨料磨具工程,2010,30(1):60-62.HOU Changhong. Summary of superabrasive cutting tools for used in electronic information industry [J]. Diamond & Abrasives Engineering,2010,30(1):60-62.

|

| [4] |

轩闯, 项刚强, 廖燕玲, 等. 半导体加工用金刚石工具现状 [J]. 超硬材料工程,2021,33(1):41-49.XUAN Chuang, XIANG Gangqiang, LIAO Yanling, et al. Current status of diamond tools for semiconductor processing industry [J]. Superhard Material Engineering,2021,33(1):41-49.

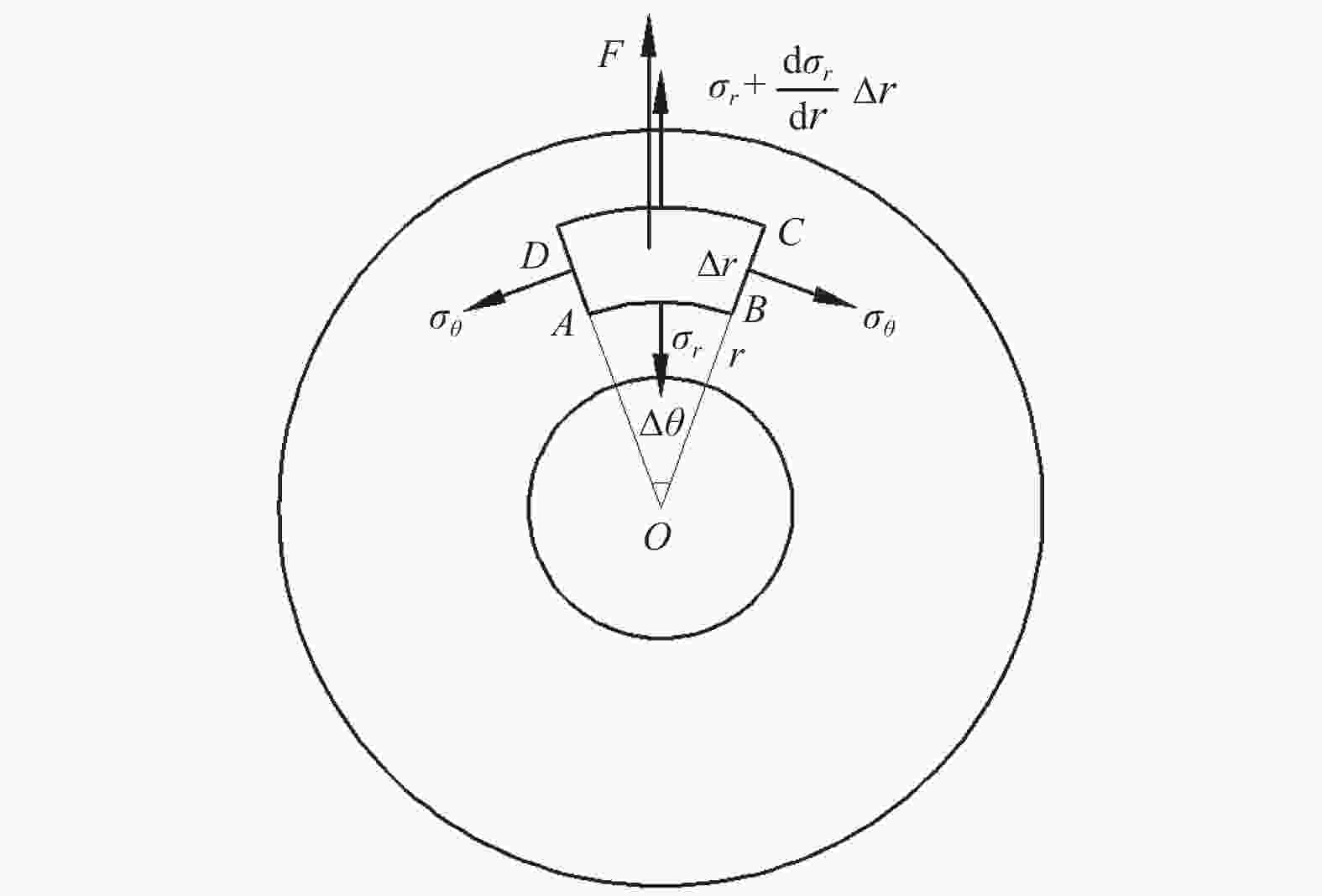

|

| [5] |

ZHONG Y, DAI Y, XIAO H, et al. Experimental study on surface integrity and subsurface damage of fused silica in ultra-precision grinding [J]. The International Journal of Advanced Manufacturing Technology,2021,115:4021-4033. doi: 10.1007/s00170-021-07439-y

|

| [6] |

马岩, 袁慧珠, 鞠仁忠, 等. 金刚石砂轮刀片划切过程性能分析与三维建模 [J]. 金刚石与磨料磨具工程,2009(5):74-77.MA Yan, YUAN Huizhu, JU Renzhong, et al. Research of performance and three-dimensional modeling of diamond blade [J]. Diamond & Abrasives Engineering,2009(5):74-77.

|

| [7] |

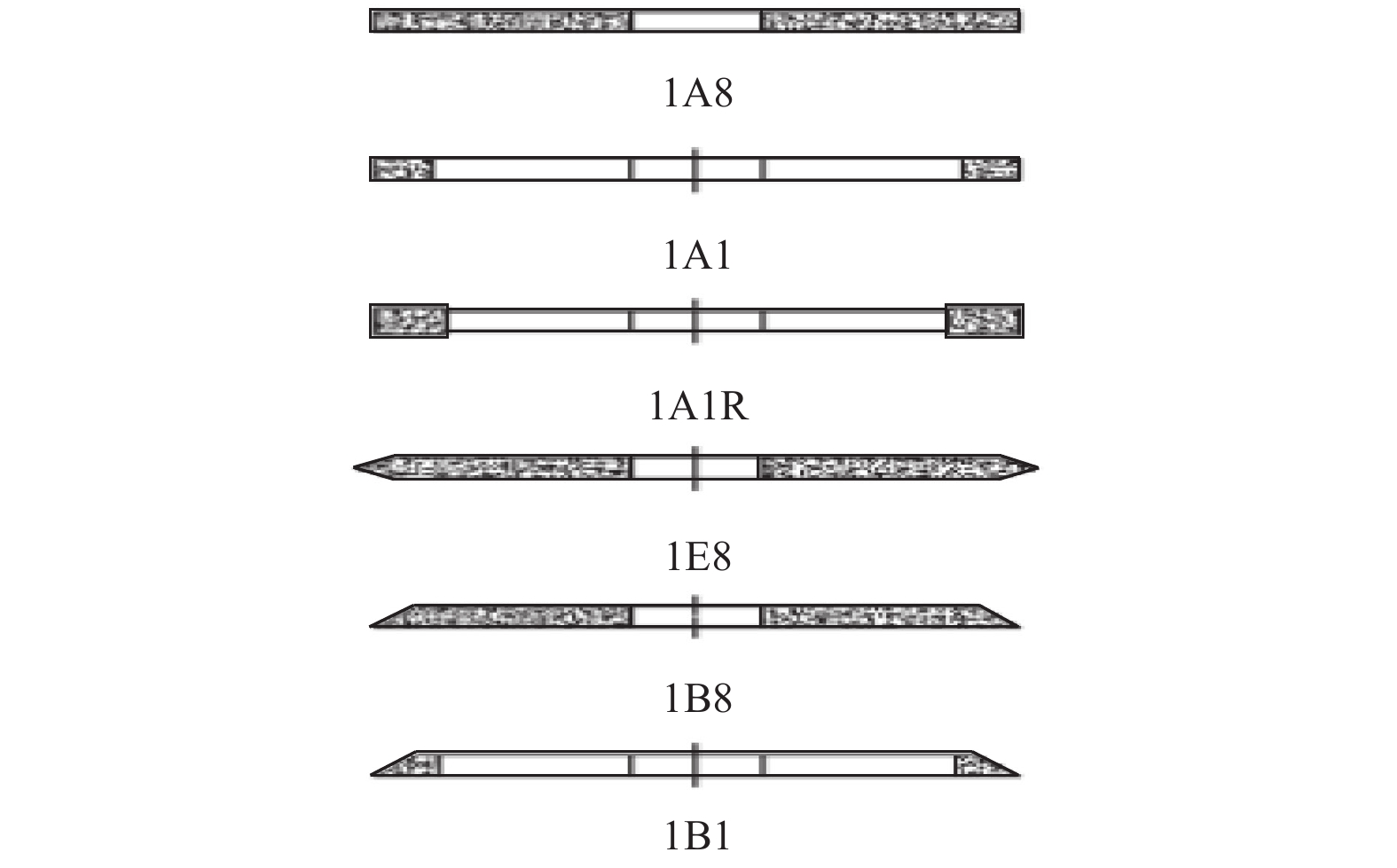

黎克楠. 超薄砂轮高速动态行为与新型结合剂设计研究 [D]. 秦皇岛: 燕山大学, 2019.LI Kenan. Study on high-speed dynamic behavior of super-thin dicing blades and design of new bond [D]. Qinhuangdao: Yanshan University, 2019.

|

| [8] |

任敬心, 华定安. 磨削原理 [M]. 北京: 电子工业出版社, 2011.REN Jingxin, HUA Dingan. Grinding principle [M]. Beijing: Publishing House of Electronics Industry, 2011.

|

| [9] |

LI C, ZHANG L, DING J, et al. Kinematic modeling of surface topography ground by an electroplated diamond wheel [J]. The International Journal of Advanced Manufacturing Technology,2021,114:2753-2765. doi: 10.1007/s00170-021-06944-4

|

| [10] |

TAWAKOLI T, REINECKE H, VESALI A. An experimental study on the dynamic behavior of grinding wheels in high efficiency deep grinding [C]. Amsterdam: Procedia CIRP, 2012, 1: 382-387.

|

| [11] |

徐芝纶. 弹性力学: 上册 [M]. 北京: 高等教育出版社, 2016.XU Zhilun. Elasticity: Volume I [M]. Beijing: Higher Education Press, 2016.

|

| [12] |

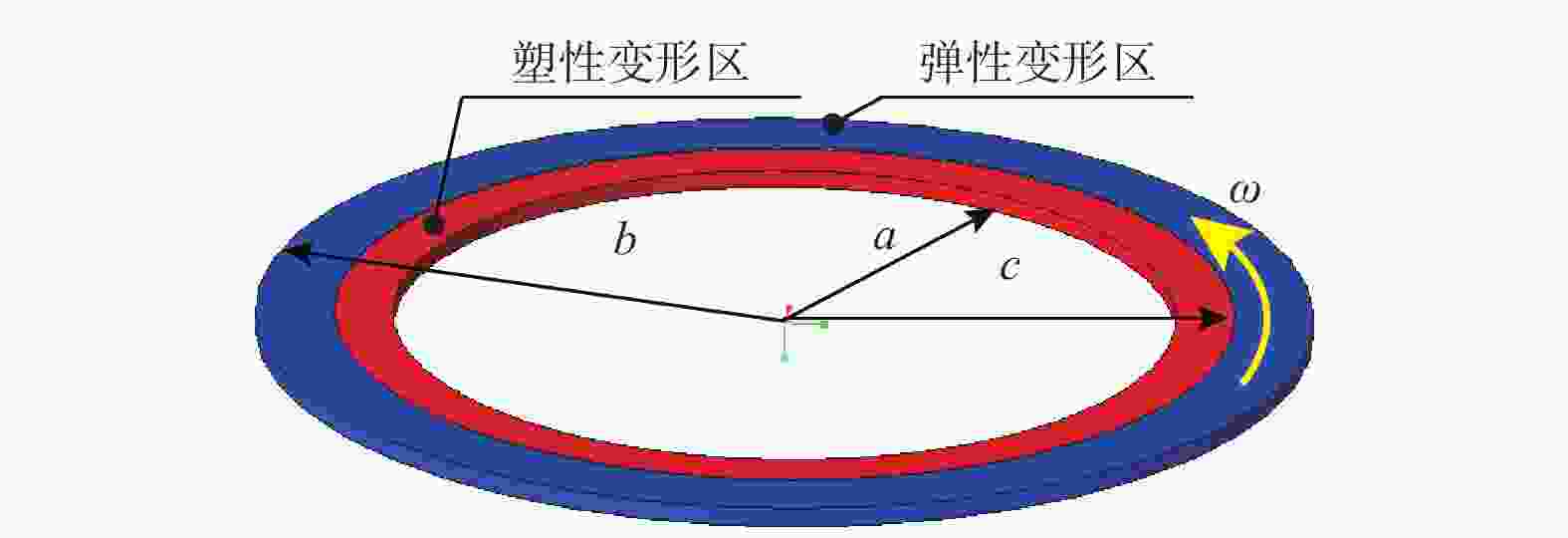

HU S. Study on the elastic-plastic interface and large deformation of axisymmetric disks under rotating status [J]. Applied Clay Science,2013,79(7):41-48.

|

| [13] |

张磊, 徐晓辉. 磨削速度和孔径比对砂轮强度与变形的影响分析 [J]. 应用科技,2010,37(7):35-39.ZHANG Lei, XU Xiaohui. Influence of grinding speed and on the grinding wheel's strength and deformation [J]. Applied Science and Technology,2010,37(7):35-39.

|

| [14] |

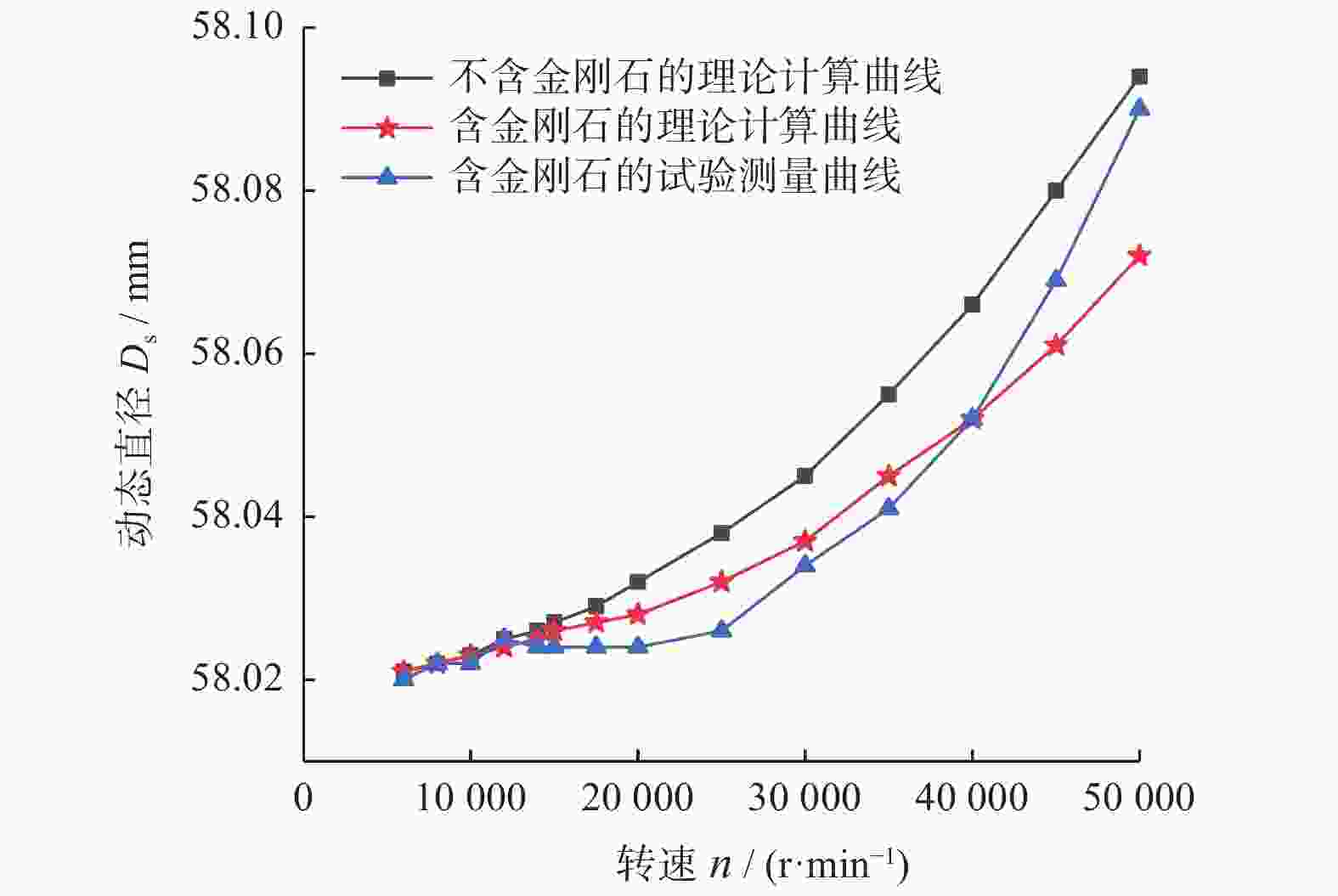

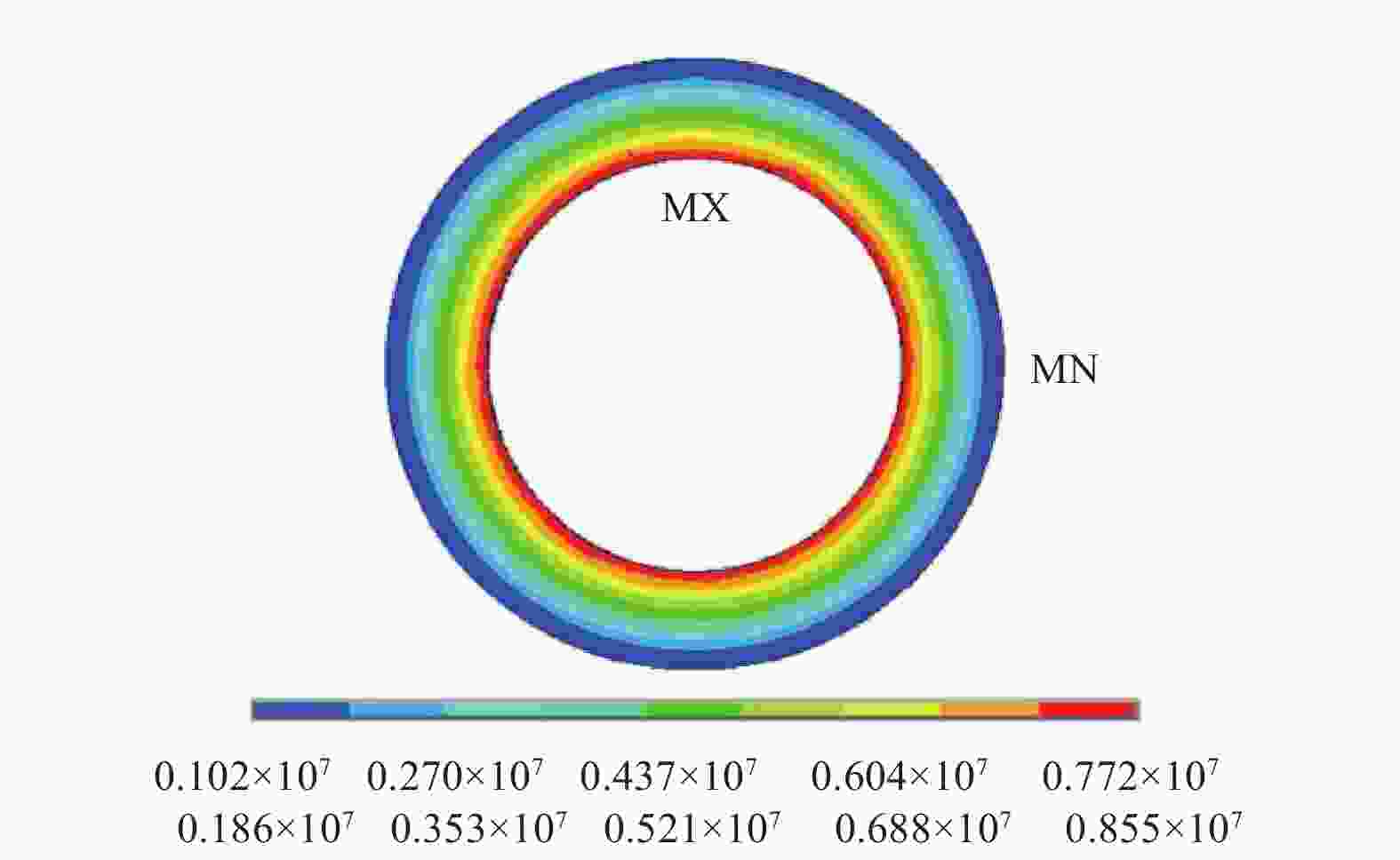

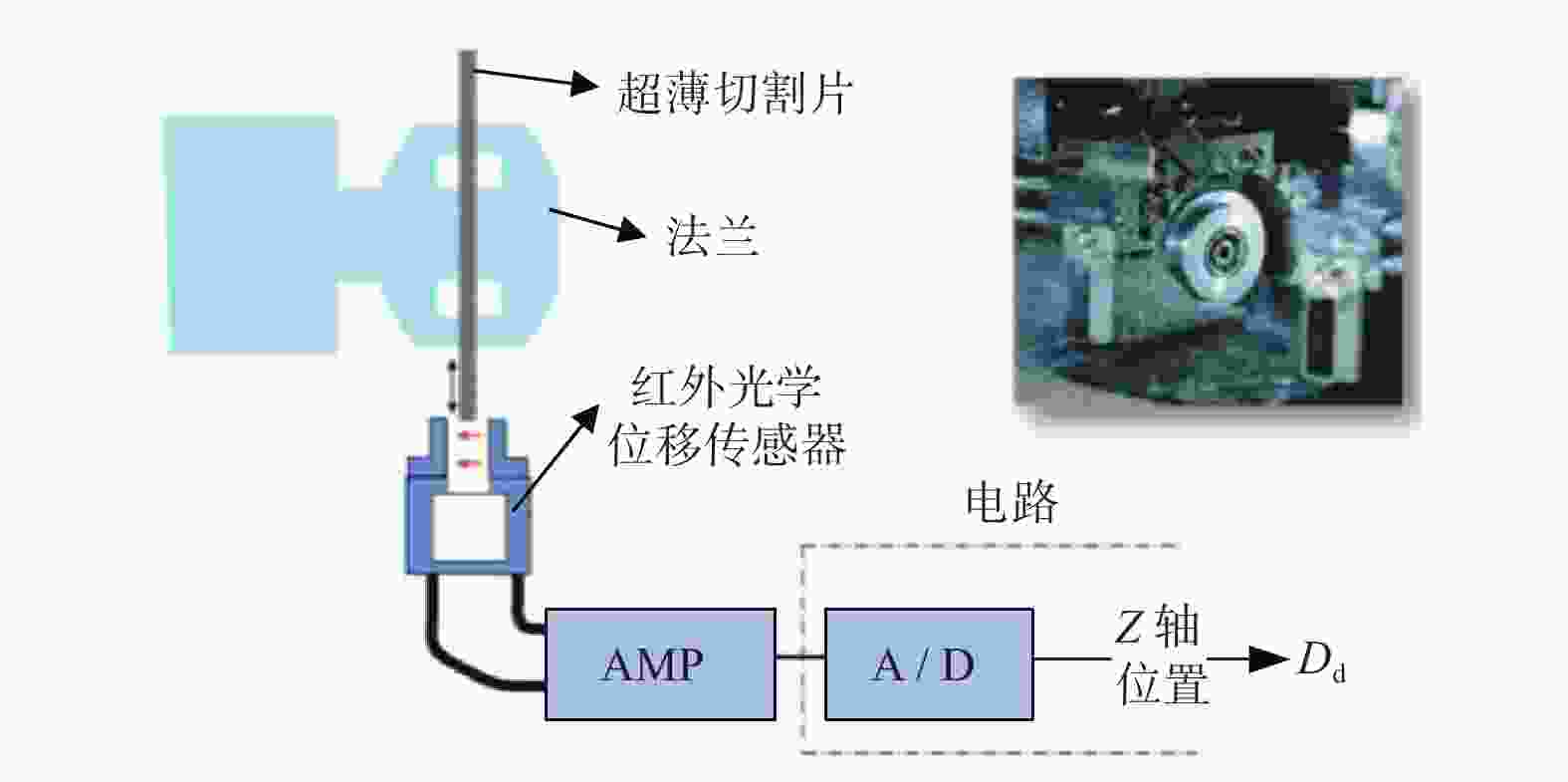

LI K, WANG M, CHEN F, et al. Analysis of the dynamic diameter of superthin diamond blades in the high speed and precision dicing process [J]. International Journal of Precision Engineering and Manufacturing,2019,20(7):1071-1081. doi: 10.1007/s12541-019-00128-7

|

| [15] |

MA Y. Research on performance of diamond blade in dicing saw based on ANSYS method [J]. Journal of Advanced Manufacturing Systems,2012,11(2):125-133. doi: 10.1142/S0219686712500114

|

| [16] |

赵忠虎, 阎红霞. 圆盘匀速转动时最大径向位移在何处? [J]. 力学与实践,2006(2):81-83.ZHAO Zhonghu, YAN Hongxia. Where is the maximum radial displacement when the disc rotates at a constant speed? [J]. Mechanics in Engineering,2006(2):81-83.

|

| [17] |

邹芹, 关勇, 李艳国, 等. TiAl合金及其复合材料的研究进展与发展趋势 [J]. 燕山大学学报,2020,44(2):95-107.ZOU Qin, GUAN Yong, LI Yanguo, et al. Advances and perspectives of TiAl alloy and its composites [J]. Journal of Yanshan University,2020,44(2):95-107.

|

| [18] |

李工, 戴凤祥, 张翼飞, 等. Al系高熵合金高温氧化性能研究进展 [J]. 燕山大学学报,2021,45(3):189-201.LI Gong, DAI Fengxiang, ZHANG Yifei, et al. Research progress of high-temperature oxidation properties of Al-based high entropy alloys [J]. Journal of Yanshan University,2021,45(3):189-201.

|

| [19] |

胡满凤, 谢晋, 刘继楠, 等. 导光均光微槽透镜阵列精密磨削及其热压微成型 [J]. 机械工程学报,2017,53(23):190-196. doi: 10.3901/JME.2017.23.190HU Manfeng, XIE Jin, LIU Jinan, et al. Precision grinding and micro hot embossing of the microgroove lens array for light transmitting and uniforming [J]. Journal of Mechanical Engineering,2017,53(23):190-196. doi: 10.3901/JME.2017.23.190

|

| [20] |

EKHTERAEITOUSSI H, REZAEIFARIMANI M. Elasto-plastic deformation analysis of rotating disc beyond its limit speed [J]. International Journal of Pressure Vessels and Piping,2012,89(1):170-177.

|

| [21] |

STRASHNOV S, ALEXANDROV S, LANG L. Description of residual stress and strain fields in FGM hollow disc subject to external pressure [J]. Materials,2019,12:440-453. doi: 10.3390/ma12030440

|

| [22] |

JALALI M, SHAHRIARI B. Elastic stress analysis of rotating functionally graded annular disk of variable thickness using finite difference method [J]. Mathematical Problems in Engineering, 2018, 2018: 1871674.

|

| [23] |

CALLIOGLU H, SAYER M, DEMIR E. Elastic-plastic stress analysis of rotating functionally graded discs [J]. Thin-Walled Structures,2015,94(9):38-44.

|

| [24] |

THAWAIT A, SONDHI L, SANYAL S, et al. Stress and deformation analysis of clamped functionally graded rotating disks with variable thickness [J]. Mechanics and Mechanical Engineering,2019,23:202-211. doi: 10.2478/mme-2019-0027

|

| [25] |

CALLIOGLU H, TOPCU M, TARAKCILAR A. Elastic-plastic stress analysis of an orthotropic rotating disc [J]. International Journal of Mechanical Sciences,2006,48(9):985-990. doi: 10.1016/j.ijmecsci.2006.03.008

|

| [26] |

彭旭龙, 杨建强. 各向异性功能梯度夹层圆环的弹性分析 [J]. 长沙理工大学学报(自然科学版),2015,12(4):50-55.PENG XUlong, YANG Jianqiang. Elastic analysis of functionally graded polar orthotropic sandwich circular ring [J]. Journal of Changsha University of Science and Technology (Natural Science),2015,12(4):50-55.

|

| [27] |

KAMAL S, DIXIT U. Design of a disk-mandrel assembly for achieving rotational autofrettage in the disk [J]. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science,2021,235(13):1-16.

|

| [28] |

KHALILI A, PEDDIESON J. Evaluation of elastic compensation using elastic/plastic rotating circular disk problems [J]. Mechanics Research Communications,2014,55(1):89-94.

|

| [29] |

LIN B, ZHOU P, WANG Z, et al. Analytical elastic-plastic cutting model for predicting grain depth-of-cut in ultrafine grinding of silicon wafer [J]. Journal of Manufacturing Science and Engineering,2018,140:121001-121007. doi: 10.1115/1.4041245

|

| [30] |

董世明, 李一凡, 徐积刚. 不同加载条件下平面应力圆盘应力和位移的全场解 [J]. 工程科学与技术,2017,49(2):54-61.DONG Shiming, LI Yifan, XU Jigang. Full-field solution to stresses and displacements in the plane stress disk under different loading conditions [J]. Advanced Engineering Sciences,2017,49(2):54-61.

|

| [31] |

王启智. 对圆盘、圆环和圆孔研究与应用的感悟 [J]. 力学与实践,2015,37(3):372-376.WANG Qizhi. Perception about the study and application of disc, circular rings and circular hole [J]. Mechanics in Engineering,2015,37(3):372-376.

|

| [32] |

谢桂芝, 黄含, 盛晓敏, 等. 工程陶瓷高效深磨磨削力和损伤的研究 [J]. 湖南大学学报(自然科学版),2008, 38(5):26-30.XIE Guizhi, HUANG Han, SHENG Xiaomin, et al. Investigation on the grinding force and the ground damages in the high efficiency deep grinding of advanced ceramics [J]. Journal of Hunan University (Natural Sciences),2008, 38(5):26-30.

|

| [33] |

杨绪啟, 姚巨坤, 田欣利, 等. 平面碳化硅深切削缓进给磨削力的正交试验研究 [J]. 机床与液压,2018,46(11):96-100.YANG Xuqi, YAO Jukun, TIAN Xinli, et al. Orthogonal experiment research on cutting deeply and feed slowly grinding force of plane SiC [J]. Machine Tool & Hydraulics,2018,46(11):96-100.

|

| [34] |

吴玉厚, 沙勇, 李颂华, 等. 氮化硅陶瓷磨削力对表面质量的影响 [J]. 陶瓷学报,2019,40(6):718-724.WU Yuhou, SHA Yong, LI Songhua, et al. Experimental study on the effect of grinding force of silicon nitride ceramic on a surface quality [J]. Journal of Ceramics,2019,40(6):718-724.

|

| [35] |

王克军, 刘璇, 李辉, 等. 硬脆材料端面微磨削的磨削力及实验研究 [J]. 科学技术与工程,2016,16(29):212-216.WANG Kejun, LIU Xuan, LI Hui, et al. Modeling and experimental research on micro end grinding force of hard brittle material [J]. Science Technology and Engineering,2016,16(29):212-216.

|

| [36] |

WU J, CHEN G, CHEN F. Positioning accuracy control of dual-axis dicing saw for machining semiconductor chip [J]. The International Journal of Advanced Manufacturing Technology,2020,109:2299-2310. doi: 10.1007/s00170-020-05798-6

|

| [37] |

张庆玲, 张荣强, 金淼. 应变控制方式下ZG270-500材料特性试验研究 [J]. 燕山大学学报,2019,43(5):449-454.ZHANG Qingling, ZHANG Rongqiang, JIN Miao. Experimental study of ZG270-500 material characteristics under strain control modes [J]. Journal of Yanshan University,2019,43(5):449-454.

|

| [38] |

李蓓智. 高速高质量磨削理论、工艺、装备与应用 [M]. 上海: 上海科学技术出版社, 2012.LI Beizhi. Theory, technology, equipment and application of high-speed and high-quality grinding [M]. Shanghai: Shanghai Science and Technology Press, 2012.

|

| [39] |

李阳. 金刚石圆锯片的力学性能研究及工艺优化 [D]. 济南: 济南大学, 2017.LI Yang. Research on the mechanical performance and process optimization of diamond circular saw blade [D]. Jinan: Jinan University, 2017.

|

| [40] |

张进生, 王志, 吴军涛. 基于ANSYS的组合结构金刚石圆锯片基体离心力效应的分析 [J]. 金刚石与磨料磨具工程,2007(3):9-14.ZHANG Jinsheng, WANG Zhi, WU Juntao. Analysis by ANSYS for effect of centrifugal force on combined diamond saw blade [J]. Diamond & Abrasives Engineering,2007(3):9-14.

|

| [41] |

SONDHI L, THAWAIT A, SANYAL S, et al. Stress and deformation analysis of functionally graded varying thickness profile orthotropic rotating disk [J]. Materials Today: Proceedings,2020,33:5455-5460. doi: 10.1016/j.matpr.2020.03.258

|

| [42] |

KIZAKI T, HAO Y, OHASHI T, et al. Capability of a grinding wheel reinforced in hoop direction with carbon fiber [J]. CIRP Annals-Manufacturing Technology,2020,69:285-288. doi: 10.1016/j.cirp.2020.04.105

|

| [43] |

代东波. 超高速磨削CBN砂轮径向形变量研究 [D]. 广州: 广州大学, 2016.DAI Dongbo. Study on radial deformation of CBN grinding wheel in ultra-high speed grinding [D]. Guangzhou: Guangzhou University, 2016.

|

| [44] |

高东恩. 超高速砂轮基体动静特性的研究 [D]. 郑州: 河南工业大学, 2019.GAO Dongen. Research on the dynamic and static characteristics of ultra-high speed grinding wheel body [D]. Zhengzhou: Henan University of Technology, 2019.

|

| [45] |

YAMADA T, MORGAN M, LEE H, et al. Calculation of effective ground depth of cut by means of grinding process model [J]. Key Engineering Materials,2012,496:7-12.

|

| [46] |

JIANG B, SHEN J, XU X. Study on force characteristics for high speed sawing of quartz glass with diamond blade [J]. Materials Science Forum, 2014, 800/801: 144-149.

|

| [47] |

SHEN J, LU L, GONG Y, et al. Study on the influence of variation of contact arc zone on the single-pass sawing of sapphire wafer [J]. International Journal of Precision Engineering and Manufacturing,2018,19(9):1265-1271. doi: 10.1007/s12541-018-0150-8

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS