Modeling of ultra-thin diamond slice and simulation of SiC wafer cutting based on Python language

-

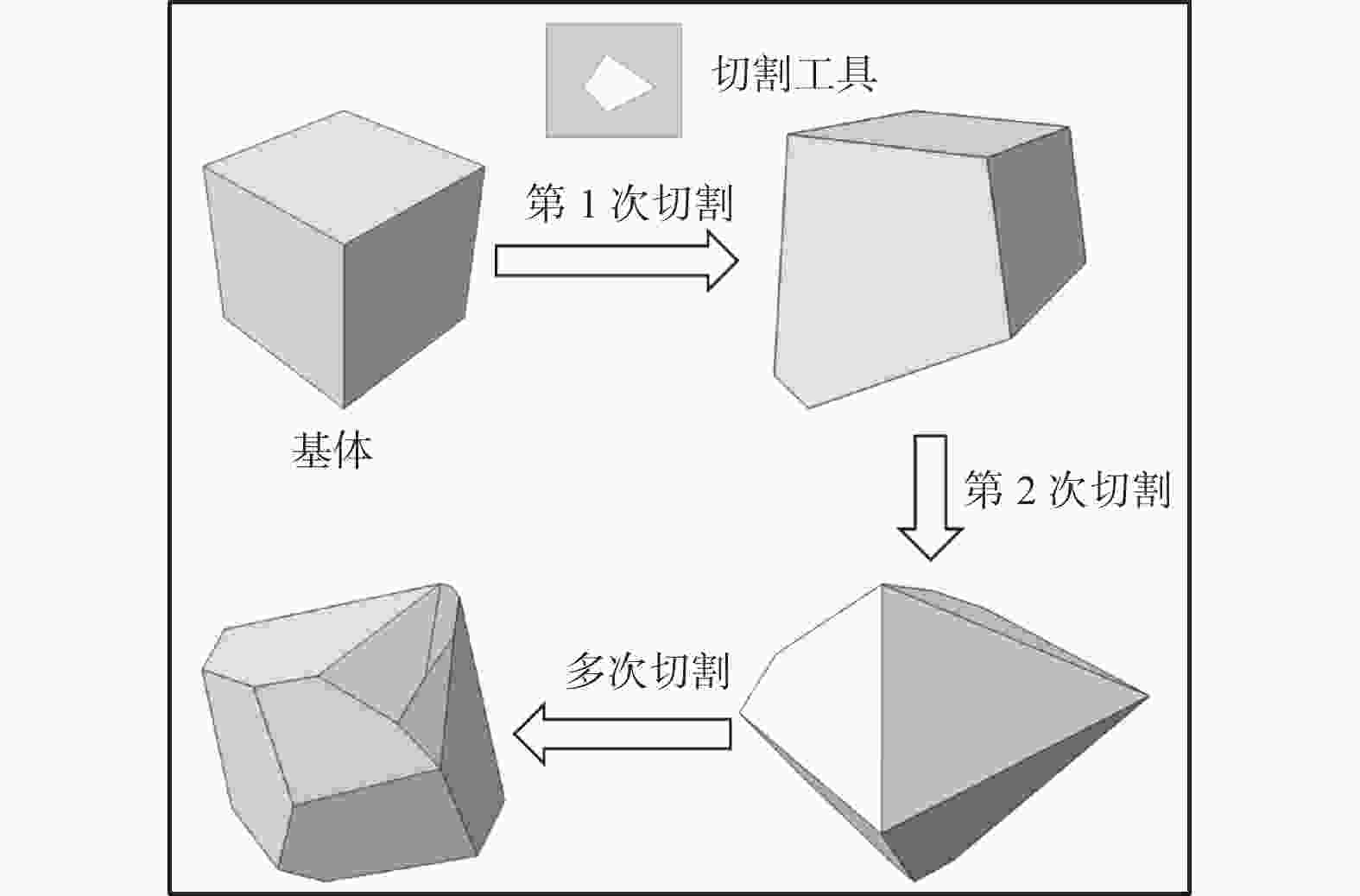

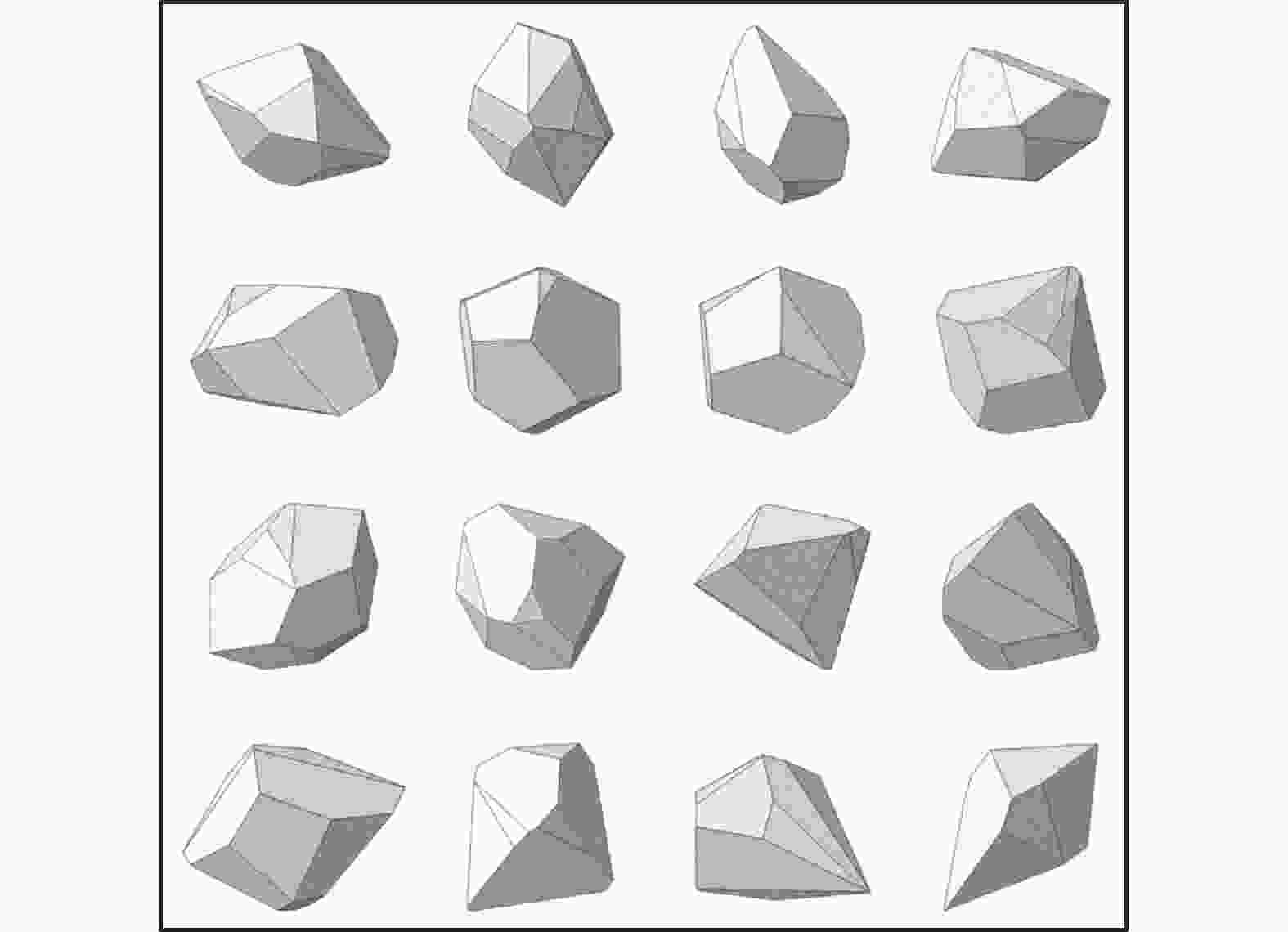

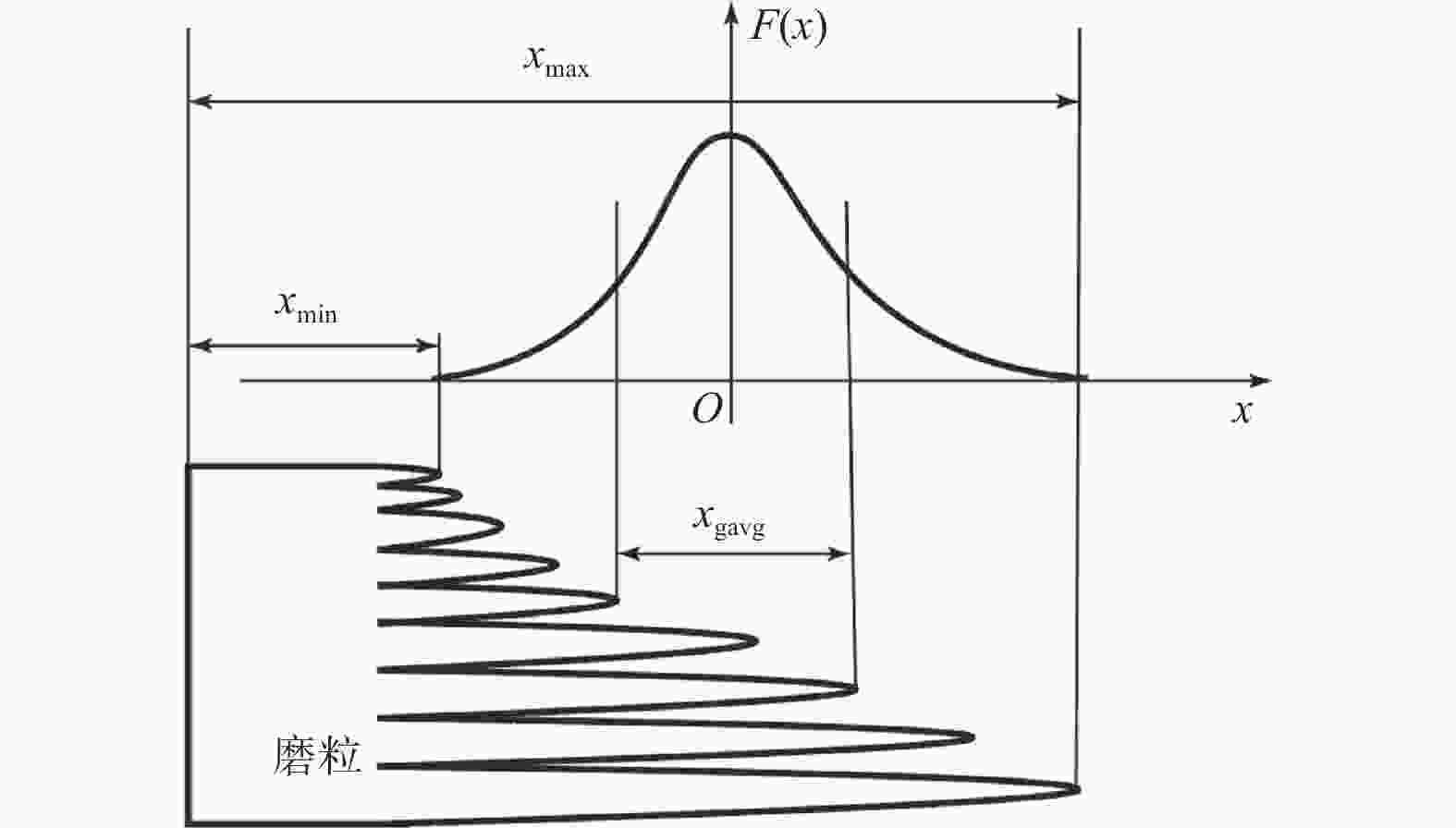

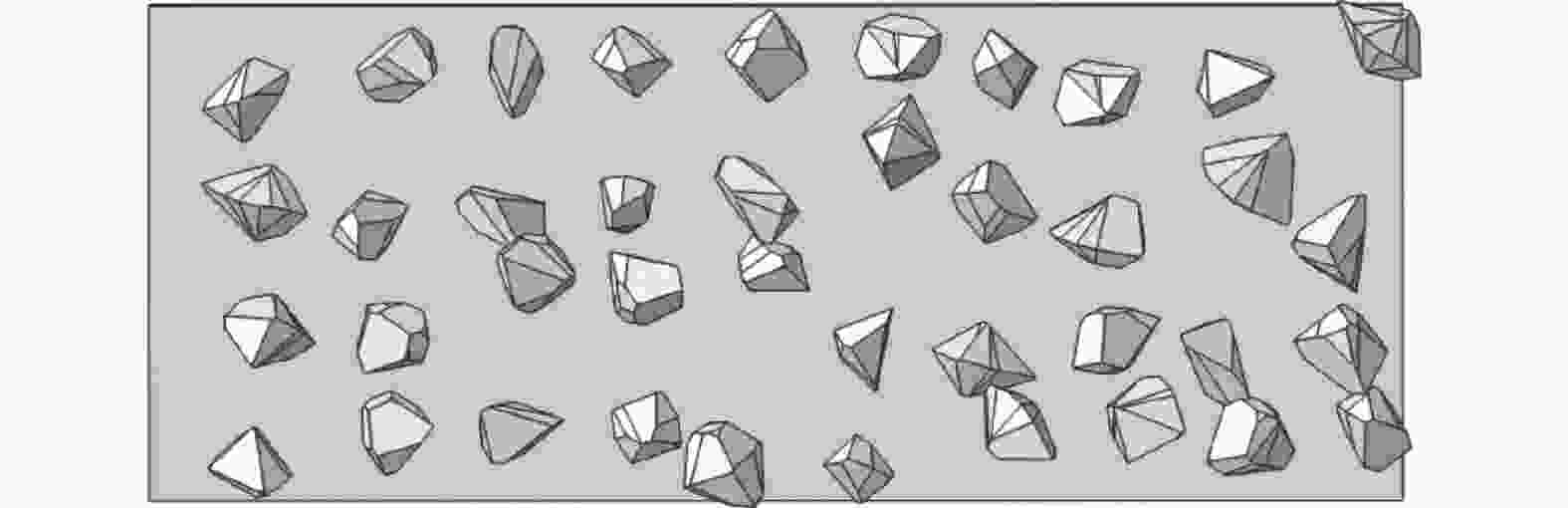

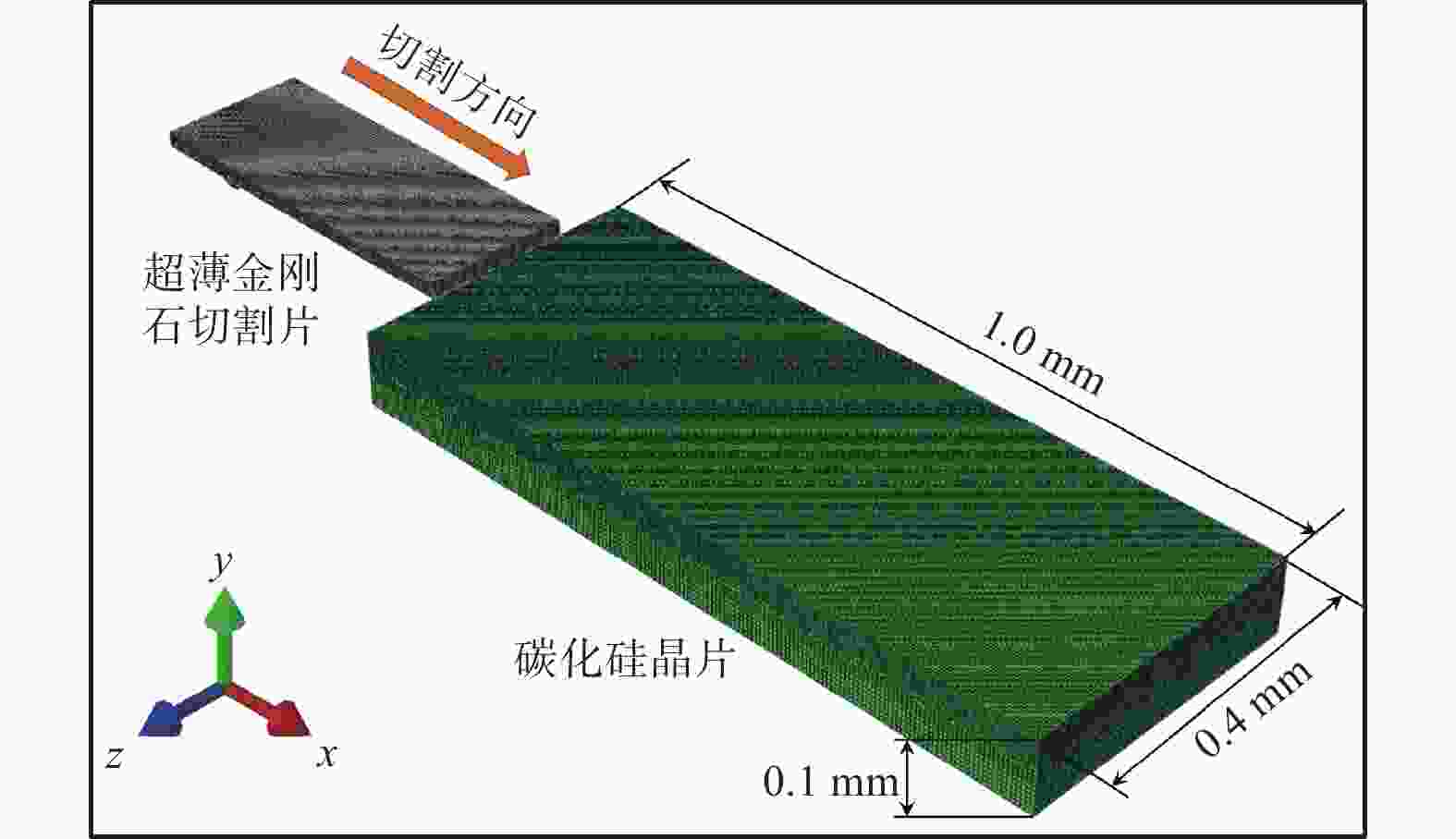

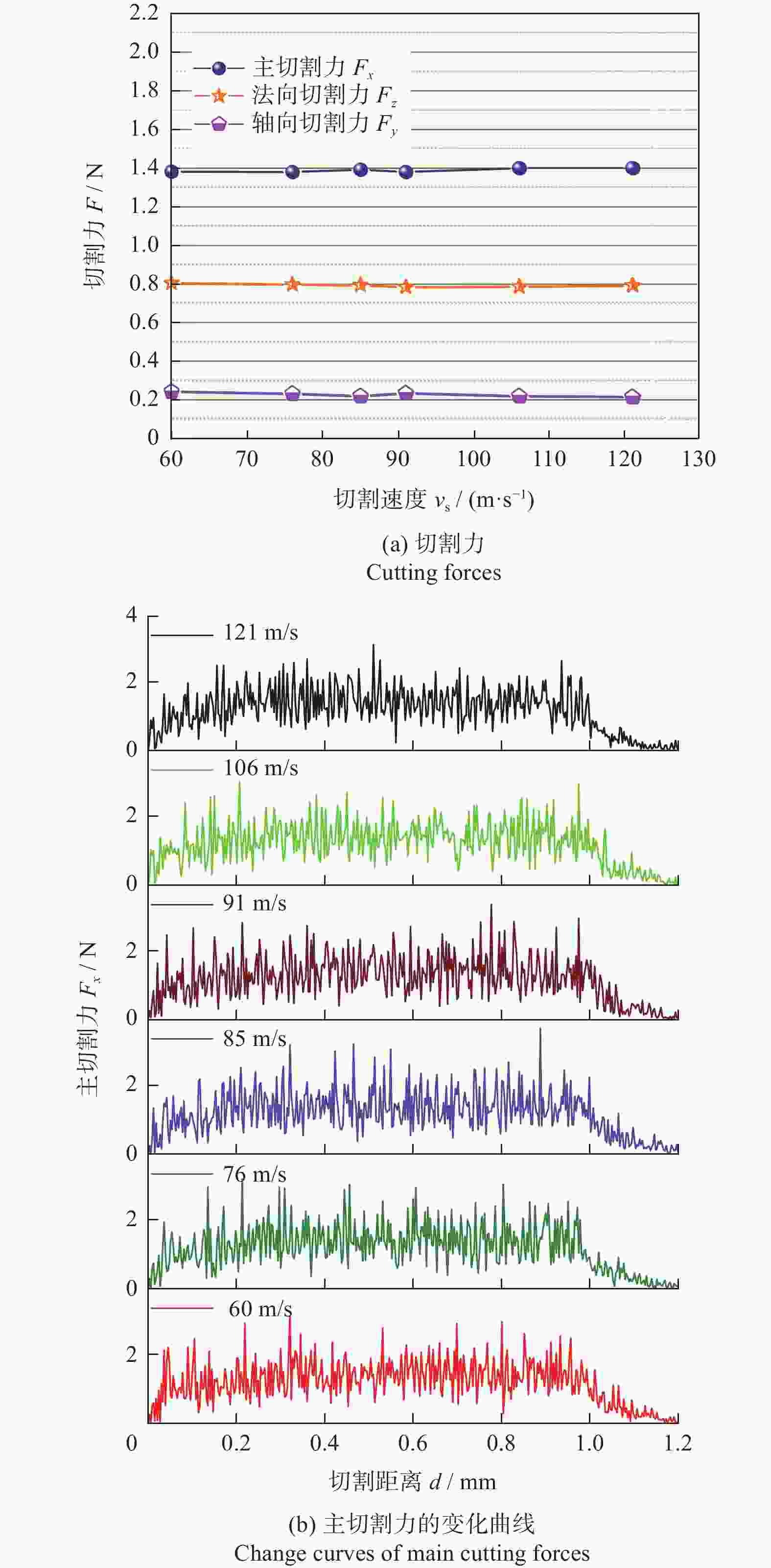

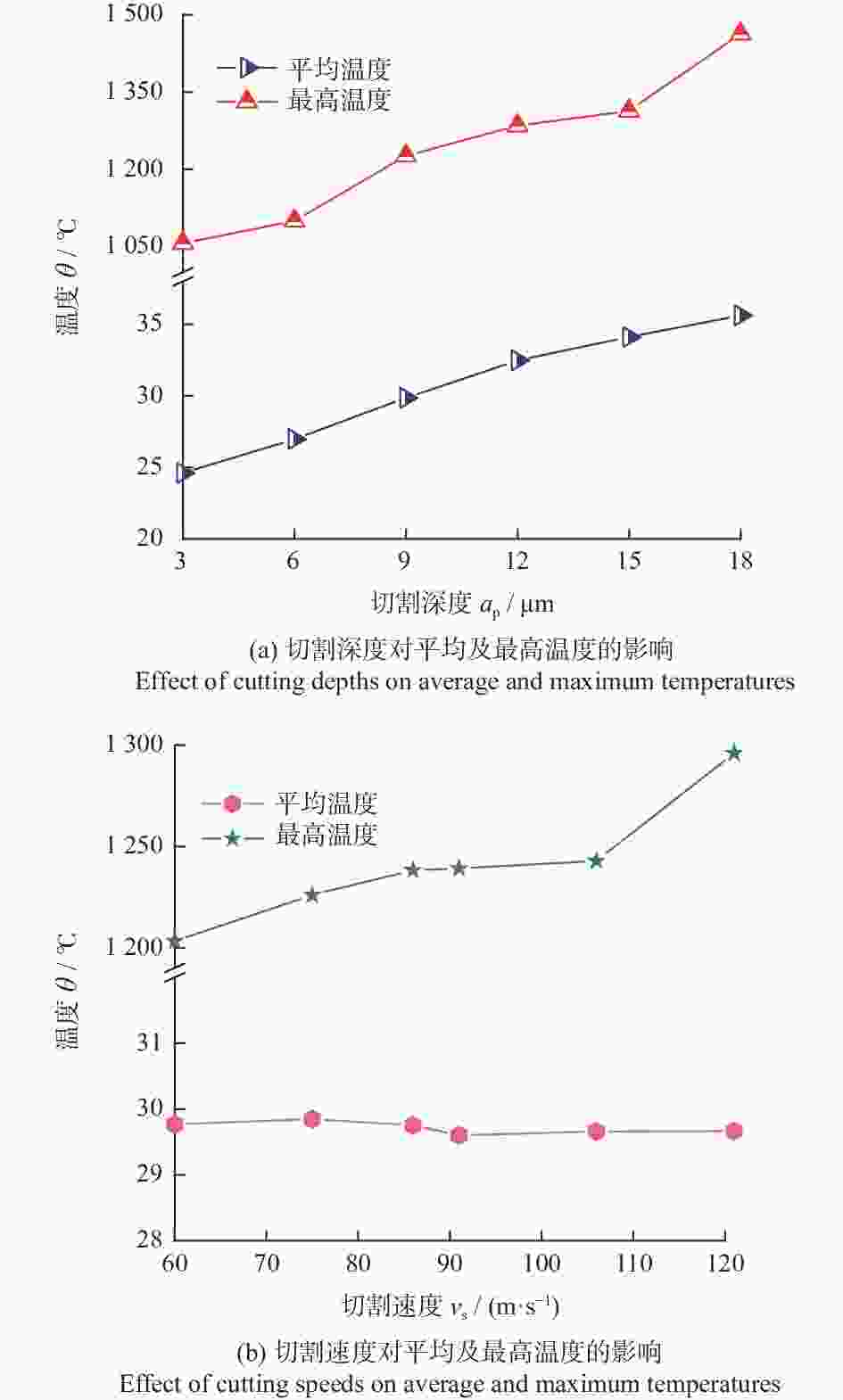

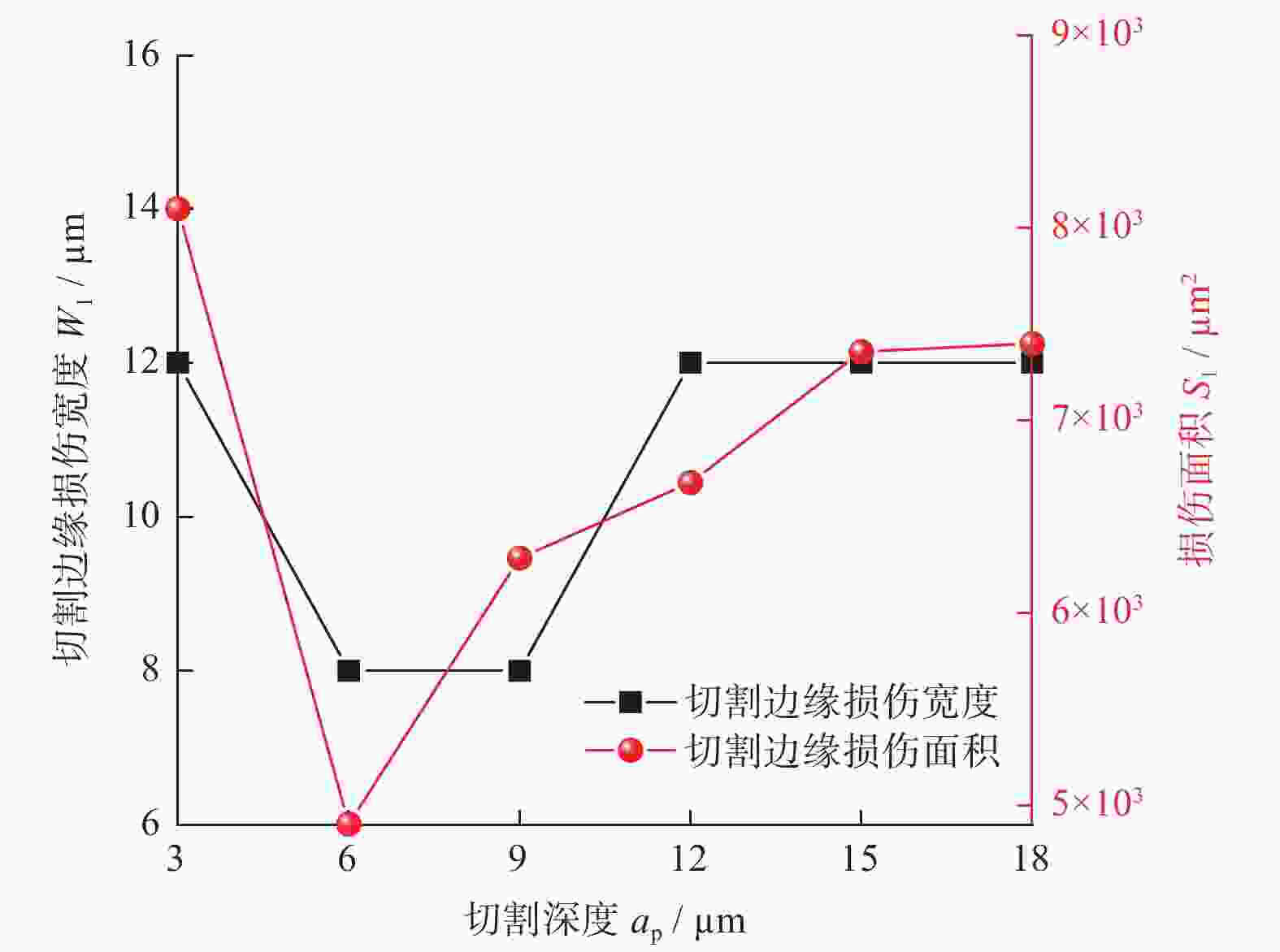

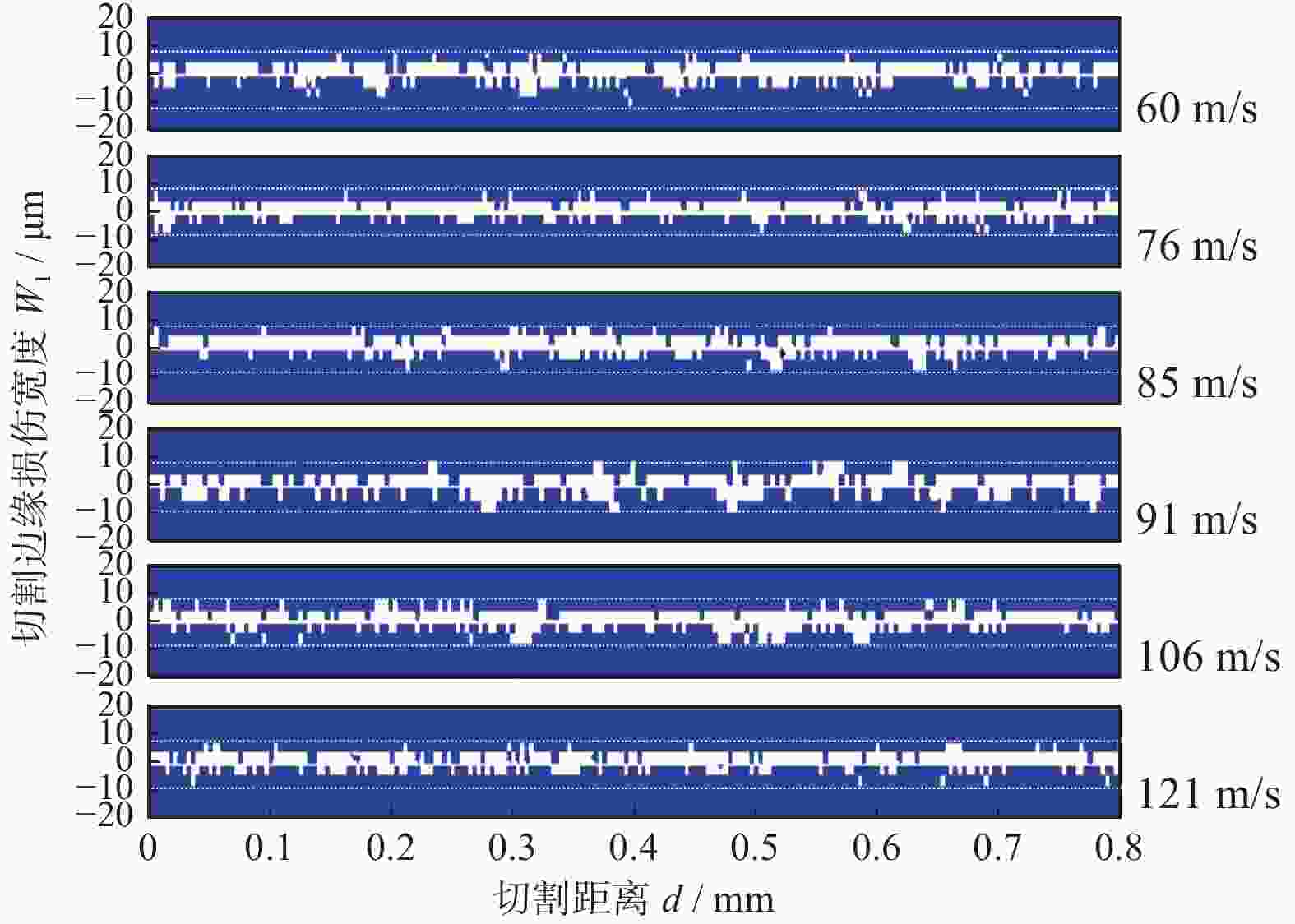

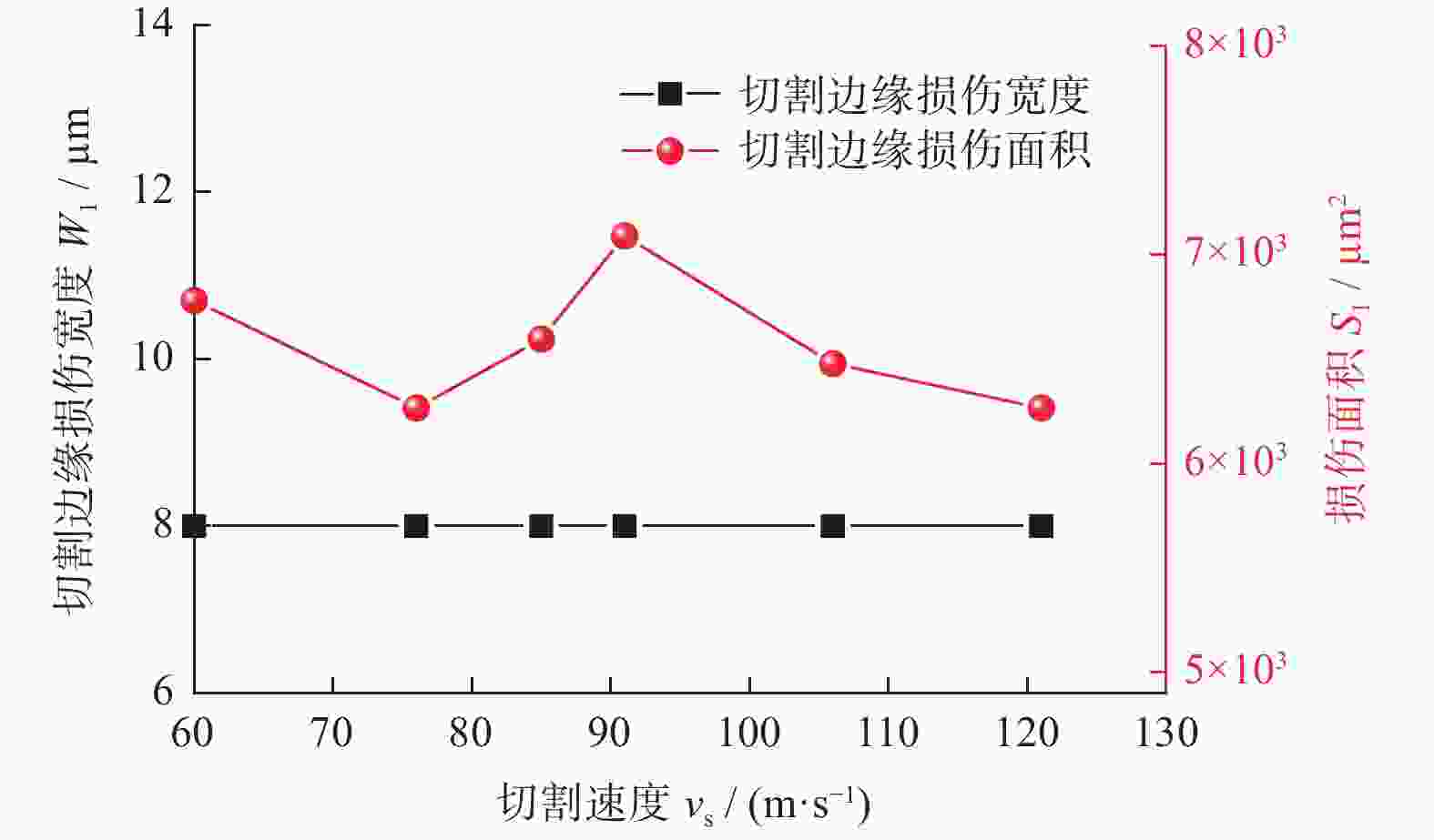

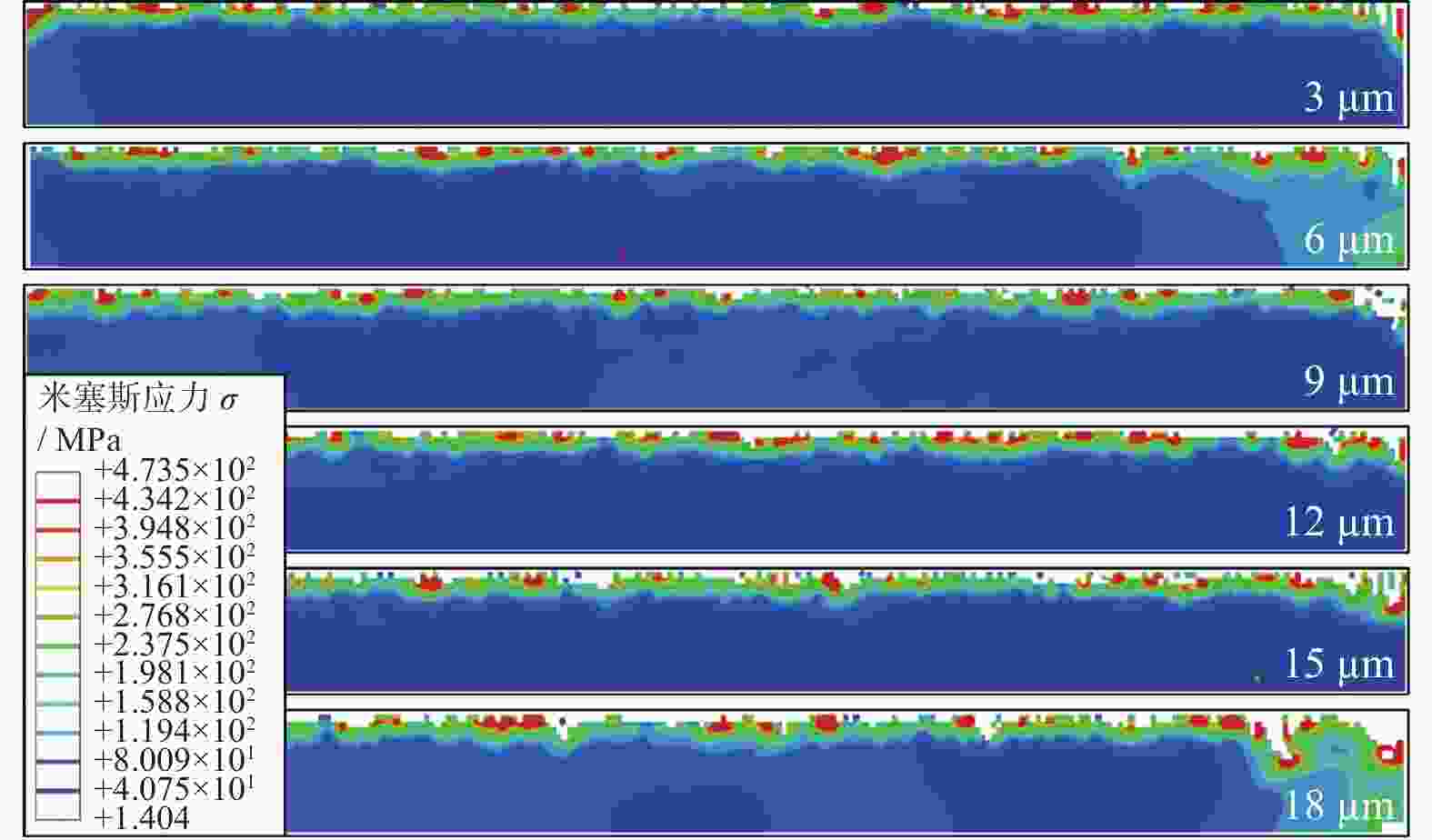

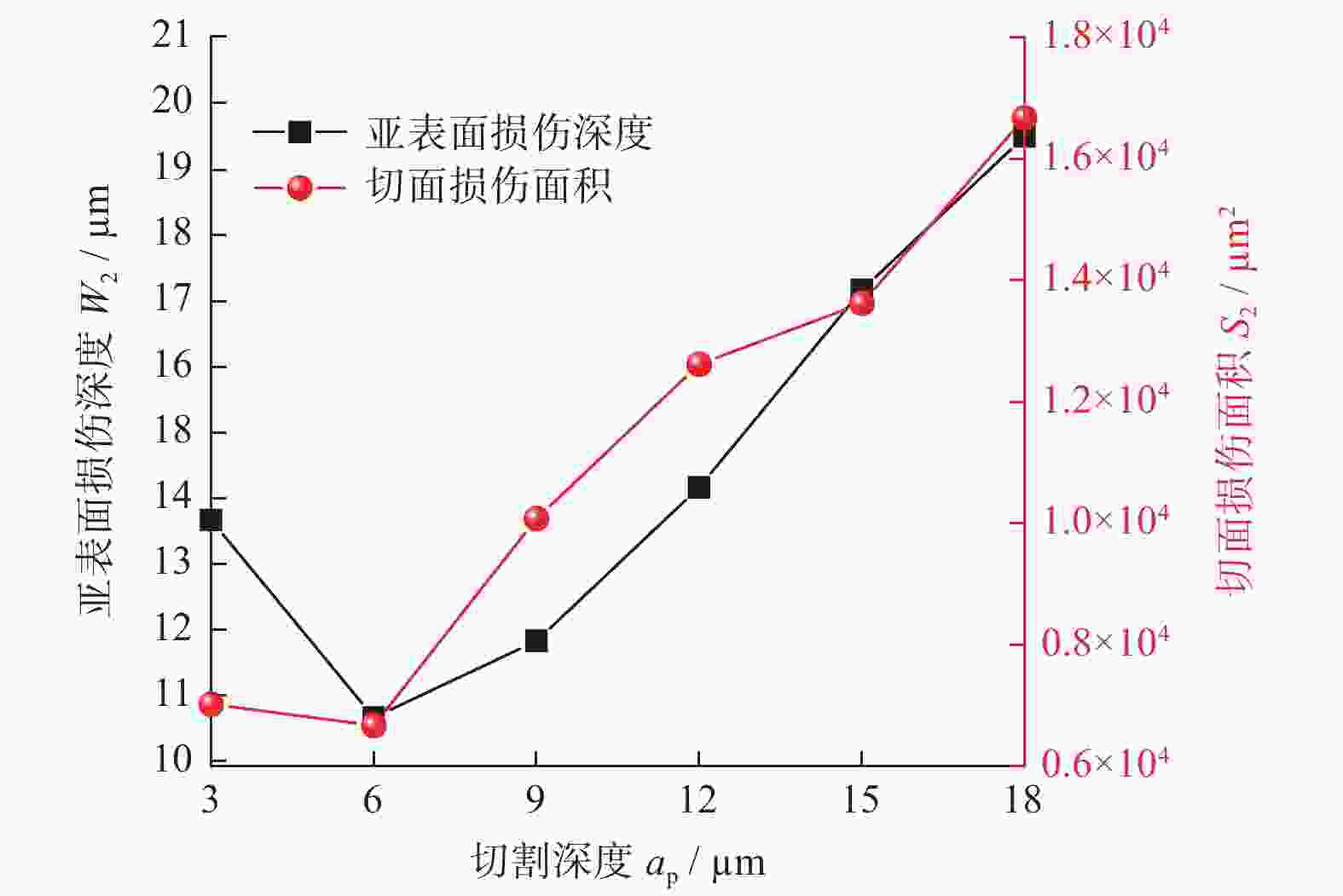

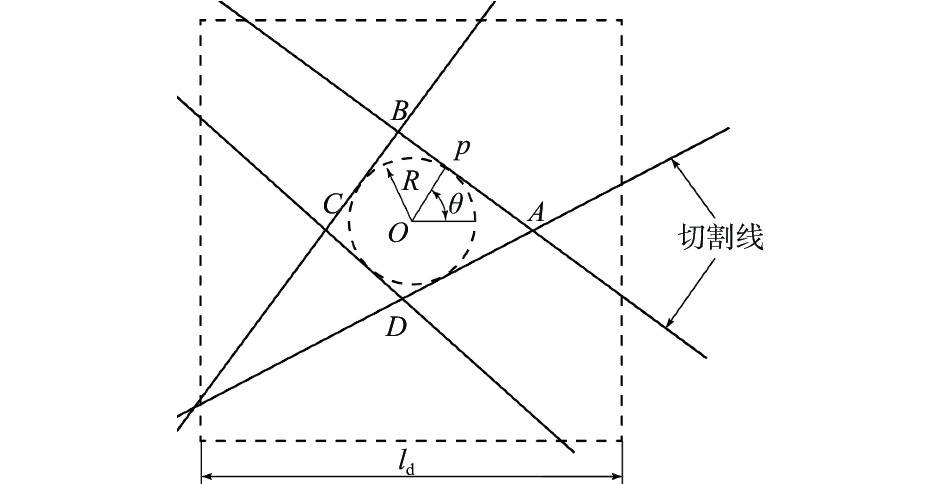

摘要: 为改善SiC晶片在切割过程中存在的边缘崩边和亚表面损伤等问题,采用Python语言与Abaqus有限元分析软件相结合的方法建立超薄金刚石切割片切割SiC晶片的模型,研究切割参数对切割过程中的切割力、切割温度、晶片切割边缘形貌、切割边缘损伤宽度以及晶片亚表面损伤深度的影响。结果表明:切割力、切割温度与切割深度正相关,切割边缘损伤程度和亚表面损伤深度存在最优值。在切割深度为6 μm时,SiC晶片的切割效果最好,其切割边缘损伤宽度为8 μm,损伤面积为4 905.56 μm2,亚表面损伤深度为10.67 μm,损伤面积为7 022.18 μm2。在切割速度为60~121 m/s的高速切割阶段,切割速度对切割力、晶片的温度、晶片切割边缘形貌及亚表面损伤均无显著影响。Abstract: To address issues like edge collapse and subsurface damage during the cutting process of SiC wafers, a model for cutting SiC wafers with ultra-thin diamond blades was established by combining Python language and Abaqus finite element analysis software. The effects of cutting parameters on cutting force, cutting temperature, wafer cutting edge morphology, cutting edge damage width and subsurface damage depth of wafer were studied. The results show that cutting force and cutting temperature are positively correlated with cutting depth, and there is an optimal value for the damage degree of the cutting edge and the subsurface damage depth. When the cutting depth is 6 μm, the cutting effect of SiC wafer is the best. The surface cutting edge damage width is 8 μm, the damage area is 4 905.56 μm2, the subsurface damage depth is 10.67 μm and the damage area is 7 022.18 μm2. In the high-speed cutting stage, where the cutting speed ranges from 60 to 121 m/s, cutting speed has no significant effect on cutting force, wafer temperature, wafer cutting edge morphology or subsurface damage.

-

Key words:

- SiC wafer /

- Python language /

- ultra-thin diamond slice /

- cutting parameters /

- damage

-

表 1 常温下SiC的物理性能参数

Table 1. Physical property parameters of SiC at room temperature

参数 取值 密度 ρ0 / (kg·m−3) 3 215 剪切模量 G / GPa 170 归一化无损强度常数 A 0.96 无损强度常数 N 0.65 归一化断裂强度常数 B 0.35 断裂强度常数 M1 1 依赖于应变率的强度常数 C 0.009 参考应变率 $ \dot{\varepsilon } $0 1 最大拉伸静水压应力 T / GPa 0.75 最大归一化无损强度 σimax 1.24 最大归一化断裂强度 σfmax 0.132 Hugoniot弹性极限下的压应力 HEL / GPa 11.7 HEL下的压应力分量 PHEL / GPa 7 弹性能转化为静水压能的损失 β 1 损伤系数 D1 0.48 损伤指数 D2 0.48 最大失效应变 $ {\stackrel{-}{\varepsilon }}_{f,\mathrm{m}\mathrm{a}\mathrm{x}}^{pl} $ 1.2 最小失效应变 $ {\stackrel{-}{\varepsilon }}_{f,\mathrm{m}\mathrm{i}\mathrm{n}}^{pl} $ 0 失效判据 FS 0.2 损伤标志 D 0 体积模量 K1 / GPa 220 第二压力常数 K2 / GPa 360 第三压力常数 K3 / GPa 0 表 2 切割过程的参数设定

Table 2. Parameter setting of cutting process

参数 类型或取值 切割片基体尺寸 0.20 mm × 0.50 mm × 0.02 mm 切割深度 ap / μm 3,6,9,12,15,18 切割速度 vs / (m·s−1) 60,76,85,91,106,121 工件尺寸 1.0 mm × 0.4 mm × 0.1 mm 初始温度 t / ℃ 20 -

[1] XUN Q, XUN B, LI Z, et al. Application of SiC power electronic devices in secondary power source for aircraft [J]. Renewable and Sustainable Energy Reviews,2017,70:1336-1342. doi: 10.1016/j.rser.2016.12.035 [2] WRIGHT N, HORSFALL A. SiC sensors: A review [J]. Journal of Physics D: Applied Physics,2007,40(20):6345. doi: 10.1088/0022-3727/40/20/S17 [3] CHOI P H, KIM Y P, KIM M-S, et al. Side-illuminated photoconductive semiconductor switch based on high purity semi-insulating 4H-SiC [J]. IEEE Transactions on Electron Devices,2021,68(12):6216-6221. doi: 10.1109/TED.2021.3117535 [4] MATSUNAMI H. Fundamental research on semiconductor SiC and its applications to power electronics [J]. Proceedings of the Japan Academy, Series B,2020,96(7):235-254. doi: 10.2183/pjab.96.018 [5] LEWKE D, DOHNKE K O, ZUHLKE H U, et al. Thermal laser separation: A novel dicing technology fulfilling the demands of volume manufacturing of 4H-SiC devices [J]. Materials Science Forum,2015,821/823:528-532. doi: 10.4028/www.scientific.net/MSF.821-823.528 [6] YANG Y L, LIU J L, CHEN G W, et al. Highly reliable four-point bending test using stealth dicing method for adhesion evaluation: 2019 International Conference on Electronics Packaging (ICEP) [C]. Niigata: IEEE, 2019. [7] OKADA T, TOMITA T, KATAYAMA H, et al. Local melting of Au/Ni thin films irradiated by femtosecond laser through GaN [J]. Applied Physics A,2019,125(10):1-6. doi: 10.1007/s00339-019-2982-1 [8] ZHANG Z, WEN Z, SHI H, et al. Dual laser beam asynchronous dicing of 4H-SiC wafer [J]. Micromachines,2021,12(11):1331. doi: 10.3390/mi12111331 [9] GE M, ZHU H, HUANG C, et al. Investigation on critical crack-free cutting depth for single crystal silicon slicing with fixed abrasive wire saw based on the scratching machining experiments [J]. Materials Science in Semiconductor Processing,2018,74:261-266. doi: 10.1016/j.mssp.2017.10.027 [10] FUJITA T, IZUMI Y, WATANABE J. Ultrafine ductile-mode dicing technology for SiC substrate with metal film using PCD blade [J]. Journal of Advanced Mechanical Design, Systems, and Manufacturing,2019,13(4):JAMDSM0073. doi: 10.1299/jamdsm.2019jamdsm0073 [11] CVETKOVIĆ S, MORSBACH C, RISSING L. Ultra-precision dicing and wire sawing of silicon carbide (SiC) [J]. Microelectronic Engineering,2011,88(8):2500-2504. doi: 10.1016/j.mee.2011.02.026 [12] JI S, LIU L, ZHAO J, et al. Finite element analysis and simulation about microgrinding of SiC [J]. Journal of Nanomaterials,2015(5):1-9. doi: 10.1155/2015/575398 [13] WEI J, WANG H, LIN B, et al. A force model in single grain grinding of long fiber reinforced woven composite [J]. The International Journal of Advanced Manufacturing Technology,2019,100(1):541-552. doi: 10.1007/s00170-018-2719-x [14] GU Y, ZHU W, LIN J, et al. Subsurface damage in polishing process of silicon carbide ceramic [J]. Materials,2018,11(4):506. doi: 10.3390/ma11040506 [15] CHAI P, LI S, LI Y. Modeling and experiment of the critical depth of cut at the ductile–brittle transition for a 4H-SiC single crystal [J]. Micromachines,2019,10(6):382. doi: 10.3390/mi10060382 [16] SONG K, XIAO G, CHEN S, et al. Analysis of thermal-mechanical causes of abrasive belt grinding for titanium alloy [J]. The International Journal of Advanced Manufacturing Technology,2021,113(11):3241-3260. doi: 10.1007/s00170-021-06795-z [17] TANG A, GUO W, YUAN Z, et al. Simulation analysis on cutting forces based on surface topography of fixed abrasive wire saw [J]. Materials Science in Semiconductor Processing,2021,132:105900. doi: 10.1016/j.mssp.2021.105900 [18] LI X, GAO Y, GE P, et al. The effect of cut depth and distribution for abrasives on wafer surface morphology in diamond wire sawing of PV polycrystalline silicon [J]. Materials Science in Semiconductor Processing,2019,91:316-326. doi: 10.1016/j.mssp.2018.12.004 [19] YANG Z, HE D, ZHANG Y, et al. Determination of the grinding force on optical glass based on a diamond wheel with an ordered arrangement of abrasive grains [J]. The International Journal of Advanced Manufacturing Technology,2021,115(4):1237-1248. doi: 10.1007/s00170-021-07204-1 [20] AURICH J C, BRAUN O, WARNECKE G, et al. Development of a superabrasive grinding wheel with defined grain structure using kinematic simulation [J]. CIRP Annals,2003,52(1):275-280. doi: 10.1016/S0007-8506(07)60583-6 [21] HERZENSTIEL P, AURICH J. CBN-grinding wheel with a defined grain pattern–extensive numerical and experimental studies [J]. Machining Science and Technology,2010,14(3):301-322. doi: 10.1080/10910344.2010.511574 [22] LI H, YU T, ZHU L, et al. Analysis of loads on grinding wheel binder in grinding process: Insights from discontinuum-hypothesis-based grinding simulation [J]. The International Journal of Advanced Manufacturing Technology,2015,78(9/10/11/12):1943-1960. doi: 10.1007/s00170-014-6767-6 [23] LI H, YU T, ZHU L, et al. Modeling and simulation of grinding wheel by discrete element method and experimental validation [J]. The International Journal of Advanced Manufacturing Technology,2015,81(9):1921-1938. doi: 10.1007/s00170-015-7205-0 [24] CHEN H P, CAO H Y, WU R L, et al. Modeling and simulation of high-speed cylindrical grinding based on 3D grinding wheel topography: MTMCE 2019 [C]. Wuhan: IOP Publishing, 2019. [25] CHEN C, TANG J, CHEN H, et al. Research about modeling of grinding workpiece surface topography based on real topography of grinding wheel [J]. The International Journal of Advanced Manufacturing Technology,2017,93(5):2411-2421. doi: 10.1007/s00170-017-0668-4 [26] ZHANG Y, FANG C, HUANG G, et al. Modeling and simulation of the distribution of undeformed chip thicknesses in surface grinding [J]. International Journal of Machine Tools and Manufacture,2018,127:14-27. doi: 10.1016/j.ijmachtools.2018.01.002 [27] WANG Y, WANG H, WEI J, et al. Finite element analysis of grinding process of long fiber reinforced ceramic matrix woven composites: Modeling, experimental verification and material removal mechanism [J]. Ceramics International,2019,45(13):15920-15927. doi: 10.1016/j.ceramint.2019.05.100 [28] MALKIN S, GUO C. Grinding technology: Theory and application of machining with abrasives [M]. New York: Industrial Press, 2008. [29] HOU Z B, KOMANDURI R. On the mechanics of the grinding process–Part I. Stochastic nature of the grinding process [J]. International Journal of Machine Tools and Manufacture,2003,43(15):1579-1593. doi: 10.1016/S0890-6955(03)00186-X [30] CRONIN D S, BUI K, KAUFMANN C, et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA: Proceedings of the 4th European LS-DYNA users conference [C]. Germany: Ulm, 2003. [31] ZHANG D, ZHAO L G, ROY A. Mechanical behavior of silicon carbide under static and dynamic compression [J]. Journal of Engineering Materials and Technology,2019,141(1):011007. doi: 10.1115/1.4040591 [32] DAI J, SU H, HU H, et al. The influence of grain geometry and wear conditions on the material removal mechanism in silicon carbide grinding with single grain [J]. Ceramics International,2017,43(15):11973-11980. doi: 10.1016/j.ceramint.2017.06.047 [33] ZHOU W, SU H, DAI J, et al. Numerical investigation on the influence of cutting-edge radius and grinding wheel speed on chip formation in SiC grinding [J]. Ceramics International,2018,44(17):21451-21460. doi: 10.1016/j.ceramint.2018.08.206 [34] HUANG Y, WANG M, LI J, et al. Effect of abrasive particle shape on the development of silicon substrate during nano-grinding [J]. Computational Materials Science,2021,193:110420. doi: 10.1016/j.commatsci.2021.110420 [35] LI P, GUO X, YUAN S, et al. Effects of grinding speeds on the subsurface damage of single crystal silicon based on molecular dynamics simulations [J]. Applied Surface Science,2021,554(2008):149668. doi: 10.1016/j.apsusc.2021.149668 [36] WAN L, LI L, DENG Z, et al. Thermal-mechanical coupling simulation and experimental research on the grinding of zirconia ceramics [J]. Journal of Manufacturing Processes,2019,47:41-51. doi: 10.1016/j.jmapro.2019.09.024 [37] SURATWALA T, STEELE R, SHEN N, et al. Lateral cracks during sliding indentation on various optical materials [J]. Journal of the American Ceramic Society,2020,103(2):1343-1357. doi: 10.1111/jace.16787 [38] NIAN D. Effects of depth of cutting on damage interferences during double scratching on single crystal SiC [J]. Crystals,2020,10(6):519. doi: 10.3390/cryst10060519 [39] DUAN N, YU Y, SHI W, et al. Investigation on diamond damaged process during a single-scratch of single crystal silicon carbide [J]. Wear,2021,486:204099. doi: 10.1016/j.wear.2021.204099 [40] ZHANG B, YIN J. The ‘skin effect’of subsurface damage distribution in materials subjected to high-speed machining [J]. International Journal of Extreme Manufacturing,2019,1(1):126-137. doi: 10.1088/2631-7990/ab103b [41] 李思, 晏永飞, 刘慧轩, 等. 高压磨料水射流切割低碳合金钢的试验研究 [J]. 辽宁石油化工大学学报,2019,39(5):88-92. doi: 10.3969/j.issn.1672-6952.2019.05.016 [42] ZHU D, YAN S, LI B. Single-grit modeling and simulation of crack initiation and propagation in SiC grinding using maximum undeformed chip thickness [J]. Computational Materials Science,2014,92:13-21. doi: 10.1016/j.commatsci.2014.05.019 [43] WANG P, GE P, GE M, et al. Material removal mechanism and crack propagation in single scratch and double scratch tests of single-crystal silicon carbide by abrasives on wire saw [J]. Ceramics International,2019,45(1):384-393. doi: 10.1016/j.ceramint.2018.09.178 [44] GAO Y, CHEN Y, GE P, et al. Study on the subsurface microcrack damage depth in electroplated diamond wire saw slicing SiC crystal [J]. Ceramics International,2018,44(18):22927-22934. doi: 10.1016/j.ceramint.2018.09.088 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS